Improved assembly type building cage type six-way joint and assembly method thereof

A prefabricated and improved technology, which is applied in the direction of construction and building construction, can solve the problems of difficult control of welding quality on site, easy deviation of force transmission, and high requirements for assembly and installation, so as to increase strength, improve seismic performance, The effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing:

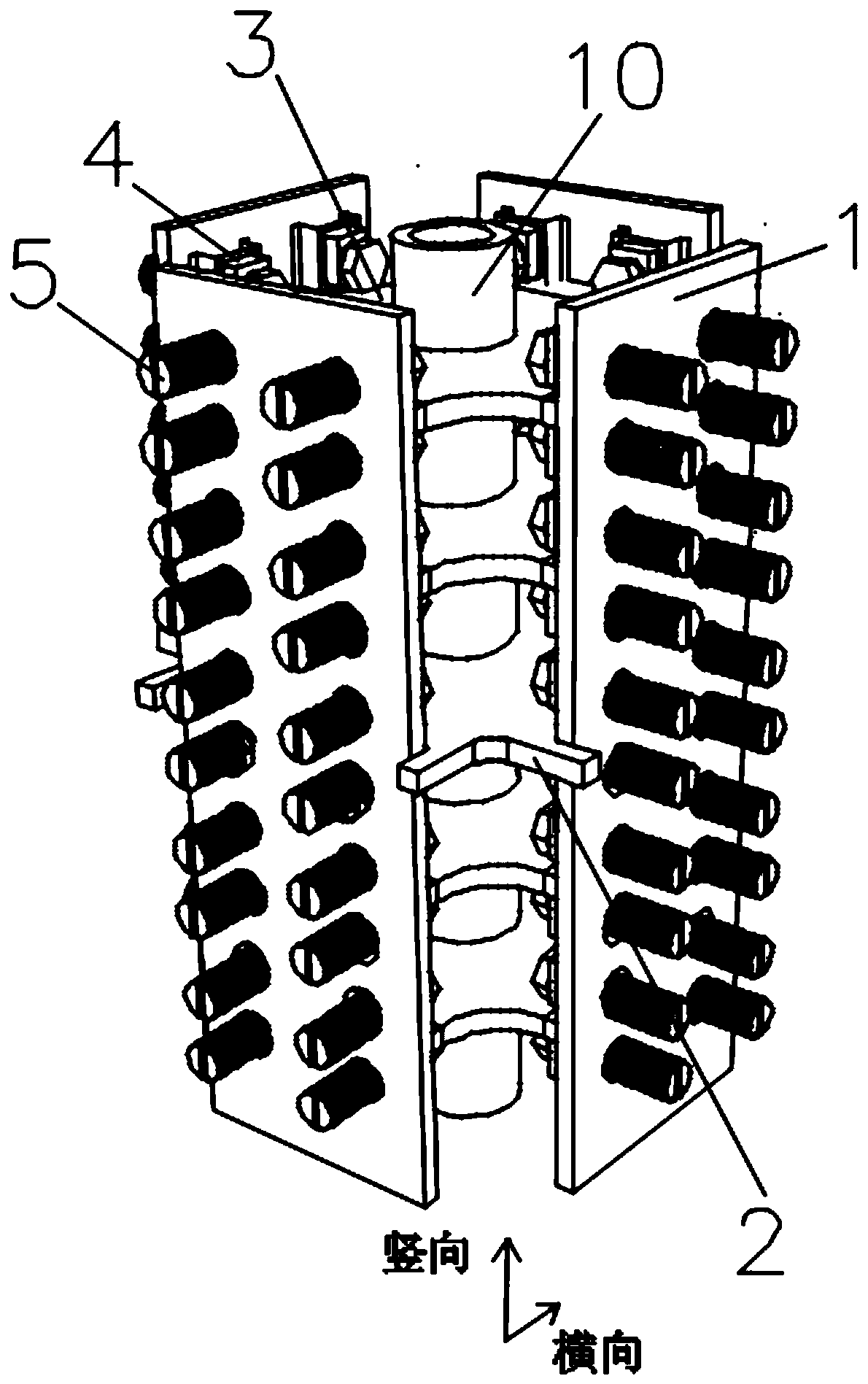

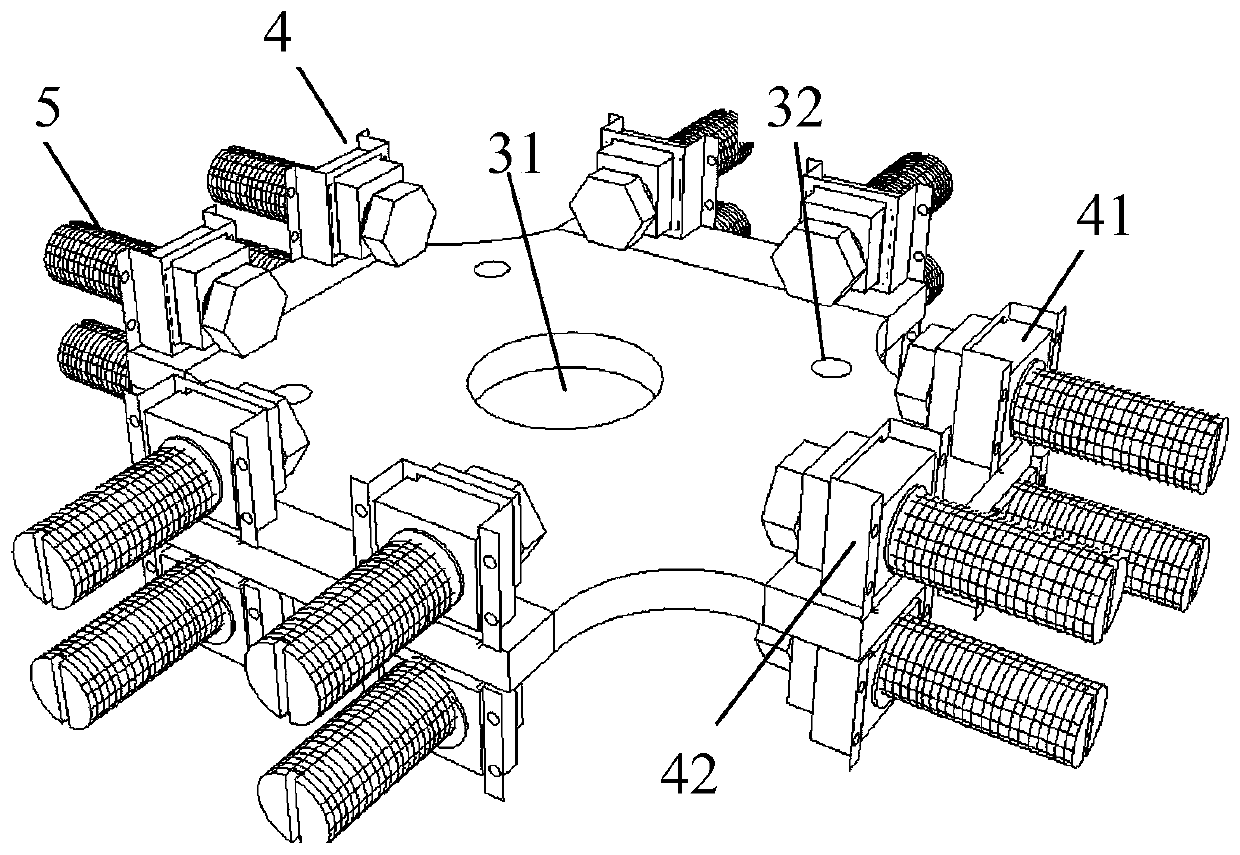

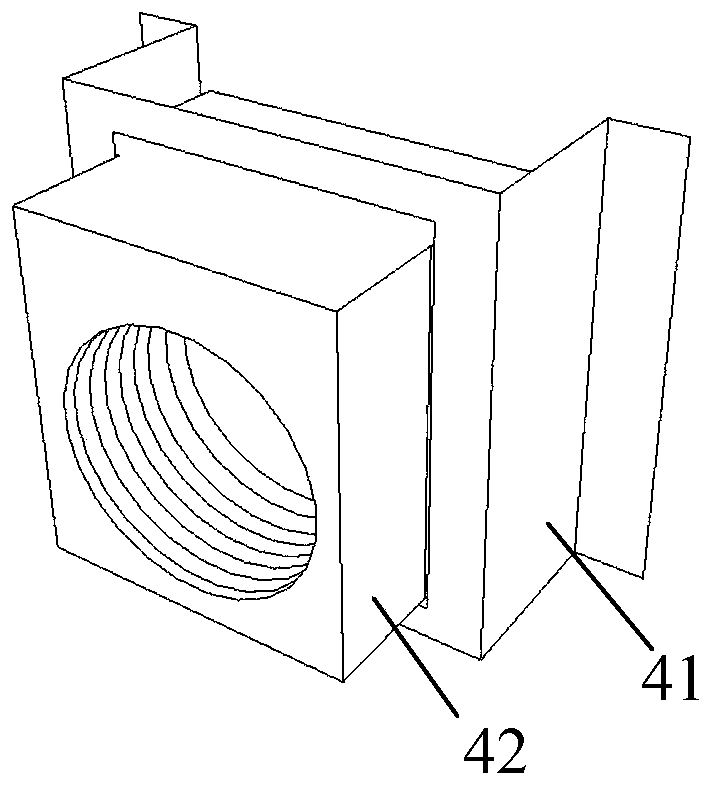

[0045] Please refer to figure 1 , figure 2 , Figure 6 , an improved prefabricated building cage-type six-way joint includes a rib plate 1, a central clamping plate 2, a star-moon plate 3, a positioning device 4, and a concave end bolt 5 (using high-strength bolts);

[0046] The rib plate 1, the central clamping plate 2 and the star-moon plate 3 together form the main structure of the cage-type six-way joint;

[0047] The positioning device 4 and the recessed bolt 5 realize the connection function of the cage hexagonal joint;

[0048] The ribs 1 have multiple pieces and the inner surfaces between them are fixedly connected by the star-moon plate 3;

[0049] There are not less than six rows of round holes on the rib plate 1;

[0050] There are multiple star-moon plates 3, which are arranged inside the ribs from top to bottom and fixed on the core tube 10; the central c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com