Patents

Literature

33 results about "Butanesultone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

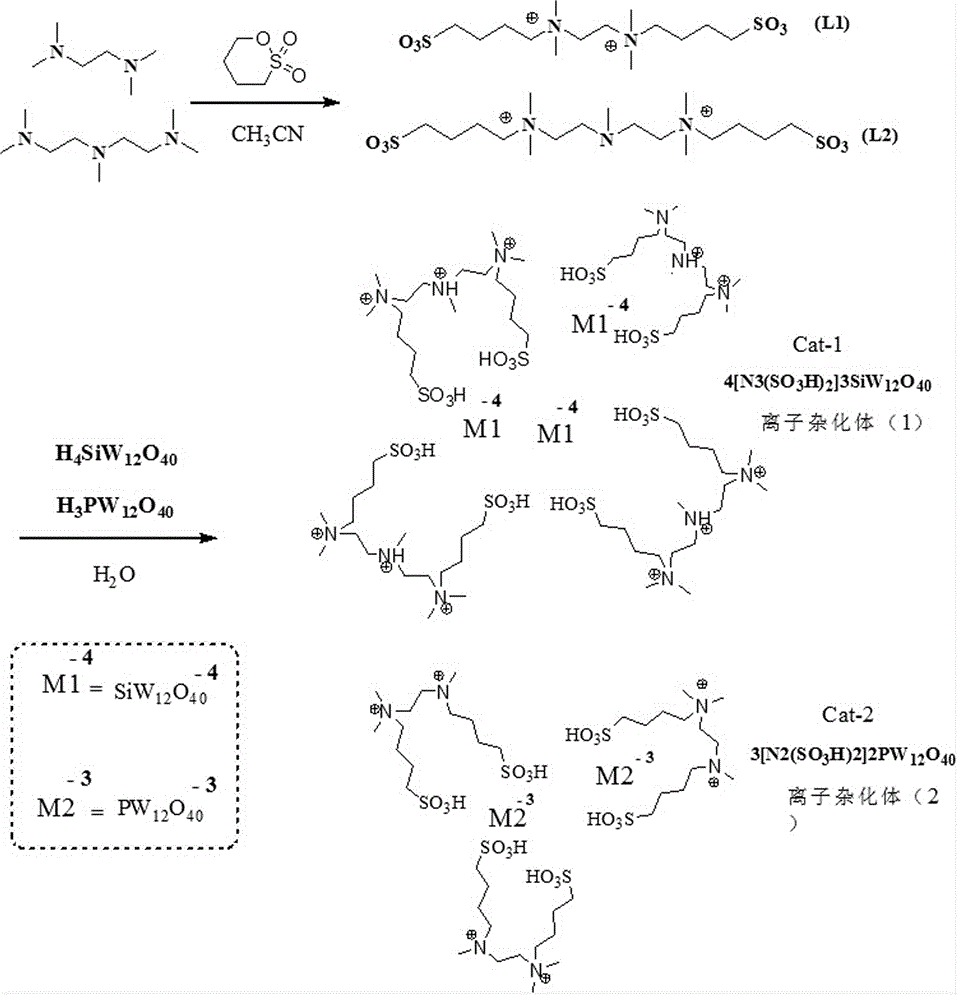

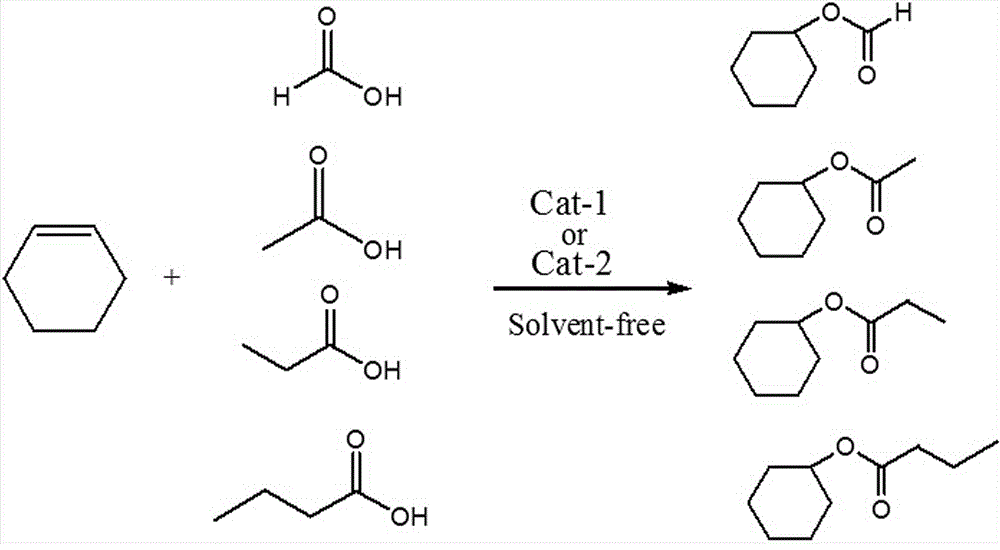

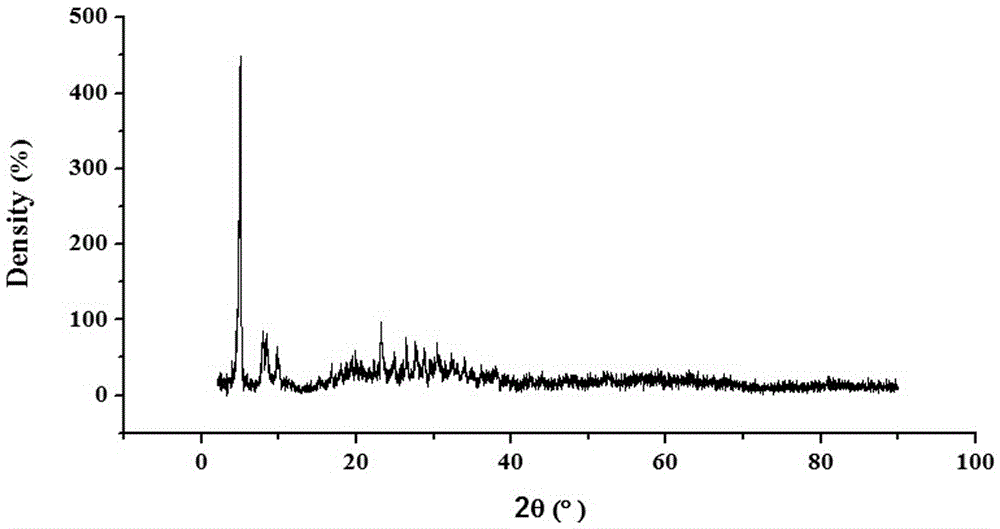

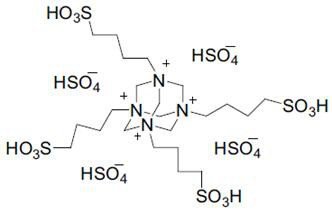

Polysulfo-functionalized heteropolyacid ionic hybrid with multiple heteropolyacid negative ions as well as preparation method and application thereof

ActiveCN106748908AHigh acid strengthHigh total acid contentOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCyclohexeneCarboxylic acid

The invention discloses a polysulfo-functionalized heteropolyacid ionic hybrid with multiple heteropolyacid negative ions as well as a preparation method and an application thereof. Two ionic hybrids with novel structures are built by taking aliphatic polyamine, 1,4-butanesultone, phosphotungstic acid and silicotungstic acid as starting materials and carrying out two steps of atomic economic reaction through quaternization and acidification. Positive ions of the ionic hybrid comprise four or three bissulfo-functionalized long-chain quaternary ammonium positive ions; negative ions matched with the positive ions comprise three Keggin configuration silicotungstic acid negative ions or two Keggin configuration phosphotungstic acid negative ions; the prepared ionic hybrid can be used for preparing cyclohexyl carboxylate. The ionic hybrid has high acid strength and high acid content; the ionic hybrid also shows high amphipathy, so the reaction between substrate cyclohexene and organic carboxylic acid is facilitated; the ionic hybrid has the characteristics of atom economy, mild reaction condition, no backflow water diversion, high separation probability of products and high purity.

