Non-metallic O-shaped ring performance testing device

A test device, non-metallic technology, applied in the field of non-metallic O-ring performance testing, can solve the problems of sealing performance affecting the overall sealing performance, imprecise, difficult O-ring friction performance, sealing performance and stress relaxation performance, etc., to achieve The loading process is stable, the economy is good, and the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

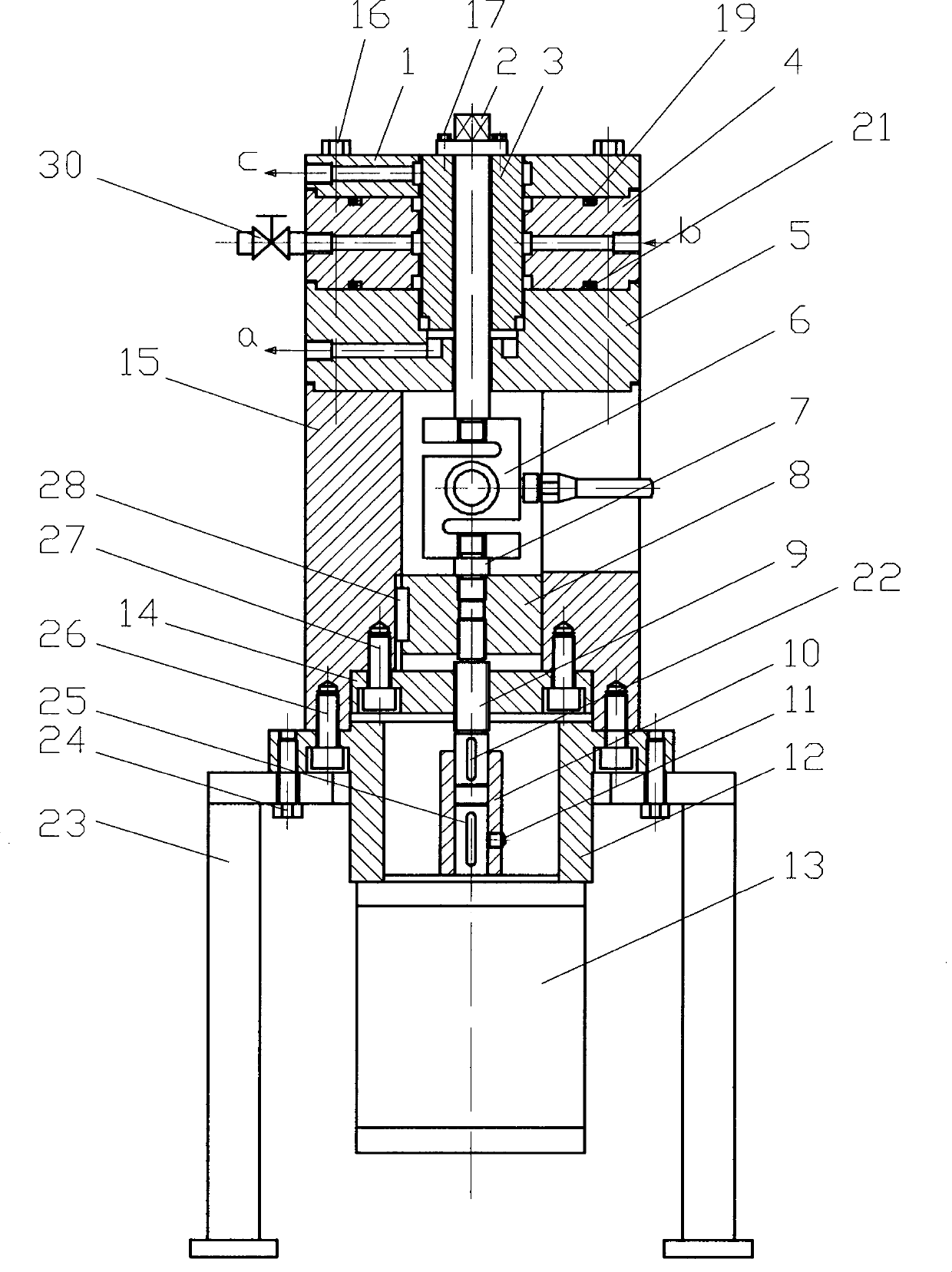

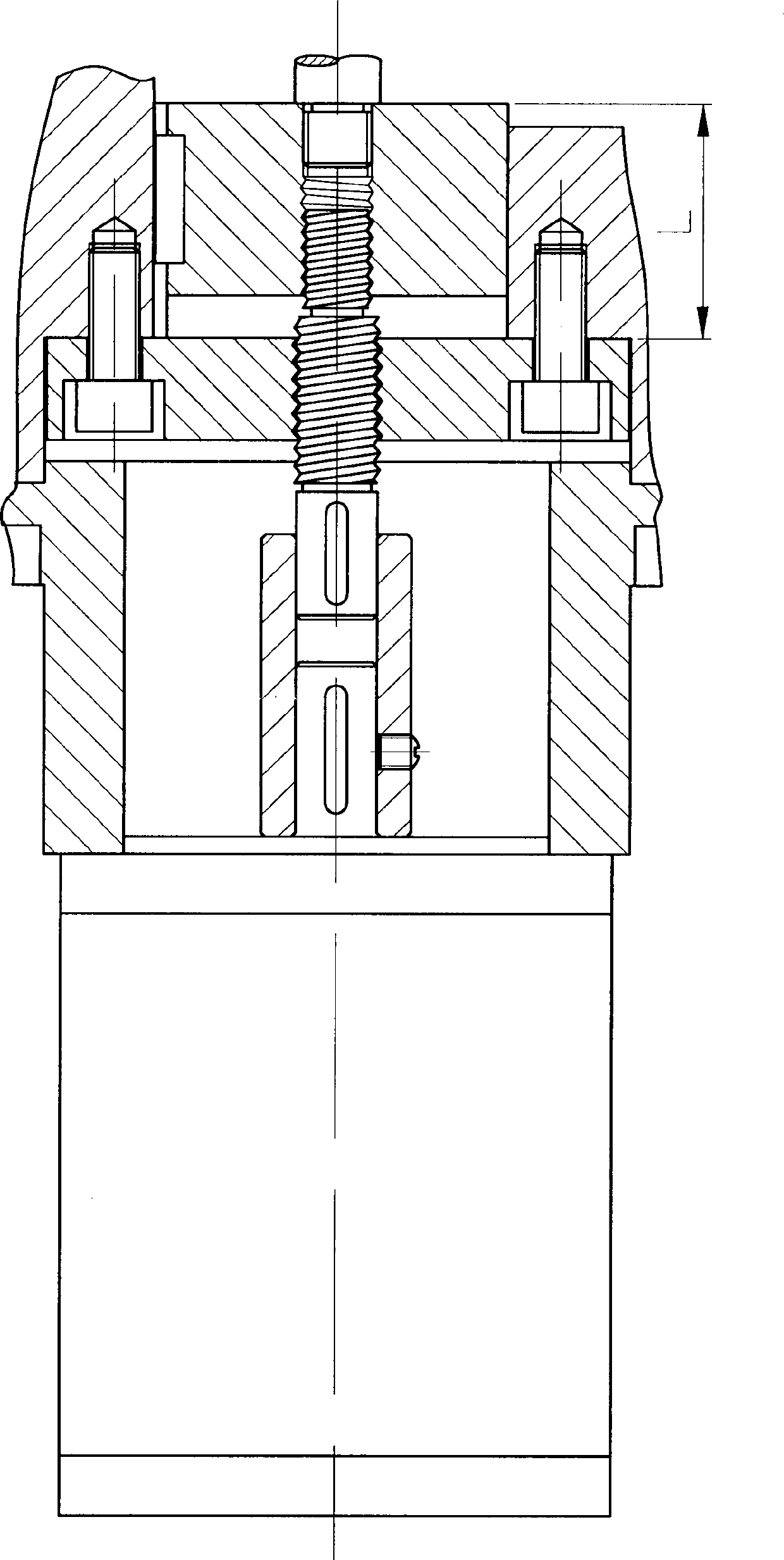

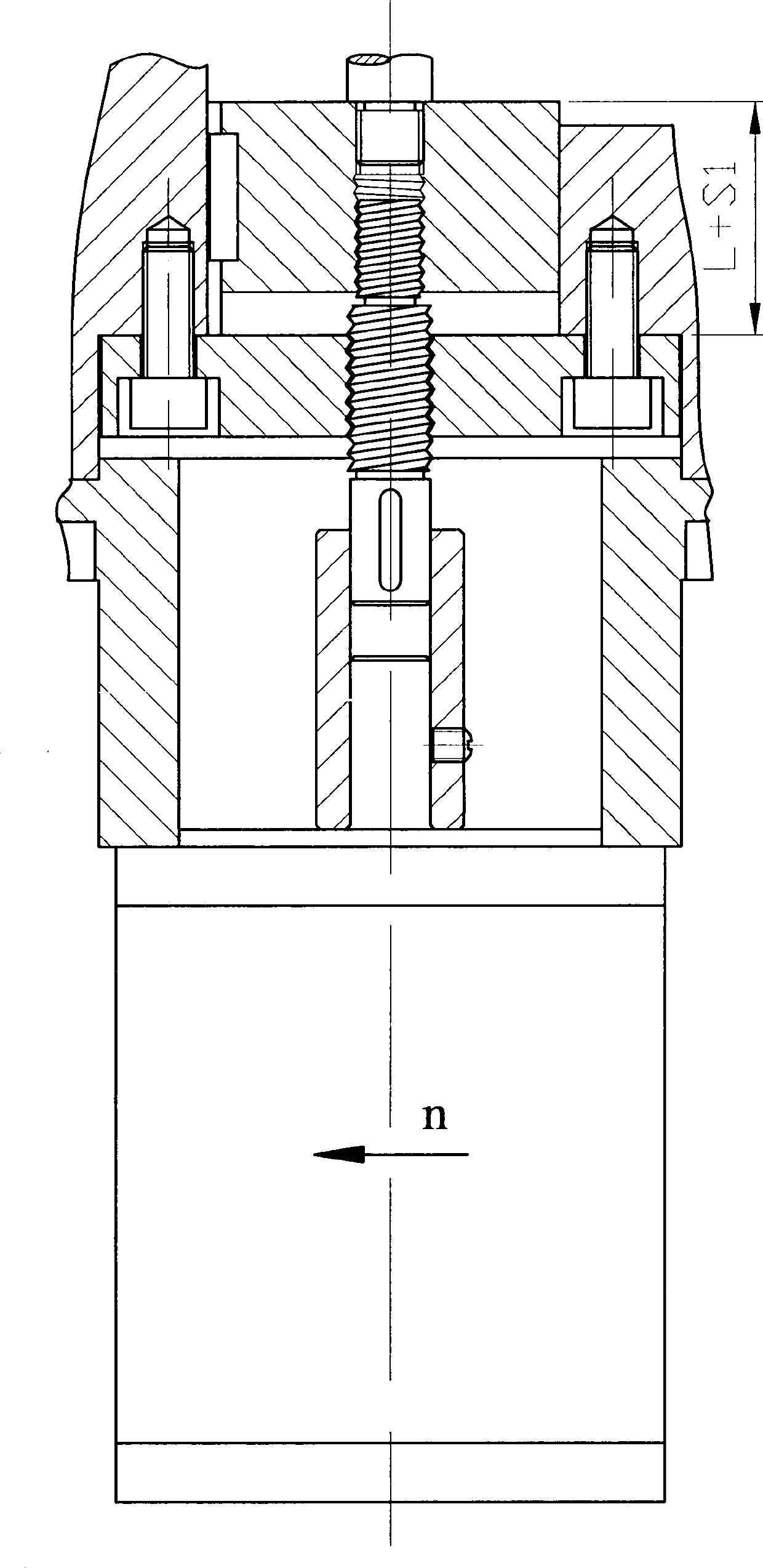

[0033] figure 1 It is a schematic diagram of a non-metallic O-ring performance test device. The non-metallic O-ring performance test device consists of upper ring 1, through-center rod 2, mandrel 3, middle ring 4, lower ring 5, force sensor 6, connecting rod 7, nut I8, differential screw 9, sleeve coupling Device 10, set screw 11, flange bracket 12, stepper motor 13, nut II14, cylindrical bracket 15, bolt I16, bolt II17, O-ring II19, O-ring IV21, guide flat key I22, four-legged bracket 23. Bolt III24, key 25, bolt IV26, bolt V27, guide flat key II28, O-ring V29, stop valve 30 and other parts, the upper ring 1 and the lower ring 4 respectively have leak detection port Ic and leak detection port IIa, There are two radial circular through-hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com