Kitchen cabinet

A cabinet and cabinet body technology, applied in the field of cabinets, can solve the problems of high technical level requirements of workers, inconvenient disassembly and maintenance, uneven quality, etc., and achieve the effects of low technical level requirements of workers, convenient disassembly and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described below with reference to the drawings.

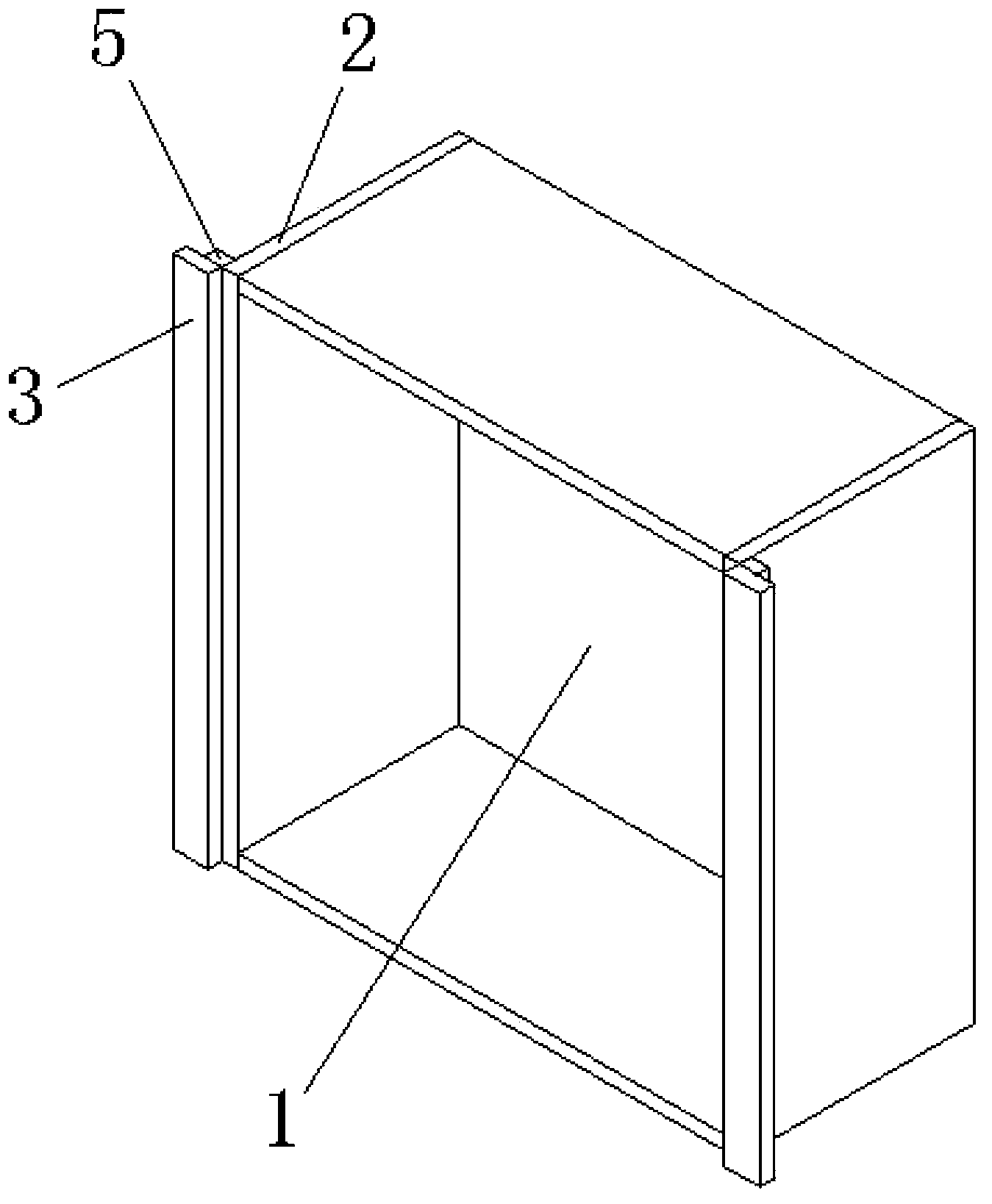

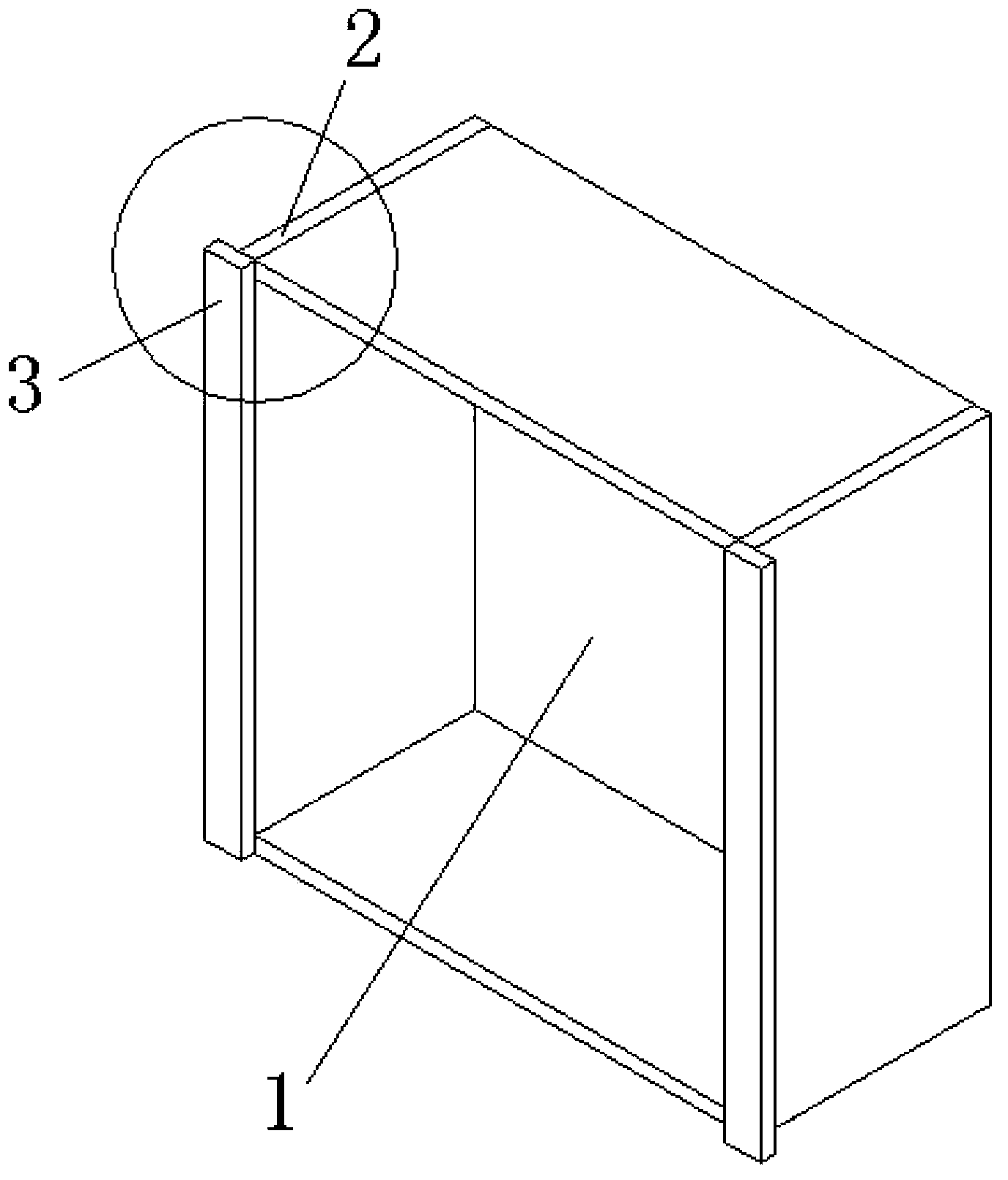

