Concrete column high-seismic-resistance fabricated connecting structure

A high-seismic, prefabricated technology, applied in the direction of building structure, earthquake resistance, building components, etc., can solve the problem that the joint section is difficult to resist high-intensity earthquakes, etc., to strengthen the ability to resist deformation, reduce difficulty, and better earthquake resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

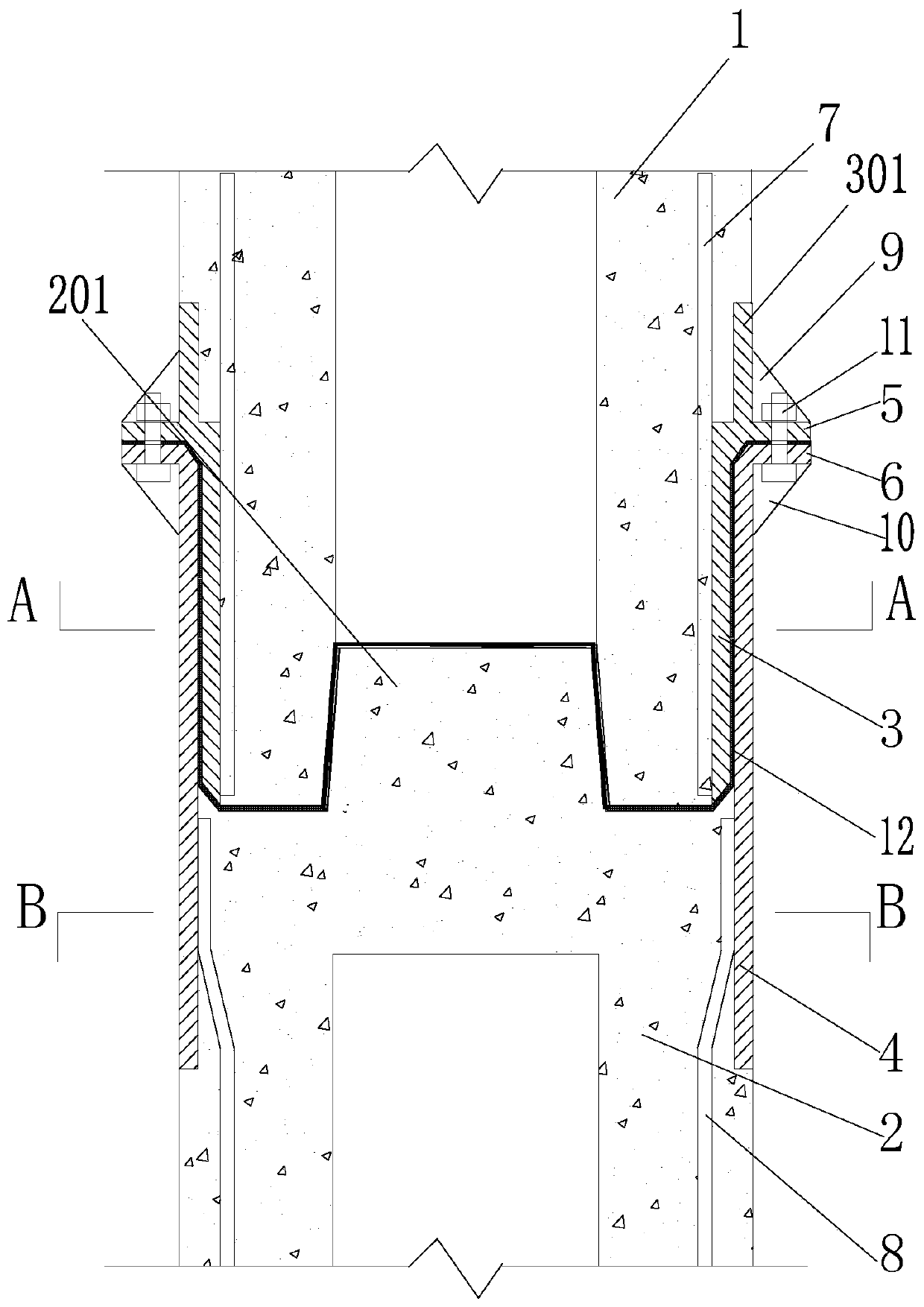

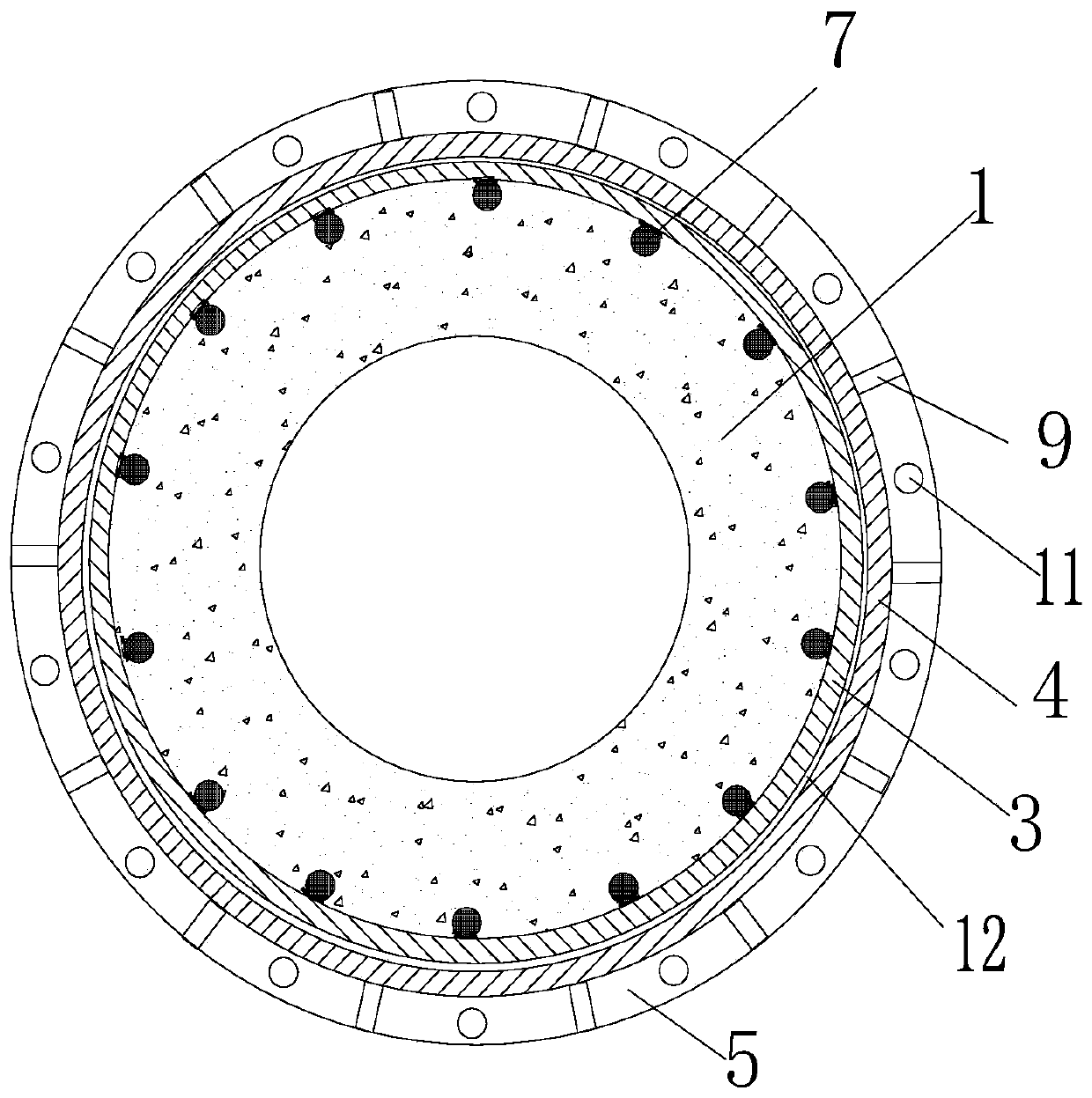

