Spanning type bailey beam bracket and construction method thereof

A construction method, Bailey beam technology, applied to bridges, bridge materials, bridge construction, etc., can solve the problems of unfavorable steel pipe pile removal construction, low recovery rate of steel pipe piles, and low clearance at the bottom of the beam, so as to shorten the construction period , Improve safety and save construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

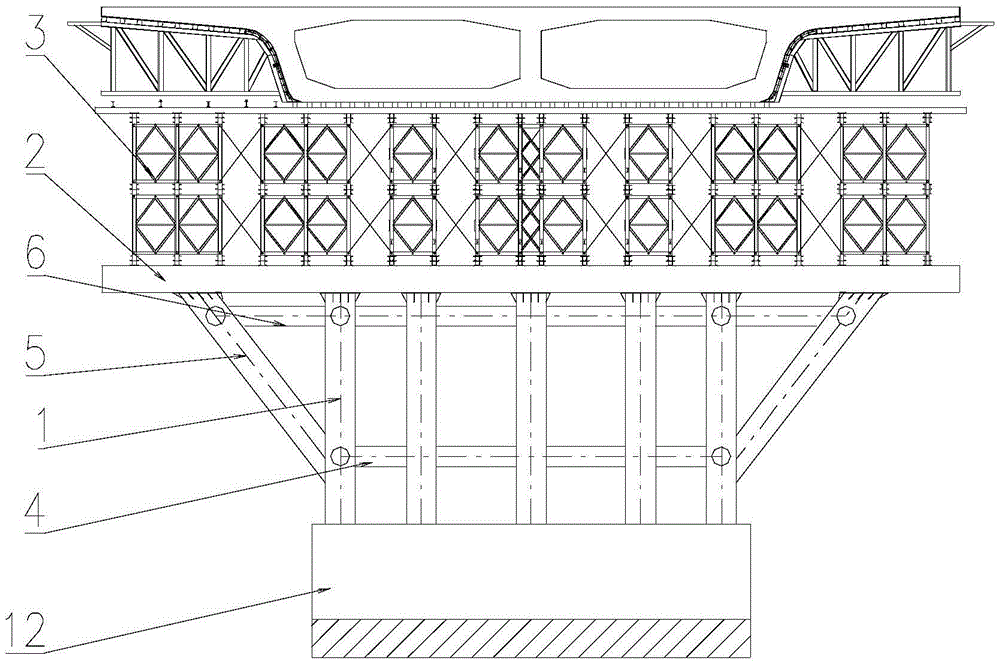

[0033] The example discloses a span-type Bailey beam support, which is used as a construction support system for pouring construction of a box girder.

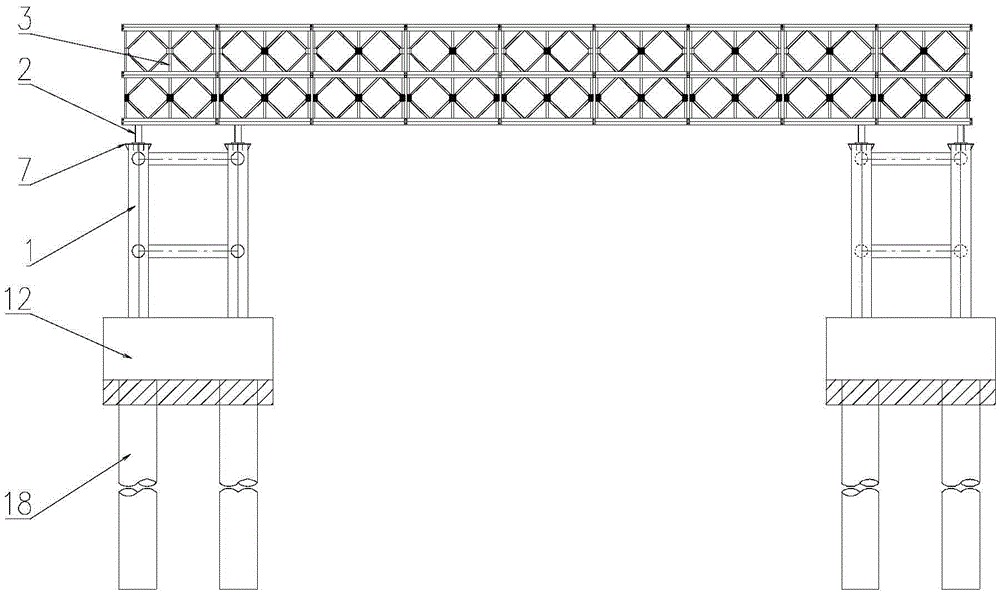

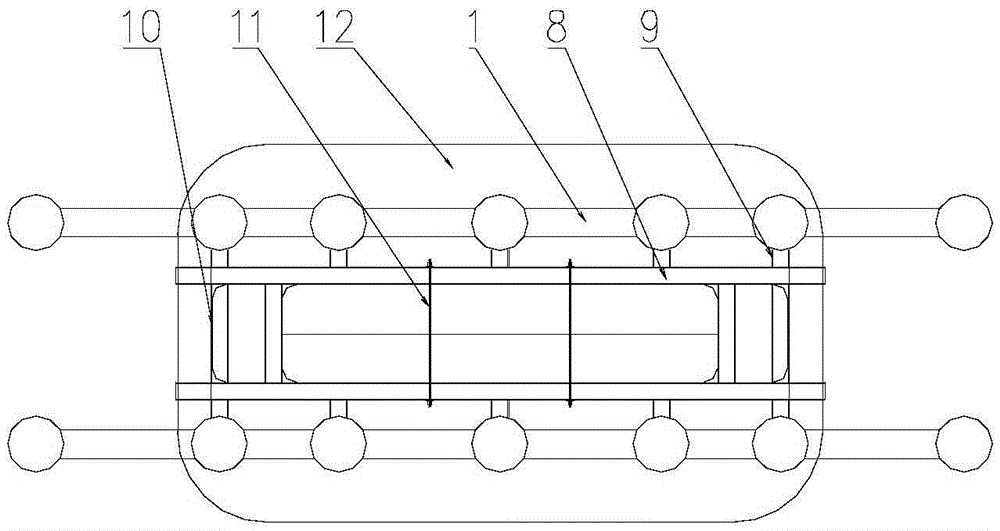

[0034] refer to figure 1 and figure 2 , the span-type Bailey beam support in this embodiment includes support foundations located on both sides, the support foundations include multiple rows of steel pipe piles 1 arranged in the transverse direction, and the tops of the steel pipe piles 1 on the same side are supported by crossbeams 2 arranged in the transverse direction , the tops of the beams on both sides are fixedly connected to the longitudinal ends of the Bailey beam 3 .

[0035] The construction method for carrying out the box girder pouring construction by using the above-mentioned span-type Bailey beam support includes the following construction steps:

[0036] 1) The sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com