Owner:MINJIANG UNIV

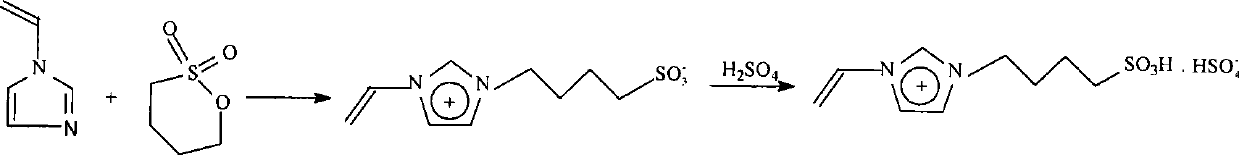

1-vinyl-3-sulfobutyl imidazole bisulfate and preparation method thereof

InactiveCN101397273AStrong acidReduce lossesOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen SulfatePtru catalyst

The invention relates to 1-ethylene-3-methylimidazolium hydrogen sulfate and a preparation method thereof, belonging to the acid ion liquid. The molecular formula is as above; the preparation method comprises the following steps: (1) 1-vinylimidazole and 1,4-butanesultone with a molar ratio of 1:1.1 are adopted for an reaction under the room-temperature of about 50 DEG C; and then zwitterionic 1-ethylene-3-methylimidazolium hydrogen sulfate is obtained after washing and drying; (2) a concentrated sulphuric acid is dropped onto the 1-ethylene-3-methylimidazolium hydrogen sulfate under the temperature less than 10 DEG C and with the molar ratio of 1:0.96 to 1.04 between the 1-ethylene-3-methylimidazolium hydrogen sulfate and the concentrated sulphuric acid, the reaction is carried out for 3 to 6 hours; then the target product is obtained after washing and drying. The 1-ethylene-3-methylimidazolium hydrogen sulfate prepared by the method contains -SO3H and HSO4<-> and is provided with two proton bits, and therefore has good Br nsted acidity; the double-bond functional group on the side chain of the product can be adopted for chemical bond combination so as to anchor the product on sold carriers and is used for preparinge solid acid catalysts.

Owner:HEBEI UNIV OF TECH

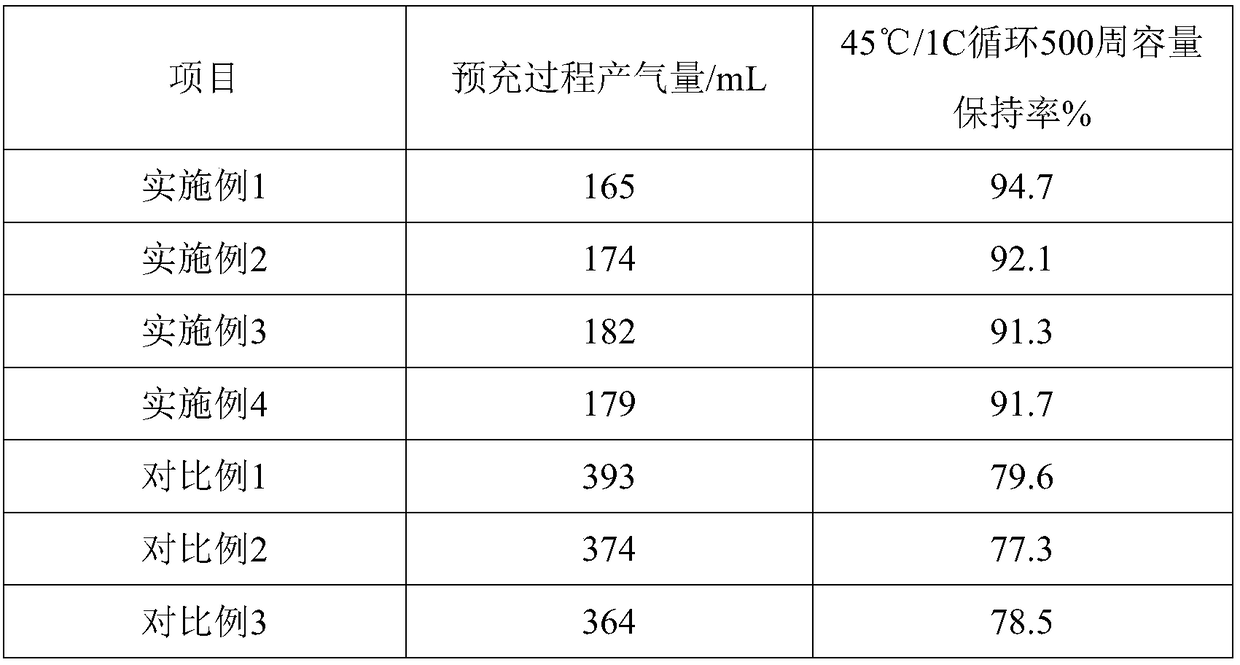

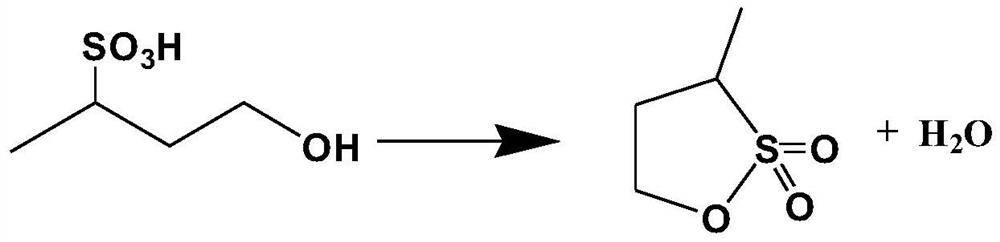

Electrolyte capable of suppressing gas production of lithium ion batteries

InactiveCN109378524AReduce gas productionImprove securitySecondary cellsOrganic electrolytesDifluorophosphatePhosphate

The invention relates to the field of lithium ion batteries, in particular to an electrolyte capable of suppressing gas production of lithium ion batteries. The electrolyte comprises lithium salt, organic solvents and additives; the lithium salt is selected from one or multiple of lithium hexafluoroarsenate, lithium tetrafluoroborate, lithium hexafluorophosphate and lithium bis(fluorosulfonyl)imide, and the concentration of the lithium salt substance ranges from 0.5 mol / L to 2.0 mol / L; the additives are selected from one or multiple of lithium difluoroborate, tetrafluoroethylene oxalic acid phosphate lithium,1,3-propane suhone, DTD, vinylethylene carbonate, propylene sulfite, 1,4-butane sultone, tris(trimethylsilyl) phosphate, fluoroethylene carbonate and lithium difluorophosphate, and theusage of the additives is equal to 2-2.5% of the total mass of the lithium salt and the organic solvents. The electrolyte is used for preparation of the lithium ion batteries, can suppress gas production rate of the lithium ion batteries during precharging, and accordingly improves production efficiency of the lithium ion batteries and performance thereof.

