Patents

Literature

50results about How to "Convenient on-site installation and construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

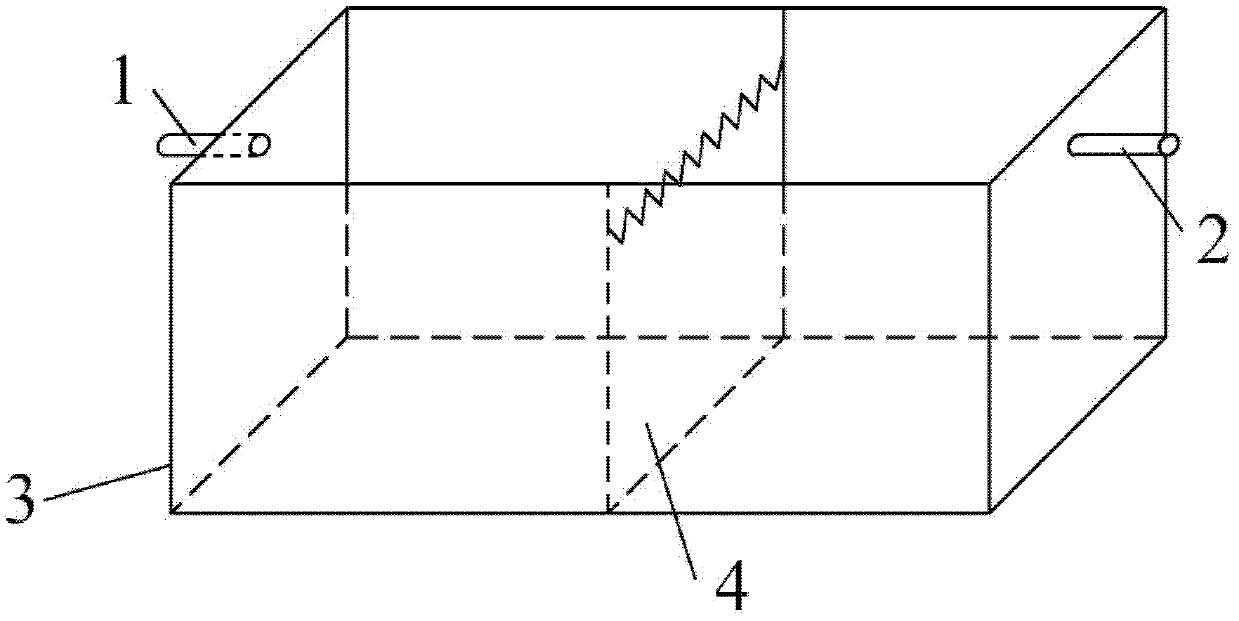

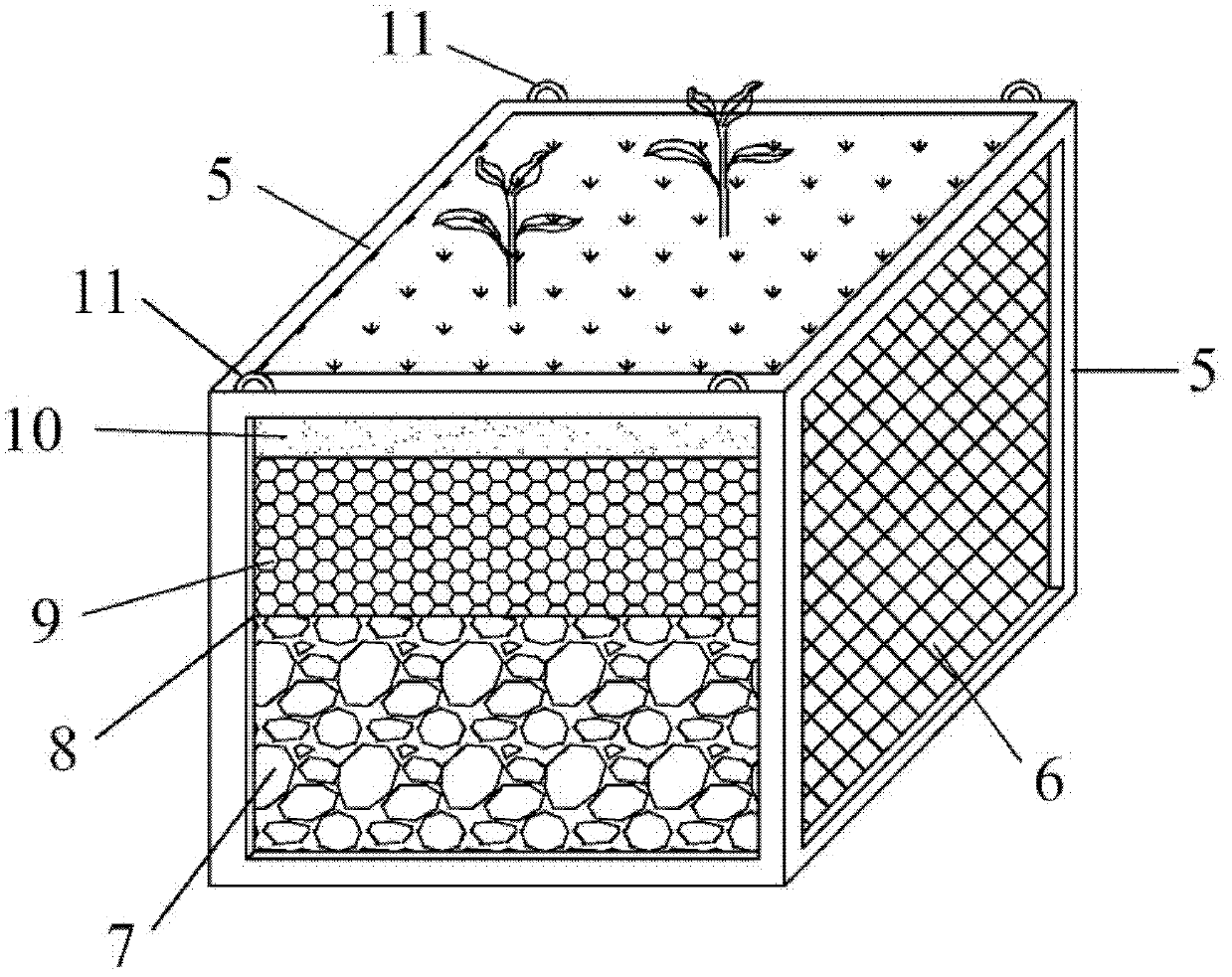

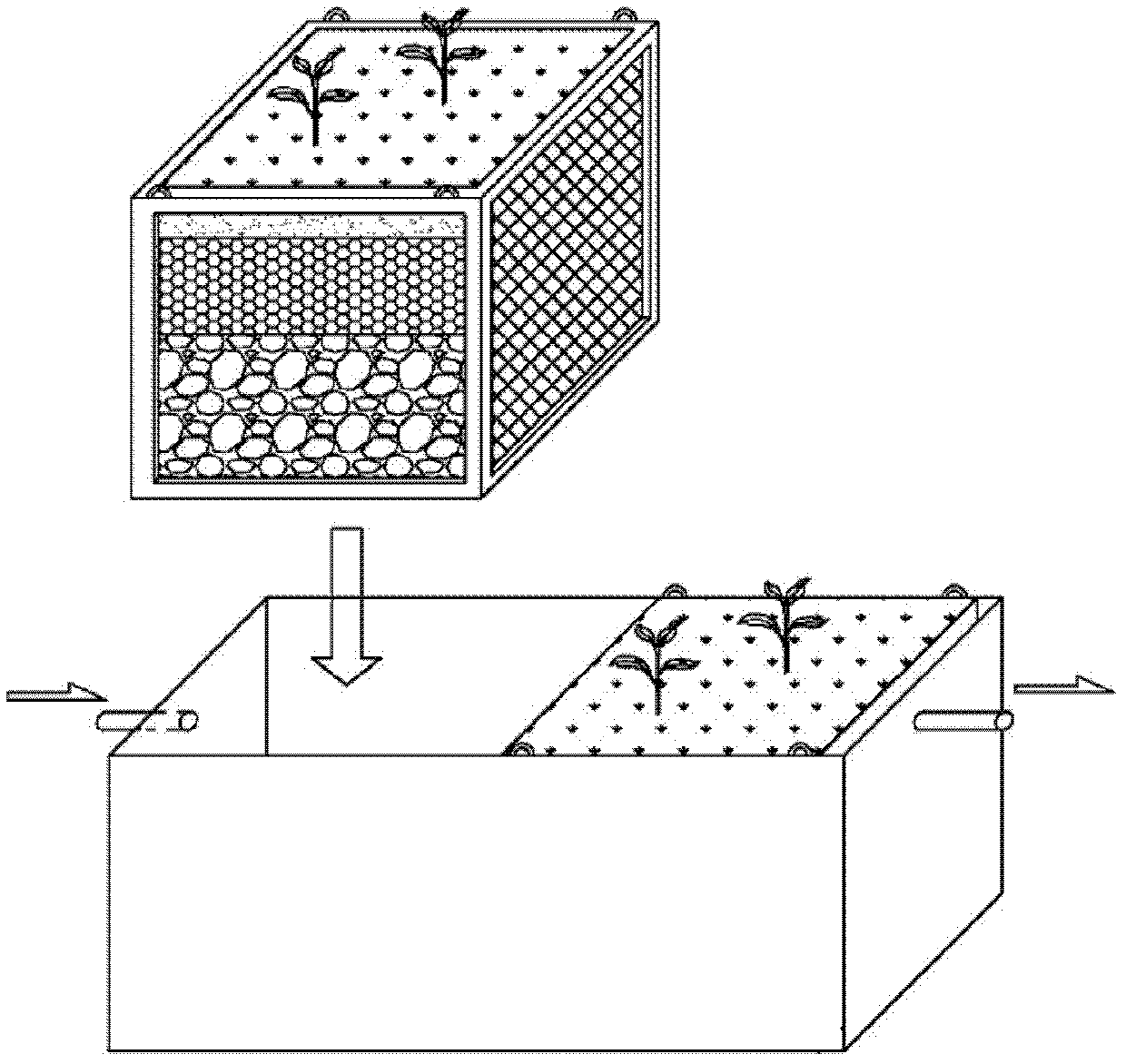

Modularized detachable constructed wetland

InactiveCN102603077ASimple structureEasy to installSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandWater quality

The invention discloses a modularized detachable constructed wetland, which is formed by a plurality of wetland modules, each module is relatively independent, and the module comprises a plurality of detachable filler units; each filler unit consists of a filler frame, a net separator and a filler layer, and the filler layer comprises a soil layer, a soil separation layer and a porous light filler layer from top to bottom. According to the water quality, the water yield and the water outlet requirement of the treated sewage, the wetland modules can be connected in series and in parallel or compositely connected to constitute a constructed wetland system. The modularized detachable constructed wetland has a simple structure, is convenient to install, is low in cost, and adapts to industrialized batch production. In the operation process of the wetland, the wetland modules and the filler units can be replaced and repaired at any time, the system is not blocked easily, the treatment effect is good, and the land can be reused.

