Installation method of no-bracket prefabricated bracket intermediate beam

An installation method and corbel technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as unfavorable operation management, poor corbel design, harmful secondary stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

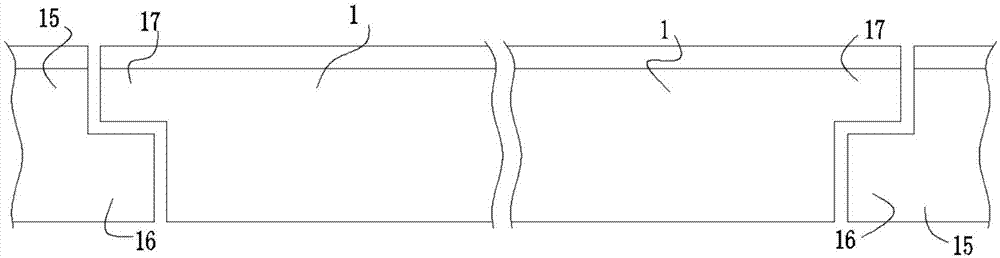

[0029] Such as Figure 2 to Figure 5 As shown, taking a 40m box girder of a certain bridge as an example, the girder weighs about 120t and is installed between fixed beams 15 at both ends. The box girder is designed without corbels.

[0030] The weight of the beam at one end of the box girder is 60t, and 8 reinforced I 56 Word steel. The construction design calculates the reserved holes for the suspender 9 to pass under the prefabricated joist beam 1, and the reserved holes for installing the cross arm 10 on both sides of the bottom of the prefabricated joist beam 1;

[0031] A method for installing prefabricated joist beams without corbels, comprising the following steps:

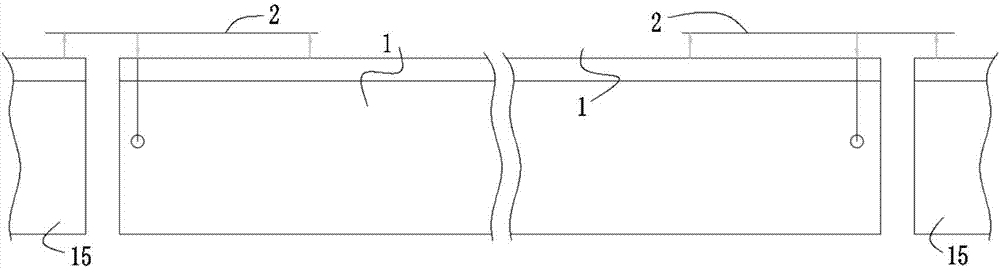

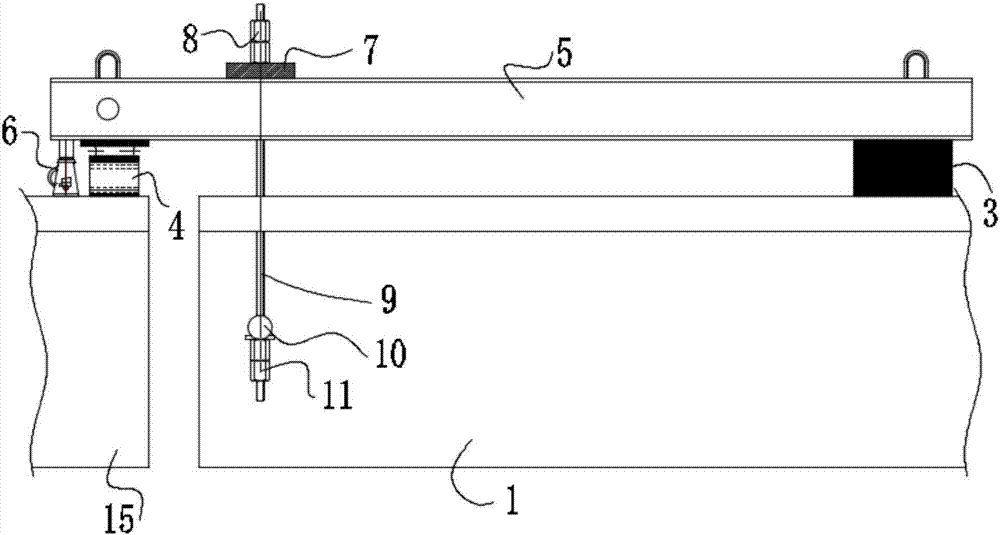

[0032] Step 1. First install the reverse beam hanger 2 at both ends of the prefabricated bracket beam 1 respectively. The reverse beam hanger 2 includes two boom assemblies, support pads 3, and a horizontal bar 5 made of I-shaped steel. , the crossbar 5 is arranged above the prefabricated bay beam 1, th...

Embodiment 2

[0040] Such as Figure 5 and Figure 6 As shown, the difference between Embodiment 2 and Embodiment 1 is that the prefabricated joist beam 1 is a T-shaped beam, and each end of the T-shaped beam is connected with four crossbars 5 through a set of suspender assemblies, and the crossarm 10 is directly Located at the bottom of the T-beam, the cross arm 10 is connected to the four cross-bars 5 above the T-beam through two suspenders 9. Compared with Example 1, Implementation 2 lacks a set of suspender components. The bottom of the joist beam 1 does not need to be provided with a reserved hole for the cross arm 10, and the others are the same as in the first embodiment.

[0041] The cross bar 5 that adopts in above-mentioned embodiment 1 and embodiment 2 is I-shaped steel, specifically I 56 Word steel, the suspender 9 adopts finish-rolled rebar, and the specific dimensions of the cross bar 5 and the suspender 9 are calculated and designed according to the weight and size of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com