Owner:福建冠城瑞闽新能源科技有限公司

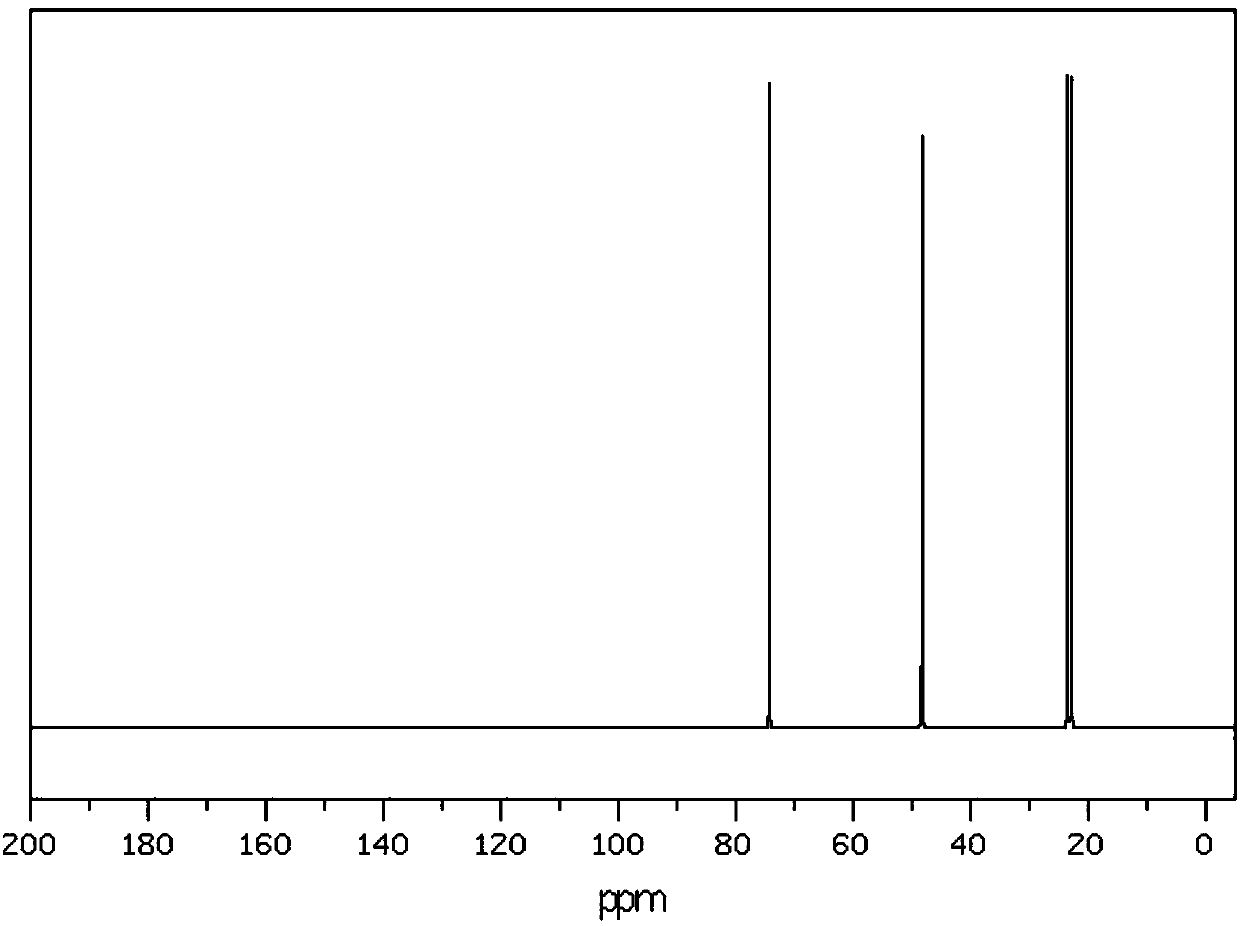

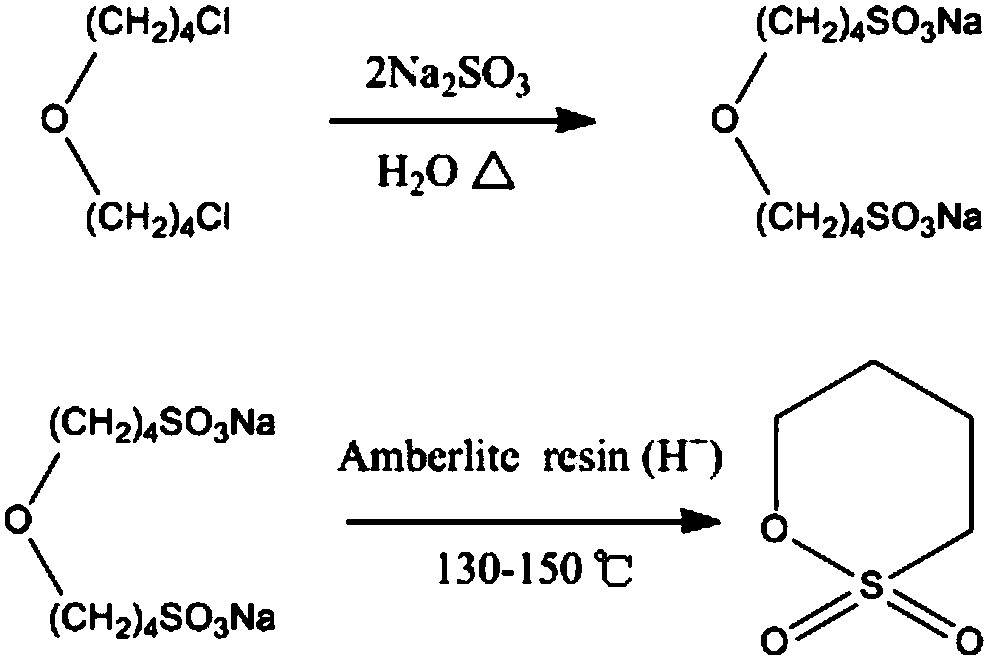

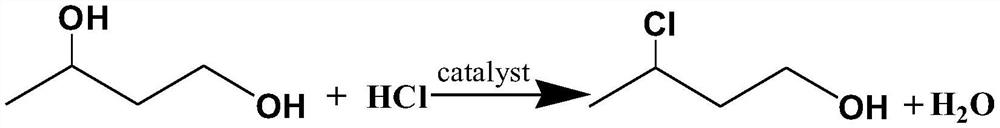

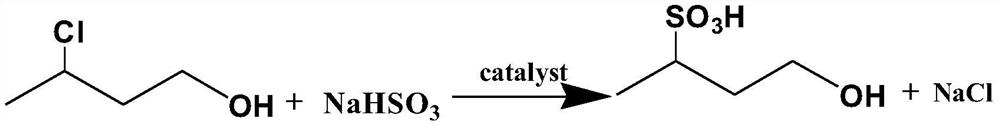

Synthesis method of high-purity 1,4-butane sultone

ActiveCN109293625AImprove the mixing effectShorten the sulfonation reaction timeOrganic chemistrySynthesis methodsFiltration

The invention discloses a synthesis method of high-purity 1,4-butane sultone. The synthesis method comprises the steps: 1, adding 4-chlorobutanol and a sodium sulfite solution into an alcohol solvent,raising the temperature until carrying out reflowing for 6 h, ending the reflowing to obtain a mixed solution A, concentrating the mixed solution A to recover the alcohol solvent, then, adding hydrochloric acid for acidification, carrying out concentration until a material becomes viscous, then, adding the alcohol solvent, separating out a sodium chloride crystal, carrying out filtration, and concentrating filtrate to recover the alcohol solvent so as to obtain 4-hydroxybutane sulfonic acid; 2, carrying out continuous flash evaporation dehydration on 4-hydroxybutane sulfonic acid at the vacuum degree of 1-8 mmHg and the temperature of 130-165 DEG C to obtain industrial-grade 1,4-butane sultone; and 3, adding an azeotrope into industrial-grade 1,4-butane sultone, carrying out normal-pressure fractional distillation to recover the azeotrope, then, carrying out reduced-pressure fractional distillation at the vacuum degree of 2-4 mmHg, and collecting fractions with the temperature of 120-121 DEG C to obtain high-purity 1,4-butane sultone. The method is simple and environment-friendly, the sulfonation yield is greatly increased, and the purity and yield of 1,4-butane sultone are greatly increased.