Owner:王启明

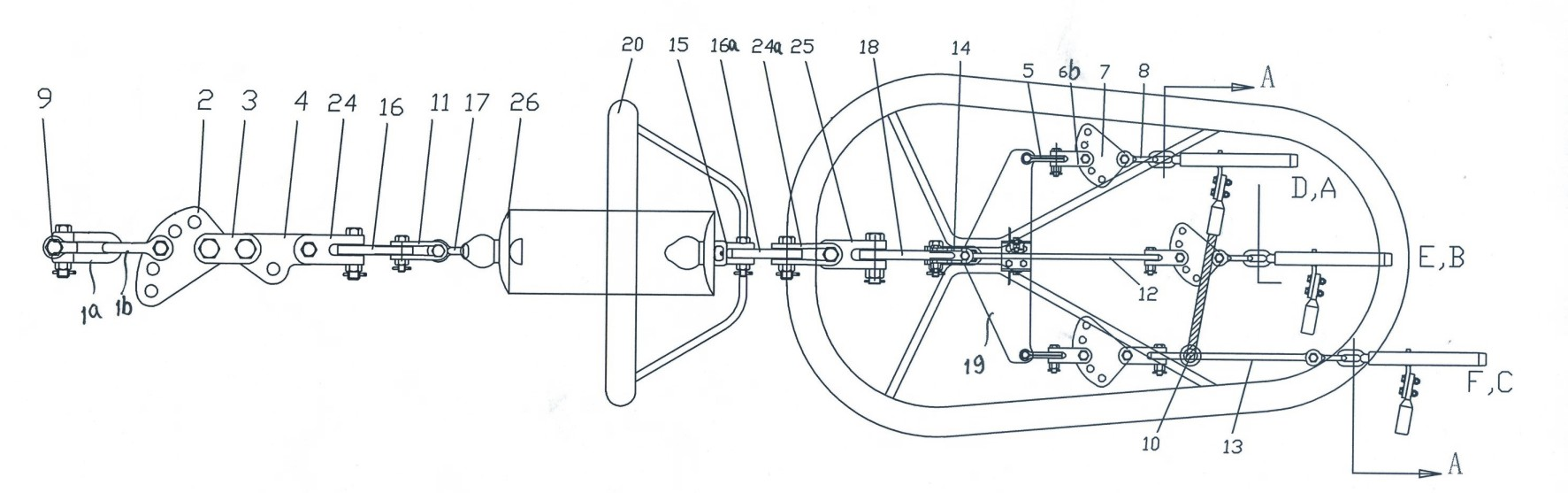

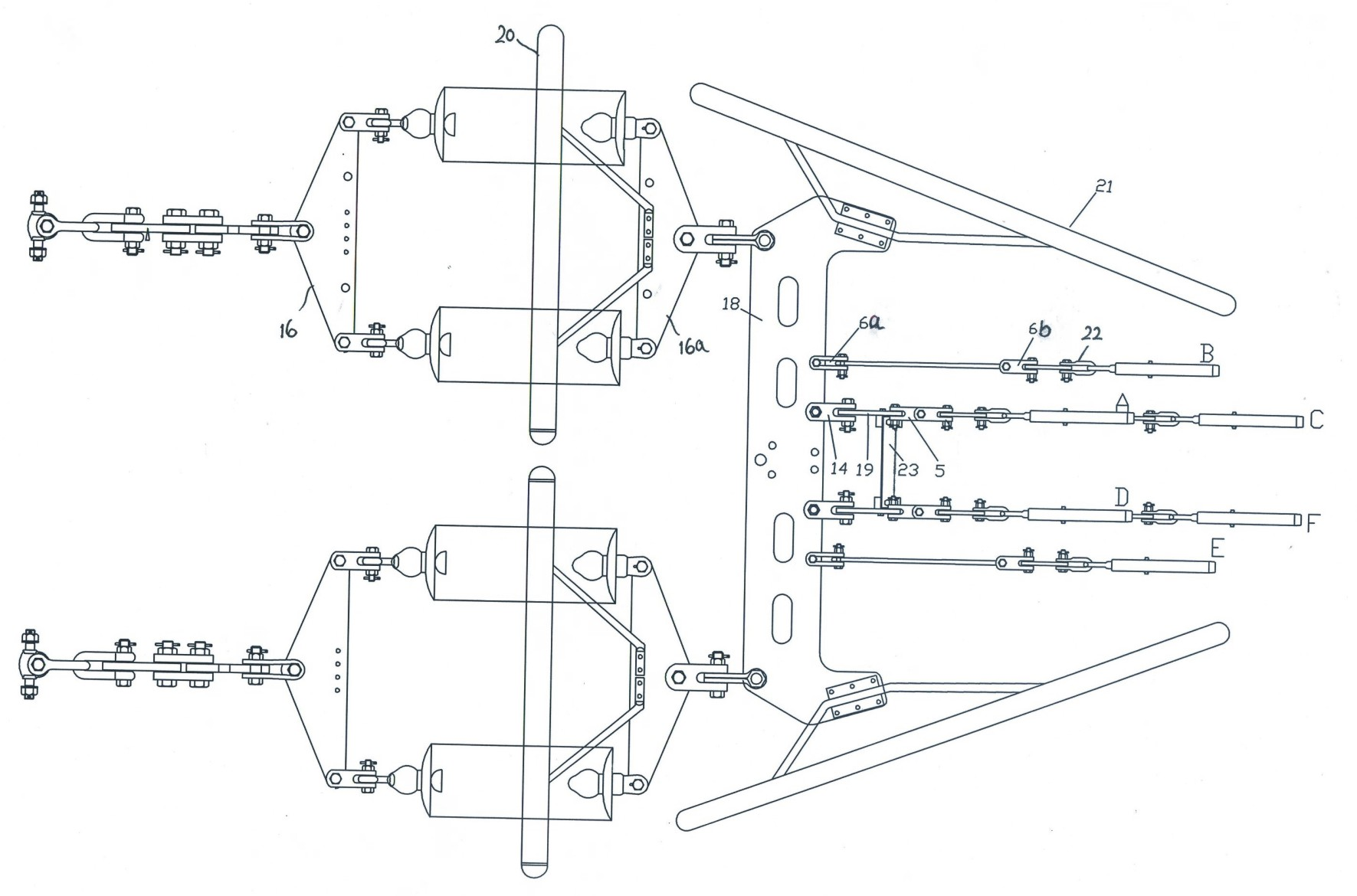

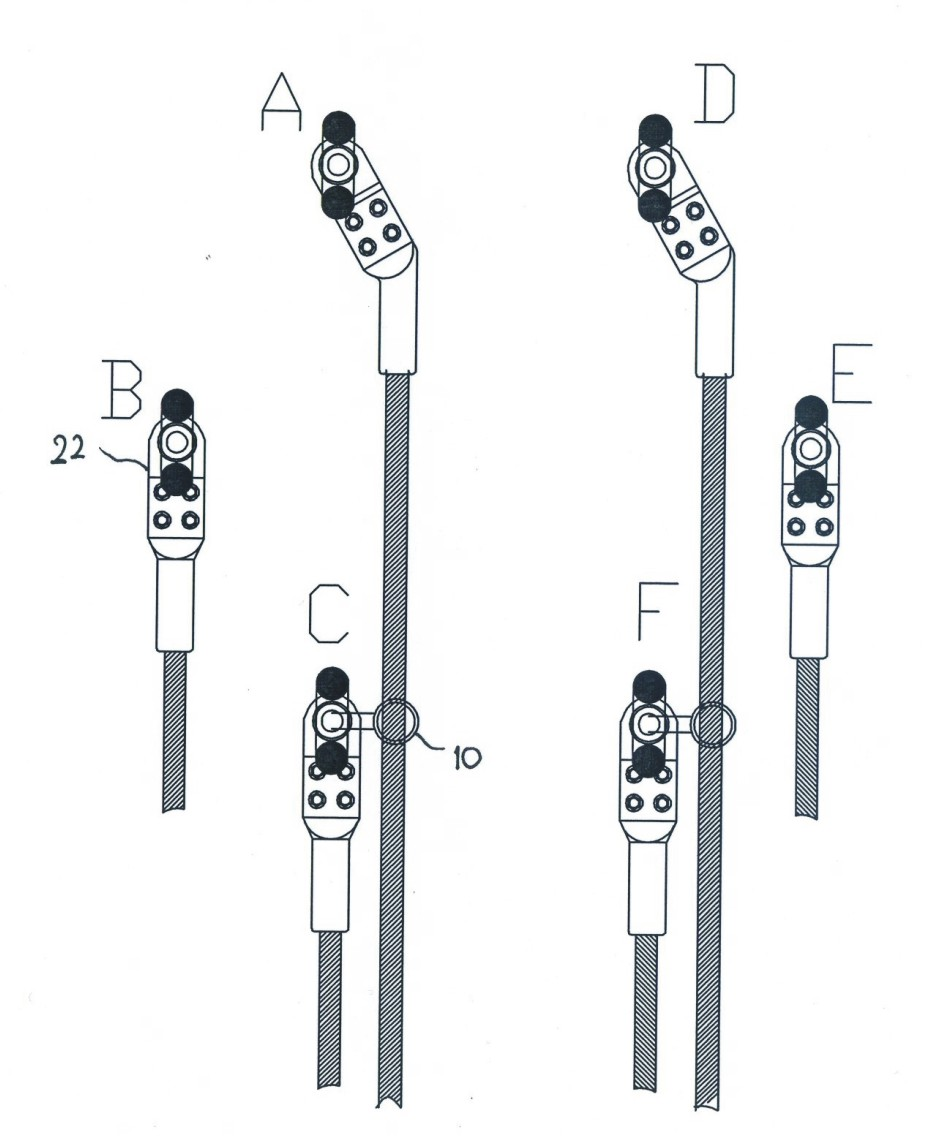

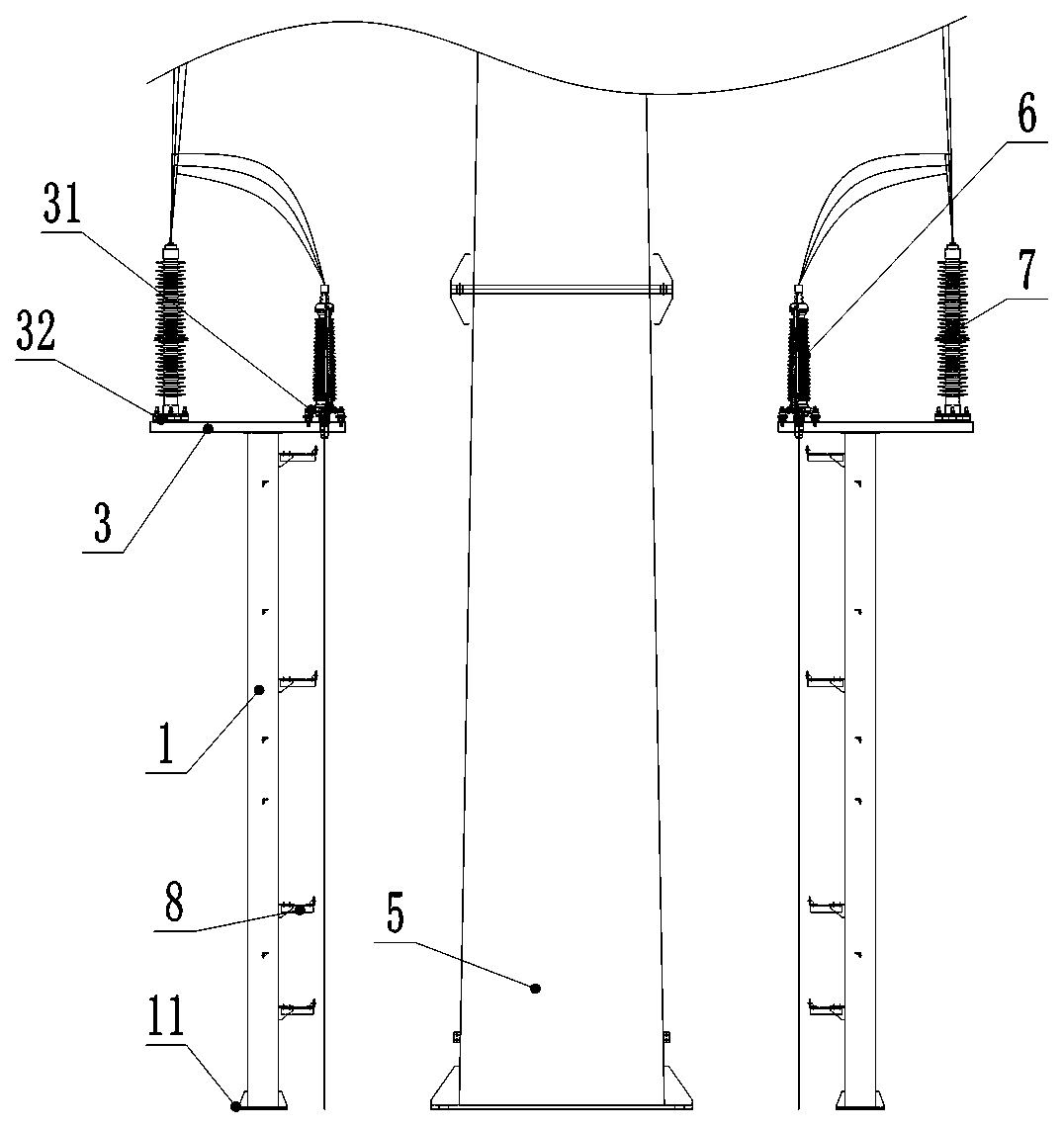

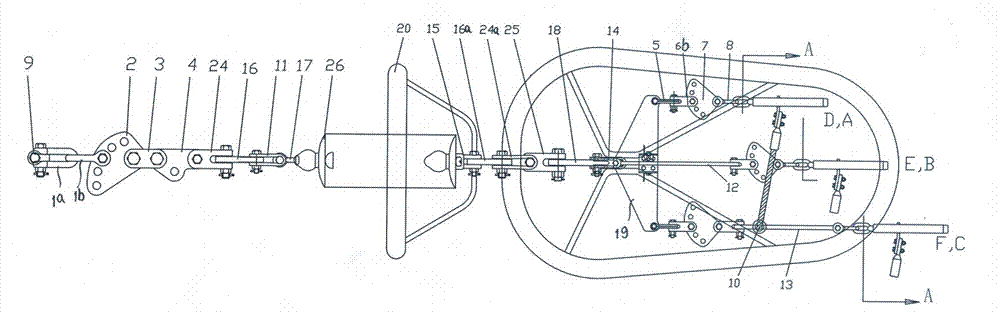

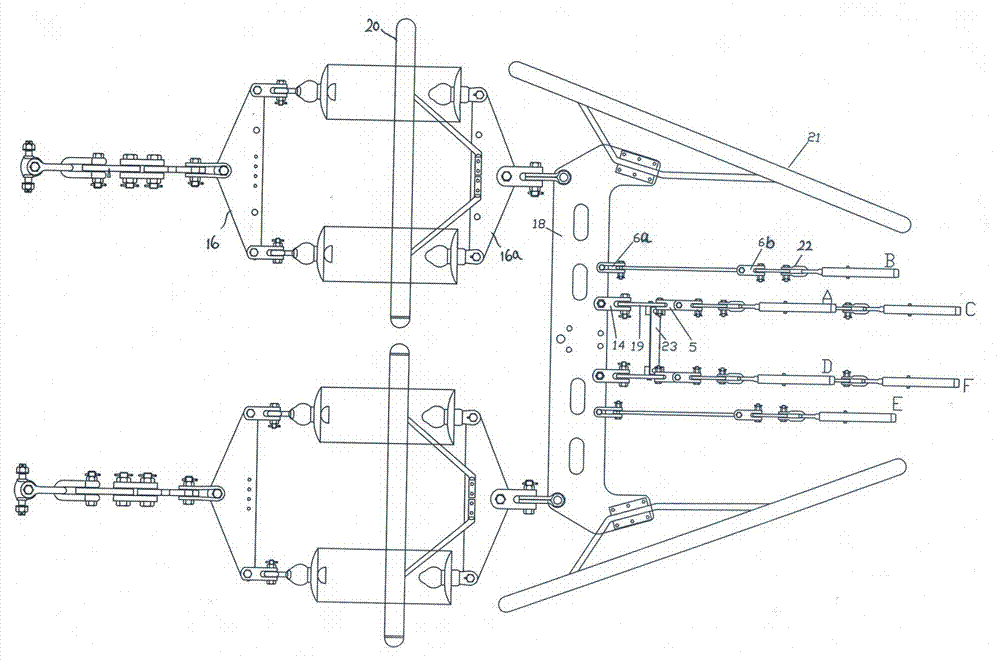

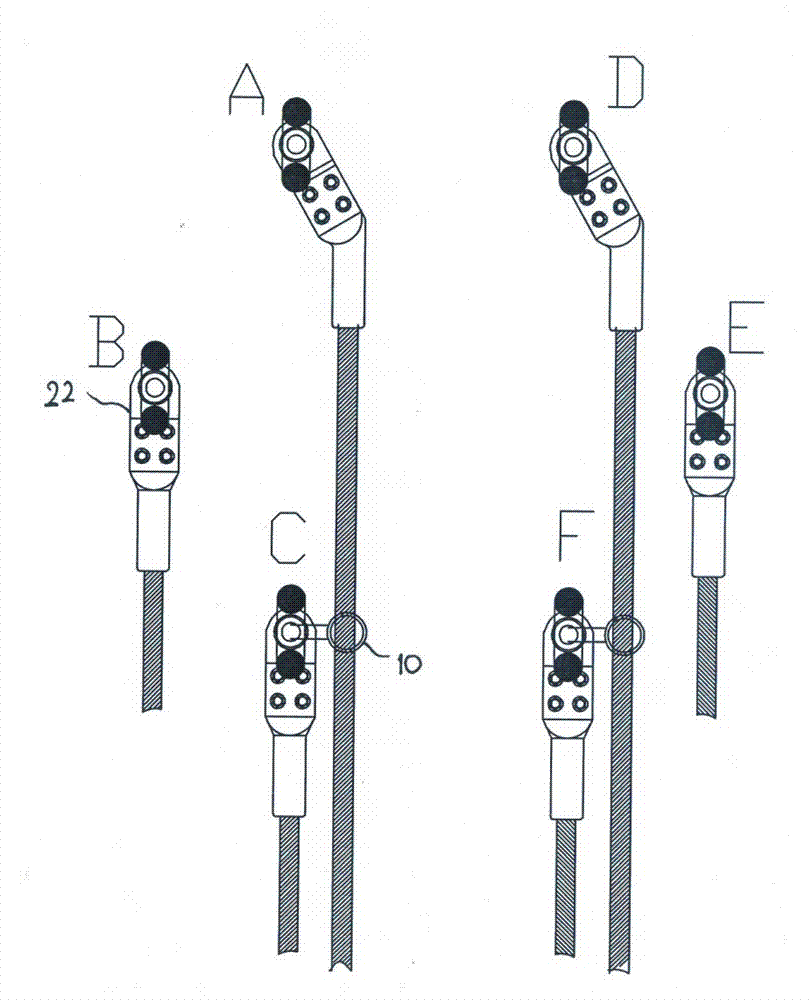

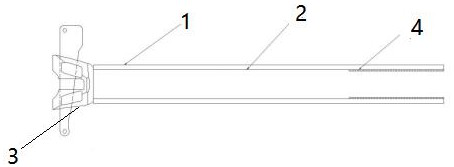

Four-link tension string for +/-800KV heavy ice area

The invention provides a four-link tension string for a + / -800KV heavy ice area, belonging to fitting strings for construction of transmission lines. The four-link tension string comprises two hanging point fittings connected with a tower, wherein after being connected with the same fitting, each hanging point fitting is connected at the left end of a first yoke plate by a bolt; the right end of the first yoke plate is connected with two insulators by a ball head hanging ring; two of the four insulators are connected on a second yoke plate and the other two insulators are connected on the other second yoke plate; the two second yoke plates are respectively connected with a combined yoke plate by a right-angle hung plate; an equalizing ring is arranged on two insulators; the equalizing ring is in open type or two-leg split type; the combined yoke plate is formed by connecting a two-variable four-link plate, two right-angle hung plates and two one-variable two-link plates by bolts; and two shielding rings are fixed at the upper and lower ends of the two-variable four-link plate by brackets. The four-link tension string has the characteristics of convenience for installation of the equalizing ring, stable structure and high strength.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP +2

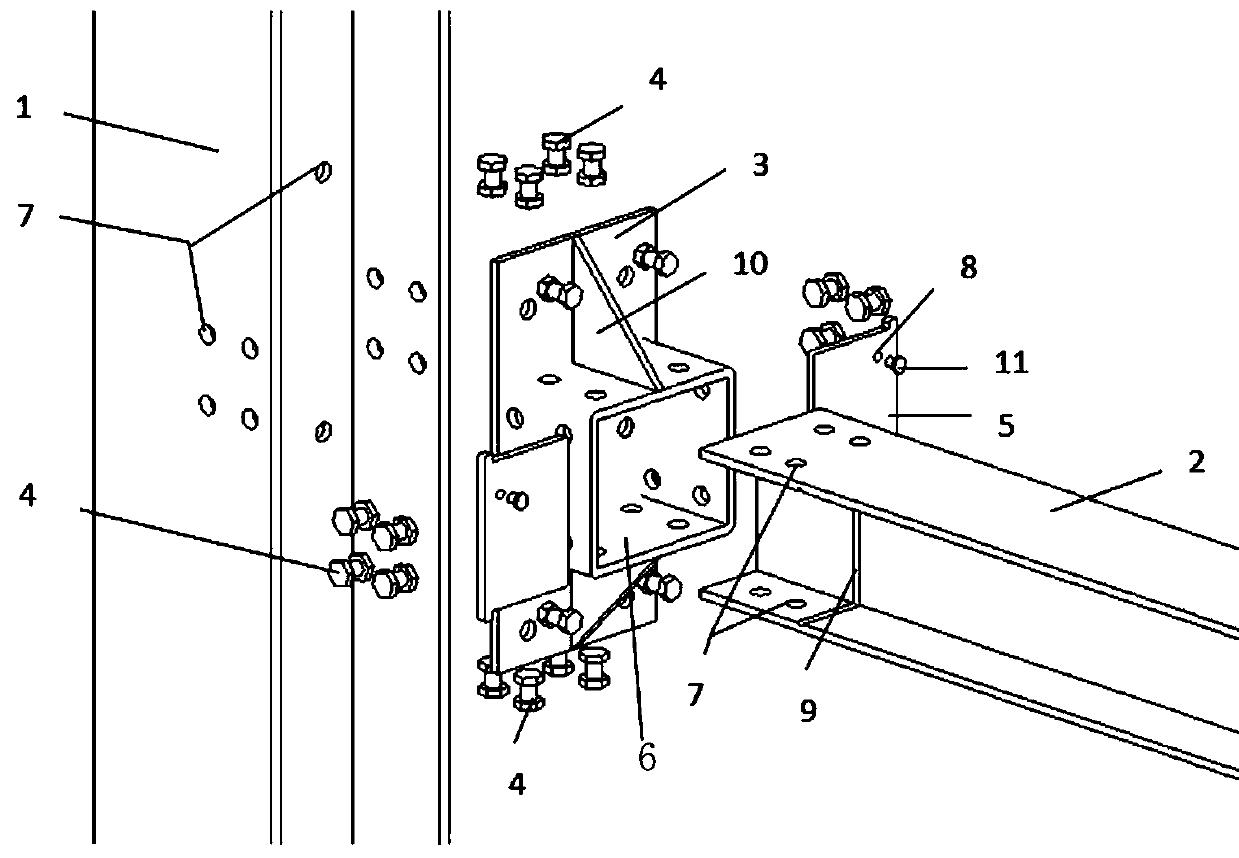

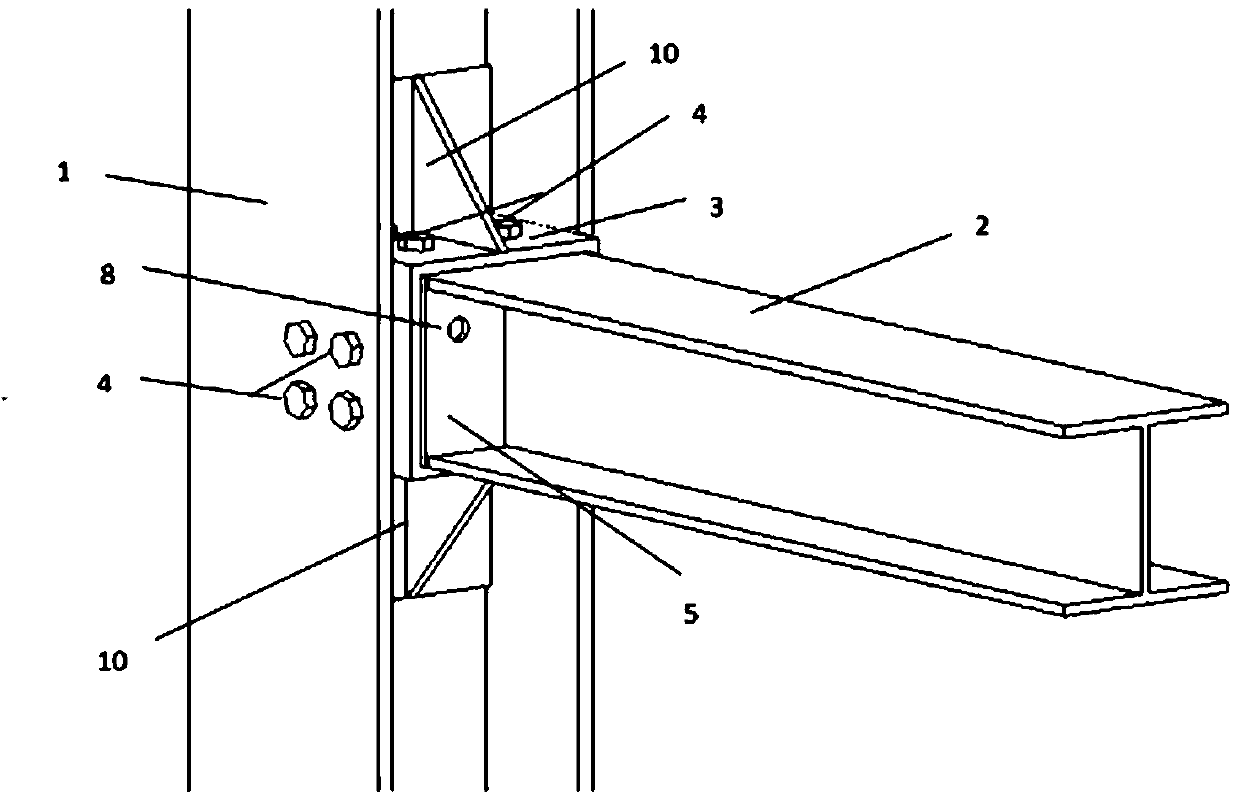

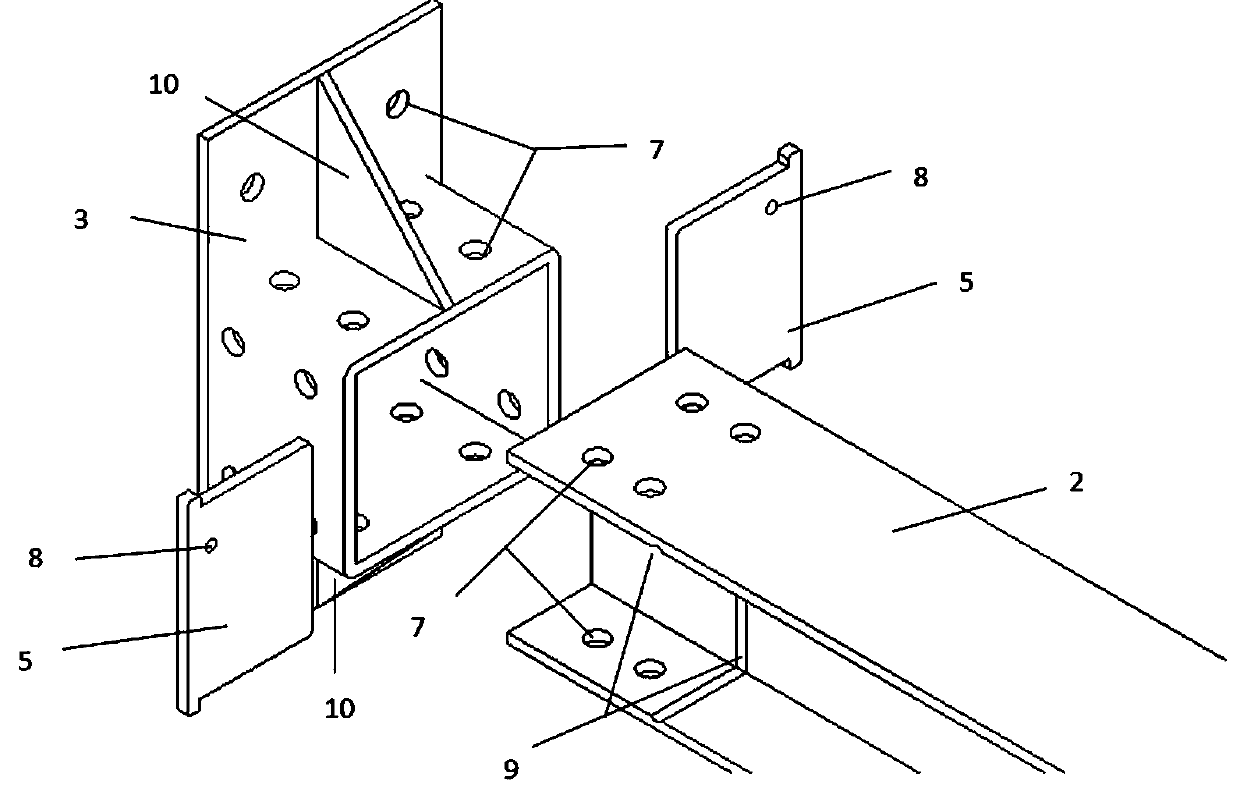

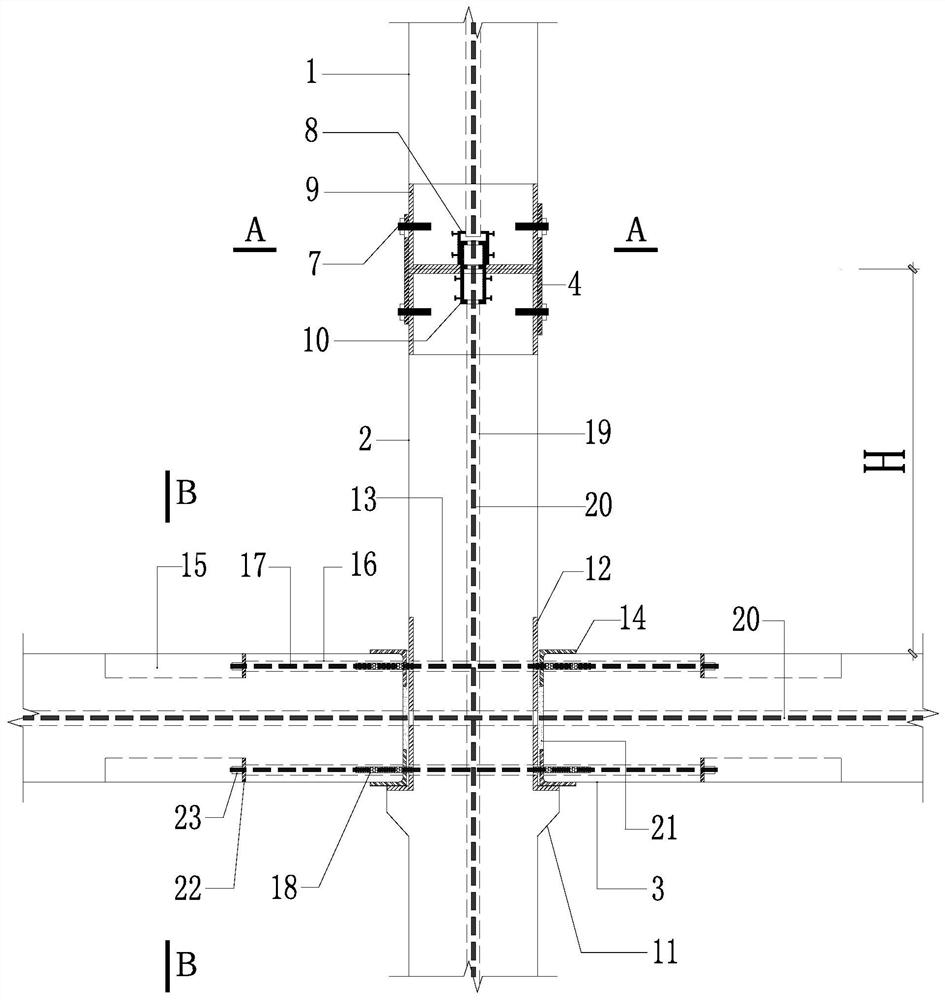

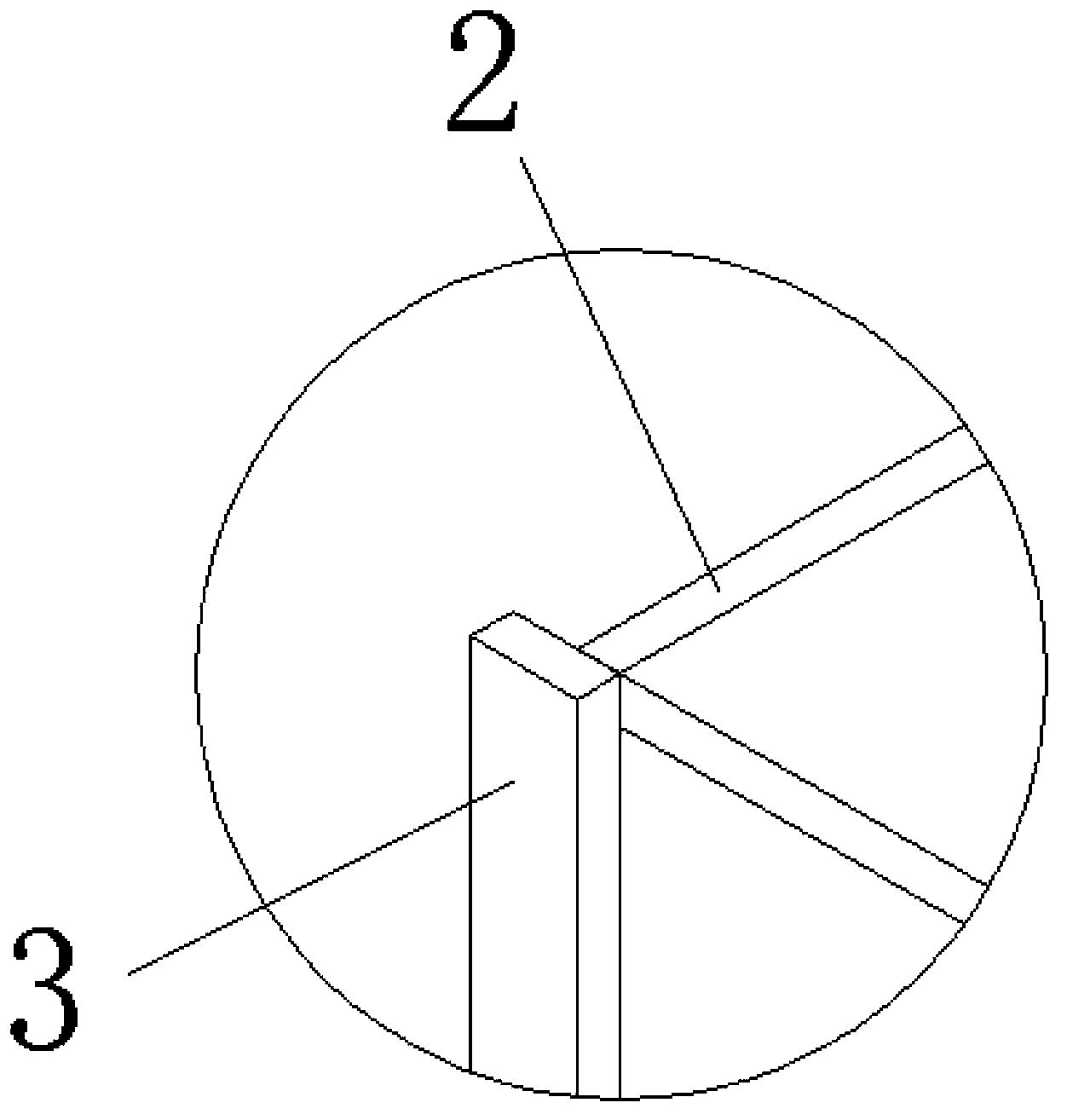

Beam-column joint of square steel pipe sleeve weak shaft connection steel structure and installation method thereof

PendingCN110424536AGuarantee node qualityQuality assuranceBuilding constructionsMetallurgySteel columns

The invention relates to a beam-column joint of a square steel pipe sleeve weak shaft connection steel structure and an installation method of the beam-column joint. The beam-column joint comprises anH-shaped steel column, a square steel pipe sleeve connecting piece and an H-shaped steel beam. The square steel pipe sleeve connecting piece is fixedly arranged in the H-shaped steel column, and theH-shaped steel beam is fixed to the square steel pipe sleeve connecting piece. Bolt holes which are corresponding in position are formed in the connection portions of the H-shaped steel column and thesquare steel pipe sleeve connecting piece and the connection portions of the square steel pipe sleeve connecting piece and the H-shaped steel beam, and are connected through high-strength bolts. TheH-shaped steel beam-column joint adopts the square steel pipe sleeve connecting piece, the force borne by the H-shaped steel beam transmits to the H-shaped steel column through the square steel pipe sleeve connecting piece, and the force transmission is clear and easy. The square steel pipe sleeve connecting piece comprises a long base plate, accessory rib plates and a closed space through the design, the closed space is defined by baffles, grouting materials can be poured into the closed space, and therefore the rigidity and the bearing capacity of the joint are advantageously guaranteed by the measures.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

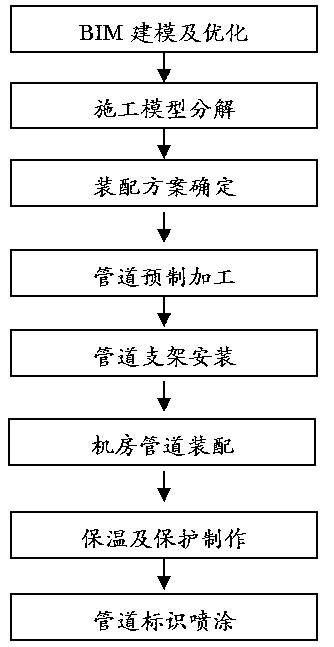

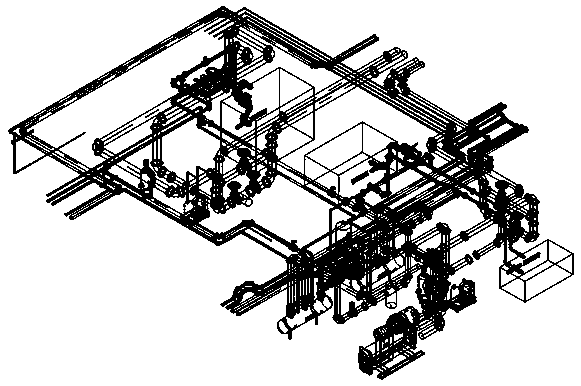

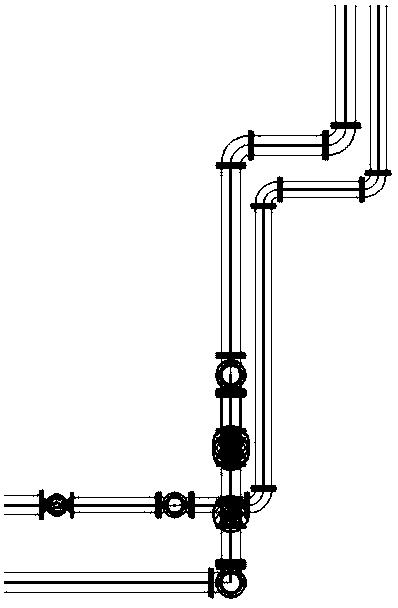

Assembling construction method for pipeline of refrigerating machine room of subway station

ActiveCN110440054AEasy to removeConvenient ArrangementPipe laying and repairArchitectural engineeringSubway station

The invention provides an assembling construction method for a pipeline of a refrigerating machine room of a subway station, and belongs to the technical field of subway machine room installation. Themethod comprises the following steps of 1, establishing and optimizing a BIM model; 2, decomposing a construction model; 3, determining an assembly scheme; 4, prefabricating the pipeline; 5, installing a pipeline support; 6, assembling the machine room pipeline; 7, performing heat preservation and fabricating outer protection; and 8, spraying a color ring mark. According to the method, the BIM building model is adopted, the construction environment is simulated, the pipeline arrangement is optimized, and field installation is facilitated; all water pipes involved adopt a factory prefabrication mode, so that the cutting and welding operation is avoided, the material utilization rate is effectively increased, and the field potential safety hazard and the environmental pollution are reduced;the water pipes adopt an assembling mode, so that the field installation construction is facilitated, the site limitation problem of construction in the limited space of a subway can be solved; and the construction period is shortened.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

