Assembled concrete full-closed noise barrier

A sound barrier and concrete technology, which is applied to noise absorption devices, buildings, climate change adaptation, etc., can solve the problems of high cost of steel structures and transparent panels, poor fire resistance of transparent sound insulation panels, and high cost of metal sound-absorbing panels. Outstanding economic and social benefits, good sound insulation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] pass below Figure 1 to Figure 9 And the way of enumerating some optional embodiments of the present invention, the technical solution of the present invention (including the preferred technical solution) is described in further detail, and any technical feature and any technical solution in this embodiment do not limit the protection scope of the present invention .

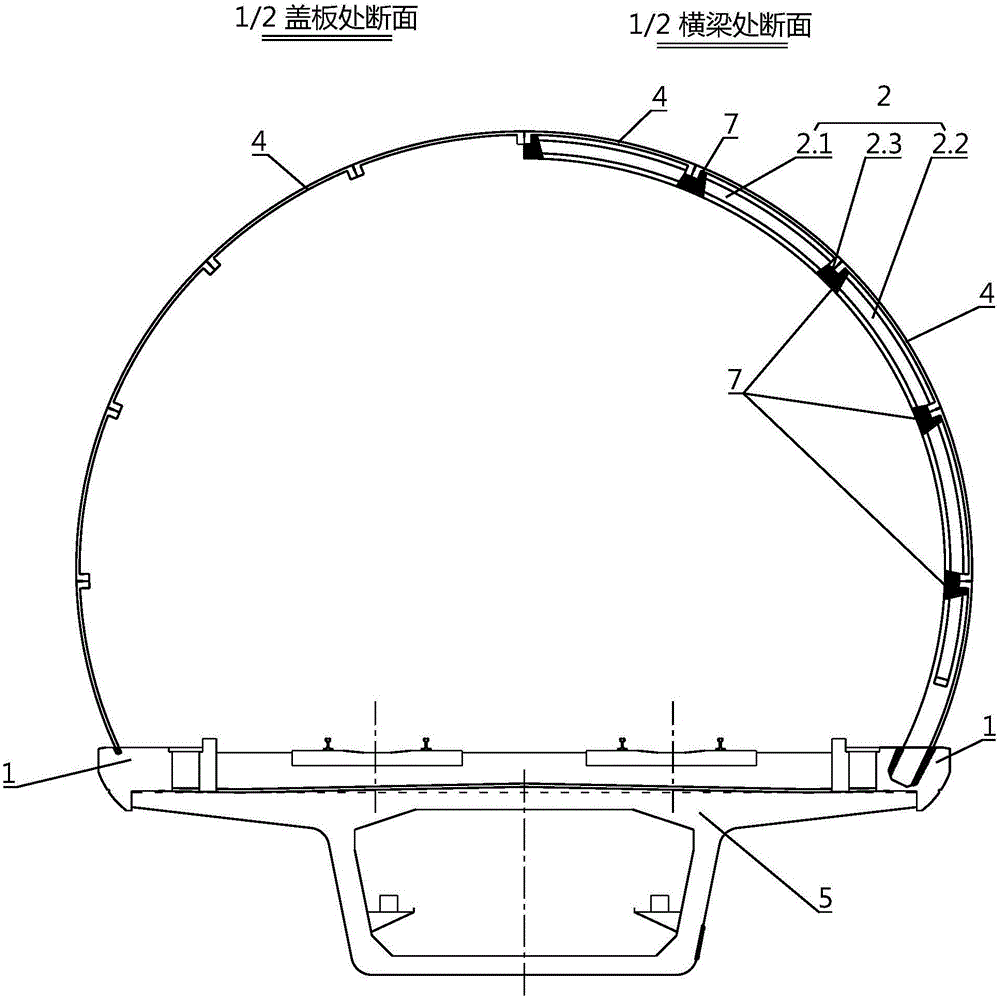

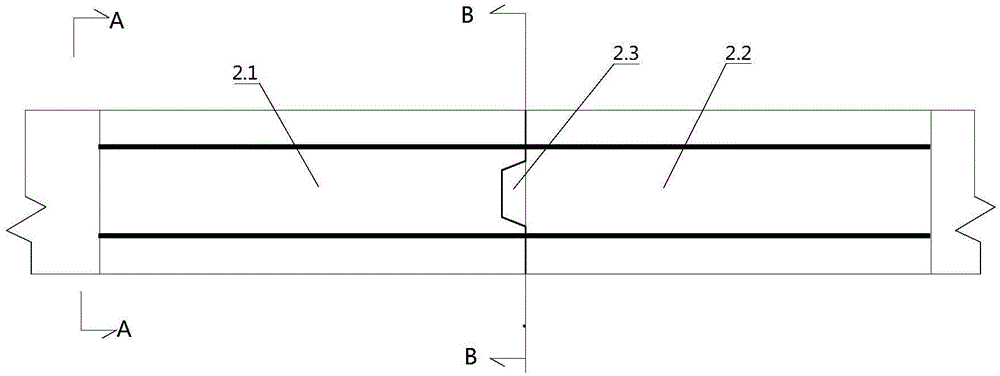

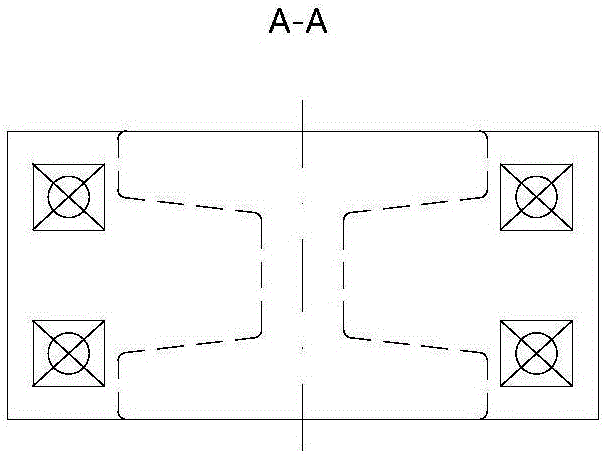

[0033] Such as figure 1 As shown, the assembled concrete fully enclosed sound barrier structure designed by the present invention mainly includes a sound barrier base 1, a beam 2, a longitudinal beam 3 and a cover plate 4, and the sound barrier base 1 is arranged at the two ends of the box girder 5 in the transverse bridge direction ; Beam 2 is made of reinforced RPC (reactive powder concrete) material, and longitudinal beam 3 and cover plate 4 are made of high-toughness fiber-reinforced cement-based composite material ECC. All components are constructed by factory prefabrication and on-site installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com