Owner:JINGCHU UNIV OF TECH

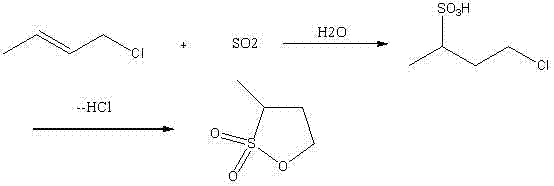

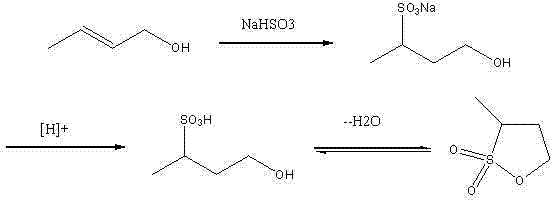

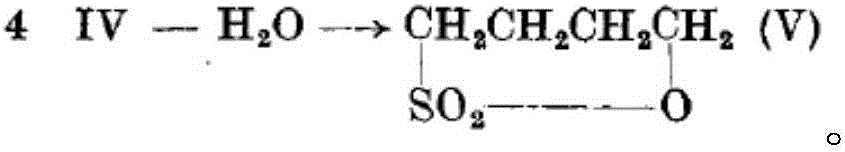

Method for synthetizing 2, 4-butane sulfonic acid lactone

The invention relates to a method for preparing 2, 4-butane sulfonic acid lactone by using butenol (crotyl alcohol) as raw materials, sulfonating the butenol to be hydroxy butane sulfonate with hydrosulphite, acidizing the hydroxy butane sulfonate to be hydroxy butane sulfonic acid, and finally dehydrating in vacuum at high temperature. The method is low in cost, mild in conditions, simple and convenient to operate, easy to control and high in yield, and is a synthetizing process suitable for industrialization, and raw materials are easy to obtain.

Owner:FUJIAN CHUANGXIN TECH DEV CO LTD

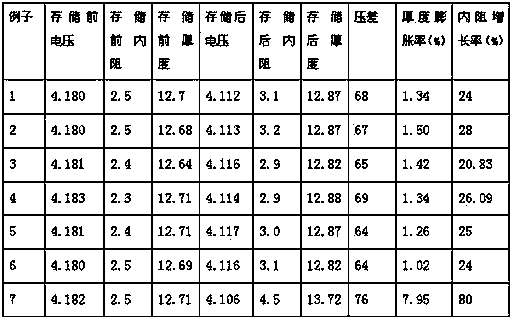

High-temperature electrolyte for ternary manganese lithium battery

InactiveCN103682441AReduce consumptionAvoid destructionSecondary cellsOrganic electrolytesHigh temperature storageManganese

The invention belongs to the technical field of electrolyte materials for lithium ion batteries, and particularly relates to an electrolyte additive for a ternary manganese lithium ion battery and an electrolyte of the ternary manganese lithium ion battery. In order to overcome the defects in the prior art such as fast battery capacity fading and short service life of a lithium battery in the common electrolyte, the invention provides the electrolyte additive of the lithium battery and the electrolyte of the lithium battery. The electrolyte additive is formed by mixing 1, 4 butane sulfonic acid lactone or 1, 3-propane sulfonic acid lactone with ethanol amine, and the electrolyte containing the additive comprises 11% to 15% of lithium salt, 82% to 88% of organic solvent and 0.5% to 4% of additives. According to the invention, a high-temperature electrolyte containing the additive is used, so that ternary manganese lithium ion battery has good high-temperature storage and recycling effects, and the effect is best when the mass mixing ratio of 1, 4 butane sulfonic acid lactone or 1, 3-propane sulfonic acid lactone to ethanol amine is 1: (1-2). The electrolyte additive for the lithium ion batteries and the electrolyte thereof are suitable for being vigorously popularized in a manufacture or application field of the lithium battery.

Owner:骆驼集团蓄电池研究院有限公司

High-temperature electrolyte for lithium-ion batteries

ActiveCN104681869AImprove performanceGuaranteed uptimeSecondary cellsElectrolytic agentMethyl carbonate

The invention belongs to the technical field of electrolyte materials for lithium-ion batteries, and particularly relates to a high-temperature electrolyte for the lithium-ion batteries. The electrolyte comprises, in percentage by mass, 11.5%-13.5% of lithium salt, 85%-87% of an organic solvent and 0.8%-2% of an additive, wherein the lithium salt is lithium hexafluorophosphate; the organic solvent is a mixed solvent of ethylene carbonate, dimethyl carbonate, ethyl methyl carbonate and propylene carbonate; the additive is formed by mixing 1,4-butane sultone or 1,3- butane sultone and ethanolamine.

