Beam-column joint of square steel pipe sleeve weak shaft connection steel structure and installation method thereof

A square steel pipe and sleeve connection technology, which is applied in the direction of building construction and construction, can solve the problems of being vulnerable to the site environment, less weak shaft connections of H-shaped steel columns, and fewer node forms, so as to ensure the stiffness and bearing capacity of the nodes, Ensure the quality of beam-column joints and facilitate installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

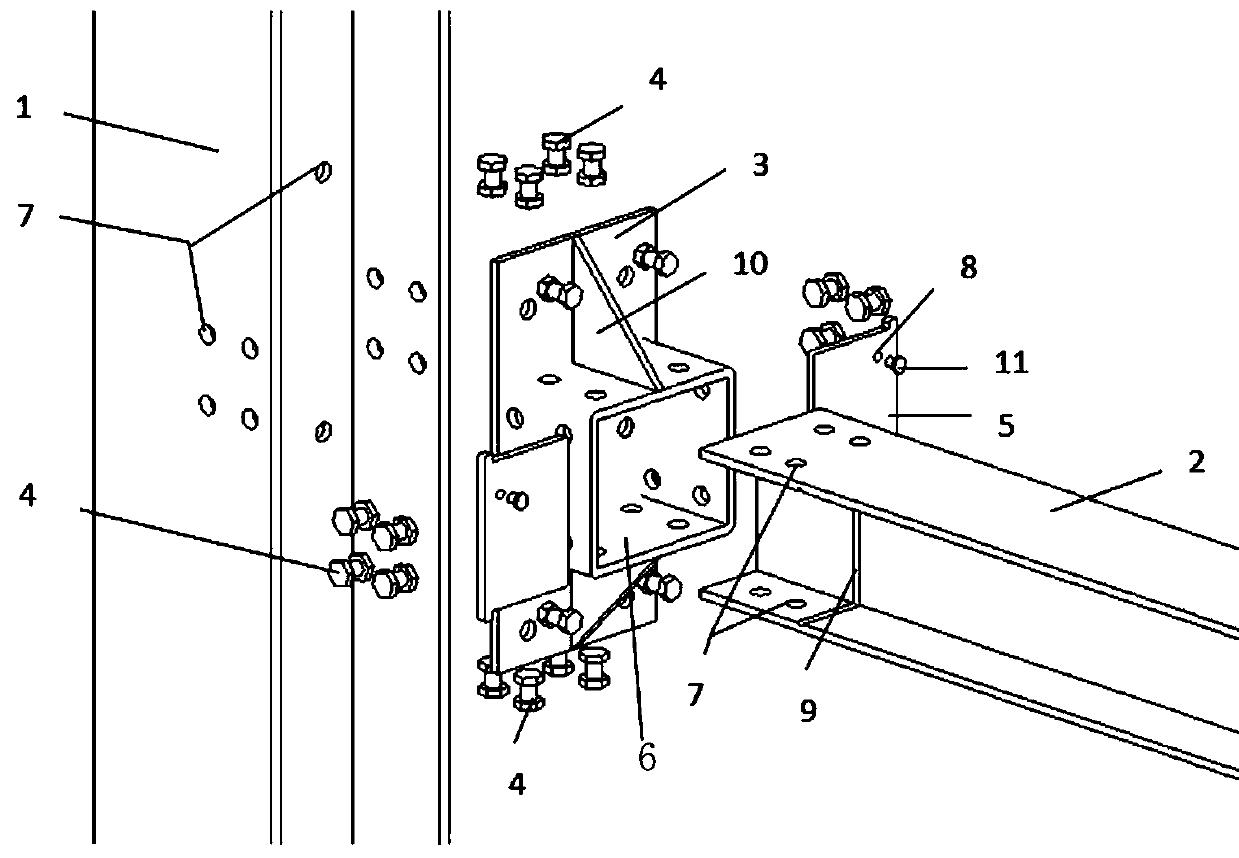

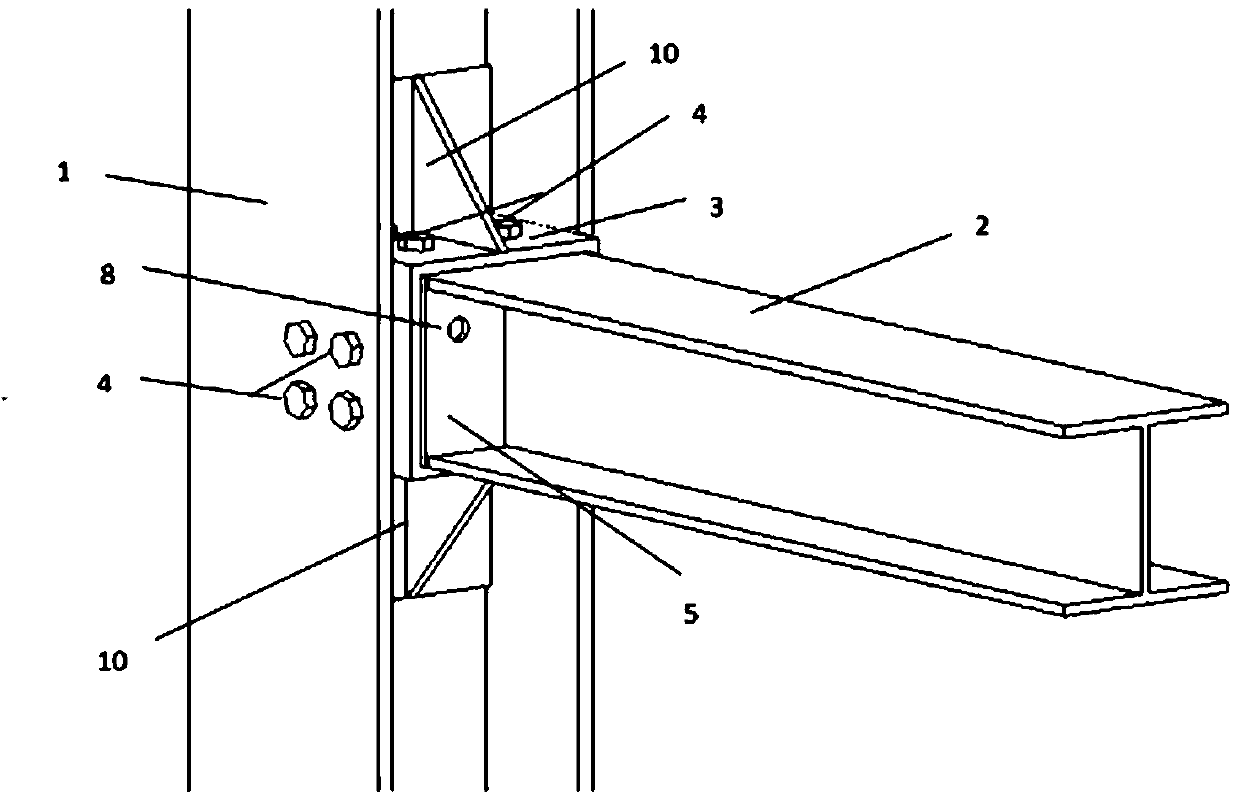

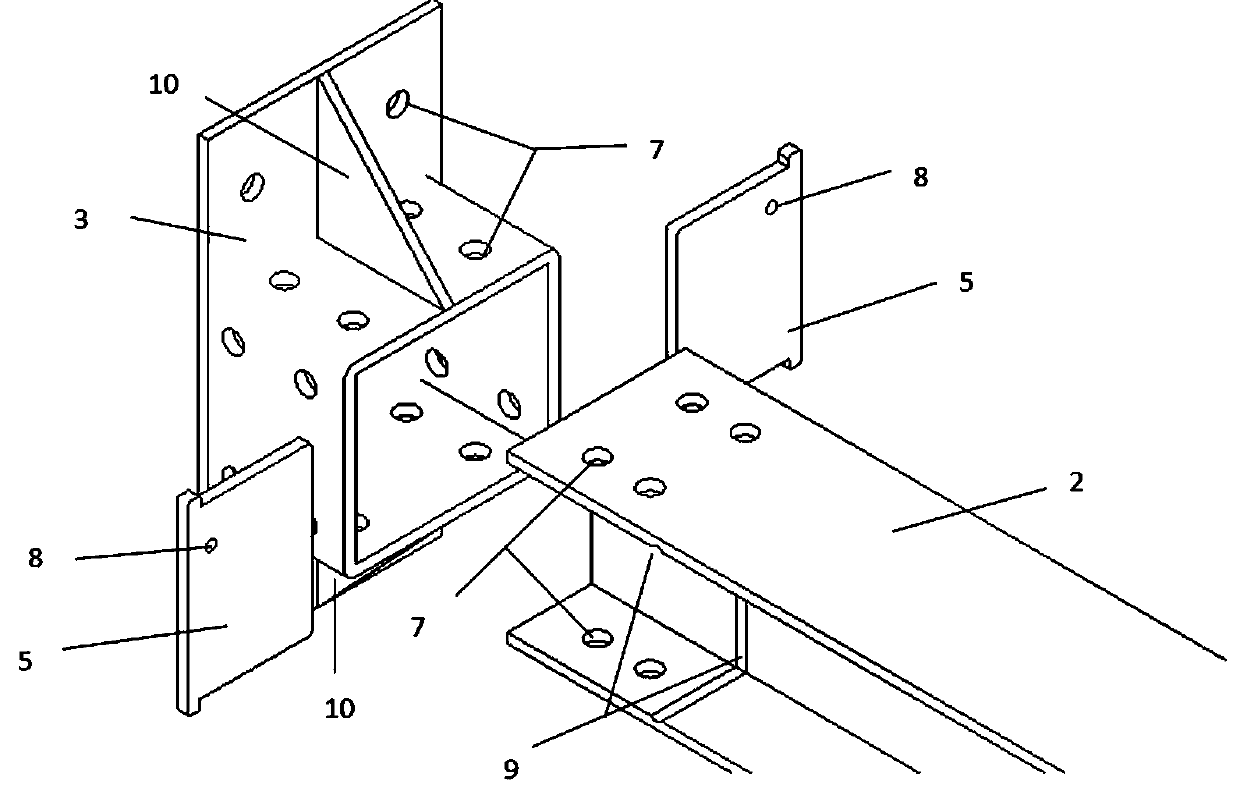

[0027] This embodiment is a rigid node connected by a weak shaft of steel structure H-shaped steel of the present invention, as attached Figure 1-4 As shown, it includes an H-shaped steel column 1 , a square steel