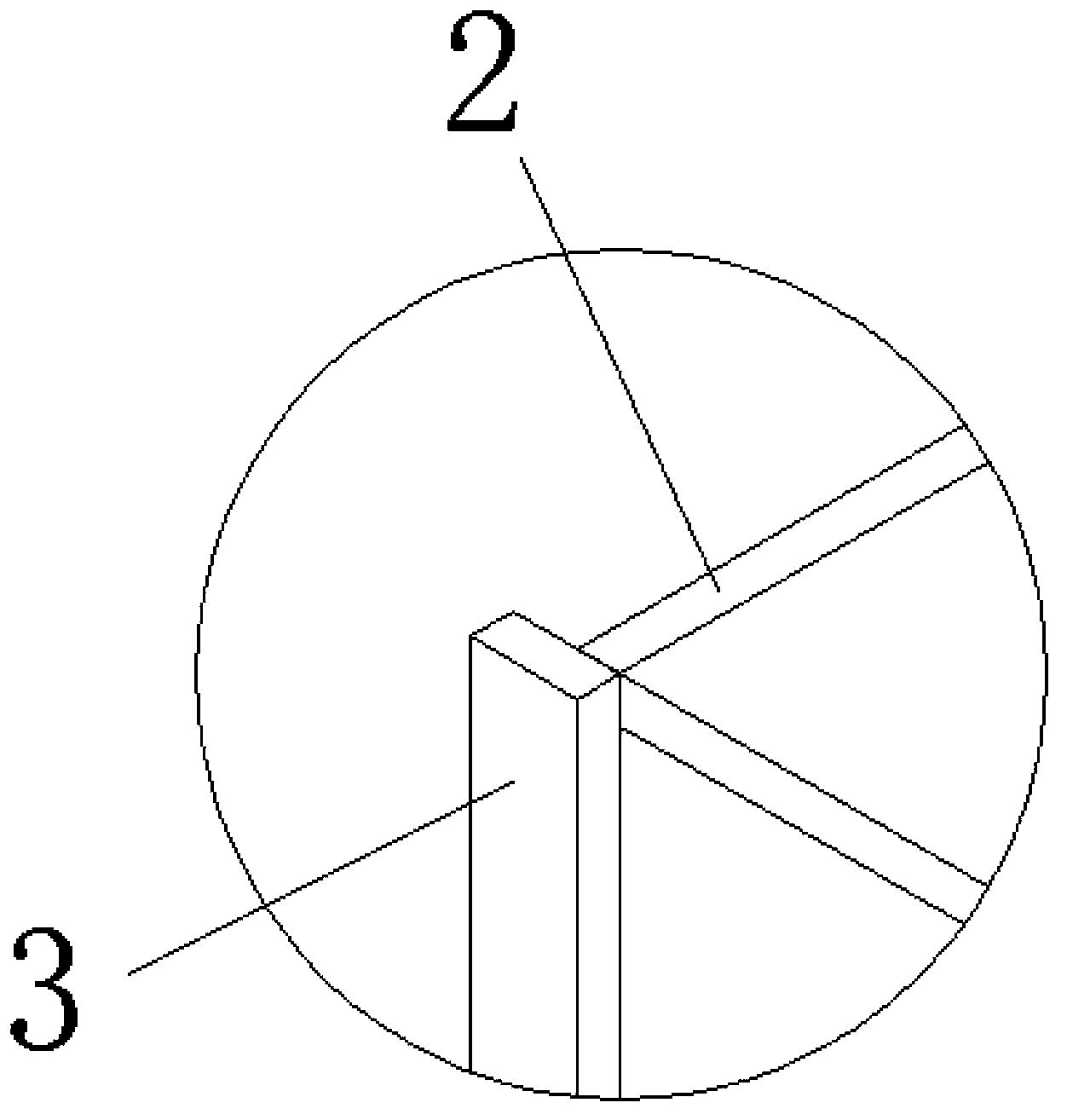

[0015] Attached Figure 2-3 It is a cabinet according to the present invention, comprising a cabinet body 1, a side panel 2, and a closing strip 3; there are two side panels 2 and the two side panels 2 are respectively arranged on the left and right sides of the cabinet 1; The closing strip 3 is fixed to the front end of the side plate 2 by glue or pin connection; the end surface of the closing strip 3 close to the cabinet 1 is flush with the inner side of the side plate 2; the height of the closing strip 3 is the same as that of the cabinet 1 Highly consistent.

[0016] Such as Figure 4 As shown, the cabinet 1 is installed on the wall 4; the closing strip 3 is located at the gap between the cabinet 1 and the wall 4, and closes the space between the cabinet 1 and the wall 4.

[0017] Due to the application of the above technical solutions, the present invention has the following advantages compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com