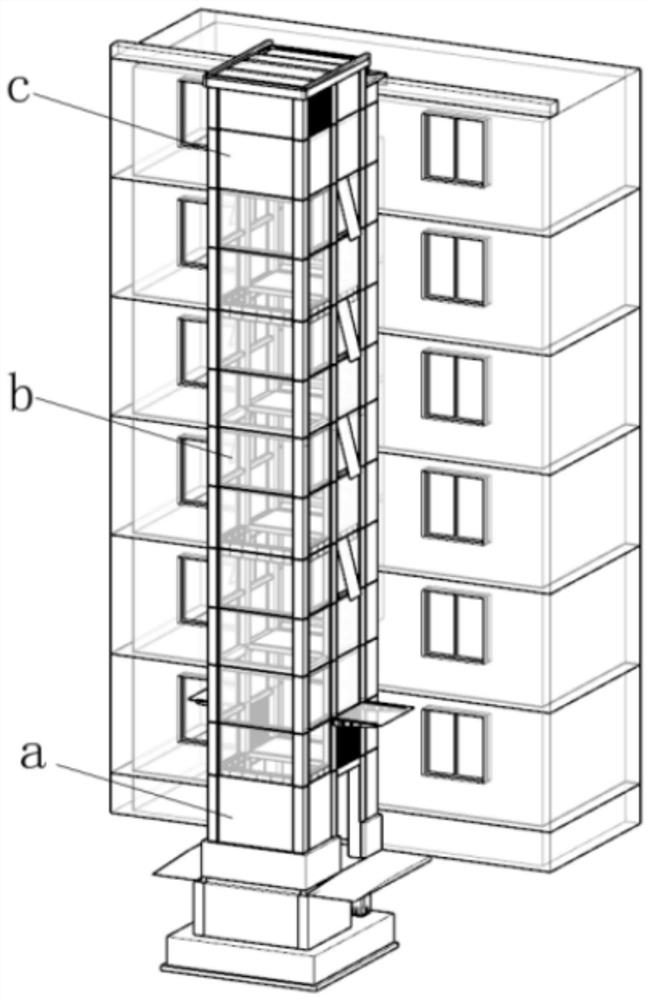

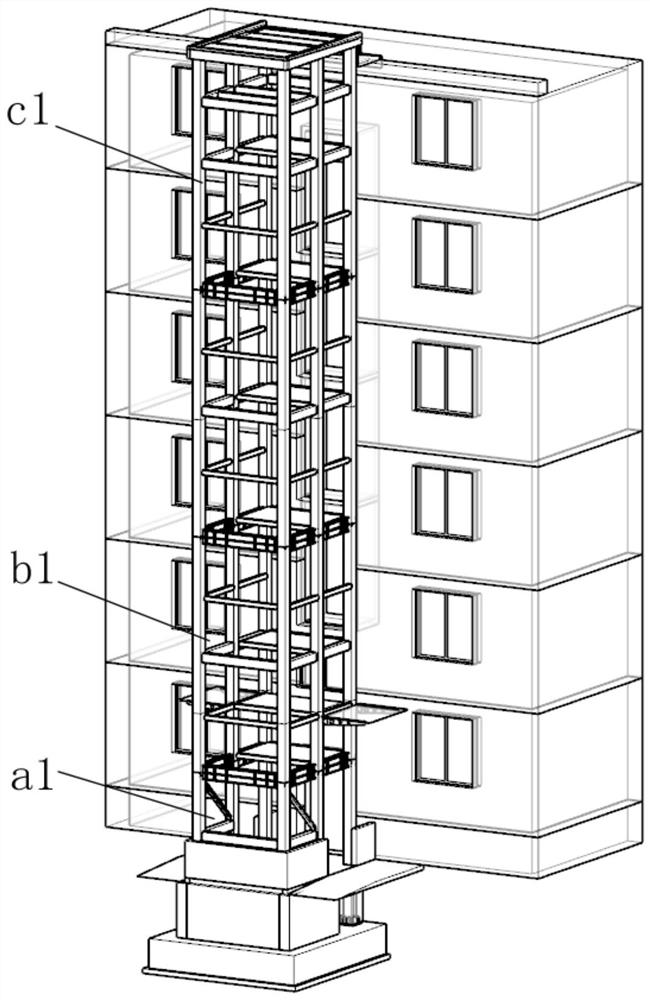

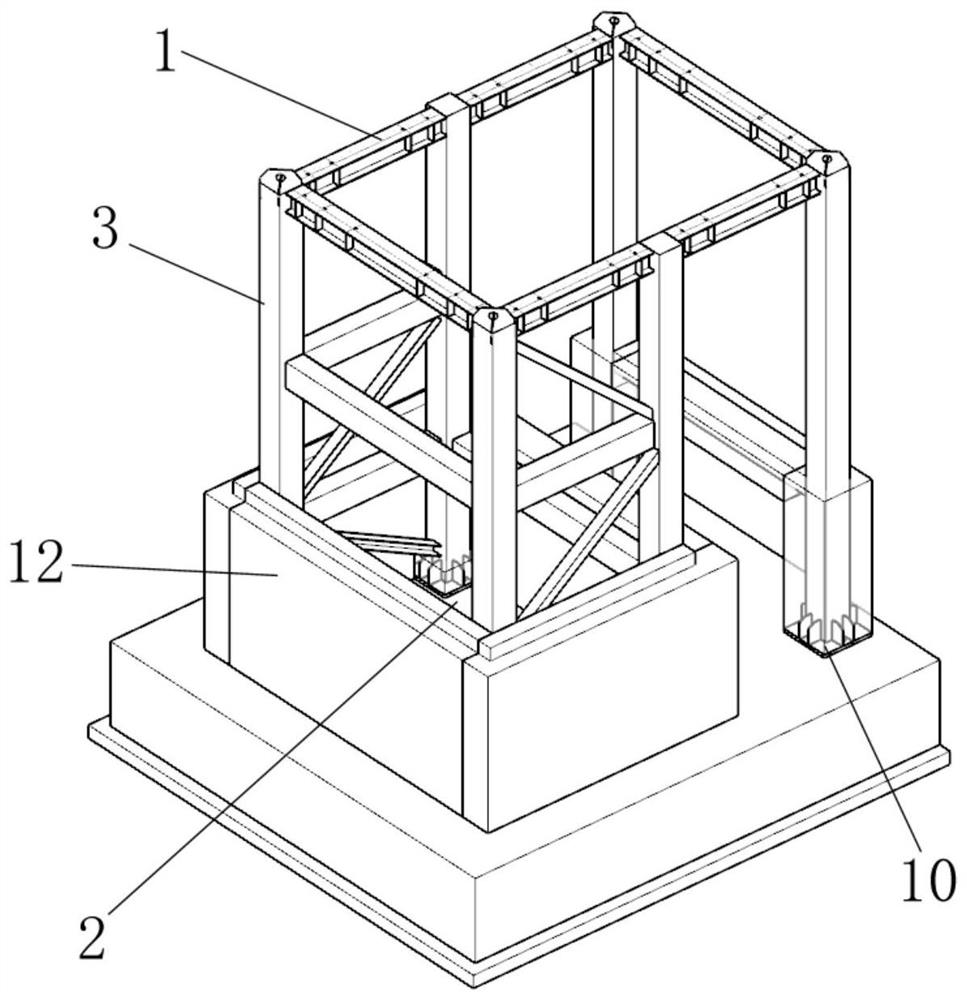

Steel structure frame and modularized additionally-installed elevator

PendingCN113152664AFirmly connectedSave materialBuilding repairsFoundation engineeringClassical mechanicsMechanical engineering

The invention discloses a steel structure frame and a modularized additionally-installed elevator. The steel structure frame comprises a basic section frame, a standard section frame and a top layer section frame. Each frame comprises a stand column and a connecting beam, the connecting beams are located on the end parts of the stand columns and perpendicular to the stand columns, and the end faces of the connecting beams are welded to the side faces of the end parts of the stand columns. Connecting cross beams are arranged at the upper ends of the stand columns of the basic section frame, the lower ends of the stand columns are used for being fixedly connected with a basic raft, connecting cross beams are arranged at the upper ends and the lower ends of the stand columns of the standard section frame and the top layer section frame, and the stand columns and the connecting cross beams form a hoistway frame; and the upper and lower adjacent two sections of frames are fixedly connected by penetrating bolts into the two upper and lower adjacent connecting cross beams. According to the modularized additionally-installed elevator adopting the frame, all the modules are prefabricated, only the adjacent modules need to be spliced and fixed up and down during field installation, firmness is high, installation and construction are convenient, time and labor are saved, and the appearance is neat and attractive.

Owner:中核建研城市更新有限公司

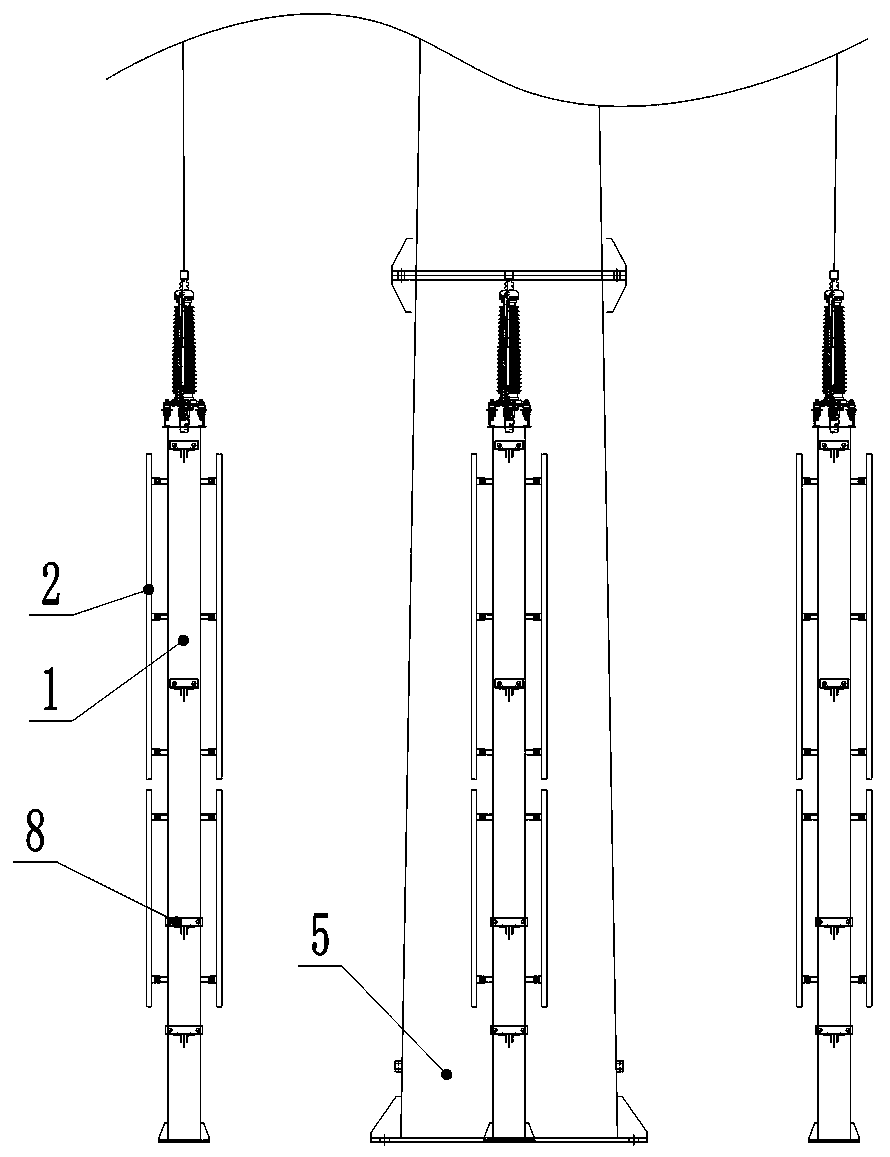

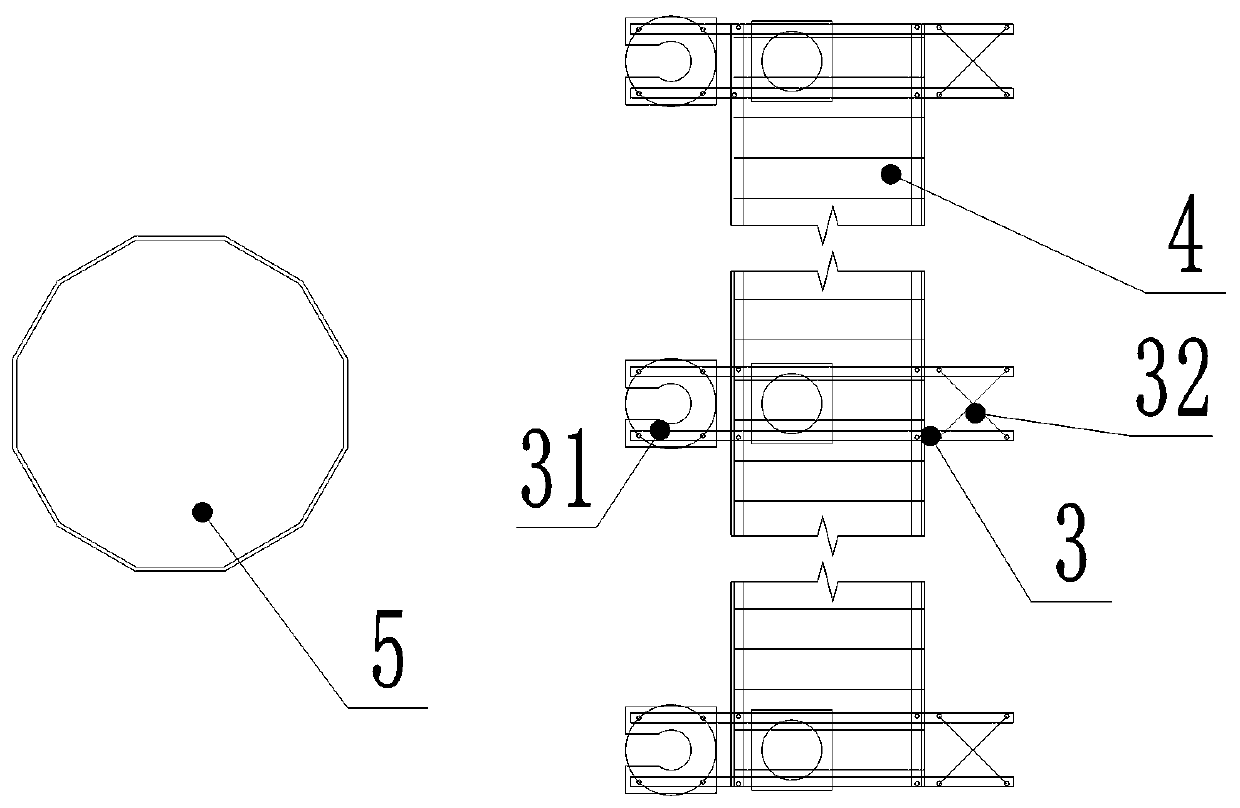

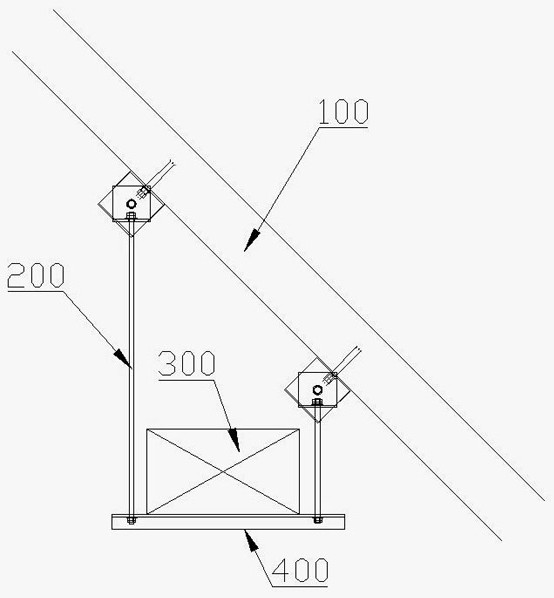

Cable terminal tower maintenance platform

PendingCN110797799AConvenient inspectionConvenient detection workCable terminationsApparatus for overhead lines/cablesArchitectural engineeringTower

The invention discloses a cable terminal tower maintenance platform, which comprises a plurality of vertical upright columns and crawling ladders arranged around the cable terminal tower. The crawlingladder extends upwards along one side of the upright column; the lower end of the upright column is fixed on the ground, and the upper end of the upright column is connected with a cross beam which is perpendicular to the upright column; one end of the cross beam is provided with a cable terminal base, and the other end of the cross beam is provided with a lightning arrester base; and a footpathused for walking is connected between the cross beams. The maintenance platform can be convenient for operation and maintenance personnel to carry out patrol and inspection work. After the operation and maintenance personnel reach the top of the upright column through the crawling ladder, they can walk on the footpath around the cable terminal tower for comprehensive inspection and maintenance ofthe cable terminal tower.

Owner:HENAN POWER TRANSMISSION & TRANSFORMATION CONSTR CO LTD +2

Double-spherical low frequency electronic label

InactiveCN108710934AEliminate orientation requirementsConvenient on-site installation and constructionRecord carriers used with machinesEngineeringUnderground pipeline

The invention discloses a double-spherical low frequency electronic label applied to identity identification of an underground pipeline node or an underground cable node. The double-spherical low frequency electronic label comprises a round shell, an elliptical shell and a low frequency electronic label body. The round shell is sealed hollow structure. The round shell is placed in the undergroundpipeline node or the underground cable node. The elliptical shell is the sealed hollow structure. A balancing weight is fixed at the bottom in the elliptical shell, so the elliptical shell is kept ina vertical state, and the elliptical shell is vertically placed in the round shell. The front face of the low frequency electronic label body is upward and the low frequency electronic label body is fixed on the top in the elliptical shell. The low frequency electronic label body comprises a shell, an antenna and a chip. An electronic label detector can read information in a chip through the roundshell, the elliptical shell and the shell of the low frequency electronic label body. According to the double-spherical low frequency electronic label provided by the invention, a direction demand when the low frequency electronic label works normally is eliminated.

Owner:BEIJING SMARTCHIP MICROELECTRONICS TECH COMPANY +1

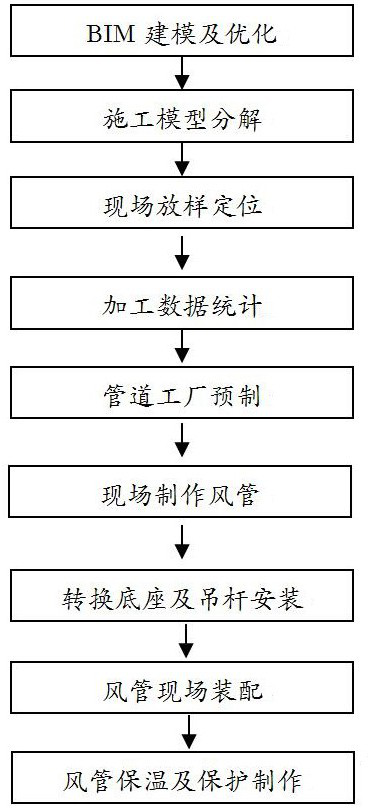

Construction Method for Assembling Ventilation Ducts in Metro Vaulted Roofs

ActiveCN110440429BConvenient ArrangementEasy to install on siteGeometric CADDucting arrangementsArchitectural engineeringAssembly (construction)

The invention provides a method for assembling and constructing a ventilation duct on a subway arched roof, which belongs to the technical field of assembled construction of ventilation and air-conditioning ducts. Step 4: Statistics of processing data; Step 5: Prefabrication of pipes in the factory; Step 6: On-site production of air ducts; Step 7: Installation of conversion bases and booms; The above method adopts BIM building model, simulates the construction environment, optimizes the pipeline arrangement, and facilitates on-site installation; the air ducts involved are all prefabricated on-site with fixed-length boards, which avoids cutting and welding operations and effectively improves material utilization; material air ducts are decomposed The assembly method is convenient for on-site installation and construction, and solves the problem of site restrictions in the limited space construction of the subway; the conversion base used improves the technical problem that the hanger cannot be vertically stressed when using the existing ceiling base to install the air duct hanger.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

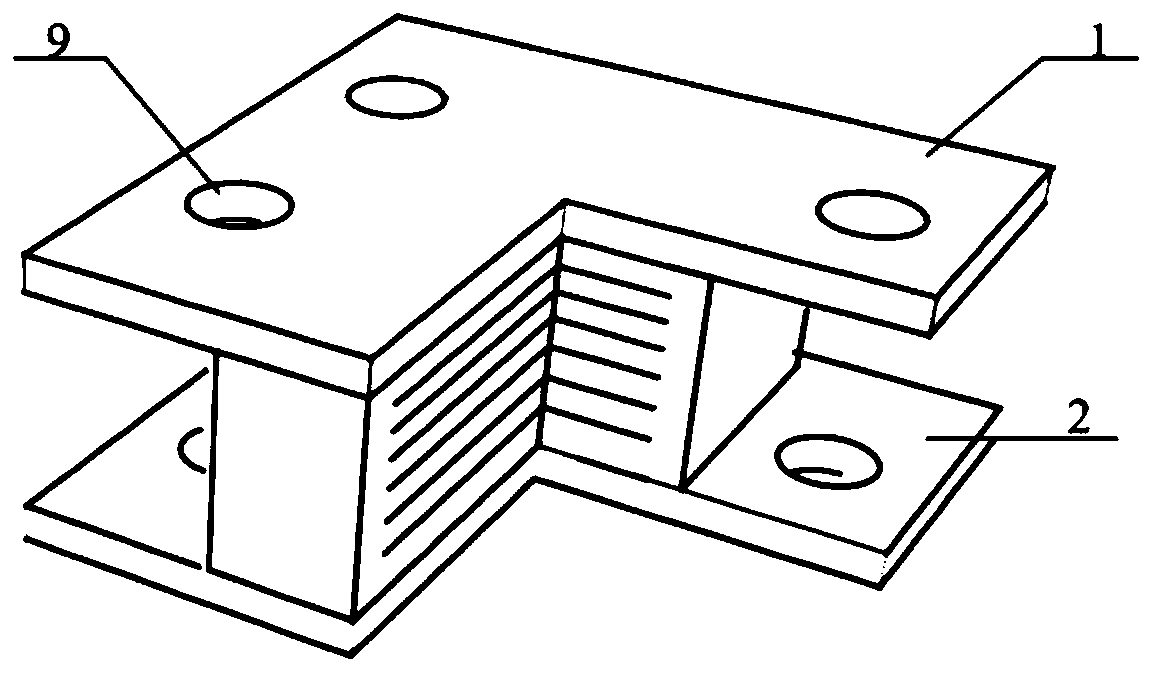

Rubber shock insulation system between steel structure module building columns

PendingCN110397176AReduce adverse effectsImprove bearing capacityProtective buildings/sheltersShock proofingVulcanizationInsulation layer

The invention relates to a rubber shock insulation system of a steel structure module building. The system comprises module columns, module beams, angular parts used for fixing the module columns andthe module beams together and a foundation. The rubber shock insulation system enables the module column or angular part on the upper part and the module column and angular part on the lower part tobe connected through a rubber shock insulation pad, through the rubber shock insulation pad, the foundation is connected with the foundation upper part, the rubber shock insulation pad comprises an upper seal plate, a lower seal plate and a shock insulation layer in the middle, the shock insulation layer is formed through vulcanization bonding after layered alternative overlapping of a thin steelplate and a thin film rubber plate. The adverse effect generated by the module building under the earthquake effect can be reduced, and the bearing force, deforming capacity, stability and other properties of the module structure can be improved.

