Precast concrete frame support shear wall panel

A technology of prefabricated concrete and shear walls, applied to walls, building materials, building components, etc., to achieve the effects of easy installation and construction, clear structural stress, and reduced number of connection parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

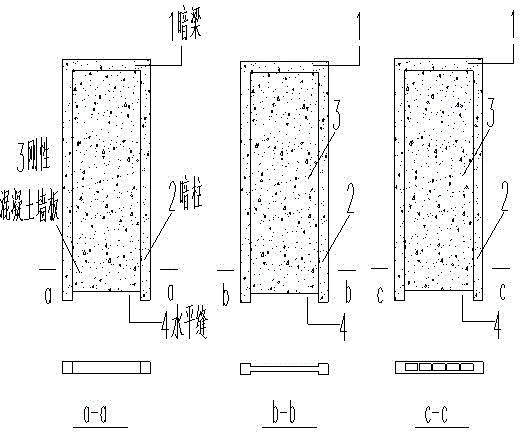

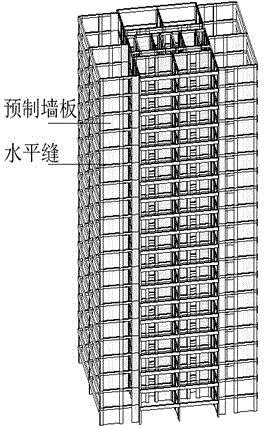

[0011] The present invention will be described in detail below with reference to the drawings and embodiments.

[0012] When the invention is manufactured in the factory, the formwork is installed, the steel bars are arranged and the concrete is poured according to the relevant design parameters. After the production is completed in the factory, it is lifted and installed after being transported to the site.

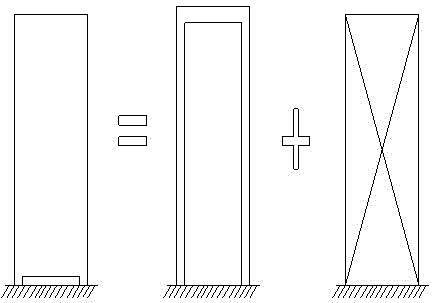

[0013] Attached image 3 In the illustrated embodiment, in the fabricated concrete frame-supported shear wall system constructed by the present invention, the layers of the concealed columns in the shear wall are connected vertically, and the central rigid concrete wall panel can be solid or hollow with rectangular cross section. For wall panels, 10mm-20mm horizontal seams are set between each layer of rigid concrete wall panels in the middle. Although it is a shear wall structure type, it is equivalent to attached Figure 4 The frame structure system shown in.

[0014] It n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com