Cable-stayed multi-layer framework structure and construction control method thereof

A multi-layer frame, cable-stayed technology, applied in the direction of structural elements, building components, building structures, etc., can solve problems such as self-weight, large additional assembly axial force, and structure burial safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

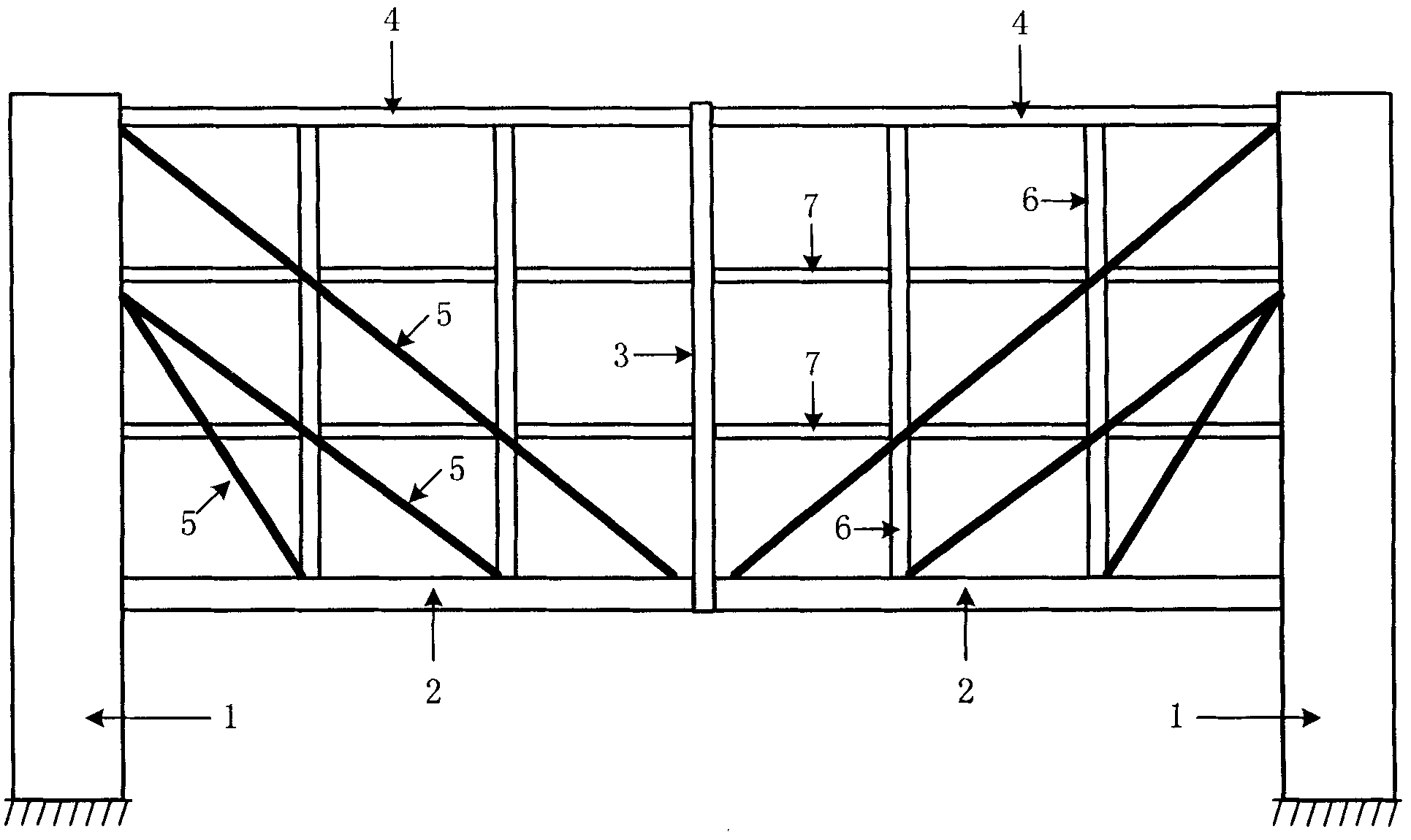

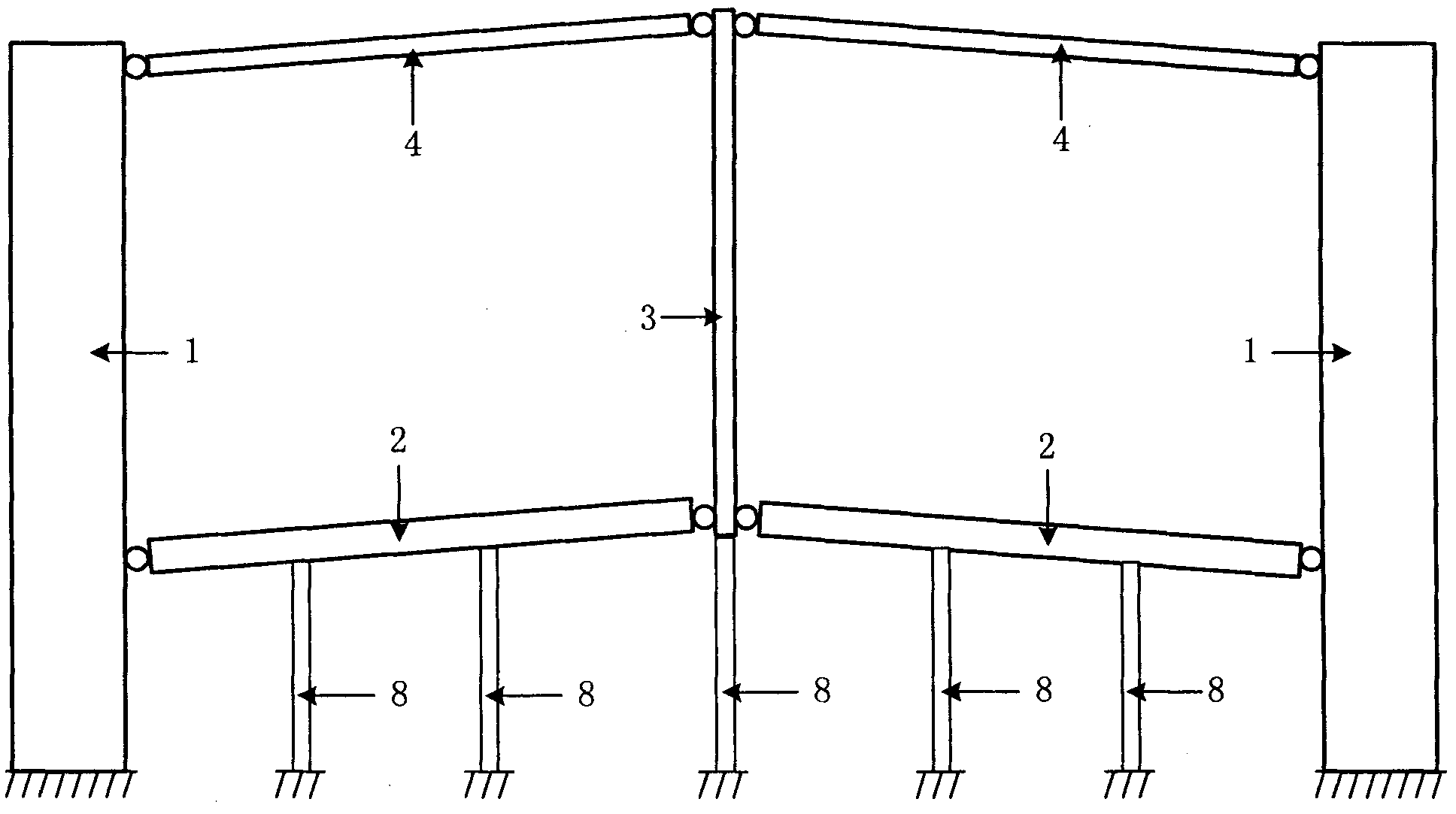

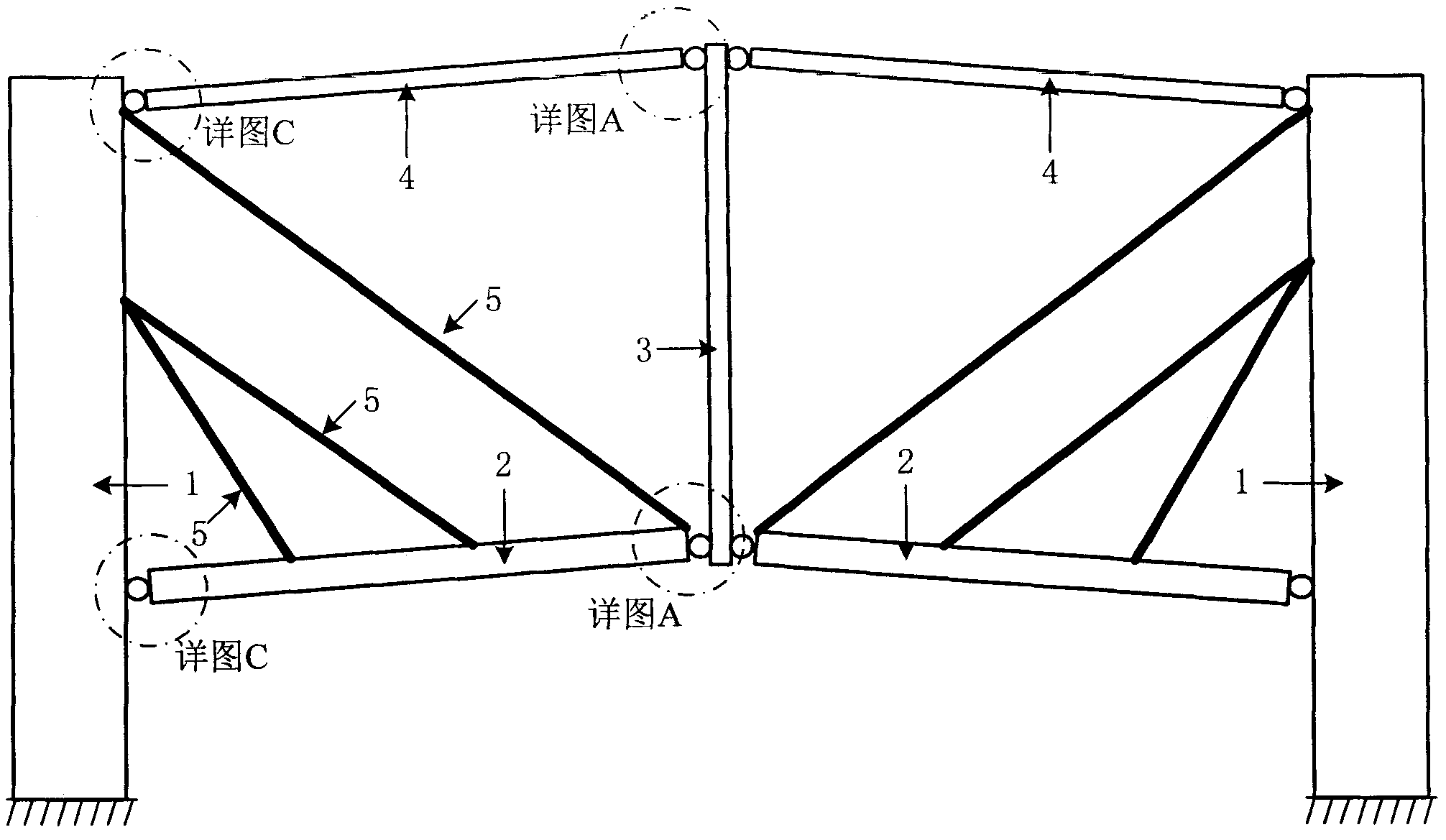

[0059] Attached below Figure 1-10 , the present invention will be described in detail.

[0060] figure 1 Middle: 1—anchor ingot structure; 2—joist beam; 3—mid-span frame column; 4—top frame beam; 5—stayed cable; 6—frame column; 7—frame beam;

[0061] figure 2 Middle: 1—anchor structure; 2—joist beam; 3—mid-span frame column; 4—top frame beam; 8—support tire frame;

[0062] image 3 Middle: 1—anchor ingot structure; 2—joist beam; 3—mid-span frame column; 4—top frame beam; 5—stayed cable;

[0063] Figure 4 Middle: 1—anchor ingot structure; 2—joist beam; 3—mid-span frame column; 4—top frame beam; 5—stayed cable; 9—first floor frame column; 10—the first floor 1st floor frame beam;

[0064] Figure 5 Middle: 1—anchor ingot structure; 2—joist beam; 3—mid-span frame column; 4—top frame beam; 5—stayed cable; 11—second floor frame column; 12—the first floor 2-story frame beam;

[0065] Figure 6 Middle: 1—anchor ingot structure; 2—joist beam; 3—mid-span frame column; 4—to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com