Owner:TIANJIN UNIV

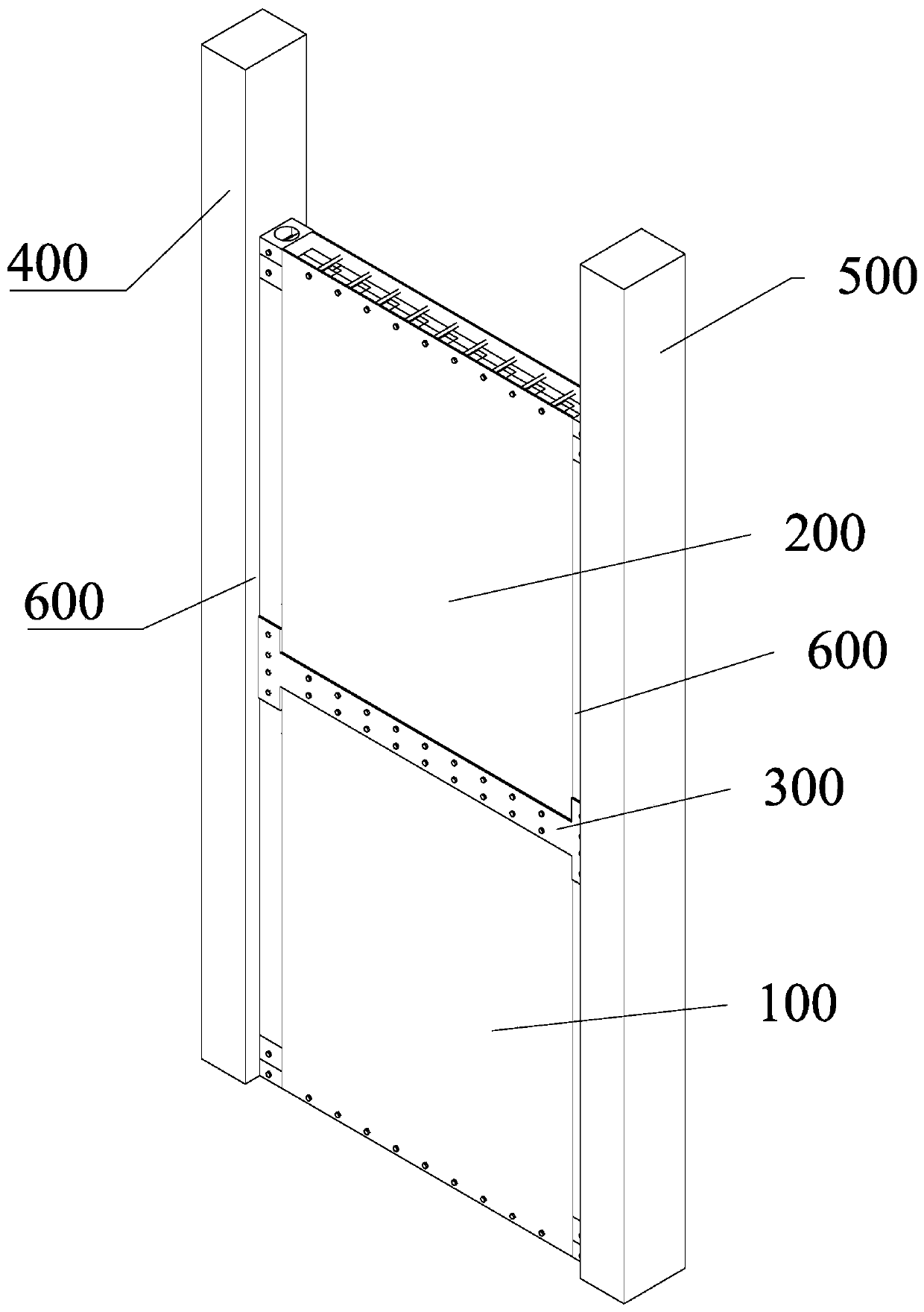

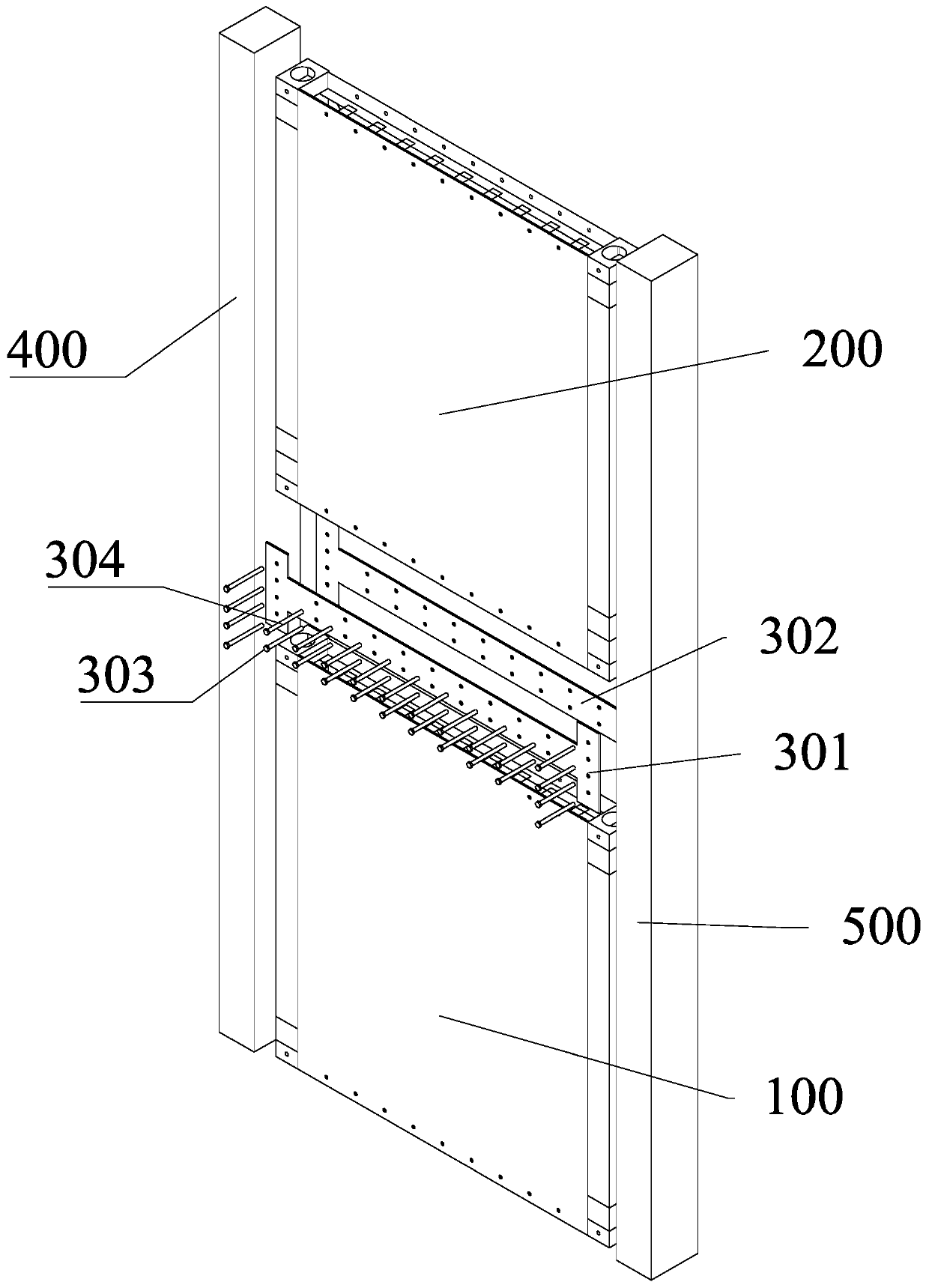

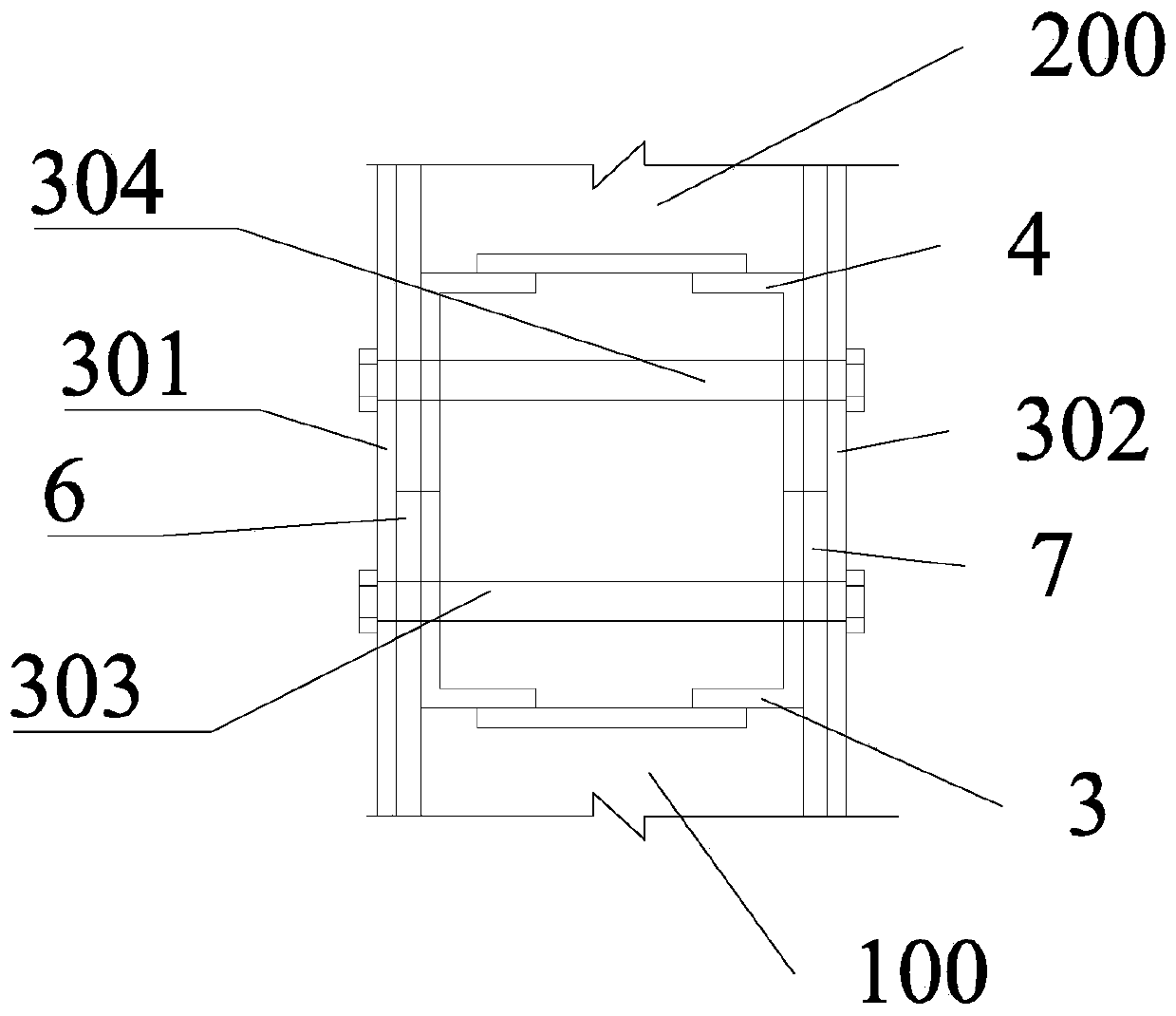

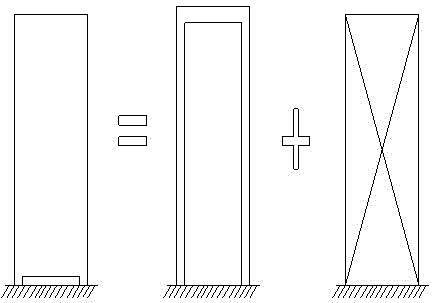

Fabricated shear wall with steel plate stud combined type diagonal bracing and construction method

PendingCN110512765AIncrease out-of-plane stiffnessIncrease height-to-thickness ratio limitWallsIn planeLateral stiffness

The invention discloses a fabricated shear wall with a steel plate stud combined type diagonal bracing and a construction method. The fabricated shear wall comprises a first shear wall unit and a second shear wall unit, wherein the first shear wall unit and the second shear wall unit are stacked up and down, and the first shear wall unit and the second shear wall unit are connected and fixed witha connecting mechanism; the first shear wall unit and the second shear wall unit are provided with shear wall structures; a shear wall frame is formed by enclosing a left concealed column, an upper concealed beam, a right concealed column and a lower concealed frame; a first facade steel plate and a second facade steel plate are fixed to the front side and the rear side of the shear wall frame; diagonal bracing members are fixed in the shear wall frame; and each diagonal bracing member comprises two steel plates, the two steel plates cross each other to form an X-shape structure, studs are arranged on the steel plates, and concrete is poured in the shear wall units. According to the fabricated shear wall with the steel plate stud combined type diagonal bracing and the construction method,the in-plane lateral stiffness, shear bearing capacity, bending bearing capacity, ductility and energy consumption of the shear wall are improved through the design of the diagonal bracing members, the shear wall units can be pre-installed in advance, and on-site construction is facilitated.

Owner:SOUTH CHINA UNIV OF TECH +2

High-level splicing energy-consuming beam column node and manufacturing method

ActiveCN111648467AImprove seismic performanceAvoid damageProtective buildings/sheltersShock proofingStructural engineeringMechanical engineering

The present invention relates to a high-level splicing energy-consuming beam column node and a manufacturing method. The node comprises a plurality of vertically arranged frame columns, wherein the plurality of frame columns are sequentially spliced in the vertical direction to form an integral structure, and the two sides of each frame column used for overlapping frame beams are provided with corbels respectively, each frame beam is lapped on each corbel, a floor panel are arranged on the upper end faces of the frame beams, and energy dissipation elements are arranged between the adjacent frame columns and between the frame columns and the frame beams respectively; and the frame columns with the corbels are supporting columns, and the height of the upper end surface of each supporting column to the floor panel is 1 / 4-1 / 3 of the floor height to achieve high-level splicing of the supporting columns and the upper frame columns above the supporting columns. According to the node, the field assembly quality and efficiency can be improved; and energy consumption plates improve the lateral stiffness of the structure and have moderate energy consumption capability, hear keys between the adjacent frame columns can limit horizontal displacement and rotation between the frame columns, and the redundancy and robustness of the structure are improved.

Owner:SHANDONG JIANZHU UNIV

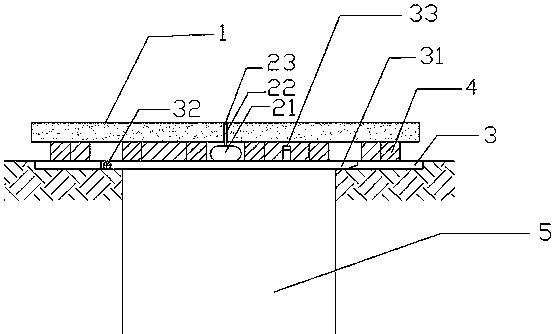

Stone-board road manhole cover with air bags and application method thereof

PendingCN111560985AIntegrity guaranteedFlexible layoutArtificial islandsUnderwater structuresArchitectural engineeringRoad surface

The invention provides a stone-board road manhole cover with air bags and an application method thereof. The stone-board road manhole cover comprises a cushion cover plate located above an inspectionwell, wherein an inspection well inner cover is fixed in the cushion cover plate, a plurality of cushion blocks are fixed to the top of the cushion cover plate, gaps are reserved between adjacent cushion blocks, stone-board cover plates are paved on the upper parts of the cushion blocks, gaps are reserved among the stone-board cover plates, rubber air bags are arranged in the gaps of the cushion blocks in the middle of the cushion cover plate, air guide tubes communicating in the rubber air bags are arranged on the rubber air bags, and the air guide tubes stretch from the gaps and the upper ends of the air guide tubes are provided with inflation ports. By lifting one side of a stone-board away from a pavement by way of inflating the rubber air bags, it is convenient and rapid and hard to hurt hands. A design of the inflation ports can keep integrity of the stone-board pavement so as to achieve an attractive effect. By arranging the cushion blocks flexibly, the stone-board road manholecover can be suitable for stone-board pavements of different specifications and is compatible, simple in structure, convenient to mount, convenient to mount and construct on site and low in cost.

Owner:秀艺(福建)园林工程有限公司

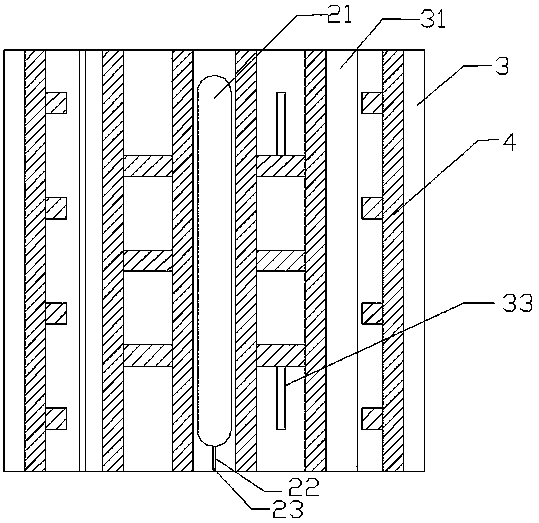

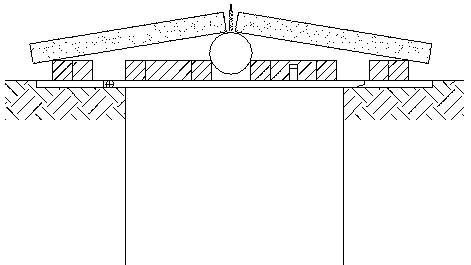

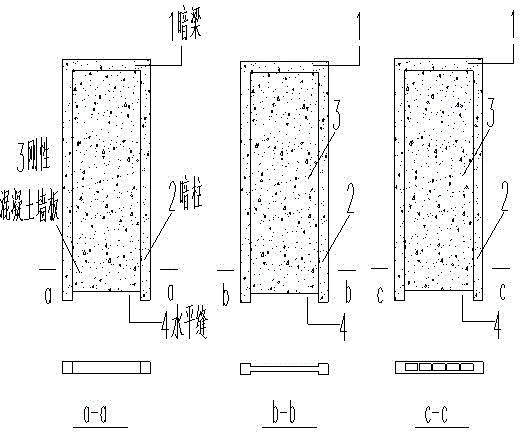

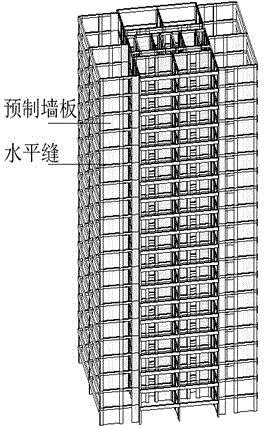

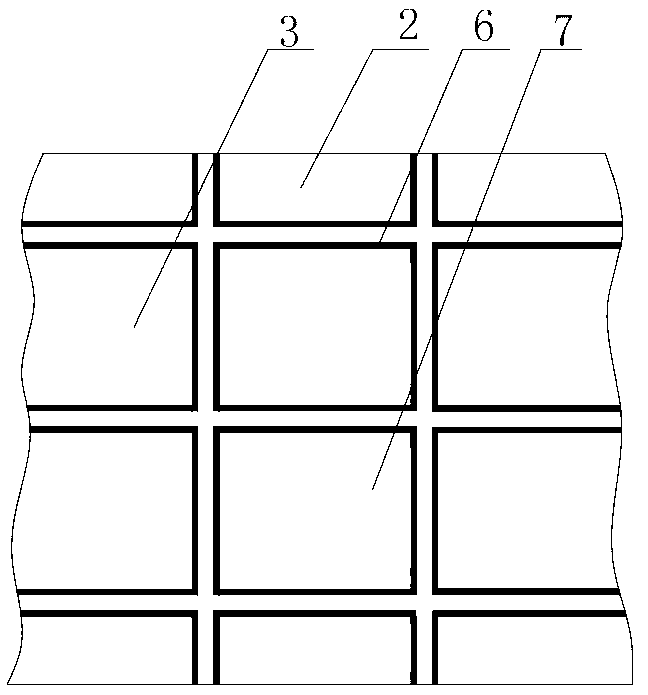

Precast concrete frame support shear wall panel

InactiveCN104060757AReduce dosageReduce in quantityConstruction materialWallsArchitectural engineeringHollow core

The invention belongs to the field of civil engineering, and particularly relates to an assembly type building structure and a concrete structure. A precast concrete frame support shear wall panel is composed of embedded columns, hidden beams and a middle rigid concrete wallboard, wherein the embedded columns and the hidden beams are arranged in a wall. A rectangular-section solid or hollow wallboard can be adopted as the middle rigid concrete wallboard. The fact that the precast concrete frame support shear wall panel is utilized for forming a frame support shear wall structure system does not mean that supports are arranged in the structure system but means that the supports are enabled to be equivalent to the frame support structure system in stress mode and fracture morphology by arranging the precast concrete frame support shear wall panel and adjusting boundary conditions. For the precast concrete frame support shear wall structure system, only the embedded columns need to be connected in the vertical direction, so that the number of connecting parts is reduced, on-site installation and construction are facilitated, the construction speed is increased, and meanwhile structural stress is more definite. According to the wall panel, as consideration is given to the middle rigid concrete wallboard according to the supports, the thickness of the wall can be reduced properly, or the wall is changed to be hollow, in this way, the consumption of concrete can be effectively lowered, the structural self-weight can be reduced, and the earthquake action of the structure can be relieved.

Owner:SHENYANG JIANZHU UNIVERSITY +2

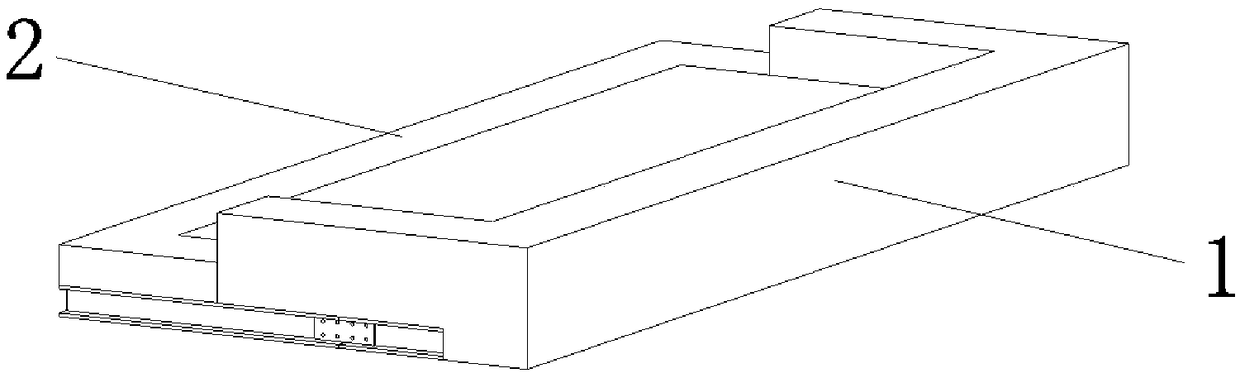

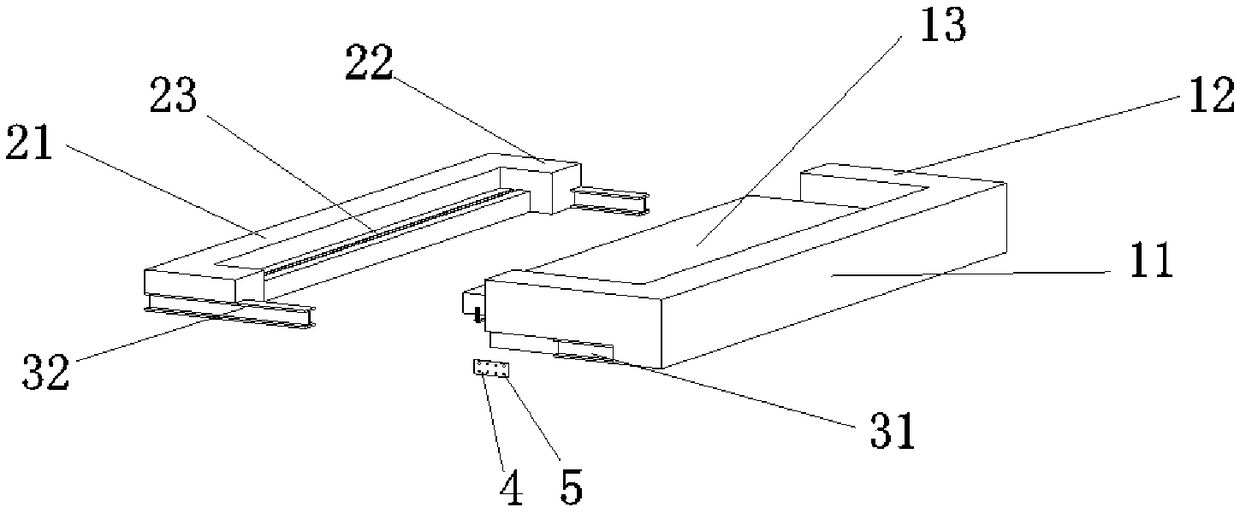

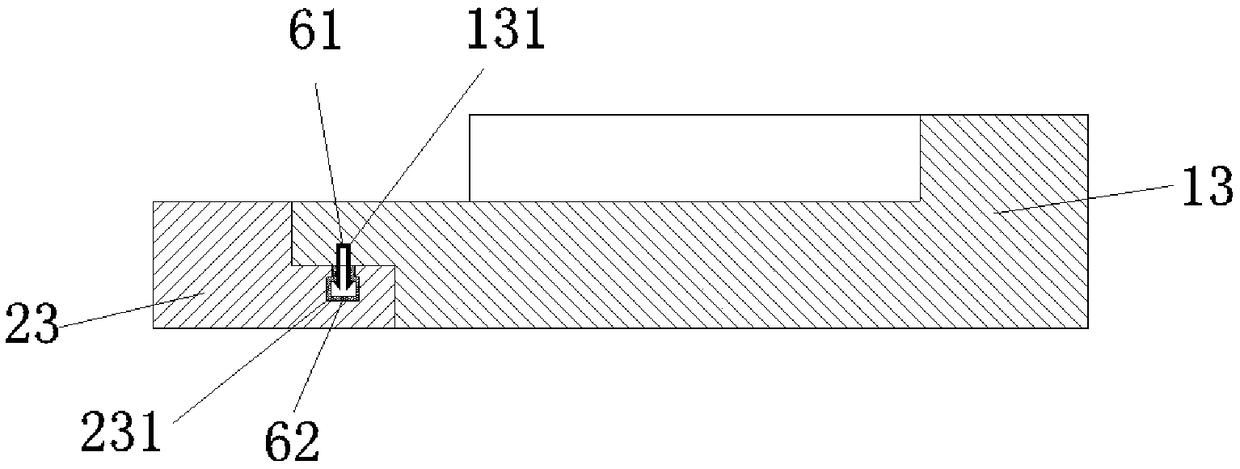

Prefabricated balcony convenient to install and fix

The invention discloses a prefabricated balcony convenient to install and fix. The prefabricated balcony comprises a prefabricated balcony body and a building body, wherein the prefabricated balcony body comprises boundary beams, a cantilever beam and a balcony slab, the left and right ends of the balcony slab are provided with the boundary beams respectively, the portion, between the two boundarybeams, corresponding to the front end of the balcony slab is provided with the cantilever beam, the rear end of the balcony slab is provided with a balcony slab lap joint part, the lower side face ofthe balcony slab lap joint part is provided with a balcony slab lap joint part groove, a latch hook is pre-buried in the balcony slab lap joint part groove, the building body comprises a floor body,a floor convex edge and a floor lap joint part, the upper side face of the floor lap joint part is provided with a floor lap joint part groove, and a lock groove is pre-buried in the floor lap joint part groove. The prefabricated balcony convenient to install and fix has the advantages that the field installation and construction are convenient, and the structure is stable and reliable.

