Method for connecting length-adjustable transverse rods of disc buckle frame

A technology of cross bars and buckles is applied in the connection of scaffolding, house structure support, house structure support, etc., which can solve the problem of inconvenient connection methods, and achieve the effect of improving flexibility and facilitating installation and construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

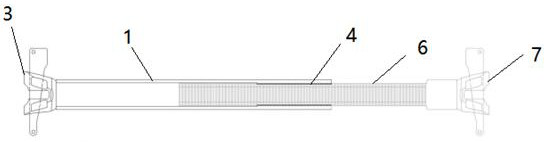

[0025] The method for connecting the length-adjustable buckle rack crossbar of the present invention comprises the following steps:

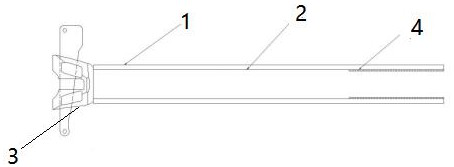

[0026] a. Provide the first crossbar of the buckle rack, the first crossbar is a hollow tube, the outer wall of the first crossbar is 1, the inner wall of the first crossbar is 2, the outer diameter of the hollow tube is 48mm, the inner diameter is 34mm, and one end of the first crossbar The first connector 3 is solidly welded, and the other end is provided with a nut 4 on the inner wall of the hollow tube; figure 1 It is a schematic diagram of the structure of the first crossbar in the embodiment of the present invention.

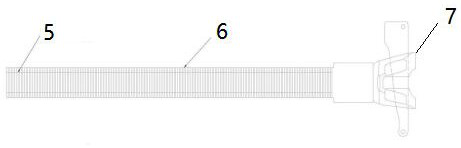

[0027] b. Provide the second crossbar of the buckle rack, the second crossbar is a screw crossbar, the inner wall of the second crossbar is 5, the outer wall of the second crossbar is 6, the outer diameter of the screw crossbar is 32mm, and the hollow inner diameter of the lead screw crossbar 20mm, one end of the second cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com