Method for preparing sulfobutyl ether-beta-cyclodextrin by adopting pipeline reactor

The technology of a pipeline reactor and sulfobutyl ether, which is applied in the field of pharmaceutical excipients, can solve the problems of high requirements on the reaction rate and efficiency of the pipeline reactor, long pipeline and difficult realization, etc., and achieves flexible reaction, improved catalytic activity, and improved conversion. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing sulfobutyl ether-β-cyclodextrin (SBE1-β-CD) with a degree of substitution of 1 in this embodiment, the specific preparation process is as follows:

[0047] (1) Add 20 ml of purified water to the reaction flask at room temperature, add 0.84 gram of sodium hydroxide during stirring, then add 20 grams of β-cyclodextrin, filter after all the β-cyclodextrin dissolves, remove insoluble matter, A solution of β-cyclodextrin is obtained.

[0048](2) Set the temperature of the pipeline reactor to 70-80°C, turn on the β-cyclodextrin solution delivery pump, and set the speed at 140rpm; after 5 minutes, turn on the 1,4-butane sultone dosing pump, and set the speed 20rpm; at the same time, turn on the sodium hydroxide solution delivery pump and set the speed at 10rpm. The ratio of the amount of substances controlling the mixed reaction of β-cyclodextrin and 1,4-butane sultone is 1:1.2.

[0049] (3) After 15 minutes of reaction in the pipeline reactor, turn on...

Embodiment 2

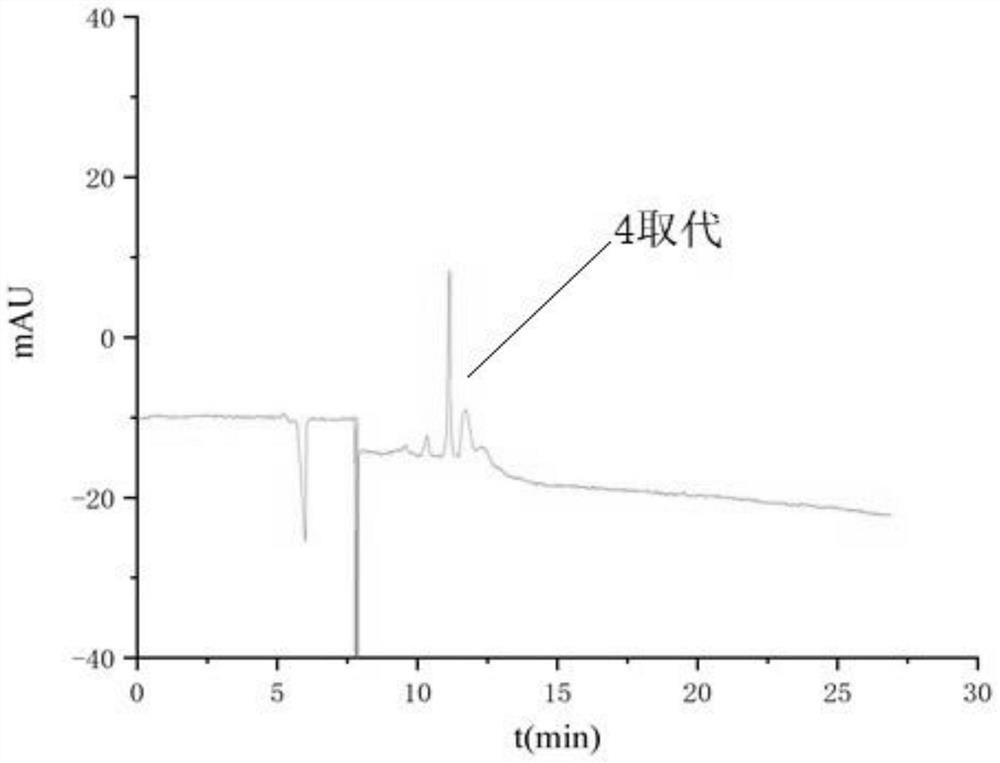

[0052] A method for preparing sulfobutyl ether-β-cyclodextrin (SBE4-β-CD) with a degree of substitution of 4 in this embodiment, the specific preparation process is as follows:

[0053] (1) Add 20 ml of purified water to the reaction flask at room temperature, add 3.5 grams of sodium hydroxide during stirring, then add 20 grams of β-cyclodextrin, filter after all the β-cyclodextrin dissolves, and remove insoluble matter, A solution of β-cyclodextrin is obtained.

[0054] (2) Set the temperature of the pipeline reactor to 70-80°C, turn on the β-cyclodextrin solution delivery pump, and set the speed at 72rpm; after 5 minutes, turn on the 1,4-butane sultone dosing pump, a total of 4 The channel is dripped with 1,4-butane sultone, and the pipeline of each channel is extended by 1.5 meters in turn, and the set speed is 72rpm; at the same time, the sodium hydroxide solution delivery pump is turned on, and the set speed is 40rpm. The ratio of the amount of substances controlling the...

Embodiment 3

[0058] A method for preparing sulfobutyl ether-β-cyclodextrin (SBE1-β-CD) with a degree of substitution of 7 in this embodiment, the specific preparation process is as follows:

[0059] (1) Add 20 ml of purified water to the reaction flask at room temperature, add 7.4 grams of sodium hydroxide during stirring, then add 20 grams of β-cyclodextrin, filter after all the β-cyclodextrin dissolves, and remove insoluble matter, A solution of β-cyclodextrin is obtained.

[0060] (2) Set the temperature of the pipeline reactor at 70-80°C, turn on the β-cyclodextrin solution delivery pump, and set the speed at 72rpm; after 5 minutes, turn on the 1,4-butane sultone dosing pump, a total of 7 The channel is dripped with 1,4-butane sultone, and the pipeline of each channel is extended by 1.5 meters in turn, and the set speed is 72rpm; at the same time, the sodium hydroxide solution delivery pump is turned on, and the set speed is 70rpm. The ratio of the amount of substances controlling the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com