Intelligent loading hopper and method for transferring materials

A technology for loading hoppers and hoppers, applied in the field of loading hoppers and transferring materials, can solve the problems of inability to achieve accurate measurement, high use costs, and inability to achieve accurate loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

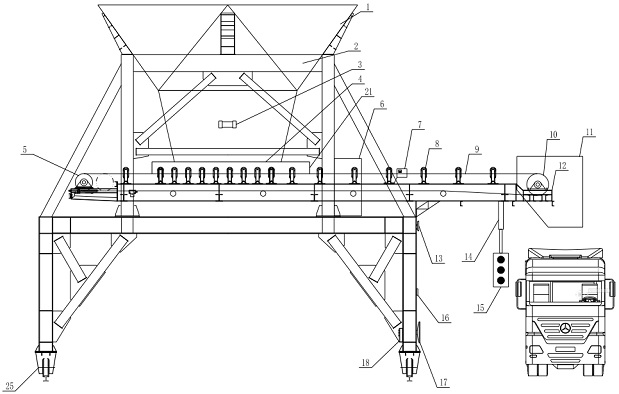

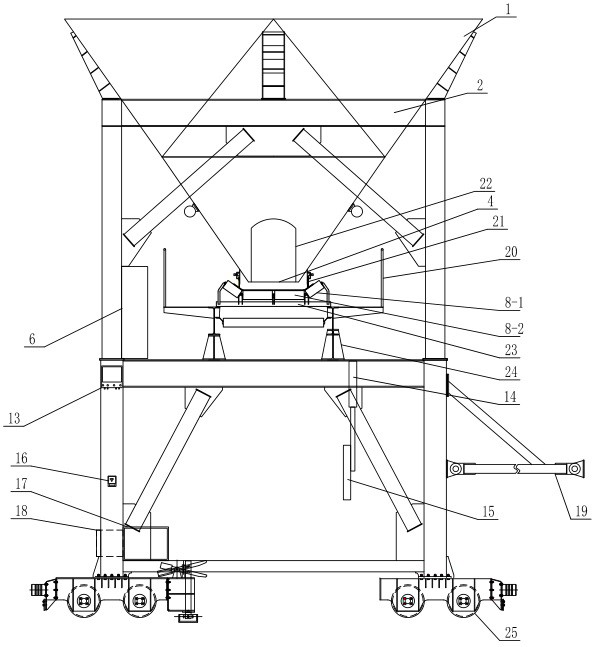

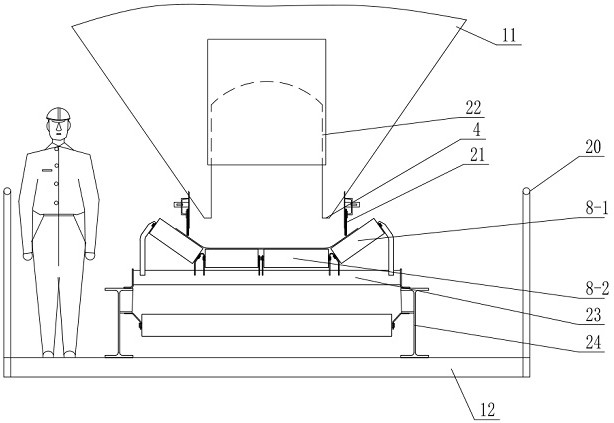

[0059] see Figure 1 to Figure 4 , an intelligent loading hopper, comprising a frame, a loading hopper 1 installed on the upper part of the frame for receiving materials, the lower end of the loading hopper 1 is provided with a discharge port 4, and the outer wall of the loading hopper 1 is provided with a vibration motor 3. The frame is provided with a connecting arm 19, and the lower end of the frame is provided with a traveling wheel 25. The connecting arm 19 is connected with the wharf door machine, and the walking wheel 25 can move on the track of the wharf door machine; The unloading hopper 11 and the conveying device for transporting the material in the loading hopper 1 to the unloading hopper 11, the lower part of the unloading hopper 11 is provided with a discharge port, the space in the lower part of the unloading hopper 11 can pass through the transfer vehicle, and the transfer vehicle can be parked in the unloading hopper. The loading position below the hopper 11 ...

Embodiment 2

[0074] The method for transferring materials using the intelligent loading hopper described in Embodiment 1 includes the following steps:

[0075] a) In the automatic loading mode, the vehicle identification subsystem and the automatic loading subsystem start at the same time; the vehicle identification subsystem reads the radio frequency card information of the transfer vehicle, and compares the radio frequency card information with the corresponding vehicle information stored in the database through the vehicle identification software. Matching, after the matching is successful, the vehicle's length, width, height, compartment bottom height, load, material type and other parameters are sent to the on-site PLC controller;

[0076] b) The on-site PLC controller collects the parking space detection signal, material level detection signal and belt scale weight measurement signal in real time; through the built-in intelligent control program, it automatically calculates the loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com