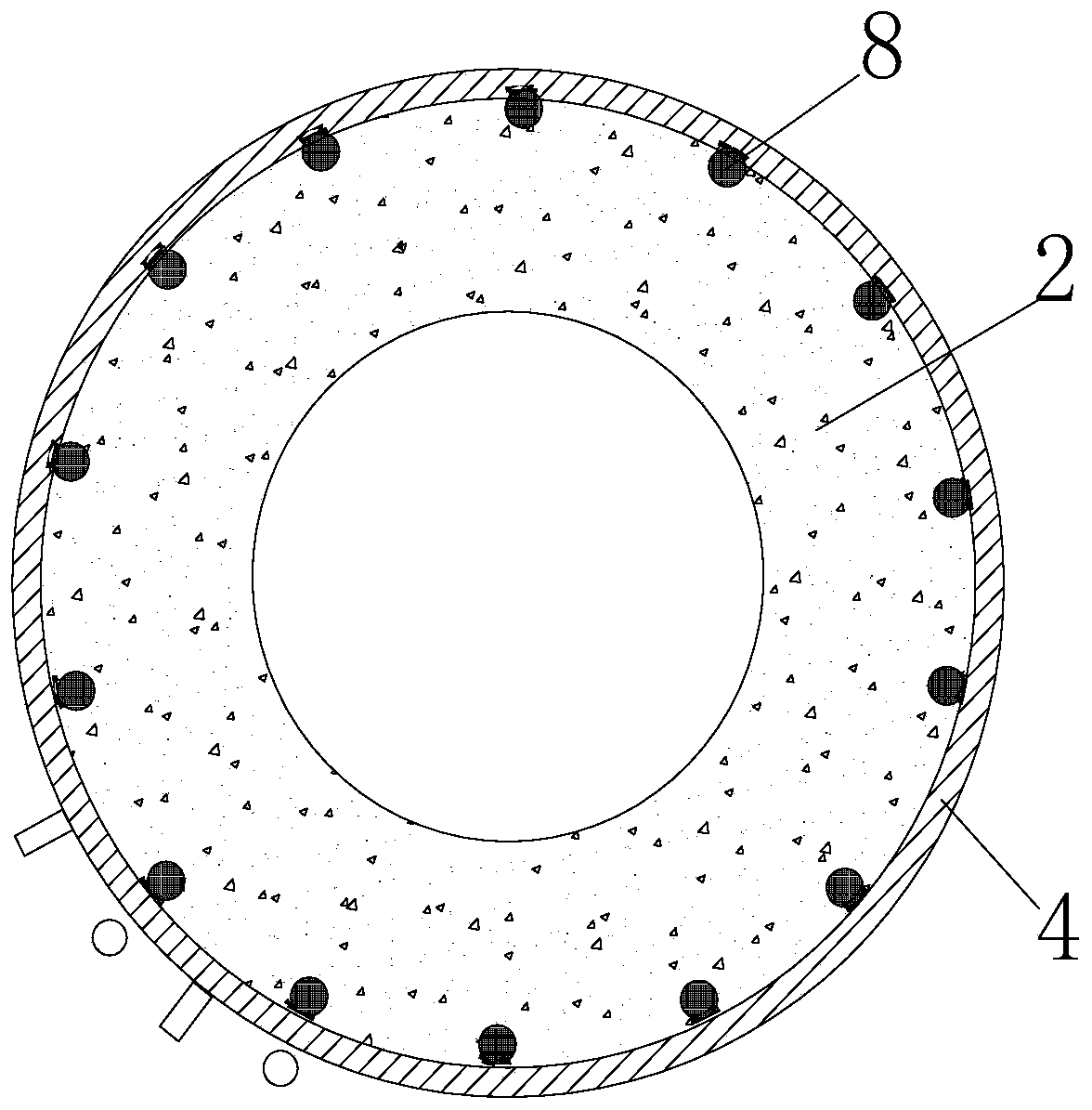

[0032] figure 1 It is a schematic diagram of the structure of the first embodiment of the present invention, figure 2 for figure 1 A cross-sectional view along the A-A direction, image 3 for figure 1 Sectional view along the BB direction; this embodiment adopts a composite beam formed by a concrete column with high seismic performance assembled connection structure, including upper section 1 and lower section 2. Both upper section 1 and lower section 2 are precast concrete columns, of course Reinforcing steel bars need to be arranged inside, which will not be repeated here; the upper section 1 and the lower section 2 are nested in the form of sleeves and fixedly connected by a flange structure; the sleeves are the upper and lower sections. The segments are respectively fixed with sleeves, and the sleeves of the upper and lower segments form a nested connection, which will not be repeated here;

[0033] A concave-convex embedded plug-in connection is formed between the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com