Assembling construction method for pipeline of refrigerating machine room of subway station

A technology for refrigerating machine rooms and subway stations. It is applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc. It can solve problems such as high risk of corrosion, many cross problems, and uneven process levels, so as to reduce on-site safety. Hidden dangers and environmental pollution, good economic and social benefits, and the effect of reducing on-site construction personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

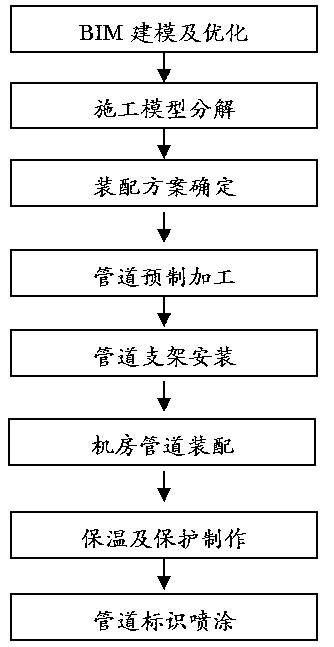

[0062] This embodiment provides a method for assembling pipelines in a refrigerator room of a subway station, which includes the following steps.

[0063] Step 1. BIM model establishment and optimization

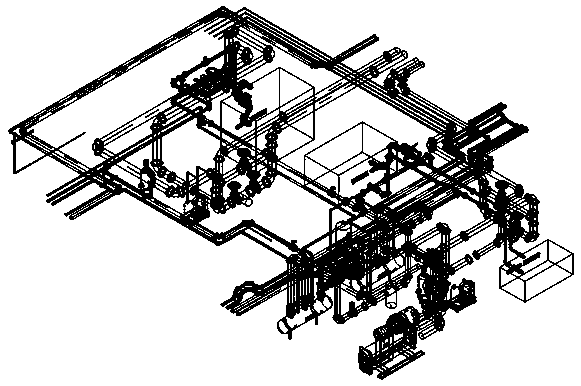

[0064] Use 3D scanning technology to scan and model the main structure of the station, and then combine BIM technology to establish a model of the installation and construction process of the pipeline in the refrigeration room, conduct collision detection with other professional pipelines in the machine room, optimize the problems found, and realize the visualization of the construction process of water pipes Confession.

[0065] Step 2. Decomposition of the construction model

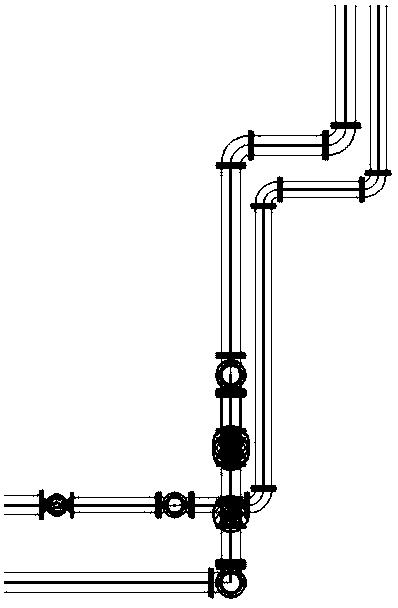

[0066] According to the optimized pipeline model of the computer room and the site survey, the established model is decomposed according to the system and location. The pipeline section must first meet the transportation and installation conditions, and secondly, the valves and components installed ...

Embodiment 2

[0107] There are a total of 7 refrigerated machine rooms in the 3 stations of the Electromechanical II Section of the West Extension Project of Beijing Metro Line 6. This technology has been applied to improve the original construction method, which is safe and efficient. In step 2, the construction model is segmented according to the above principles. The welded flange pipes in the machine room are divided into 5 model blocks and 30 pipe sections. The model blocks include:

[0108] (1) Module 1: The DN200 and DN250 cooling water pipes on the south side of the refrigeration room are divided into 7 sections, which are connected to the valves and cooling water pumps on the cooling water system;

[0109] (2) Module 2: The DN250 cooling water pipe of the large system of the refrigeration room is connected with U-shaped pipes and pipe fittings, which are divided into 12 sections and connected with valve parts;

[0110] (3) Module 3: DN200 and DN300 cooling water pipes on the south ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com