Construction method for nonstandard diaphragm wall

An underground continuous wall and construction method technology, applied in the field of building construction, can solve the problems of increased cost, unusable bucket body, bucket head and locking pipe of a hydraulic grooving machine, etc., to achieve the effect of improving construction efficiency and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

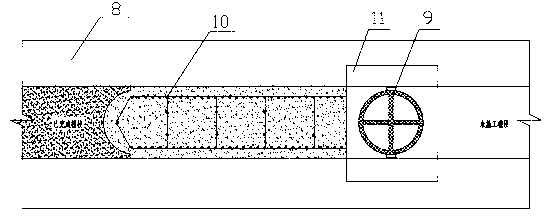

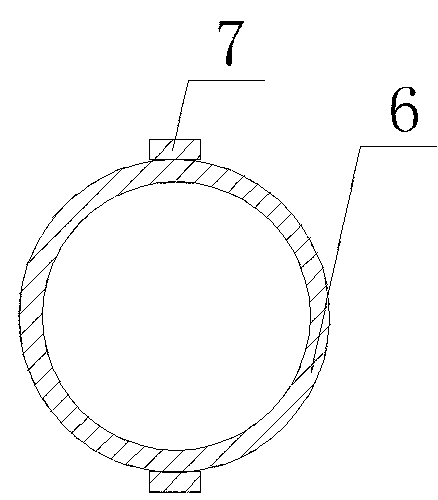

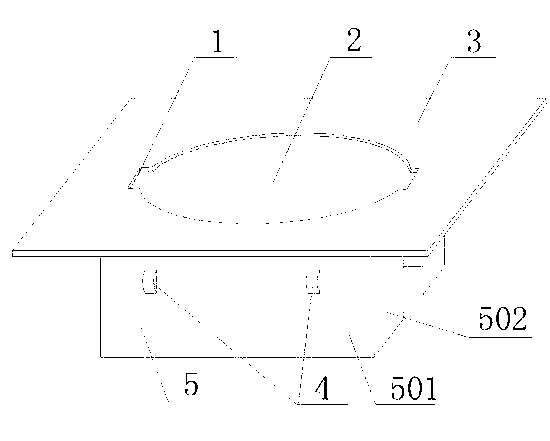

[0035] Below in conjunction with accompanying drawing, the present invention will be further described:

[0036] The standard underground diaphragm wall width is generally 600mm, 800mm, 1000mm and 1200mm. The size of the existing lock pipe and hydraulic groove forming machine grab is used in conjunction with it, and the width of the lock pipe and hydraulic groove forming machine grab is also 600mm. , 800mm, 1000mm and 1200mm in size, the non-standard underground diaphragm wall of the present invention refers to a wall whose width is 700mm, 900mm, 1100mm, etc. and the standard underground diaphragm wall is 100 mm different, and is used for thin-walled diaphragm walls with low safety factor, Thick-walled diaphragm wall is used when the cost is high. For example, for a foundation pit enclosure project with excavation depth of 15m, after calculation, it is considered that the safety factor of 800mm diaphragm wall is not enough, but the safety factor of 1000mm diaphragm wall is too ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com