Owner:浙江中天建筑产业化有限公司

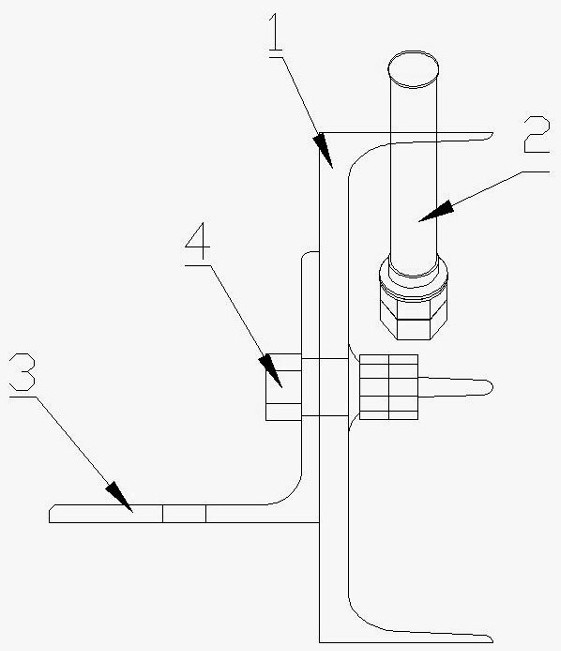

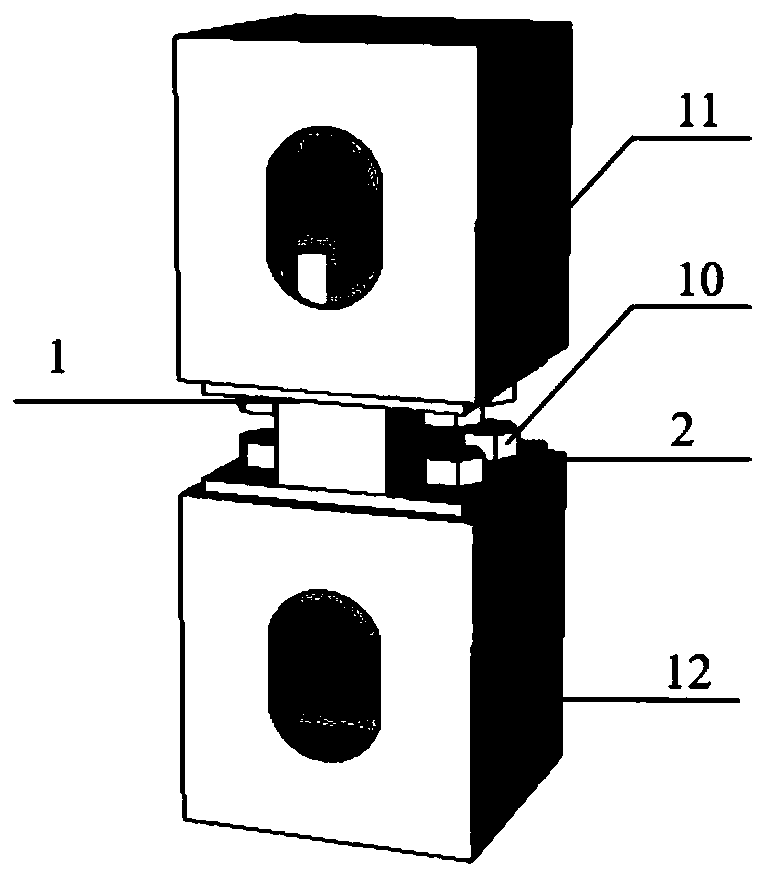

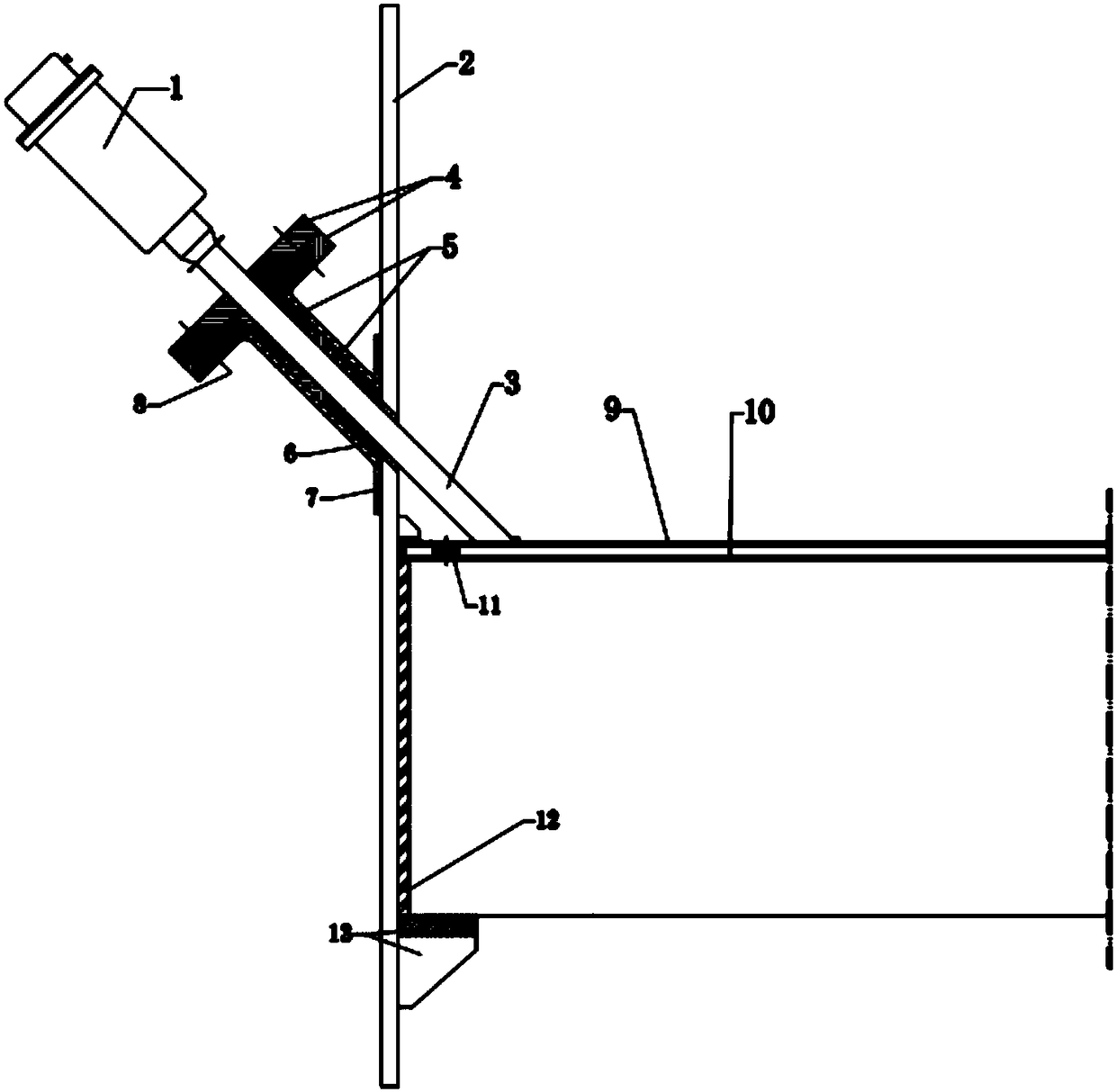

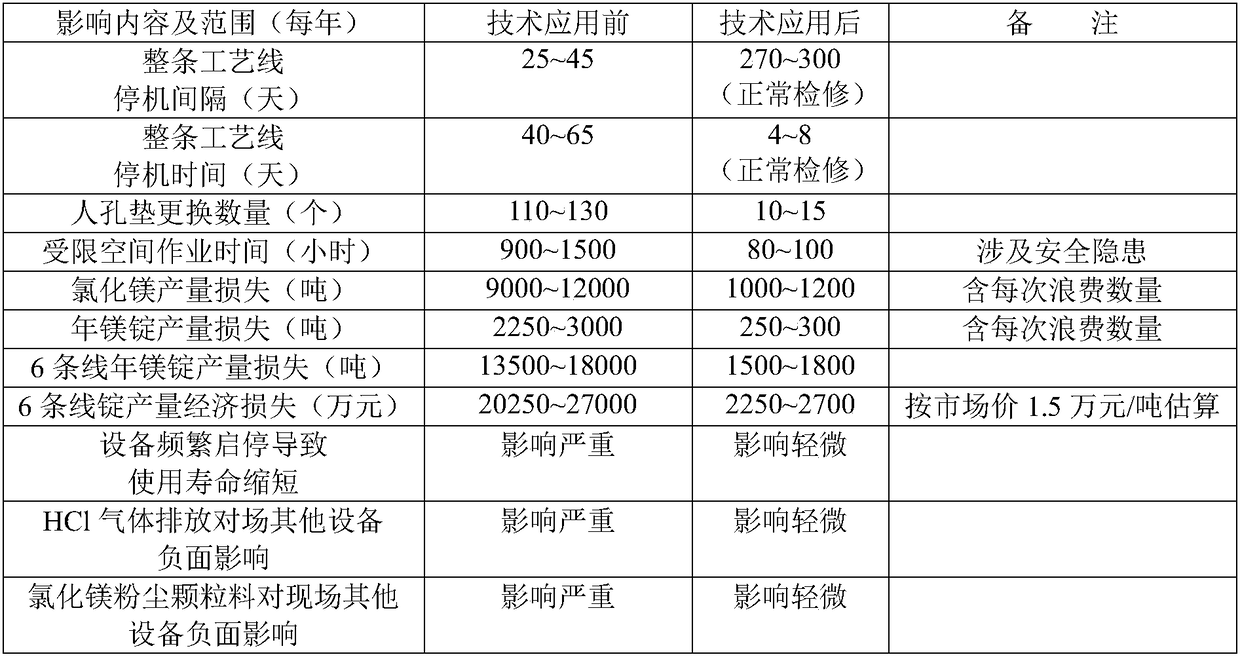

Ultrasonic anti-sticking device

PendingCN108201776AReasonable structural designLow costGas treatmentMagnesium chloridesEngineeringTower

The invention discloses an ultrasonic anti-sticking device, and belongs to the technical field of anti-sticking devices. The ultrasonic anti-sticking device comprises a tower tray support block, an ultrasonic generator, an ultrasonic guide rod, a reinforcing plate, and a sealing flange, wherein the tower tray support block is arranged between an upper tower tray and a lower tower tray of a dryingtower; the reinforcing plate is arranged at the outer side of the tower wall of the drying tower, slantwise extends upward, and is connected with the sealing flange; one end of the ultrasonic guide rod respectively penetrates through the sealing flange and the reinforcing plate, and then is arranged on the upper tower tray of the drying tower; the ultrasonic generator is arranged at the outer sideof the tower wall of the drying tower, and is arranged at the other end of the ultrasonic guide rod; a sealing layer is arranged between the reinforcing plate and the ultrasonic guide rod. The ultrasonic anti-sticking device has the advantages that the practicality is high, multiple types can be selected, the installation is flexible, the installation and construction at site are convenient, theefficiency is high, the speed is quick, the effective utilization rate of equipment is high, the service life of the equipment is long, the online continuous or intermittent working can be performed,and the safe, economic and environment-friendly effects are realized.

