Mortar plastering anti-cracking structure for irrigation canal

An anti-cracking, irrigation canal technology, applied in irrigation pipelines, marine engineering, water conservancy projects, etc., can solve problems such as time-consuming, water leakage, seepage, and inconvenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

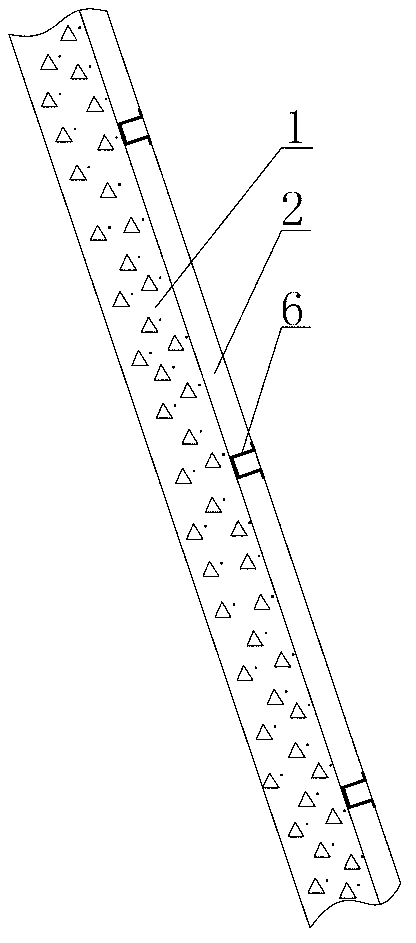

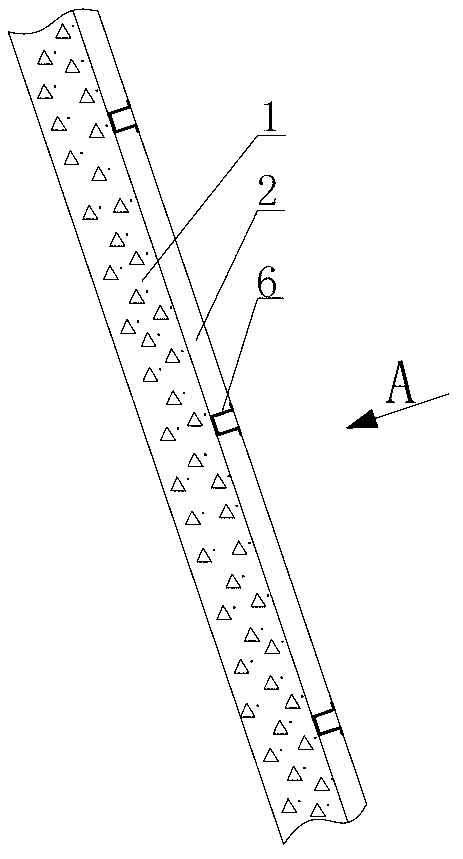

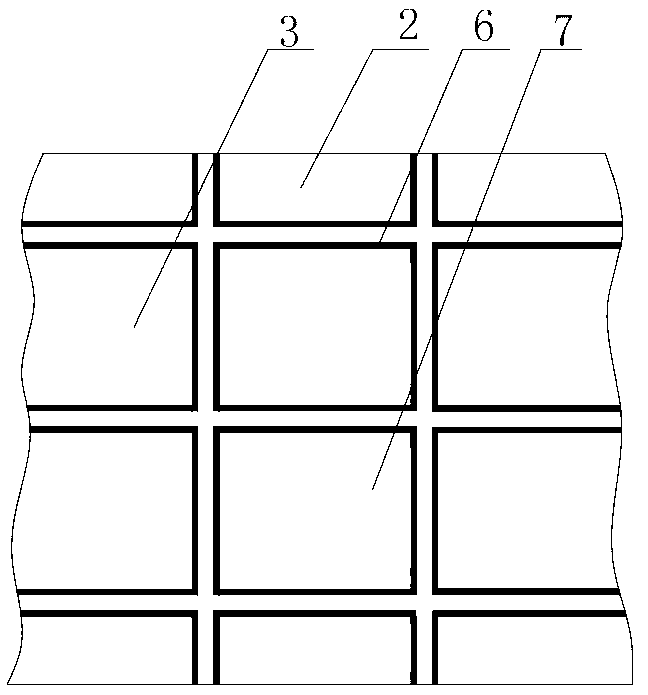

[0021] Figure 1 to Figure 7 The mortar plastered anti-cracking structure of an irrigation canal includes an anti-seepage base layer 1, a mortar plastered layer 2, a mesh grid structure 3, stepped holes 4, cement nails 5, PVC grid strips 6, and square grids 7.

[0022] A kind of anti-cracking structure of irrigation canal mortar plastering surface according to the present invention, such as figure 1 As shown, it mainly includes the anti-seepage base 1 on the slope of the drainage and irrigation canal, the mortar plastering layer 2 above the anti-seepage base 1, and the mesh grid structure 3 in the mortar plastering layer 2 above the anti-seepage base 1 part. Among them, the mesh grid structure 3 passes through the stepped hole 4 set up and down through the cement nail 5, and the mesh structure 3 and the anti-seepage base 1 are connected as a whole, and finally the mesh on the anti-leakage base 1 The mortar plastering layer 2 is filled in the grid structure 3 .

[0023] In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com