Concrete bypassing preventing device with pulp stopping plates and concrete bypassing preventing construction method for H-shaped steel joint of wall chase of underground continuous wall

A technology of underground diaphragm wall and anti-slip board, which is applied to artificial islands, water conservancy projects, underwater structures, etc., to achieve the effect of simple construction process, low cost and good anti-flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

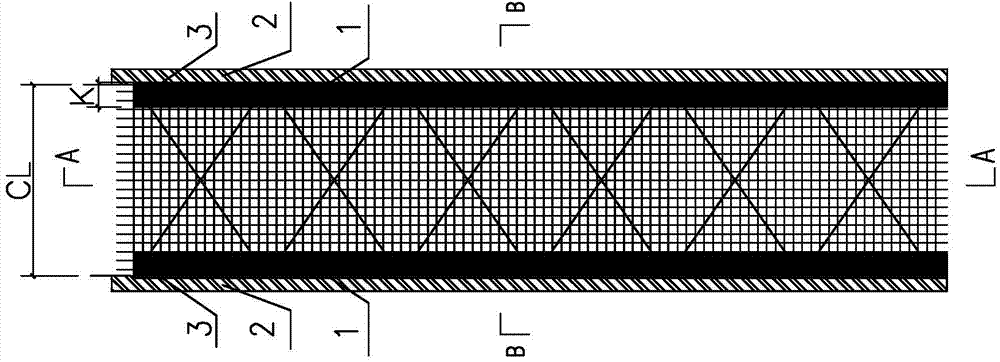

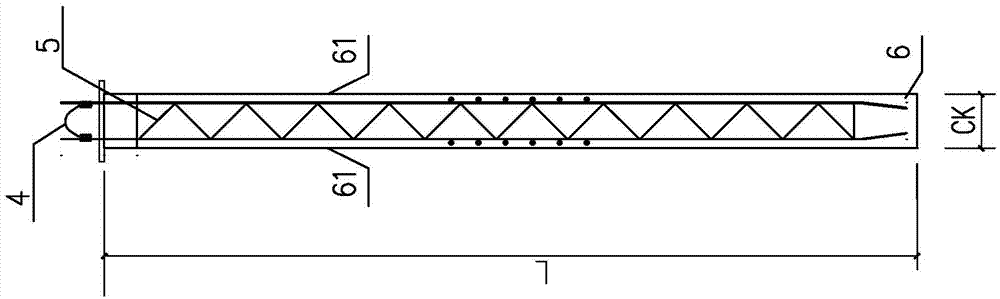

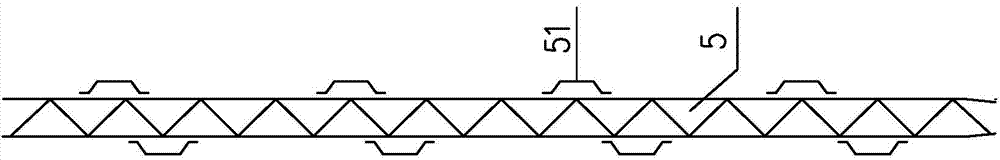

[0046] A device for preventing concrete flow-around by a grout-stopping plate of an H-shaped steel joint in a groove section of an underground continuous wall, comprising two grout-stopping plates 1 respectively arranged on the flange plates of I-shaped water-stop steel plates 2 of the ground connection wall, the grout-stopping plates 1. One end is fixedly connected with the I-shaped water-stop steel plate flange plate, and the other end is a free end. One of the slurry-stop plates 11 is fixedly connected with the inner side of the lower flange plate 21 of the I-shaped water-stop steel plate, and the other slurry-stop plate 12 It is fixedly connected with the outer side of the upper flange plate 22 of the I-shaped waterproof steel plate (see figure 1 , Figure 4-Figure 5 ).

[0047] The grout stopper 1 is a galvanized iron sheet with a thickness of 0.5mm and a length greater than 500mm of the reinforcement cage, the width K of the grout stopper is 500mm, and a steel bar with...

Embodiment 2

[0050] A construction method for preventing the flow of concrete by the H-shaped steel joint slurry plate of the groove section of the underground continuous wall. The method for preventing the concrete bypass flow construction of the H-shaped steel joint slurry plate, which includes the following steps (see Figure 4 , Figure 5 ):

[0051] A. Material preparation: Prepare the pulp stop board and the pulp stop board bead, choose the galvanized iron sheet with a thickness of 0.5mm and a length greater than the length of the steel cage 400-600mm as the pulp stop board, the width K of the pulp stop board is 400-600mm, and the diameter φ= The 18mm steel bar is used as the bead 3 of the grout plate;

[0052] B. Set the inner side of the H-shaped steel lower flange plate: first lay the inner side of the H-shaped steel lower flange plate 21 on both sides of the steel mesh sheet, lay the anti-slip plate 11, and overlap the flange plate 21 by 100mm, and then arrange the reinforceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com