Owner:骆驼集团武汉光谷研发中心有限公司

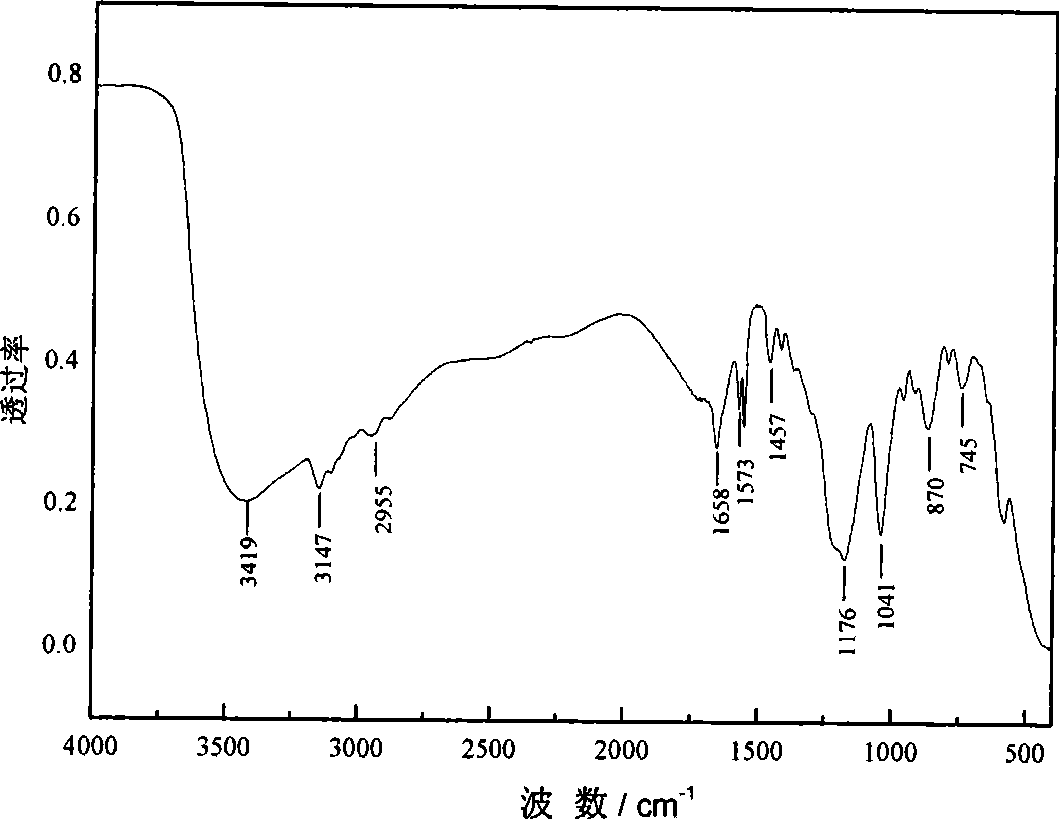

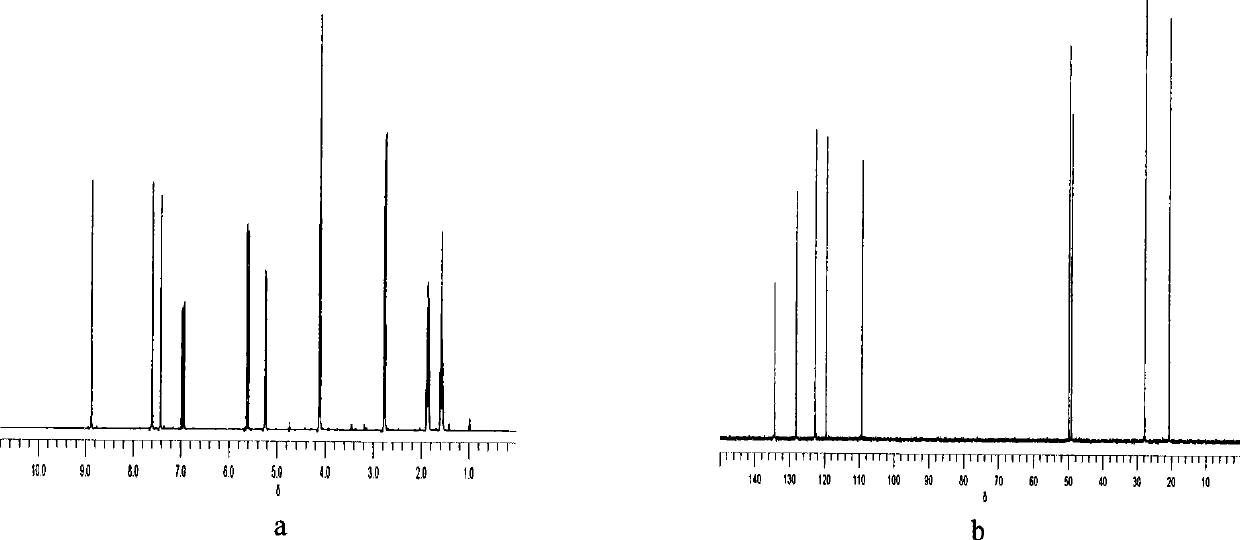

1,4-butane sultone and synthesis process thereof

1,4-butane sultone and a synthesis process thereof relate to the field of fine chemical engineering. The synthesis process comprises the steps: performing sulfonation on 3-butylene-1-alcohol or 3-butylene-1-chlorine serving as a raw material and a sulfonating agent under the oxidation-reduction of an initiator; performing acidification after the reaction is finished; performing lactonization by high vacuum dehydration cyclization and azeotropic dehydration cyclization; and finally refining to obtain a 1,4-butane sultone finished product. The synthesis process of the 1,4-butane sultone, provided by the invention, is easily available in raw materials, few in synthesis steps, high in yield, high in product purity and suitable for industrialized production. The invention also provides the 1,4-butane sultone which is prepared by the synthesis process and has high purity.

Owner:湖北吉和昌化工科技有限公司

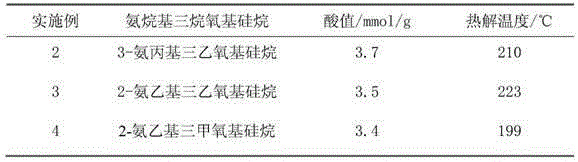

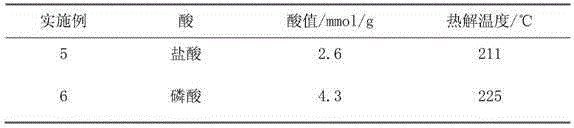

Immobilized ionic liquid solid acid catalyst and preparation method thereof

InactiveCN104525252AImprove thermal stabilityHigh acid valueOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSilanesSolid acid

The invention provides an immobilized ionic liquid solid acid catalyst and a preparation method thereof. The preparation method comprises the following steps: reacting aminoalkyltrialkoxy silane with propanesultone or butanesultone to obtain trialkoxysilicon-containing ylid, acidifying by using an acid, adding a hydroxy group-containing carrier, and reacting to obtain the immobilized ionic liquid solid acid catalyst. The catalyst material has the advantages of high heat stability, high acid value of above 2.5mmol / g, large surface area, good catalysis effect, and repeated use.

Owner:SHAOXING UNIVERSITY

Lithium battery electrolyte

InactiveCN112993397AReduce gas productionImprove cycle lifeSecondary cells servicing/maintenanceElectrolytic agentButanesultone

The invention relates to the technical field of lithium batteries, in particular to a lithium battery electrolyte which comprises a lithium salt, an organic solvent, a functional additive and a film-forming additive. The film-forming additive is prepared from one or more of vinylene carbonate, vinylethylene carbonate, fluoroethylene carbonate, 1, 4-butanesultone, 1, 3-(1-propylene) sultone, ethylene sulfate and methylene methanedisulfonate; the molar concentration of the lithium salt is 0.1 mol / L-2 mol / L, the molar concentration of the organic solvent is 0-0.5 mol / L, and the molar concentration of the functional additive is 0.5-5 mol / L. The film-forming additive is added into the lithium battery electrolyte, so that the solvent can form a compact SEI film on the surface of the carbon material, the gas production rate of the lithium battery, especially the gas production rate at high temperature, can be greatly reduced, and the cycle life and the storage life of the lithium titanate battery can be prolonged.

Owner:QINGDAO QIANYUN HIGH TECH NEW MATERIAL

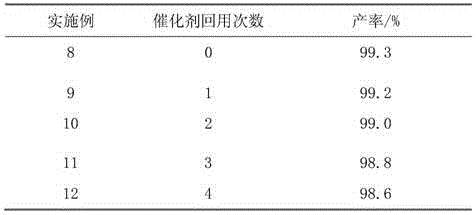

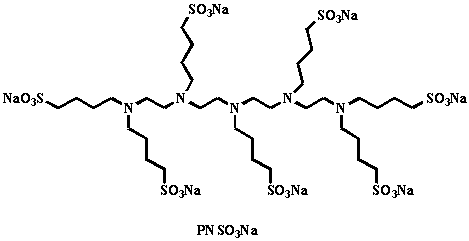

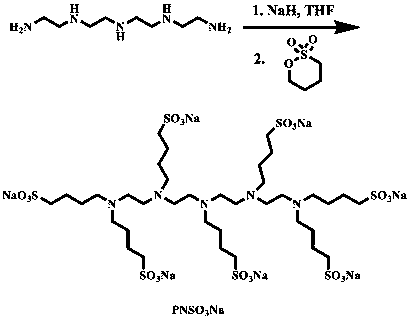

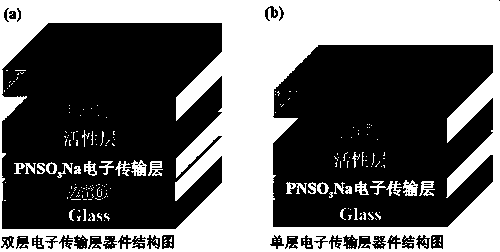

Production method of novel hyperbranched sodium sulfonate small-molecular electron transfer layer

ActiveCN107652211ASimple processLower interface barrierFinal product manufactureSulfonic acids salts preparationFiltrationSide chain

The invention discloses a production method of a novel hyperbranched sodium sulfonate small-molecular electron transfer layer. The above hyperbranched sodium sulfonate small-molecular electrolyte is prepared through a one-step simple reaction. The production method comprises the following steps: adding tetraethylenepentamine into a dried tetrahydrofuran solution, adding NaH in ice bath and nitrogen atmosphere, performing room temperature stirring for 2 h, rising the temperature of the obtained reaction solution to 50 DEG C, reacting the reaction solution overnight, adding excess 1,4-butanesultone through a constant-pressure dropping funnel, cooling the obtained solution to room temperature after the reaction is finished, performing suction filtration, collecting obtained filter residues, dissolving the filter residues in deionized water, and performing dialysis purification by a dialysis bag with the aperture being 1000 in order to obtain the pale yellow target product PNSO3Na. A hyperbranched side chain polar group makes the small molecule realize processing of water, alcohol and other environmentally-friendly polar solvents and form an interface dipole, so the water content is reduced, and the interface contact is improved. The novel hyperbranched sodium sulfonate small-molecular electron transfer layer can be used as a good cathode interface layer for photovoltaic cells, LEDs and FETs.