Owner:张孝亮 +3

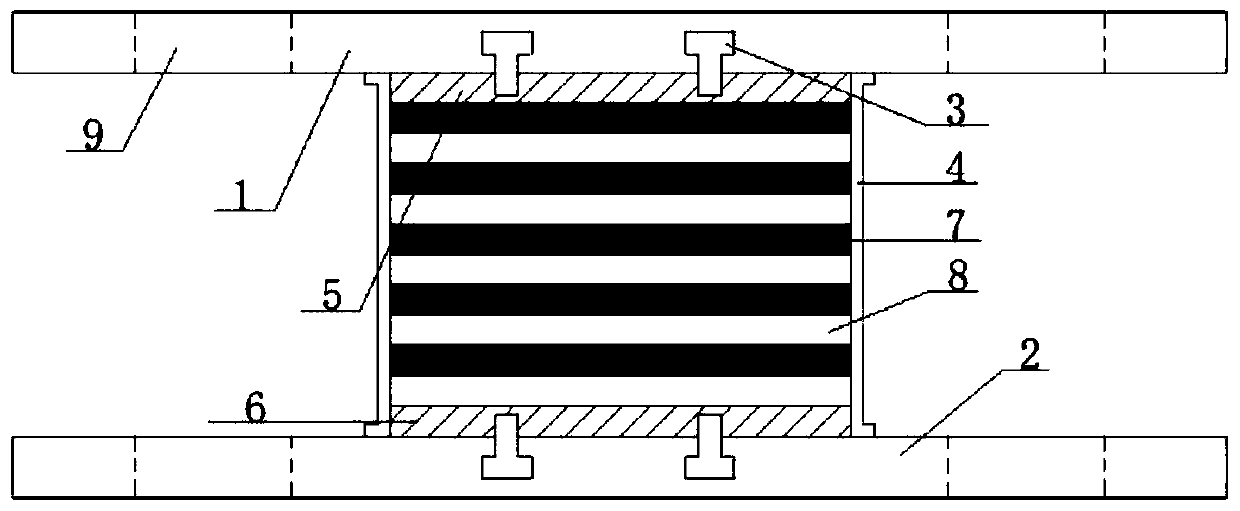

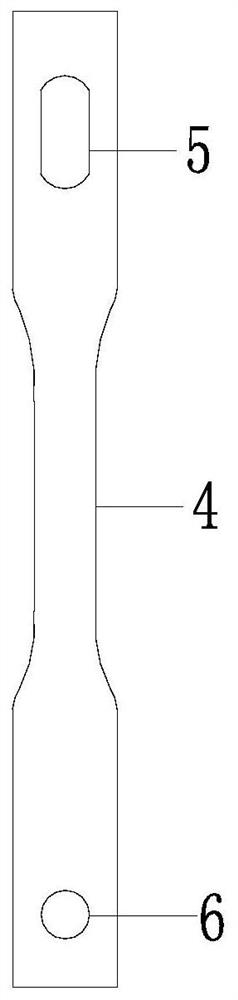

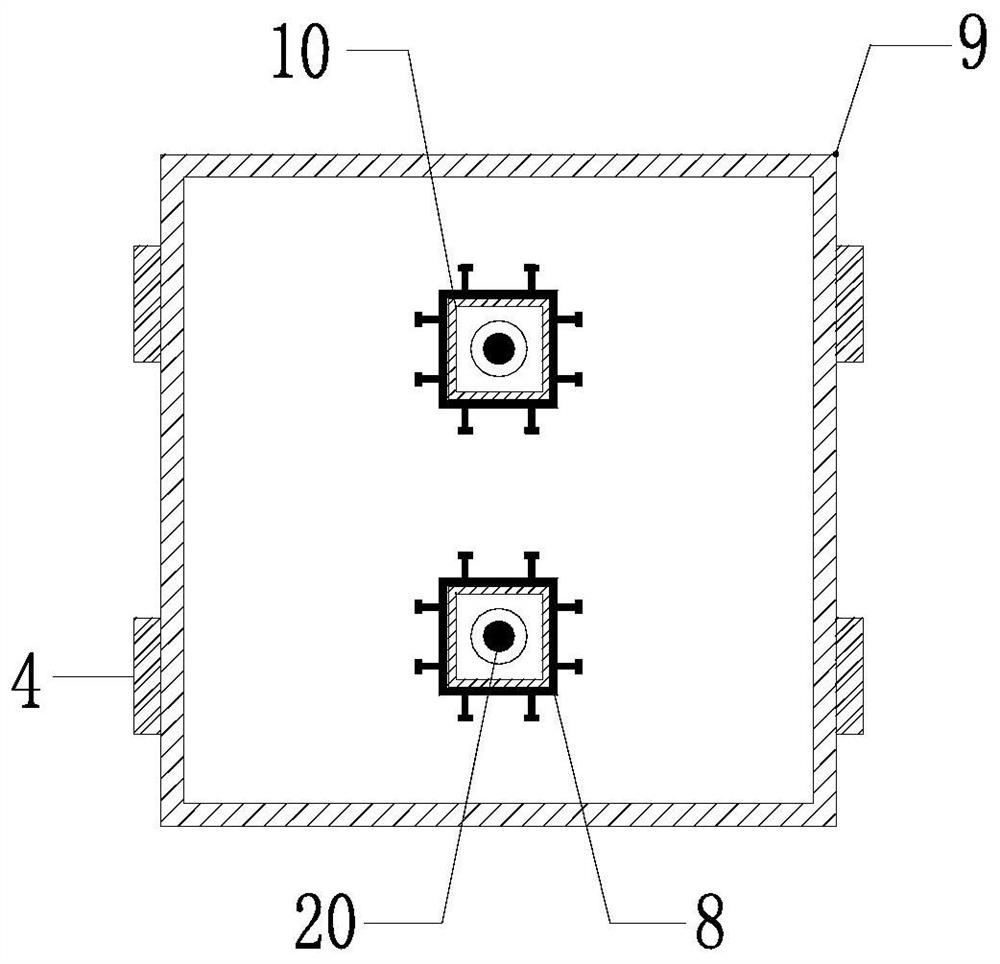

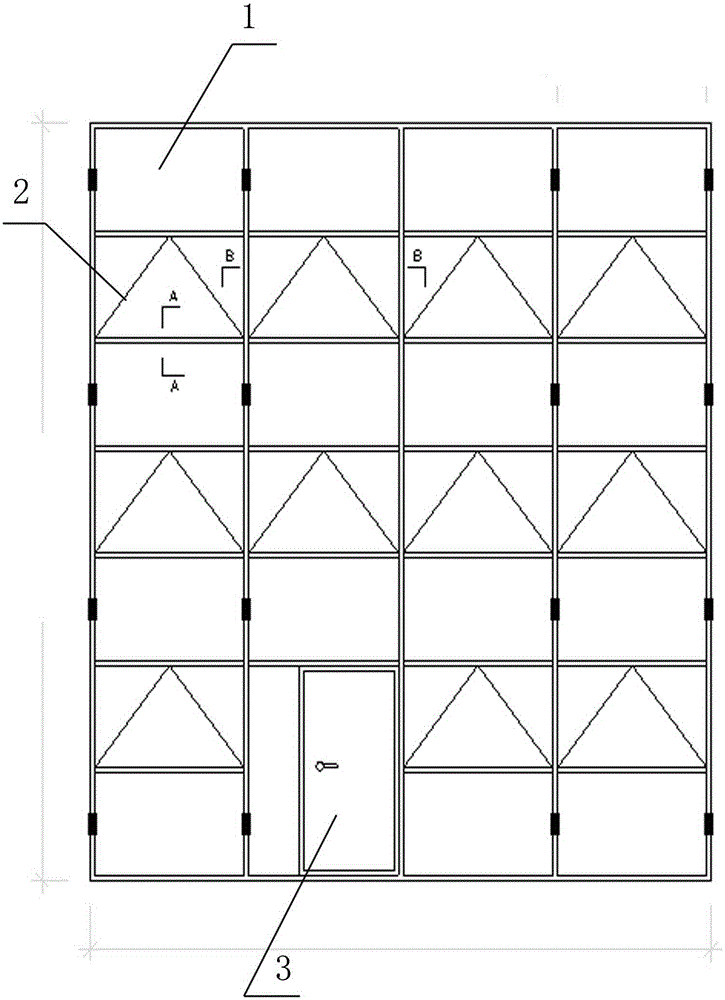

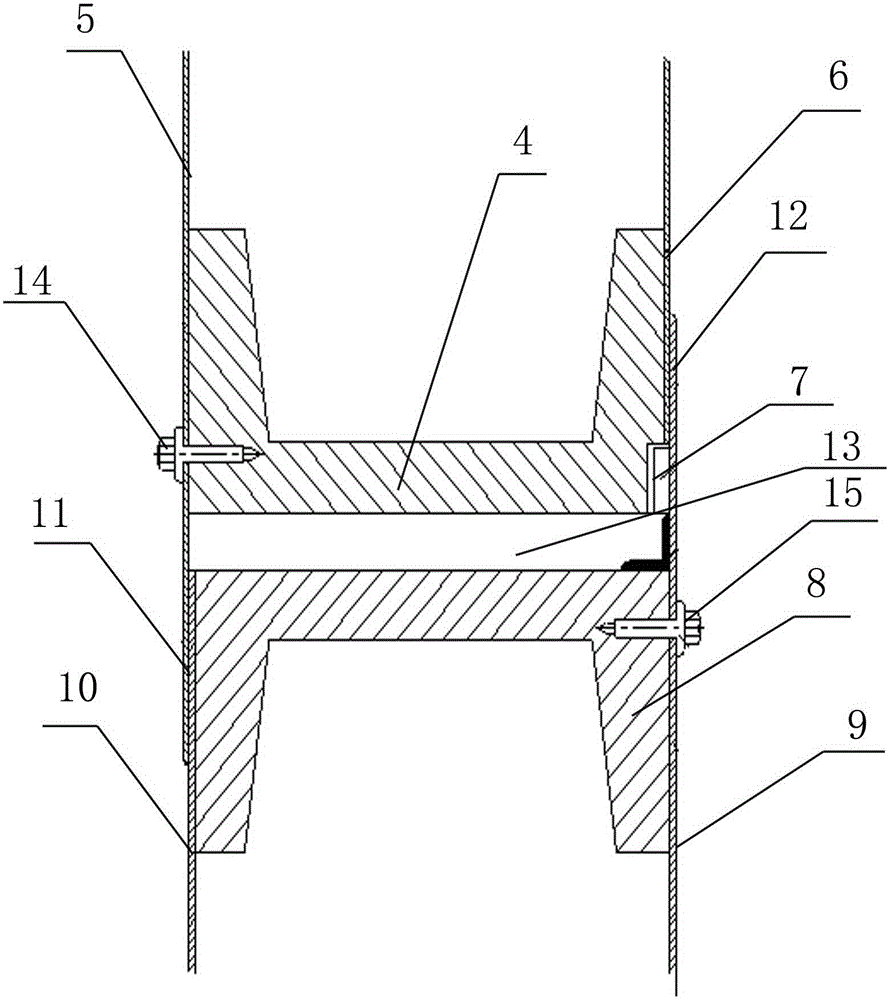

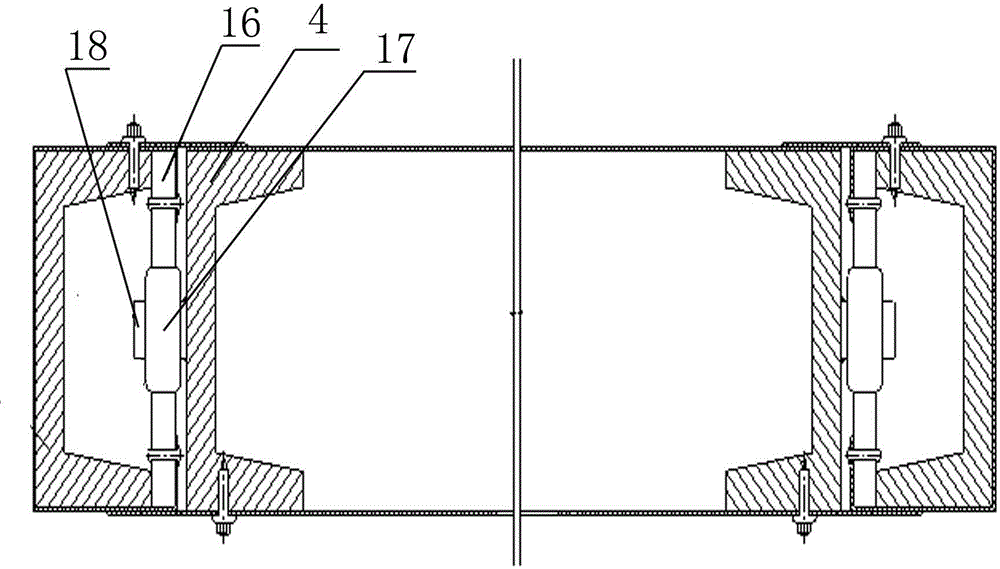

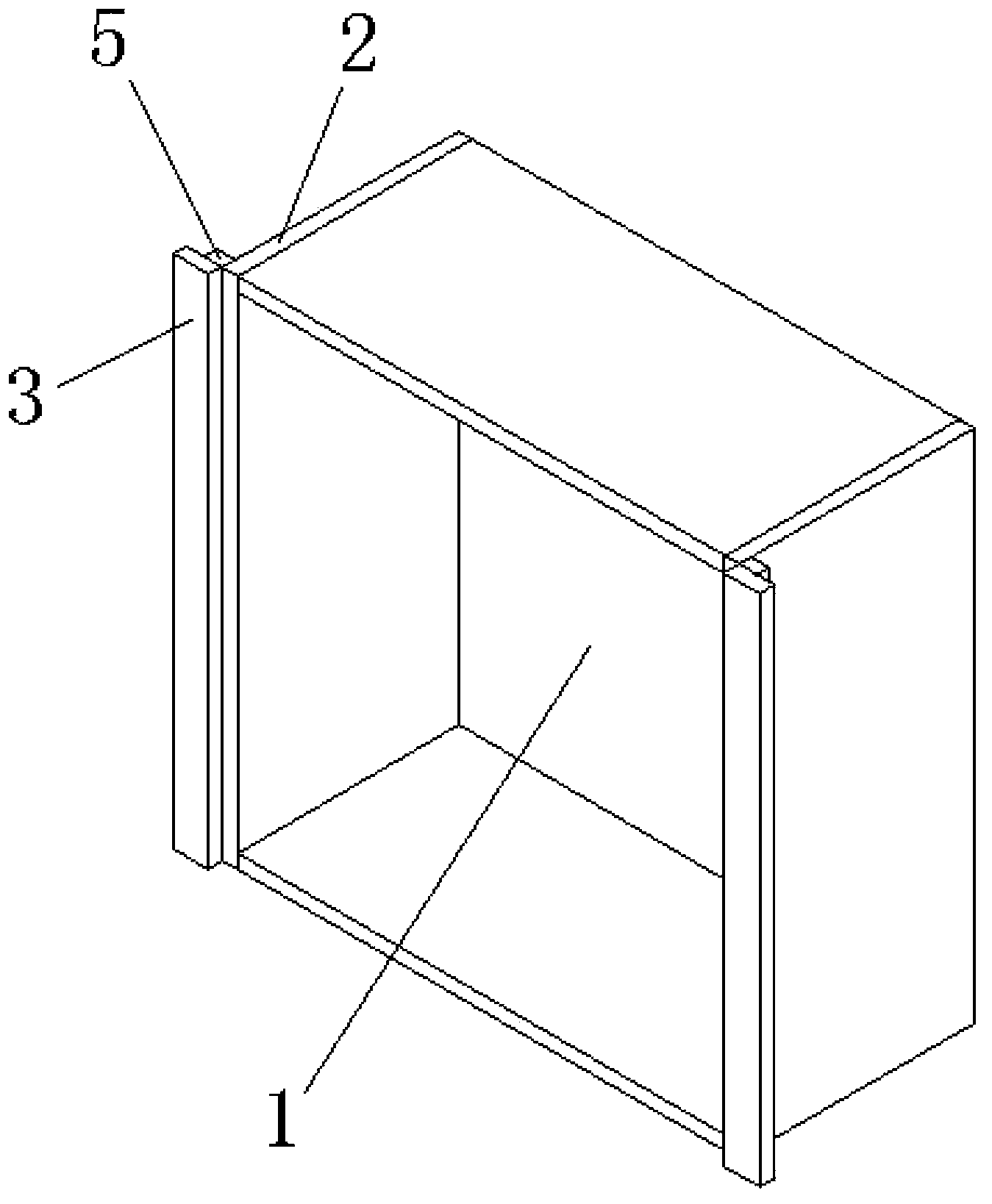

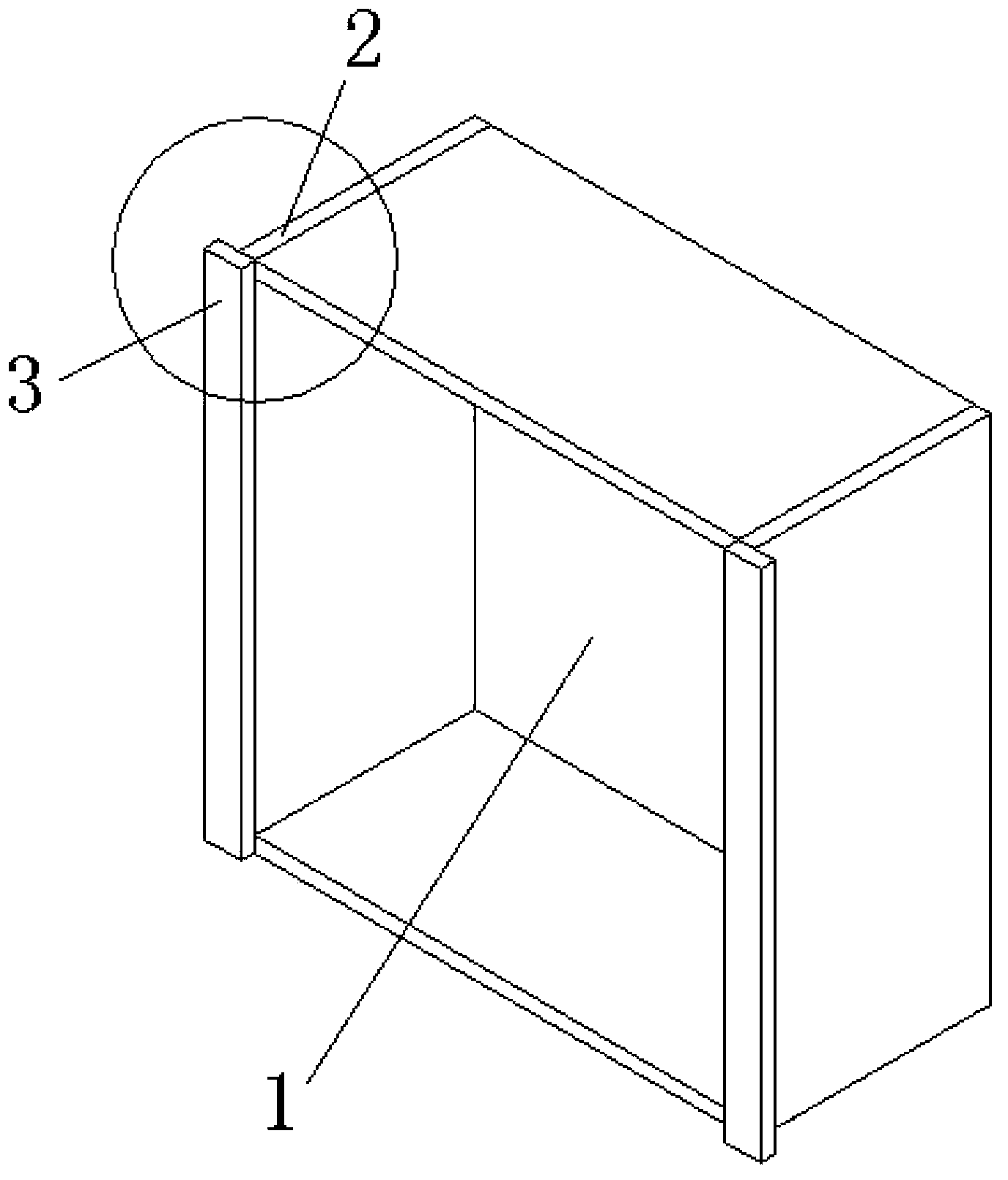

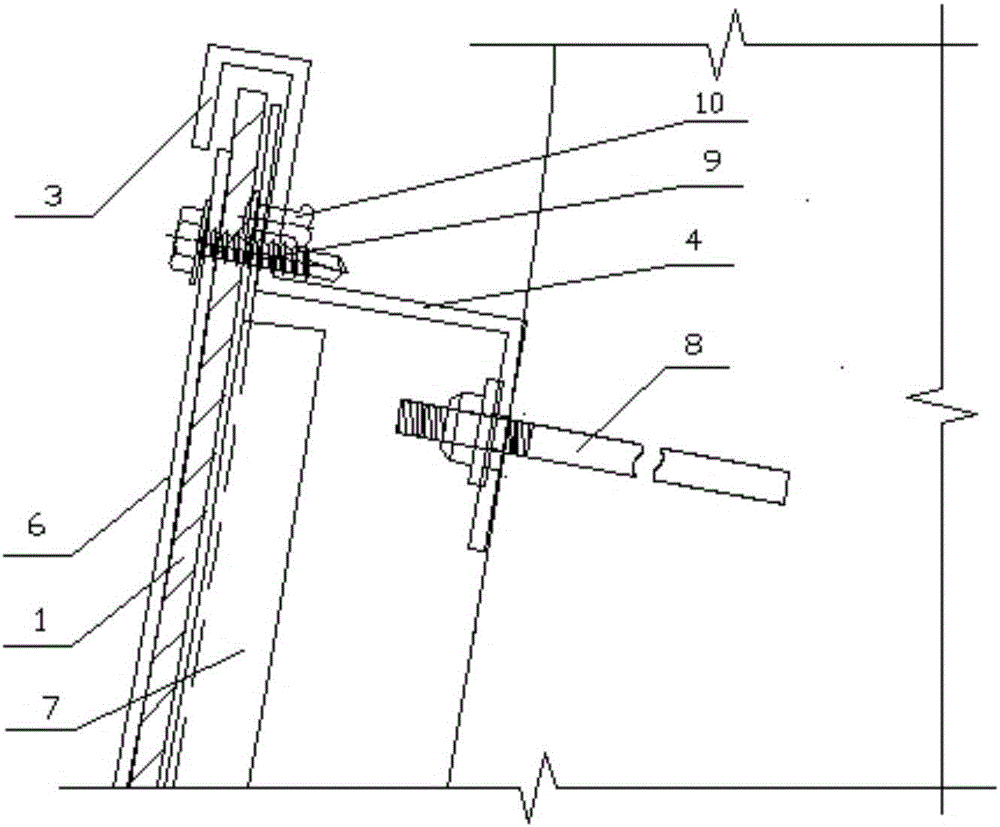

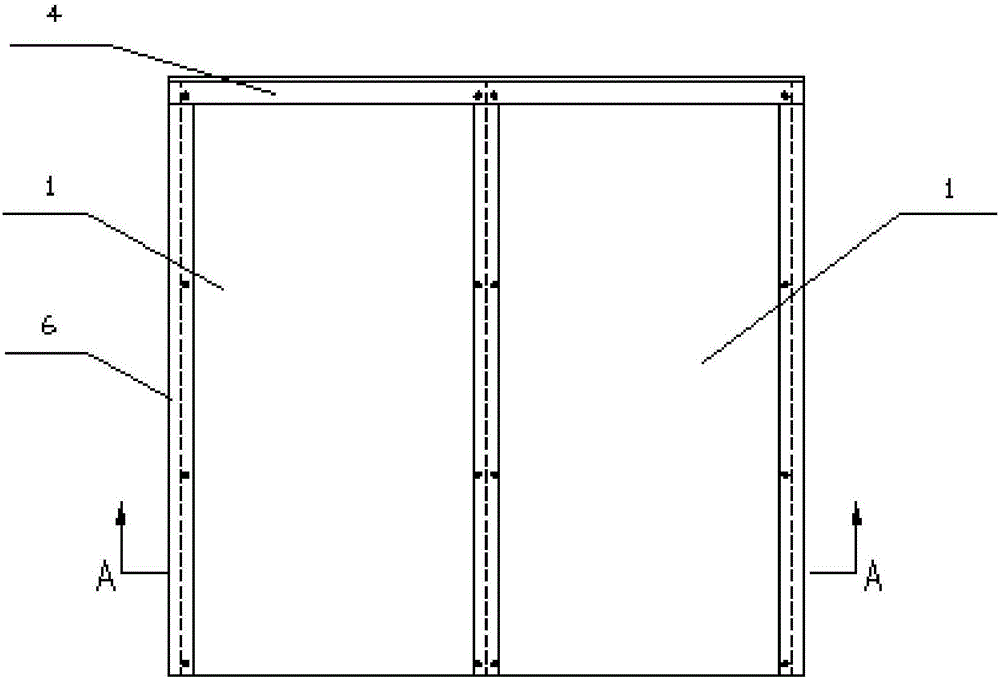

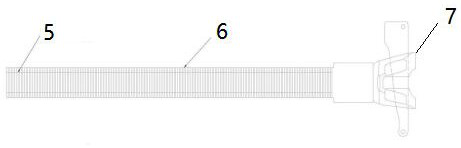

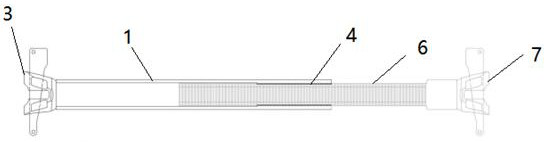

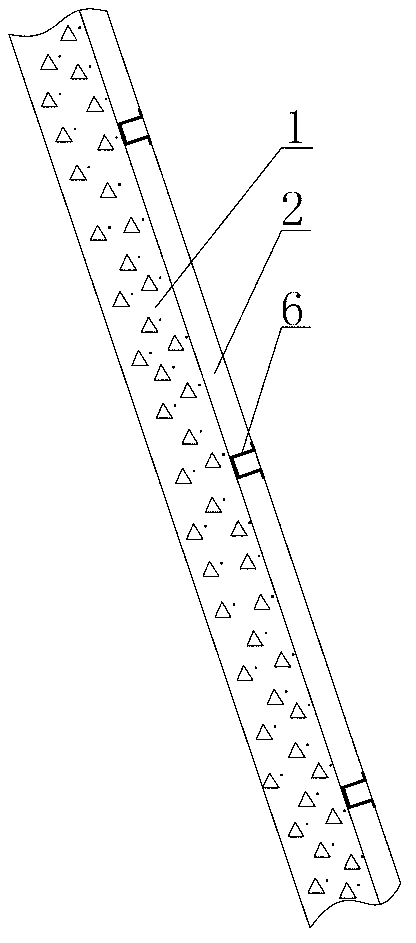

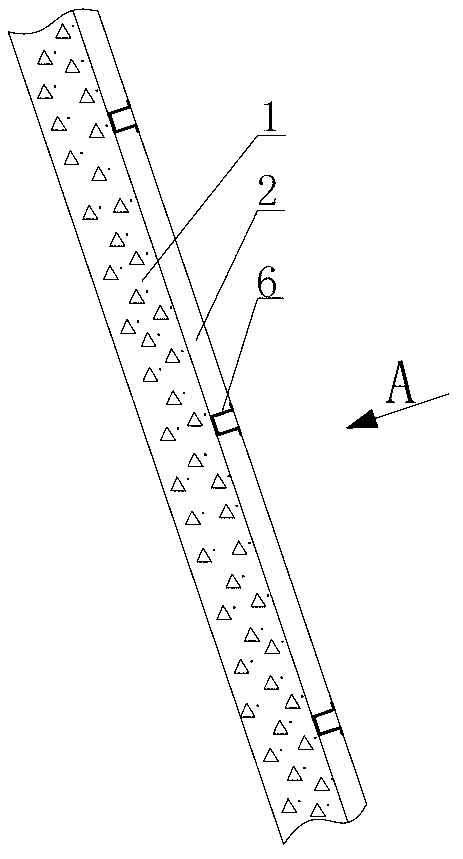

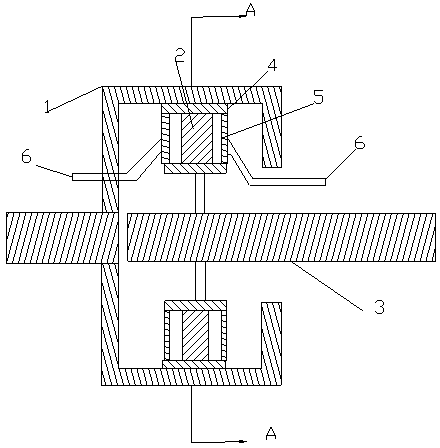

Detachable explosion venting door

InactiveCN105186307AProtection securityReduce indoor air pressureSubstation/switching arrangement casingsWar-like protectionEngineeringMechanical engineering

Disclosed in the invention is a detachable explosion venting door. The detachable explosion venting door is characterized in that a plurality of layers of decompression wall bodies (1) and a plurality of layers of pressure relief devices (2) are distributed at intervals in an up-down mode to form a pressure relief door body. An access door (3) is formed in the bottom of the pressure relief door body. One pressure relief device (2) at each layer is formed by splicing of a plurality of movable pressure relief plate assemblies; each movable pressure relief plate assembly contains a movable plate skeleton (4); an outer side movable pressure relief plate (5) is connected to the outer side of the movable plate skeleton (4) and an inner side movable pressure relief plate (6) is connected to the inner side of the movable plate skeleton (4); and an automatic latching mechanism (7) is arranged on the inner side movable pressure relief plate (6). The decompression wall body at each layer is formed by splicing of a plurality of movable wall body assemblies; each movable wall body assembly contains a wall body skeleton (8); and a decompression wall body inner side panel (9) and a decompression wall body outer side panel (10) are respectively arranged at the inner side and outer side of the wall body skeleton (8).

Owner:STATE GRID CORP OF CHINA +3

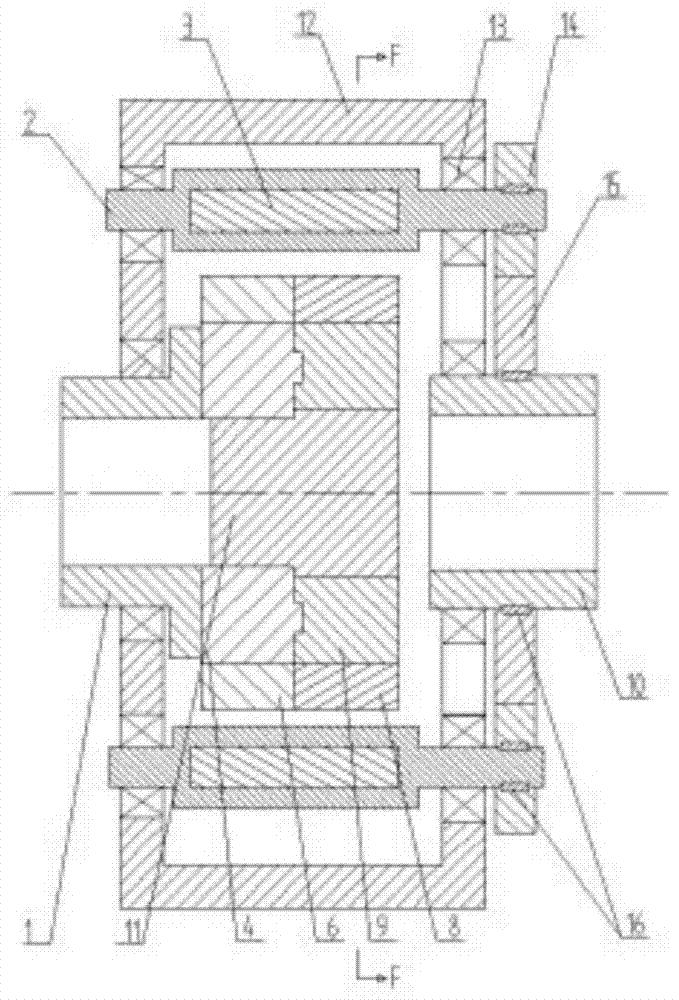

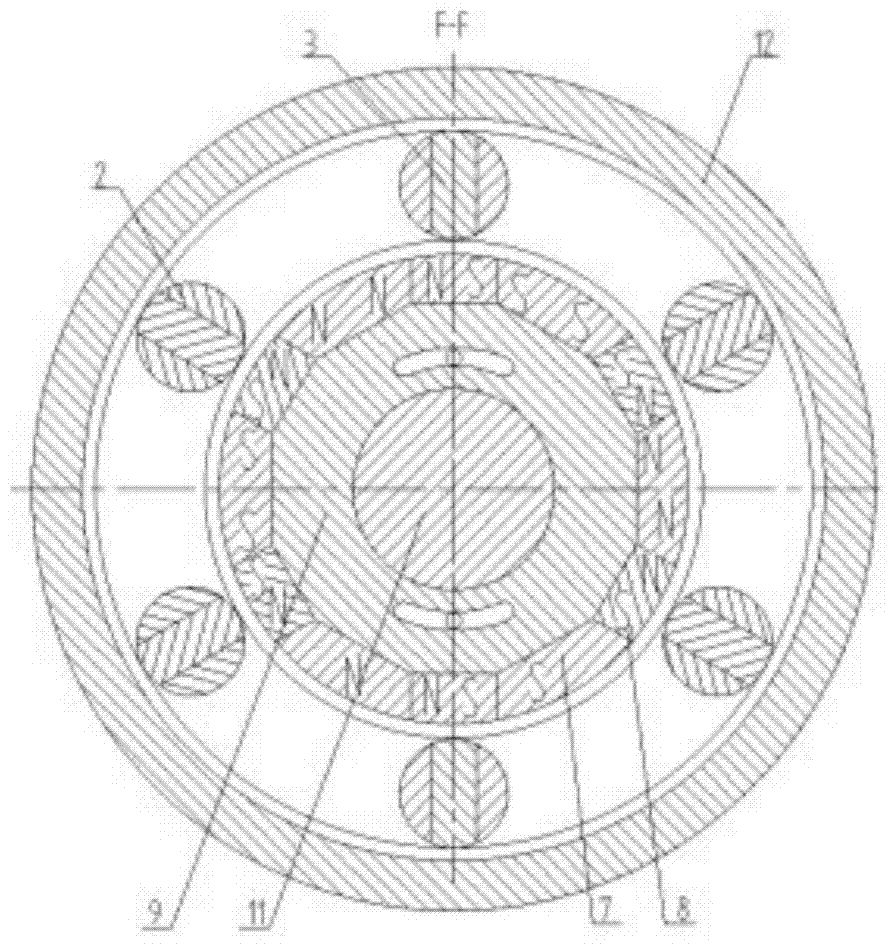

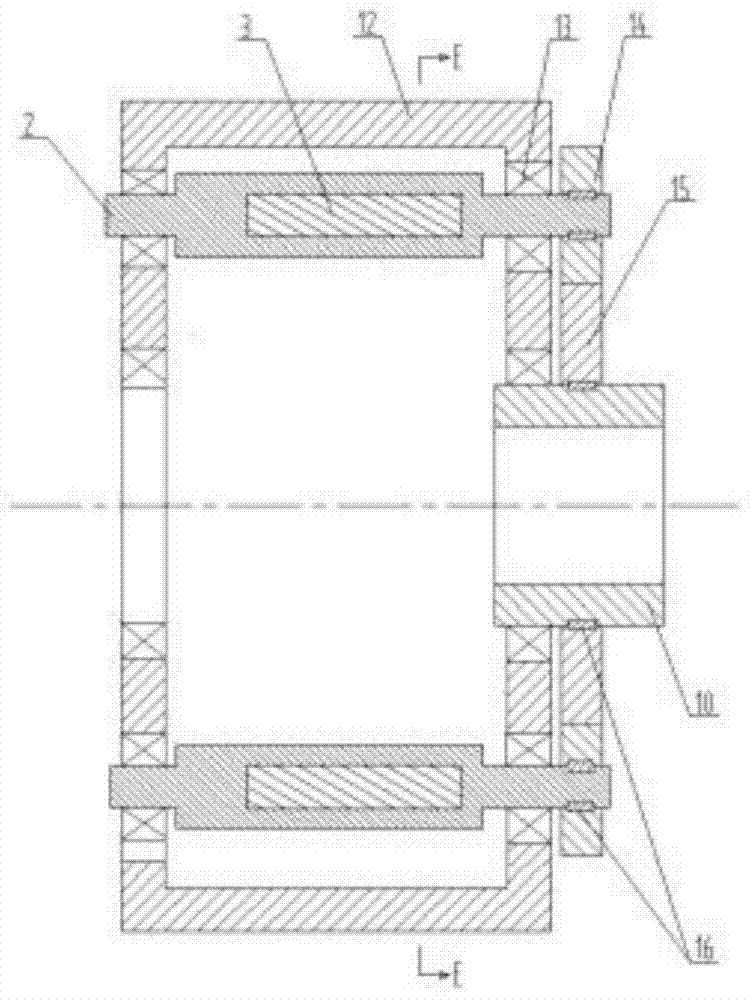

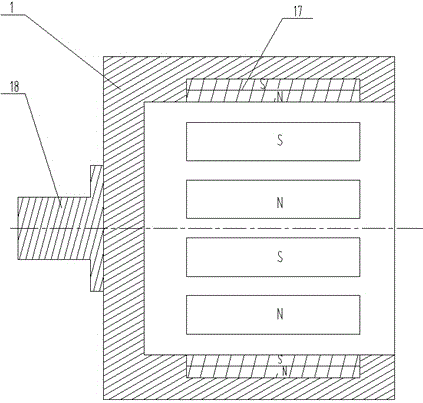

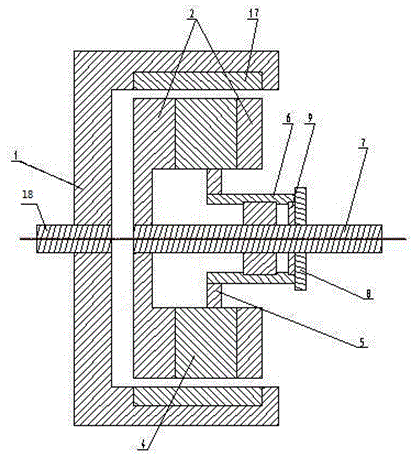

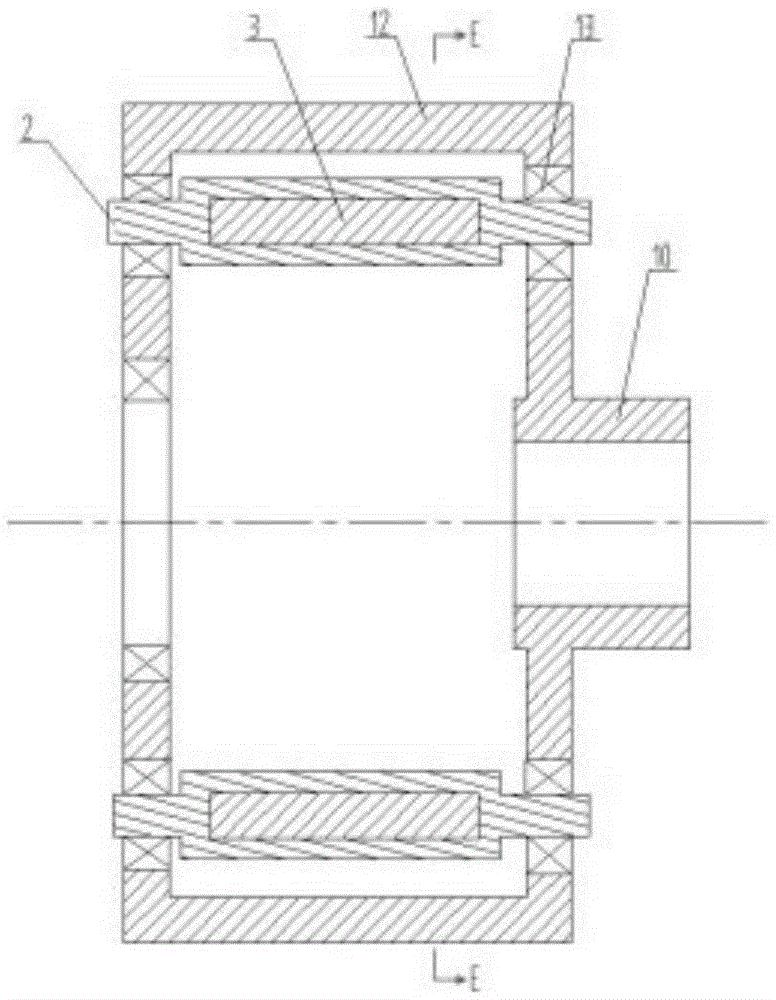

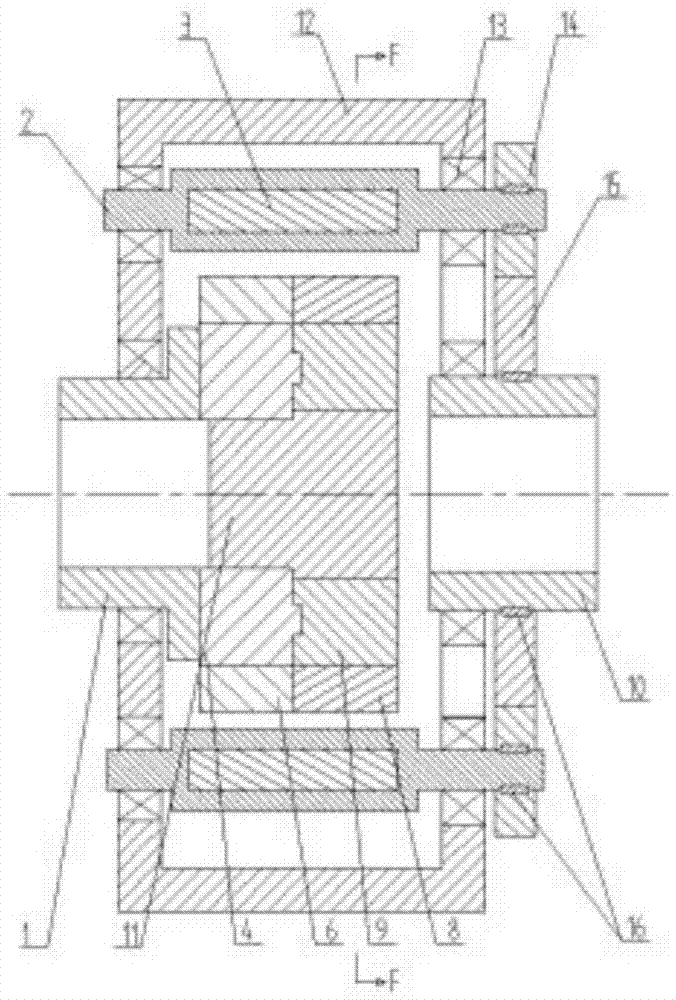

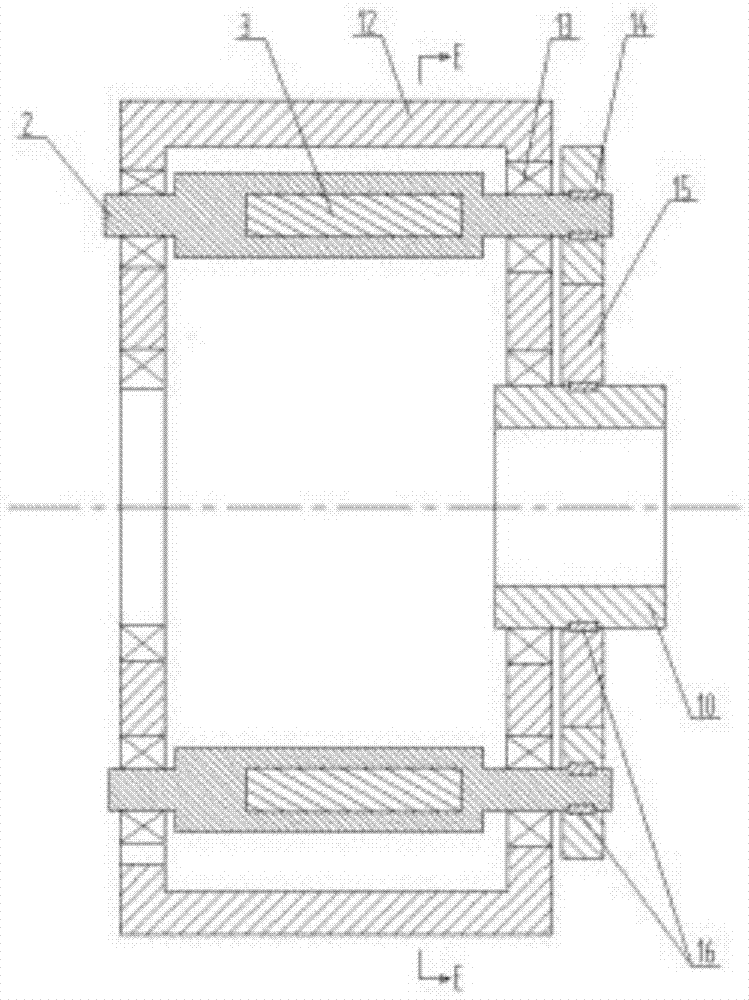

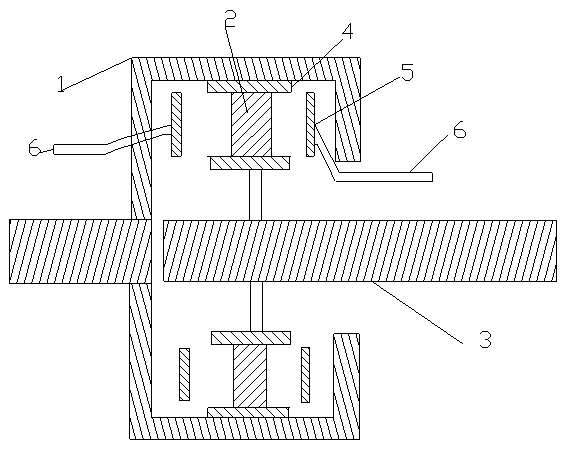

A permanent magnet governor with fixed magnetic gap

ActiveCN105449980BRealize speed regulation functionBroaden the fieldPermanent-magnet clutches/brakesDrive shaftRare earth

