Arch-after-girder construction method of large-span steel box tacked arch bridge

A technology of beam-first-arch and construction method, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of prolonging the construction period of box girder, increasing the cost of beam yard, unfavorable construction organization, etc., so as to shorten the construction period and achieve good economy. Benefit, to ensure the effect of the overall construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

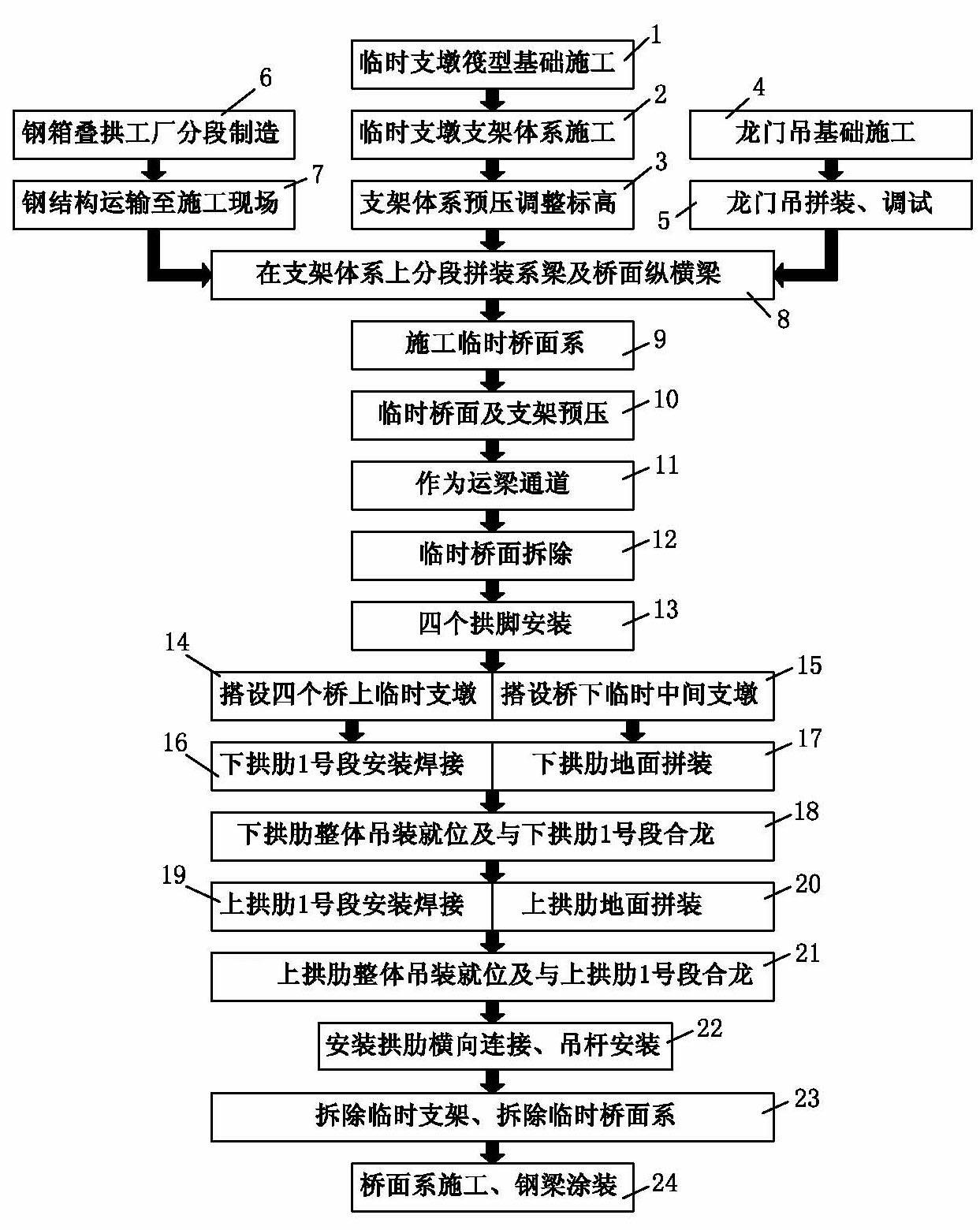

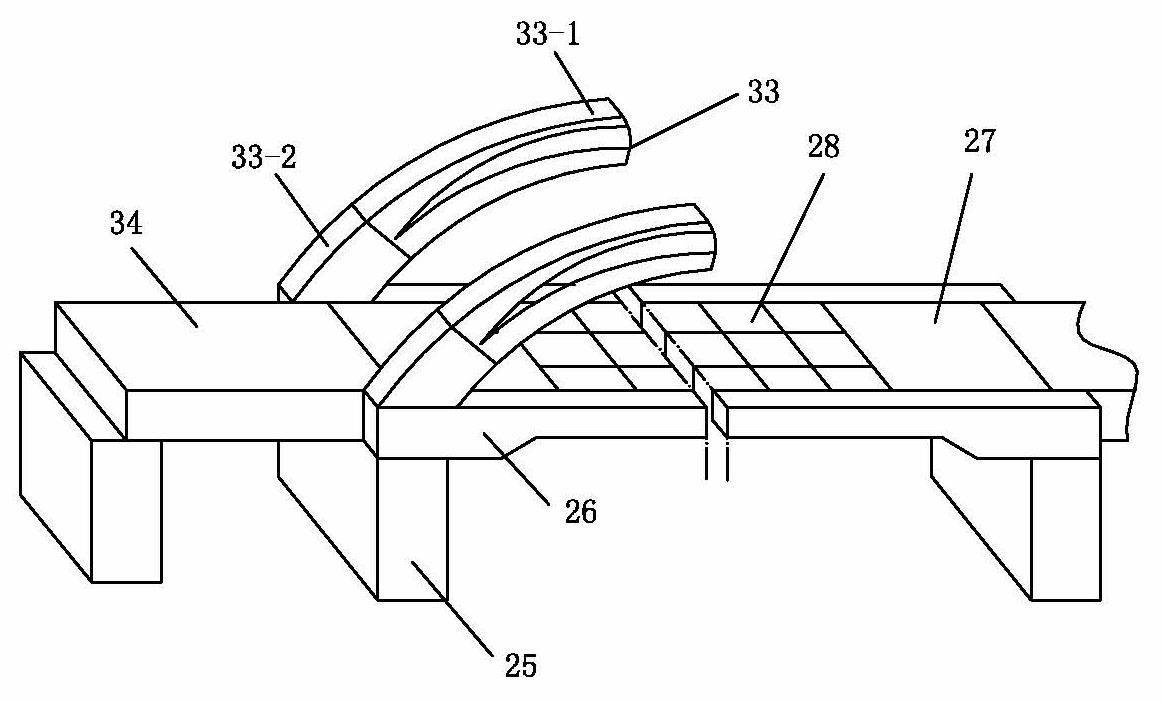

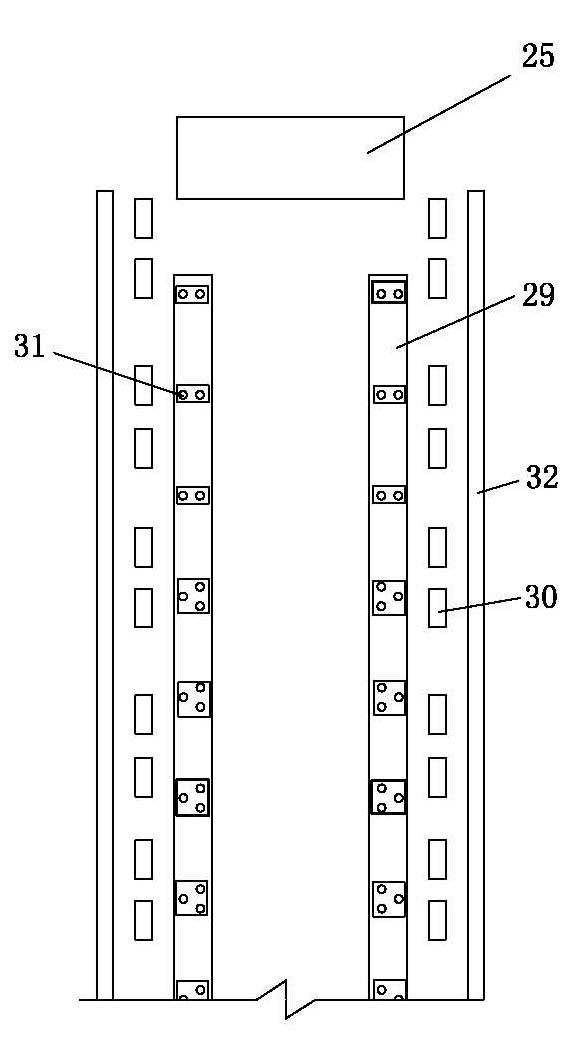

[0028] For an example of the construction method of the long-span steel box stacked arch bridge "beam first and then arch", see figure 2 , image 3 , Figure 4 with Figure 5 , the method includes the tie beam 26 spanning the piers 25 at both ends, the structural construction of the end beam 27 and the vertical and horizontal beam 28, the construction of the arch span structure and the construction of the bridge deck, and the sequence of steps includes:

[0029] a. At first build two temporary reinforced concrete strip foundations 29 respectively at the ground projections of the steel beam bottoms on both sides of the steel structure bridge to be built, and set up steel beam assembly platforms 30 on the outside of the two strip foundations, the platforms The height is less than 1.2 meters. A plurality of temporary buttresses 31 are arranged on the reinforced concrete strip foundation. The gantry crane track foundation is correspondingly built on the outside of the two-row s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com