Owner:NANCHANG HANGKONG UNIVERSITY

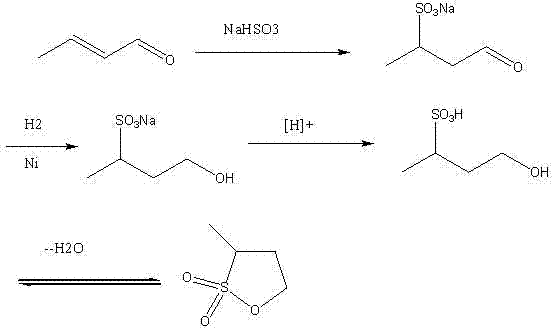

Synthesis method of 2, 4-butane sultone

The invention discloses a synthesis method of 2, 4-butane sultone, which comprises the following steps: 1, dissolving 1, 3-propane sultone in a first organic solvent under the protection of inert gas in the whole process, then adding sodium hydrogen in batches, and heating to 40-50 DEG C after the sodium hydrogen is added; 2, dropwise adding a methylation reagent, and carrying out heat preservation reaction after dropwise adding; and 3, cooling to room temperature, adding ice water and a second organic solvent for extraction, and carrying out negative pressure rectification on the second organic solvent layer to obtain the final product 2, 4-butane sultone. The synthesis method has the advantages of low raw material cost, simple operation steps, mild reaction conditions, few reaction steps, easiness in purification and the like.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

Activation method of lithium manganate battery

InactiveCN111725557AImprove high temperature performancePromote environmental protectionCell electrodesSecondary cells charging/dischargingButanesultoneElectrical battery

The invention provides an activation method of a lithium manganate battery. A positive electrode active material of the lithium manganate battery is lithium manganate, the chemical formula of the lithium manganate is LiMn(1-x)NixO2, and x is equal to 0-0.1; the electrolyte of the lithium manganate battery contains vinylene carbonate and 1,4-butane sultone, and the volume ratio of vinylene carbonate to 1,4-butane sultone is 1: 2; the activation method comprises the following steps of measuring the open-circuit voltage of the lithium manganate battery when the storage voltage is stored for a preset time, comparing the open-circuit voltage is compared with the first preset voltage, carrying out different activation steps according to the comparison result, carrying out battery evaluation on the specific battery before activation according to the activation method, and then determining the proper activation step. The battery obtained through the activation step can recover the high capacity and has the high cycle performance.