The invention relates to a permanent magnet speed regulator with a fixed magnetic gap, and the speed regulator comprises a first internal magnetic rotor, a second internal magnetic rotor, and an external magnet rotor frame, wherein a driving shaft coaxially passes through the first and second internal magnetic rotors, and the external magnet rotor frame is connected with a driven shaft. The external magnet rotor frame is provided with an external magnetic rotor through a bearing. In addition, one end, close to the driven shaft, of the external magnetic rotor is provided with an external magnetic rotor planetary gear. A driven shaft planetary gear is disposed between the external magnetic rotor planetary gear and the driven shaft. The speed regulator employs a fixed magnetic gap structure, so the speed regulator greatly increases the engagement area, reduces the assembly difficulty, reduces the generated heat, enlarges the range of speed regulation, saves rare earth materials, and greatly improves the capability of torque transmission. Because the speed regulator employs a planetary gear transmission structure, the speed regulator achieves a function of 0-%N speed regulation of input and output rotating speeds through changing the gear ratio of the external magnetic rotor planetary gear to the driven shaft planetary gear. In addition, the speed regulator employs a bearing structure, and prevents the continuous shaking of the driven shaft in two directions from causing that the driven shaft cannot rotate normally in one direction to drive a load.

Owner:刁俊起

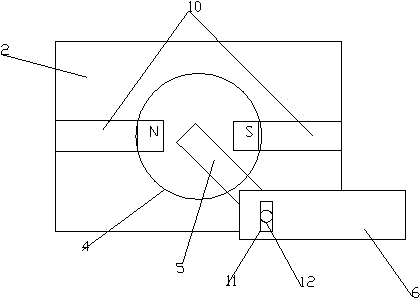

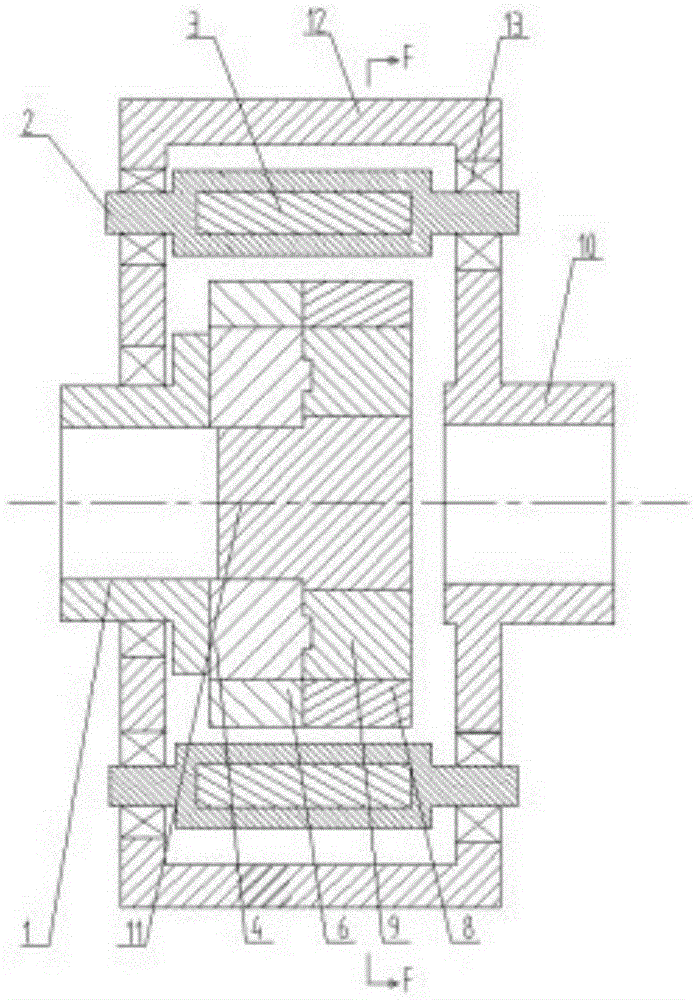

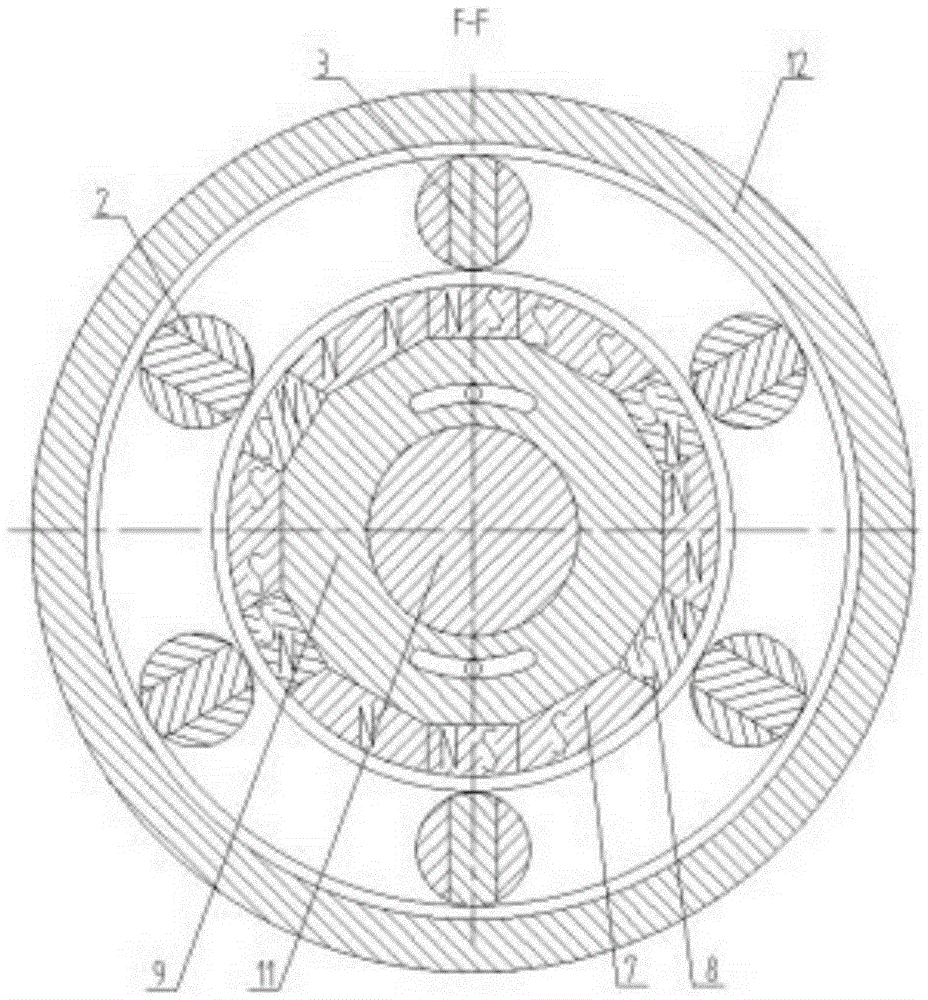

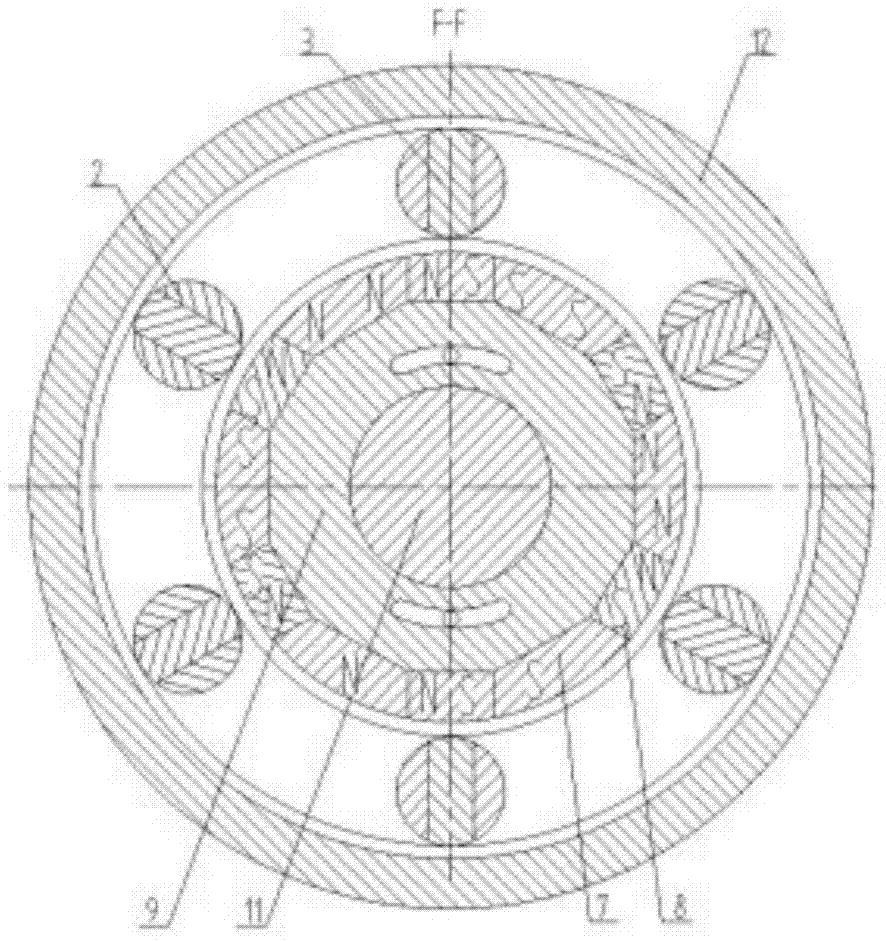

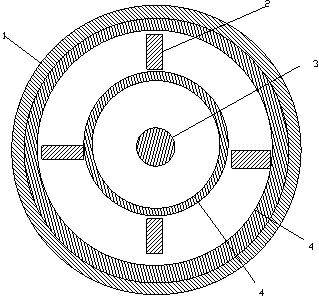

Permanent magnet speed controller with fixed magnetic gap

InactiveCN104362829AIncrease meshing areaReduce generationDynamo-electric brakes/clutchesElectric motor controlMagnetic polesTorque transmission

The invention relates to a permanent magnet speed controller with a fixed magnetic gap. The permanent magnet speed controller comprises an outer magnet rotor and an inner magnet rotor, wherein at least two outer permanent magnets are uniformly distributed along the circumferential direction of the inner circumferential surface of the outer magnet rotor; the magnetic poles of the outer permanent magnets are arranged along the radial direction, and the magnetisms of exposed magnetic pole surfaces of every two adjacent outer permanent magnets are different; at least one rotatable permanent magnet is distributed along the circumferential direction of the outer circumferential surface of the inner magnet rotor; the rotatable permanent magnet is cylindrical, and the pole N and the pole S are arranged along the diameter direction; and one end of the rotatable permanent magnet is provided with a magnetic circuit regulator. Due to the adoption of the fixed magnetic gap, the meshing area of the speed controller is greatly increased, the assembling difficulty is lowered, the heat generation is reduced, the speed control range is widened, rare earth materials are saved, the torque transfer capacity is greatly improved, the function of controlling the speed at the input and output rotating speed of 0-N% is achieved, the material consumption is reduced, the mounting space is saved, and more importantly, the convenience is brought for field installation and construction.

Owner:刁俊起

Four-link tension string for +/-800KV heavy ice area

The invention provides a four-link tension string for a + / -800KV heavy ice area, belonging to fitting strings for construction of transmission lines. The four-link tension string comprises two hanging point fittings connected with a tower, wherein after being connected with the same fitting, each hanging point fitting is connected at the left end of a first yoke plate by a bolt; the right end of the first yoke plate is connected with two insulators by a ball head hanging ring; two of the four insulators are connected on a second yoke plate and the other two insulators are connected on the other second yoke plate; the two second yoke plates are respectively connected with a combined yoke plate by a right-angle hung plate; an equalizing ring is arranged on two insulators; the equalizing ring is in open type or two-leg split type; the combined yoke plate is formed by connecting a two-variable four-link plate, two right-angle hung plates and two one-variable two-link plates by bolts; and two shielding rings are fixed at the upper and lower ends of the two-variable four-link plate by brackets. The four-link tension string has the characteristics of convenience for installation of the equalizing ring, stable structure and high strength.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP +2

Kitchen cabinet

InactiveCN103371634AEasy to disassembleLow skill level requiredKitchen cabinetsMechanical engineering

Owner:SINO MAPLE JIANGSU CO LTD

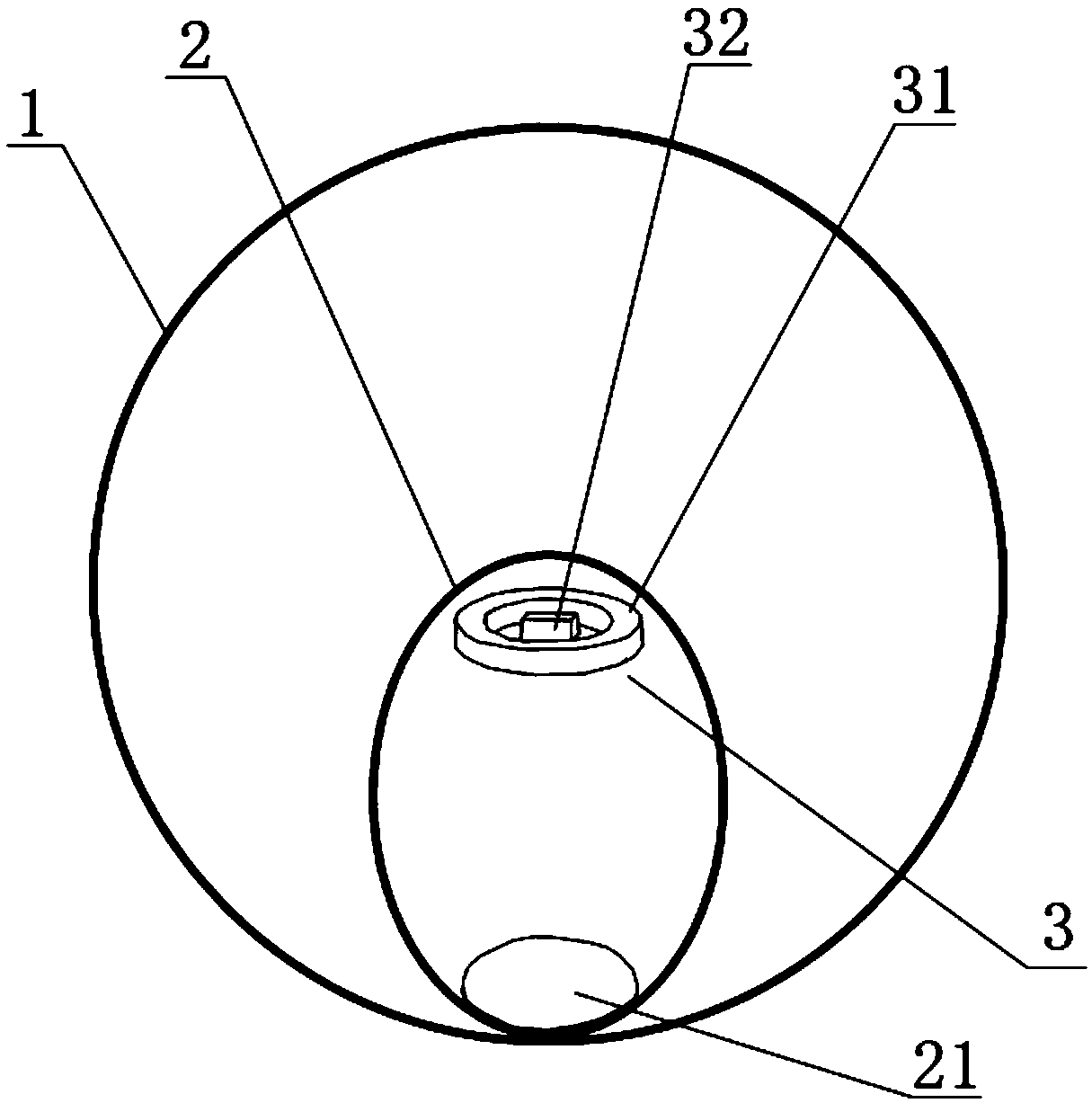

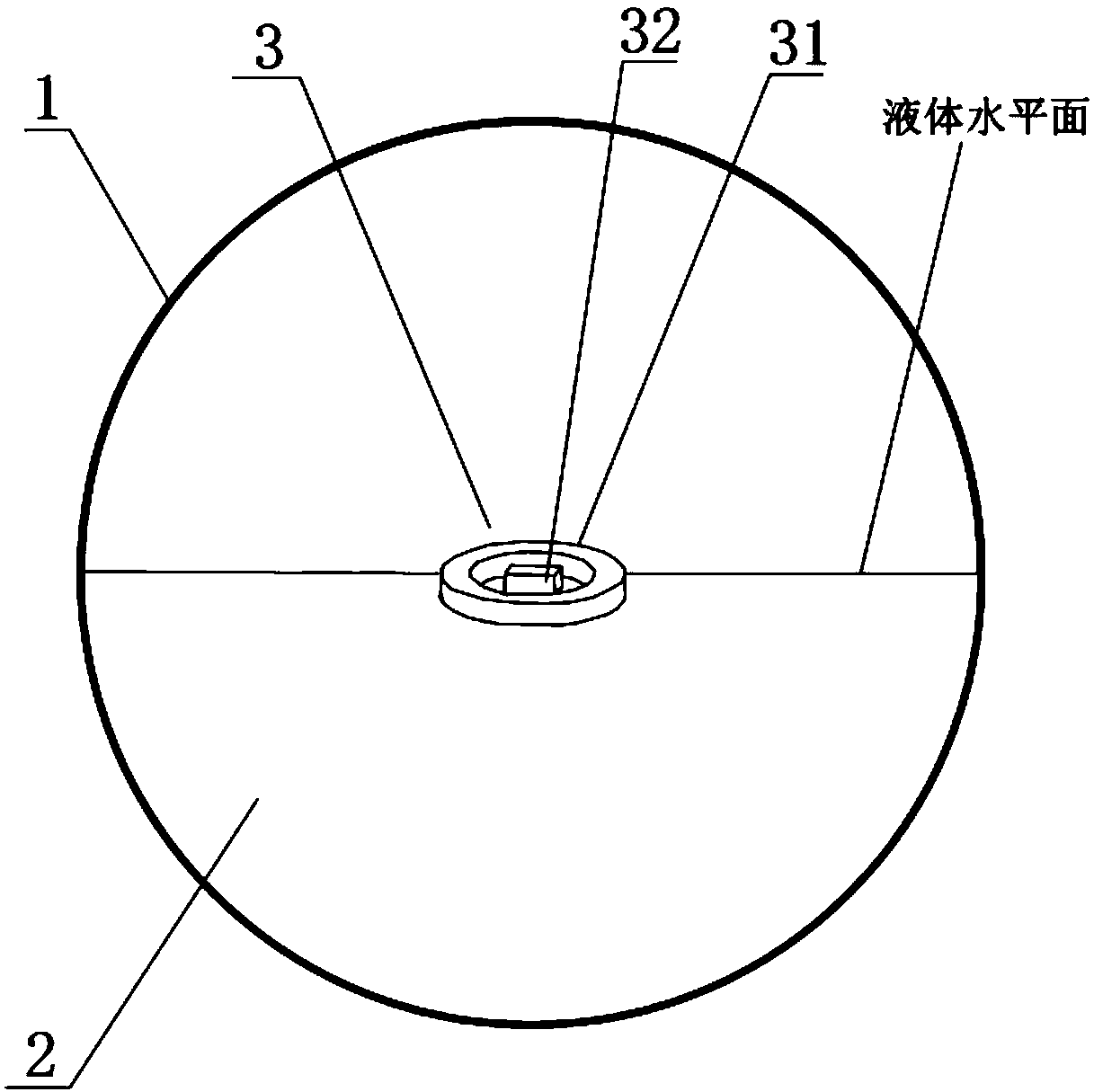

Single-ball low-frequency electronic tag

InactiveCN108665047AEliminate orientation requirementsConvenient on-site installation and constructionRecord carriers used with machinesElectronic taggingEngineering

The invention discloses a single-ball low-frequency electronic tag, and is applied to the identification of an underground pipeline node and an underground cable node. The single-ball low-frequency electronic tag comprises a circular outer shell, liquid and a low-frequency electronic tag body. The circular outer shell is a sealed hollow structure, and the circular outer shell is arranged in the underground pipeline node or the underground cable node; the liquid is accommodated in the circular shell body; the front face of the low-frequency electronic tag body is upward floating in the liquid,and the low-frequency electronic tag body comprises a shell, an antenna and a chip. The antenna is circular, and the antenna is sealed in the shell; the chip is horizontally arranged at the central part of the antenna, and the chip is welded on the inside of the shell; wherein an electronic tag detector can read the information in the chip through the shell of the circular outer shell and the low-frequency electronic tag body. Therefore, the single-ball low-frequency electronic tag eliminates the direction requirement of the low-frequency electronic tag in the normal operation, and greatly facilitates the field installation and construction.

Owner:BEIJING SMARTCHIP MICROELECTRONICS TECH COMPANY +1

Permanent magnet speed adjuster with fixed magnetic gap

ActiveCN105245084AIncrease meshing areaReduce generationPermanent-magnet clutches/brakesDrive shaftRare earth

The invention relates to a permanent magnet speed adjuster with a fixed magnetic gap, which comprises a first inner magnetic rotor, a second inner magnetic rotor and an outer magnetic rotor frame, wherein a driving shaft concentrically passes through the first inner magnetic rotor and the second inner magnetic rotor; the outer magnetic rotor frame is connected with a driven shaft; the outer magnetic rotor frame is provided with an outer magnetic rotor via a bearing; the first inner magnetic rotor and the second inner magnetic rotor are both provided with at least two first inner permanent magnets and second inner permanent magnets distributed circumferentially and uniformly along the outer circumferential surfaces; and the first inner magnetic rotor is provided with a magnetic circuit adjustment executor driving the first inner magnetic rotor to rotate relative to the second inner magnetic rotor. As the fixed magnetic gap structure is adopted, the meshing area of the speed adjuster is greatly improved, the assembly difficulty is reduced, heat generation is reduced, the speed adjustment range is increased, rare earth materials are saved, and the torque transfer capability is greatly improved. As the bearing structure is adopted, the phenomenon that as the driven shaft shocks back and forth along two directions, the driven shaft can not rotate normally along one direction to drive a load can be avoided.

Owner:刁俊起

Permanent magnet speed regulator with fixed magnetic gap

ActiveCN105449980ARealize speed regulation functionExpand the scope of usePermanent-magnet clutches/brakesDrive shaftRare earth

The invention relates to a permanent magnet speed regulator with a fixed magnetic gap, and the speed regulator comprises a first internal magnetic rotor, a second internal magnetic rotor, and an external magnet rotor frame, wherein a driving shaft coaxially passes through the first and second internal magnetic rotors, and the external magnet rotor frame is connected with a driven shaft. The external magnet rotor frame is provided with an external magnetic rotor through a bearing. In addition, one end, close to the driven shaft, of the external magnetic rotor is provided with an external magnetic rotor planetary gear. A driven shaft planetary gear is disposed between the external magnetic rotor planetary gear and the driven shaft. The speed regulator employs a fixed magnetic gap structure, so the speed regulator greatly increases the engagement area, reduces the assembly difficulty, reduces the generated heat, enlarges the range of speed regulation, saves rare earth materials, and greatly improves the capability of torque transmission. Because the speed regulator employs a planetary gear transmission structure, the speed regulator achieves a function of 0-%N speed regulation of input and output rotating speeds through changing the gear ratio of the external magnetic rotor planetary gear to the driven shaft planetary gear. In addition, the speed regulator employs a bearing structure, and prevents the continuous shaking of the driven shaft in two directions from causing that the driven shaft cannot rotate normally in one direction to drive a load.