pipe sleeve connector 3 fixed in the H-shaped steel column 1 , and an H-shaped steel beam 2 fixed on the square steel pipe sleeve connector 3 . Considering the difficulty of on-site welding and installation, the square steel pipe sleeve connector 3 is applied to the H-shaped steel beam-column weak-axis joints, and reinforcement measures are taken for the joints to form a clear force transmission, high bearing capacity, and free site. Suitable for welding and easy installation, the weak shaft connection of the square steel pipe sleeve connects the beam-column joints of the steel structure.

[0028] The square steel pipe sleeve connector 3 includes a square steel pipe 6 , bolt holes 7 are provided on the web and flange of the H-shaped steel column 1 , and bolt holes 7...

Embodiment 2

[0038] This embodiment is a hinge node connected by a weak axis, as shown in the attached Figure 5 , 6 As shown, on the basis of Embodiment 1, the bottom plate and triangular rib plate of the square steel pipe sleeve connector 3 are removed, and the baffle plate 5 and the grouting material are not provided, and the end face of the H-shaped steel beam 2 and the web of the H-shaped steel column 1 There is a certain distance between the boards.

[0039] The installation method of this embodiment is:

[0040] Step 1: Connect the web plate of the H-shaped steel column with the inner plate of the square steel pipe of the square steel pipe sleeve connector through high-strength bolts, and pass the flange of the H-shaped steel column with the square steel pipe left and right sides of the square steel pipe sleeve connector. High-strength bolt-to-hole connection.

[0041] Step 2: Insert the H-shaped steel beam into the square steel pipe of the square steel pipe sleeve connector, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com