Construction method for carrying out shear strengthening on concrete box girder by adopting corrugated steel web

A technology of corrugated steel webs and concrete box girders, applied in bridge reinforcement, bridges, bridge construction, etc., can solve the problems of affecting the appearance of the bridge, increasing the self-weight of the bridge, and the limited improvement of the shear bearing capacity, etc., to achieve structural and structural The effect of clear stress, prevention of concrete cracks, and improvement of concrete performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

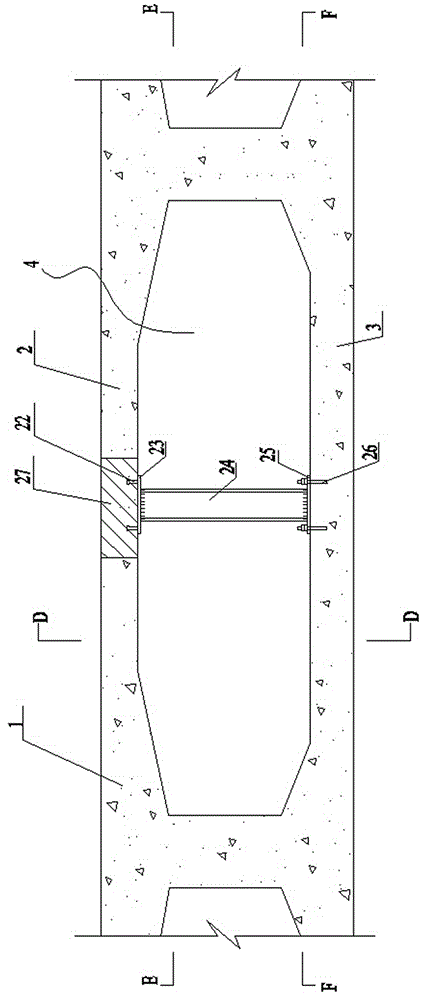

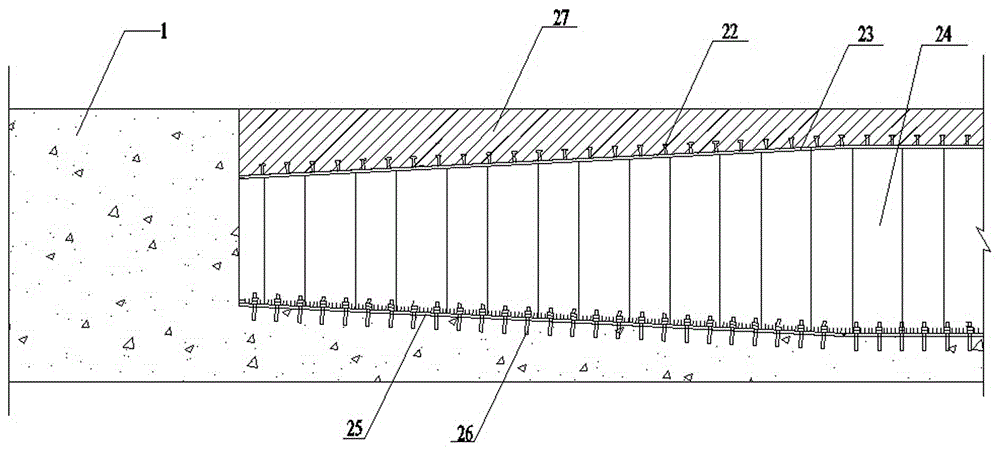

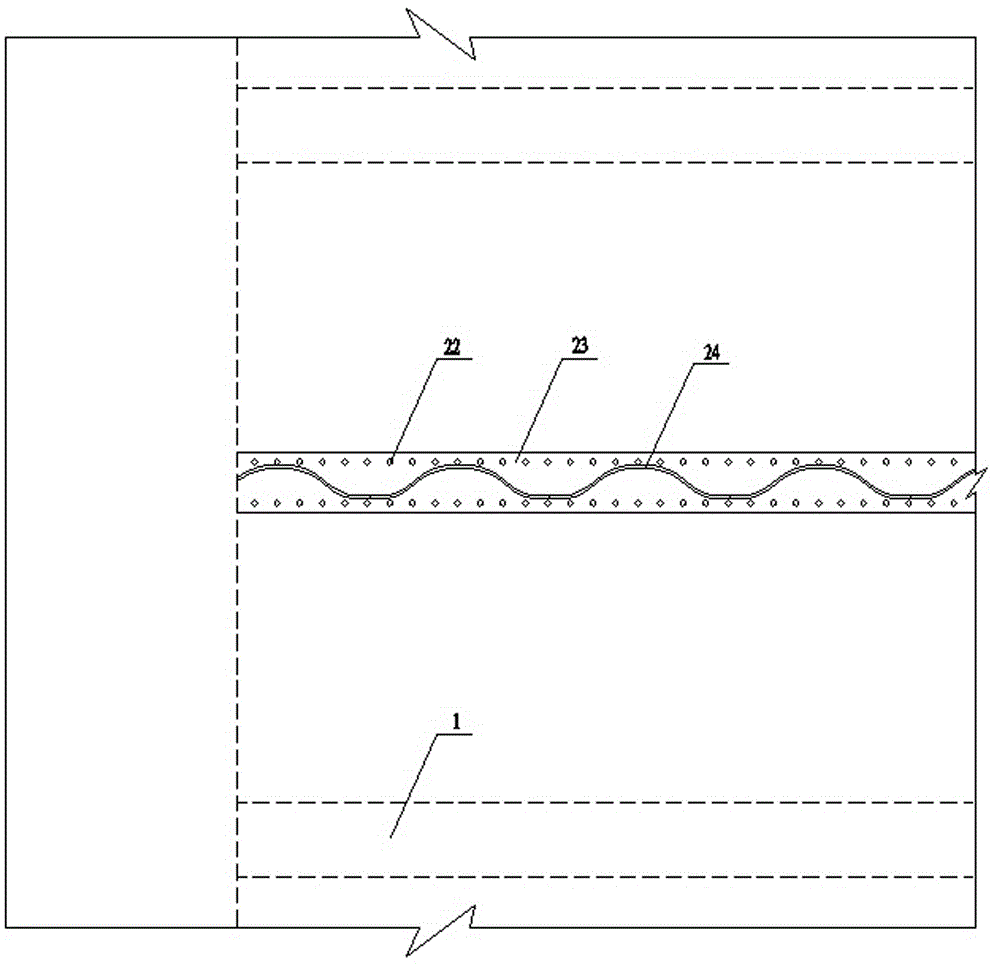

[0023] Anchor bolt 26 selects chemical anchor bolt in the present embodiment, combines Figure 1 to Figure 4 Shown, adopt corrugated steel web of the present invention to carry out the construction method of concrete box girder anti-shear reinforcement, carry out according to the following steps successively:

[0024] 1) Carry out construction lofting and positioning on the box girder top plate 2 and box girder bottom plate 3: determine the following positions through the lofting: the center line of the longitudinal box girder box chamber 4, that is, the center direction of the corrugated steel web; the opening size of the box girder top plate; The location of the anchor bolt holes in the bottom plate of the box girder;

[0025] 2) Opening of box girder roof 2: according to step 1) the opening size of the box girder roof for lofting and positioning, chisel away the concrete of box girder roof 2 within the range of lofting, and avoid damage to the original steel bars during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com