Owner:刁俊起

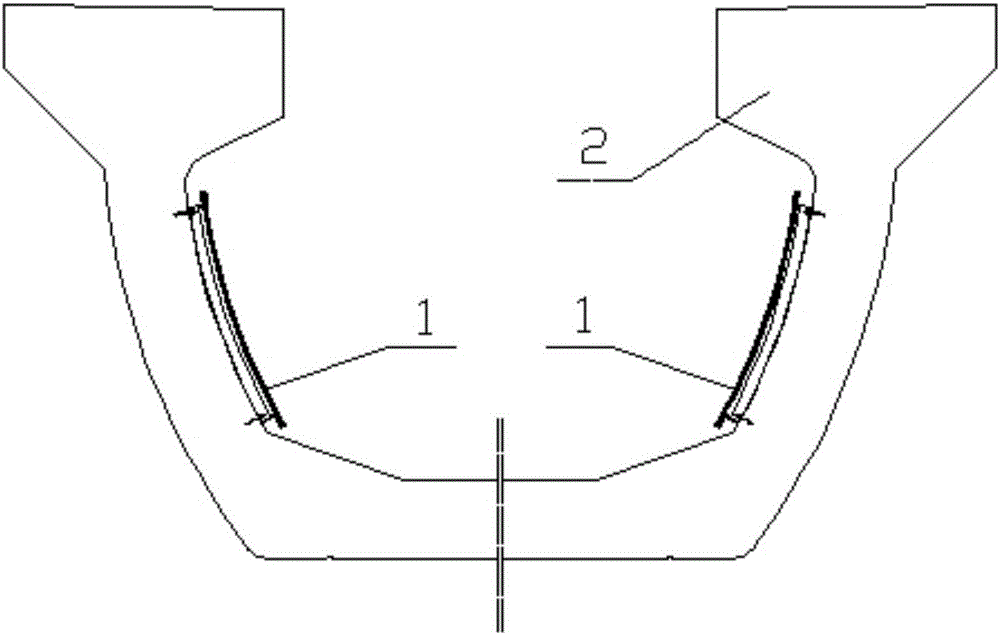

Foamed aluminum substrate sound barrier of U-shaped beam of metro

InactiveCN106638342AImprove corrosion resistancePrevent spillageNoise reduction constructionSound barrierShaped beam

The invention discloses a foamed aluminum substrate sound barrier of a U-shaped beam of metro and is mainly used for absorbing sounds and reducing noises for U-shaped beam of metro. The sound barrier comprises a top supporting piece and a bottom supporting piece which are fixed to two sides of the U-shaped beam of a metro track as well as a sound absorbing plate, a pressure plate and a vertical supporting piece which are arranged therebetween. The supporting piece is Z-shaped, a mounting groove which extends outward and is opened downward is formed in the upper portion of the supporting piece, and a supporting leg which extends outward is arranged in the lower portion. The sound absorbing plate is a double-sided fluorocarbon sprayed foam aluminum plate of a through hole structure, the thickness of which is greater than or equal to 5mm, the coating thickness of which is greater than or equal to 40mu m, the porosity of which is 55-65%, the average pore diameter is less than or equal to 0.7mm and the sound absorbing coefficient NRC is greater than or equal to 0.75; the sound absorbing plate is a cambered surface, a concave surface of which faces the direction of a metro locomotive, and the radius dimension of the cambered surface is 1990-2200mm, preferably 2066mm. The sound barrier can prevent noises from overflowing, is convenient to mount, and not only is convenient for field installation and construction, but also is convenient for rectification and detachment.

Owner:LIAONING RONGDA NEW MATERIALS TECH CO LTD

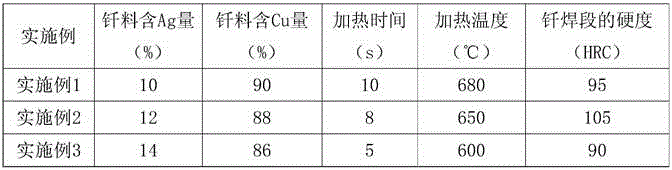

Welding technology for mineral insulated cable

InactiveCN106099602AConvenient on-site installation and constructionNot susceptible to moistureSoldered/welded connectionsEngineeringExtrusion

The invention discloses a mineral insulated cable welding process, which includes a cold extrusion welding process for welding conductors of a first mineral insulated cable and a second mineral insulated cable, and welding the first mineral insulated cable and the second mineral insulated cable The sheaths are welded together by a brazing process. The invention has low processing cost, simple operation, high welding reliability, can ensure the mechanical strength and complete electrical conductivity of the welded mineral insulated cable, and realizes large-length delivery.

Owner:上海安捷防火智能电缆有限公司

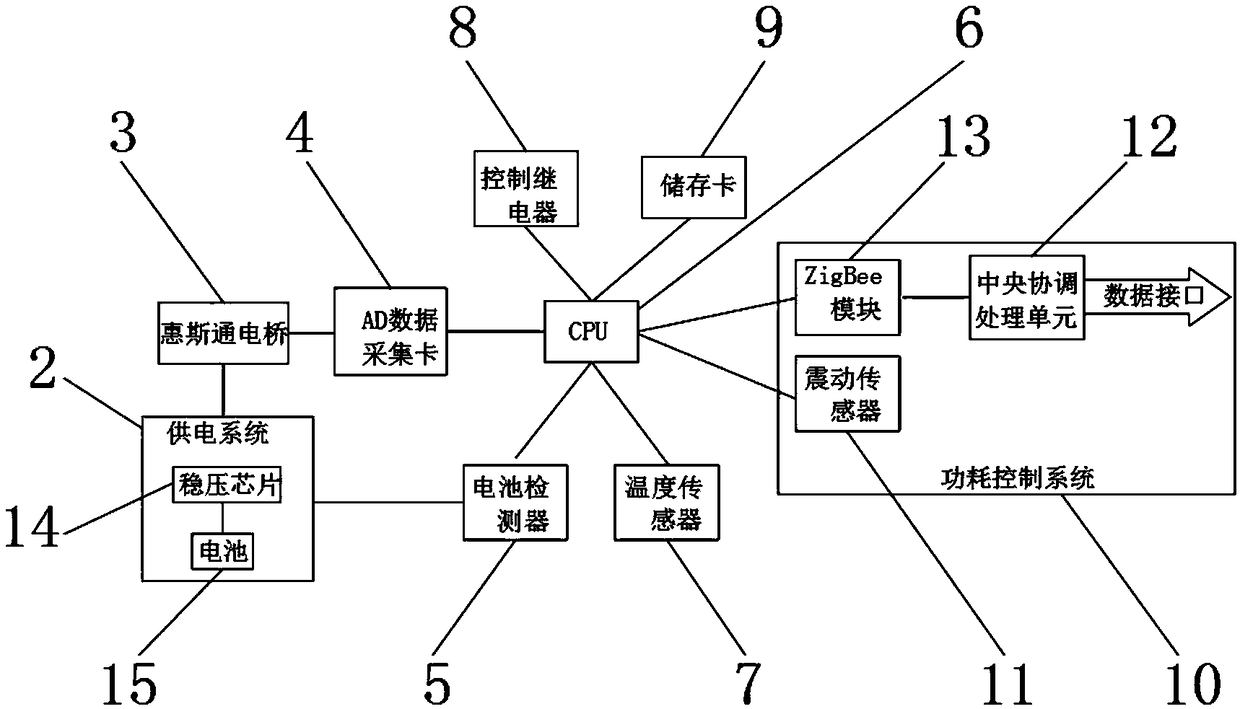

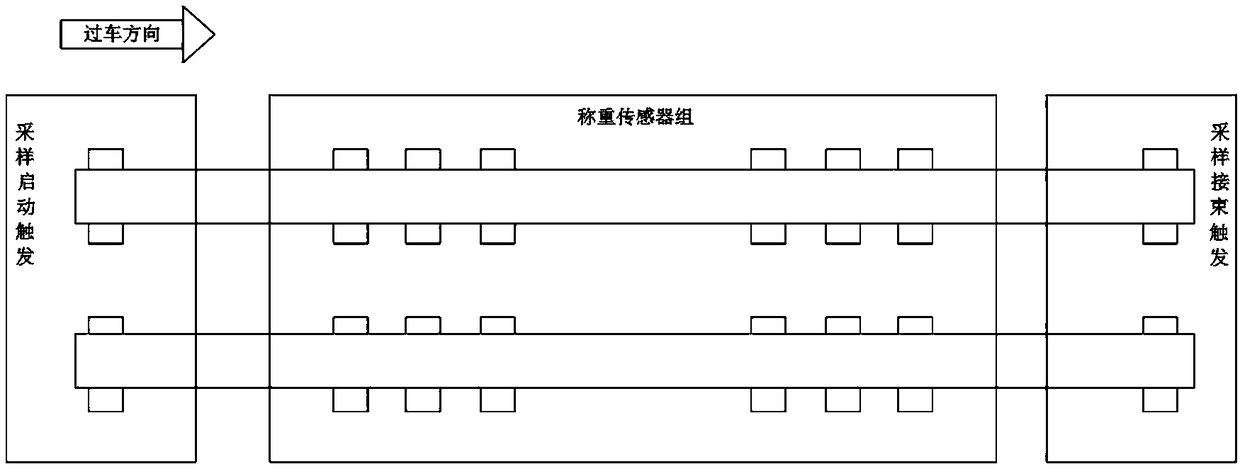

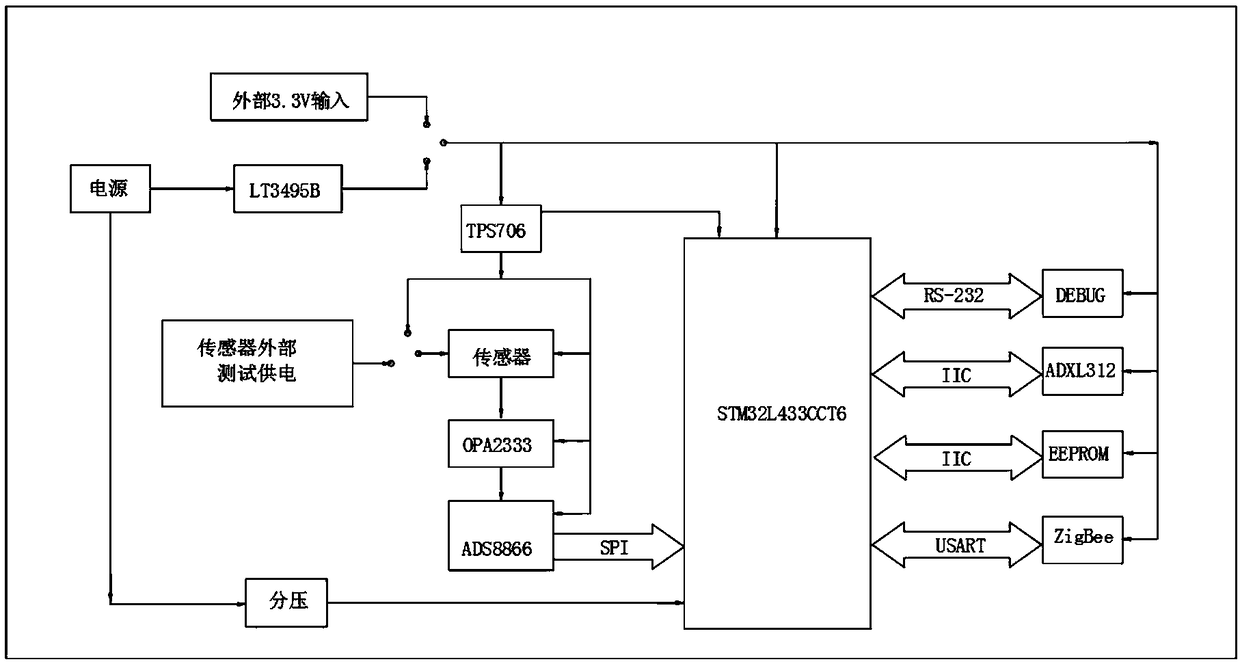

High-speed wireless dynamic weighing sensor system

ActiveCN109341830AReduce the error factorReduce construction costsTransmission systemsSpecial purpose weighing apparatusLine sensorControl system

The invention discloses a high-speed wireless dynamic weighing sensor system. The system includes a weighing sensor, a power supply system, a Wheatstone bridge, an AD data collection card, a battery detector, a CPU, a temperature sensor, a control relay, a storage card and a power consumption control system. The power supply system is respectively and electrically connected with the Wheatstone bridge and the battery detector. The Wheatstone bridge is electrically connected with the AD data collection card. The weighing sensor is electrically connected with the AD data collection card. The battery detector is electrically connected with the CPU. The weighing sensor in the system of the invention has only one externally connected antenna, on-site installation and construction are enabled tobe more convenient, human error factors are reduced, construction costs are reduced, the weighing sensor system uses almost no wire joint on 32 sensors as compared with wired sensors, costs are greatly reduced, too much invalid data collection and transmission can be avoided through the power consumption control system, and system running efficiency is improved.

Owner:HANGZHOU QIANJIANG WEIGHING TECH

Method for connecting length-adjustable transverse rods of disc buckle frame

PendingCN113914603AResolve connectionConvenient on-site installation and constructionScaffold connectionsEngineeringMechanical engineering

A method for connecting length-adjustable transverse rods of a disc buckle frame is characterized by comprising the following steps: a, providing a first transverse rod of the disc buckle frame, wherein the first transverse rod is a hollow pipe, the outer diameter of the first transverse rod is 48 mm, the inner diameter of the first transverse rod is 34 mm; b, providing a second transverse rod of the disc buckle frame, wherein the second transverse rod is a lead screw transverse rod, the outer diameter of the lead screw transverse rod is 32 mm; and c, movably connecting the first transverse rod with the second transverse rod, and inserting the lead screw transverse rod of the second transverse rod serving as a screw rod into a nut of the first transverse rod, and adjusting the length of thetransverse rods of the disc buckle by means of the quantity of the screwed screws. The method for connecting the length-adjustable transverse rods of the disc buckle frame has the advantages that the length of the transverse rods can be adjusted within a certain range, the problem of connection of vertical rods which do not meet modulus is solved, field installation and construction are facilitated, the flexibility of arrangement of the vertical rods of the disc buckle frame body is greatly improved, and the whole frame body is horizontally connected through the transverse rods and is stable and reliable.

Owner:MCC5 GROUP CORP SHANGHAI

Mortar plastering anti-cracking structure for irrigation canal

InactiveCN103290819AProduction limitAvoid crackingIrrigation ditchesMarine site engineeringGratingPolyvinyl chloride

The invention discloses a mortar plastering anti-cracking structure for an irrigation canal. The mortar plastering anti-cracking structure comprises an anti-leakage base layer for a slope surface of the irrigation canal and a mortar plastering layer on the anti-leakage base layer, and is characterized in that a netted grating structure is arranged in the mortar plastering layer on the anti-leakage base layer, a plurality of vertically through stepped holes are formed in the netted grating structure, and cement nails are arranged in the stepped holes and are nailed on the anti-leakage base layer under the cement nails. The mortar plastering anti-cracking structure has the advantages that PVC (polyvinyl chloride) dividing strips are spliced to form the netted grating structure, the netted grating structure is arranged in the mortar plastering layer, the vertically through stepped holes are formed in the netted grating structure, and the cement nails penetrate the stepped holes, so that the netted grating structure can be integrally connected with the anti-leakage base layer, and the mortar plastering layer is filled among a plurality of meshes which are formed by the netted grating structure in an enclosed manner and have the minimum sizes.

Owner:朱少鹏

Permanent magnet speed governor for fixing magnetic gap

ActiveCN104201864AIncrease meshing areaReduce power consumptionDynamo-electric gearsPermanent magnet rotorRare earth

The invention relates to a permanent magnet speed governor for fixing a magnetic gap. The permanent magnet speed governor comprises a cylindrical conductor rotor and a p-m rotor in the conductor rotor; the p-m rotor comprises at least one permanent magnet; the two length ends of the permanent magnet are respectively an N pole and an S pole; fixed magnetizers and movable magnetizers are arranged on the two magnet pole end surfaces and two length sides of the permanent magnet, and can form a closed magnetic loop. As the permanent magnet speed governor adopts a fixed magnetic gap structure, the meshing area of the speed governor is greatly improved, the assembling difficulty is reduced, a rare earth material is reduced, and the torque transmission capability is greatly improved; a magnetic circuit adjusting structure is adopted, the power consumption of actuating and adjusting mechanisms is greatly reduced, and the size of each actuating and adjusting mechanism is reduced to the utmost extent, so that the whole size of the speed governor is greatly reduced, not only the material consumption is reduced, the mounting space is saved, and convenience is brought to the construction of field mounting.

Owner:洁盟科技有限公司

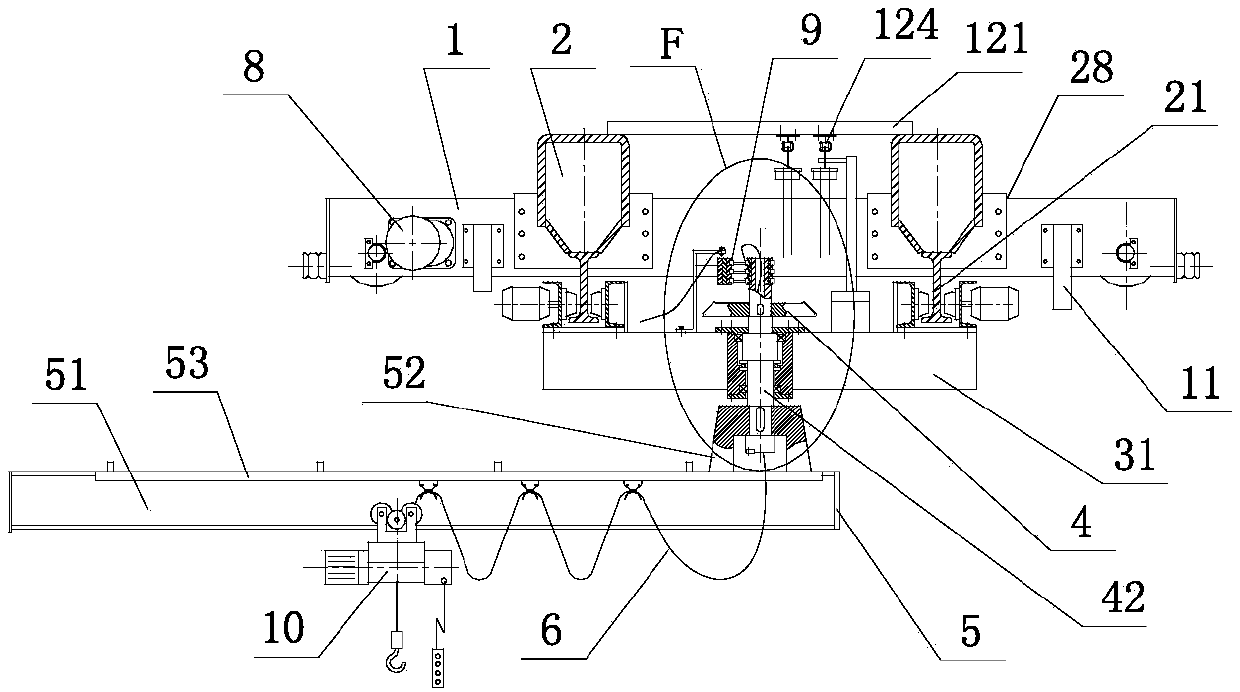

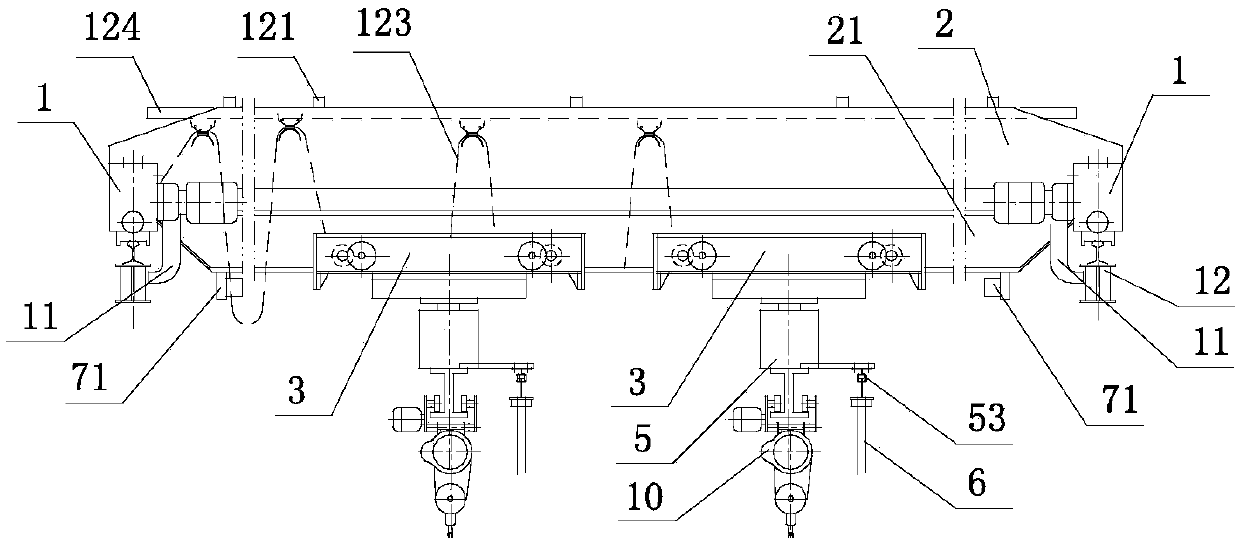

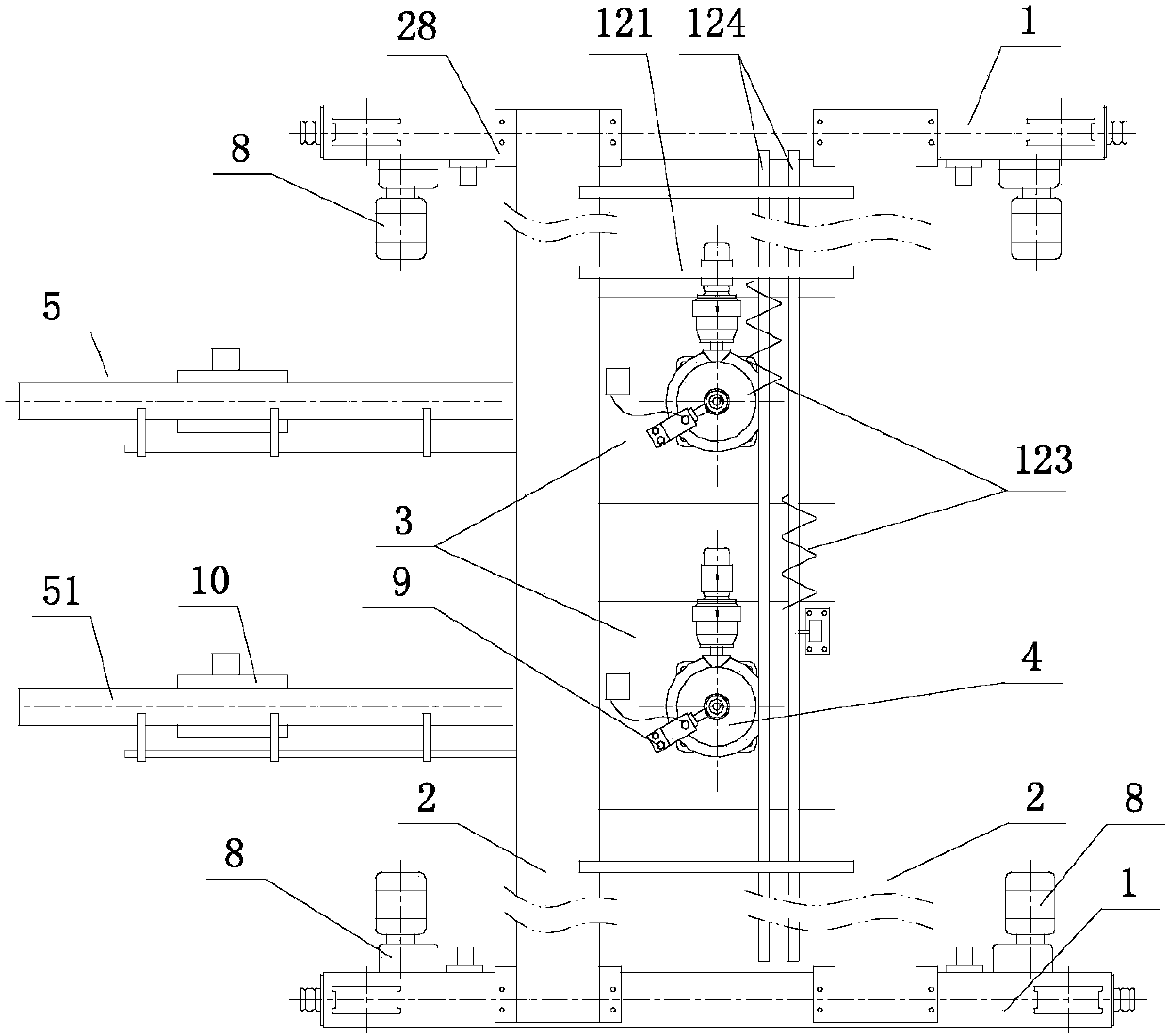

Crane provided with two hanging end beam trolleys and cantilever beams capable of rotating at any angle

InactiveCN107867647AImprove efficiencyEasy to cooperate with liftingLoad-engaging girdersTravelling cranesCantilevered beamDual beam

This application discloses a crane with two suspended end girder trolleys and a cantilever beam that can rotate at any angle, including a double girder bridge frame with end girders and main girders; Turning device; two suspended end beam trolleys are connected to the rails below the two main beams; a rotating mechanism with fan gear transmission is installed on the suspended end beam trolley; the lower end of the boom shaft in the rotating mechanism is connected to the cantilever member, and the upper end is connected to the collector Slip ring; the cantilever member includes a cantilever beam and a suspension seat; the suspension seat is welded at one end of the cantilever beam; the cantilever beam is made of I-beam; the cantilever beam is provided with a guide rail; The hanging cable; one end of the hanging cable passes through the center hole of the boom shaft and is connected to the collector slip ring; the electric hoist is connected to the cantilever beam, and the cantilever beam is located under the main beam and can be extended outside the workshop, and can Rotate at any angle on the horizontal plane.

Owner:福州市鼓楼区奇韵通自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com