Owner:陆信甫

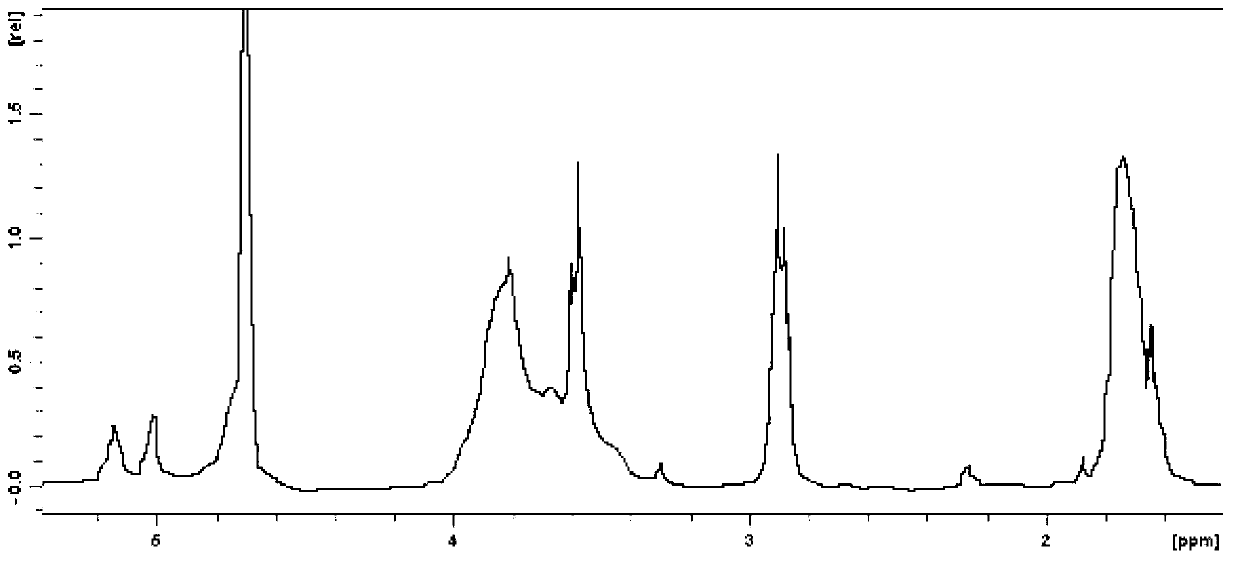

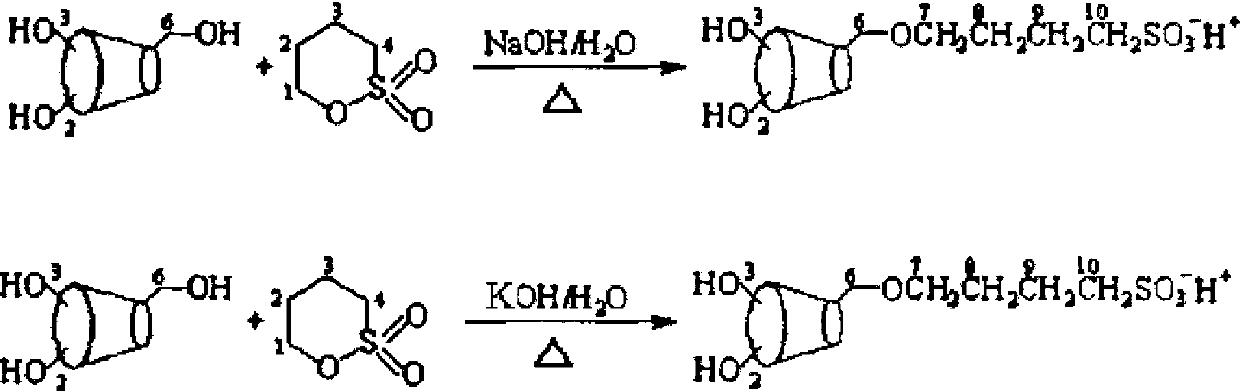

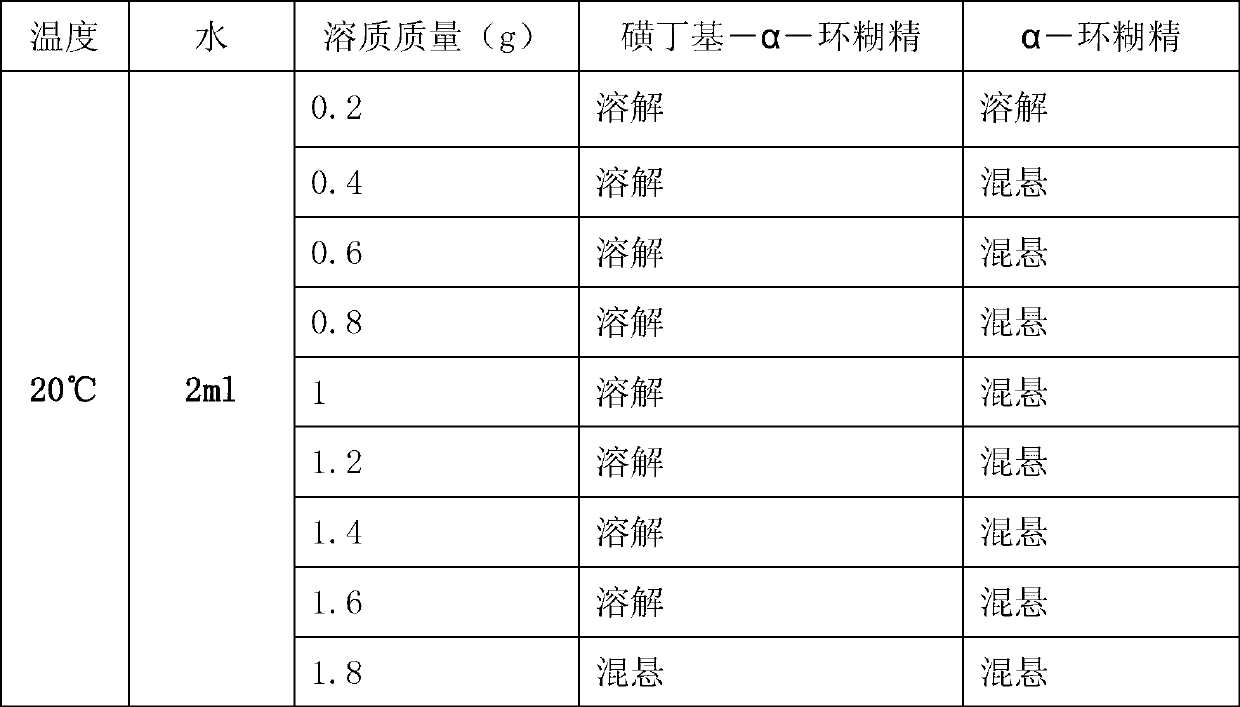

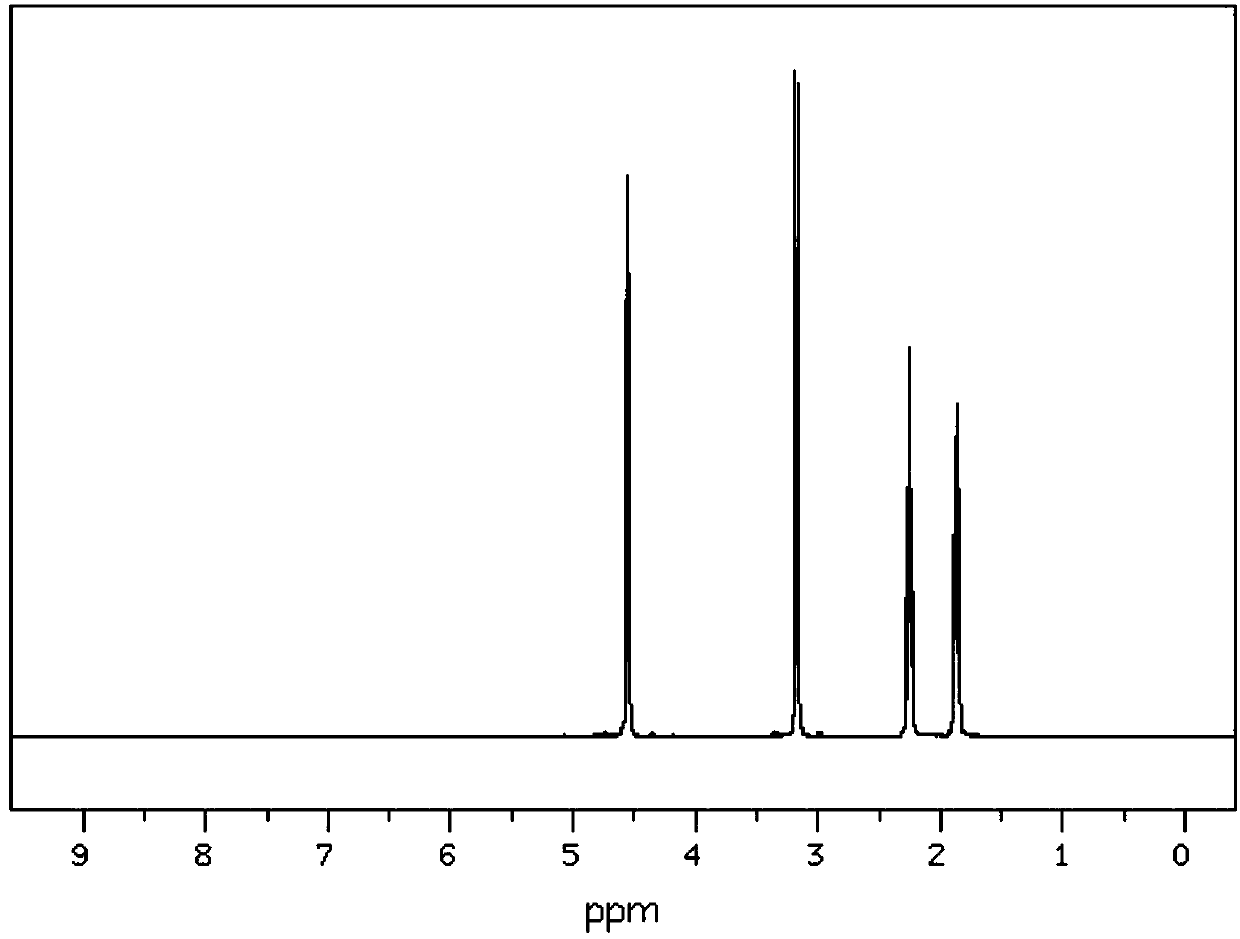

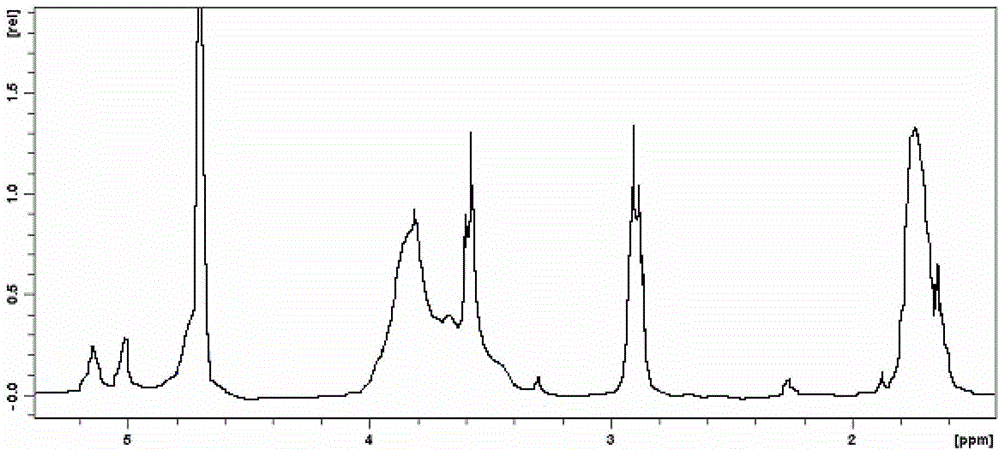

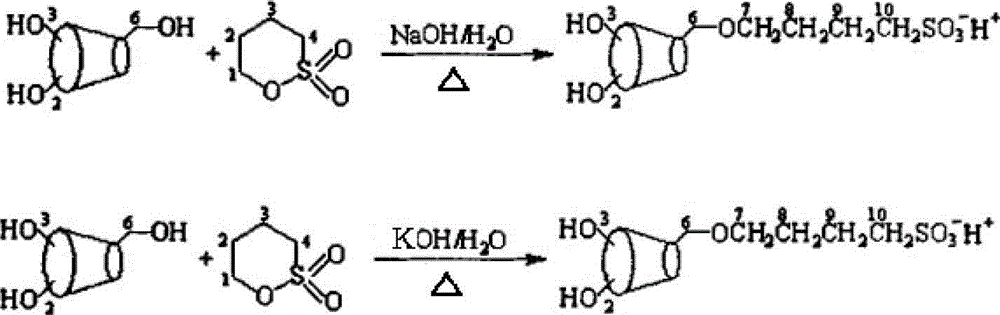

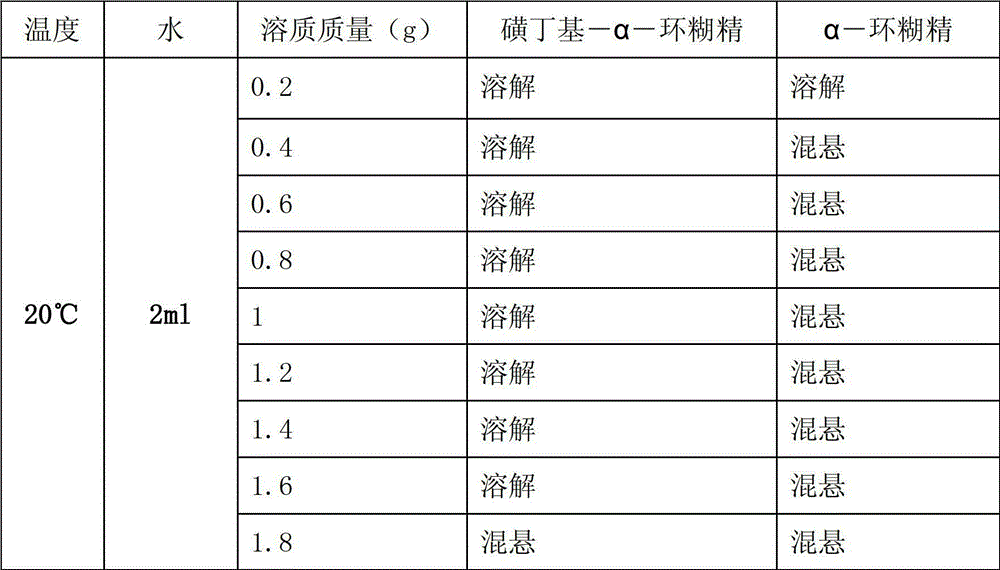

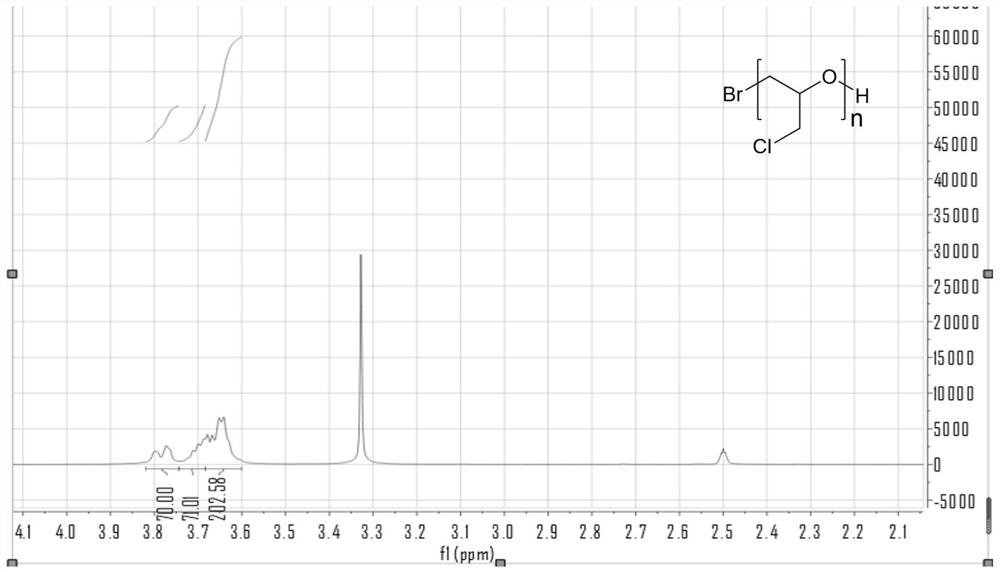

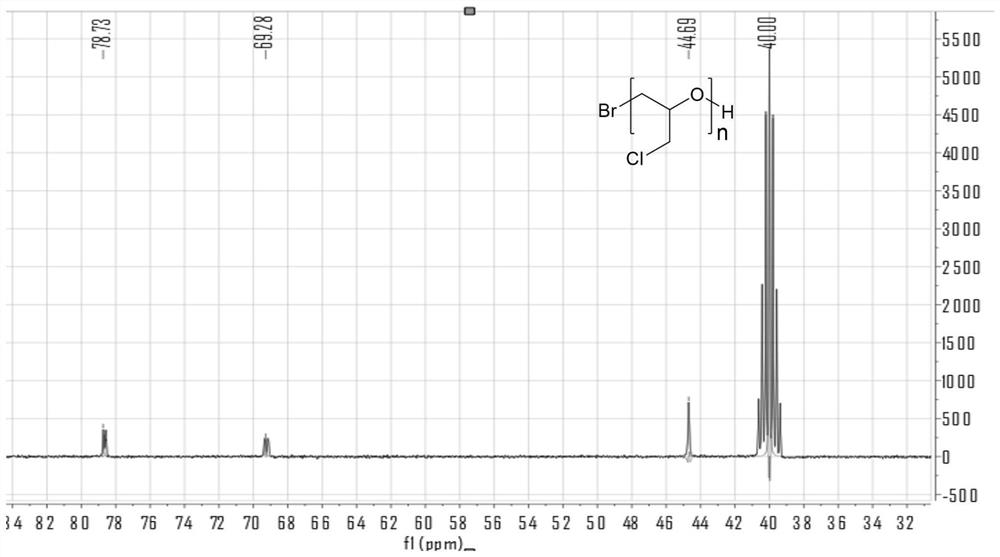

Sulfobutyl-alpha-cyclodextrin and preparation method thereof

ActiveCN102993338AThe preparation conditions are mild and controllableImprove stabilitySolubilityButanesultone

The invention provides sulfobutyl-alpha-cyclodextrin and a preparation method thereof. The structural formula of the sulfobutyl-alpha-cyclodextrin is shown in the specification, wherein R=H, and the molecular weight is 1,108.17-2,605; and the sulfobutyl-alpha-cyclodextrin is prepared by the reaction of 1,4-butanesultone and alpha-cyclodextrin in a strong alkali solution. The water solubility of the sulfobutyl-alpha-cyclodextrin provided by the invention reaches 80g at 20 DEG C and is improved by 4 times over the existing alpha-cyclodextrin. The preparation method of the sulfobutyl-alpha-cyclodextrin provided by the invention is simple and has high reaction efficiency; the prepared sulfobutyl-alpha-cyclodextrin has strong stability and good water solubility; the whole preparation method has strong operability; and the sulfobutyl-alpha-cyclodextrin can be conveniently prepared into various guest molecule inclusion compounds and compositions.

Owner:SHAANXI UNIV OF SCI & TECH

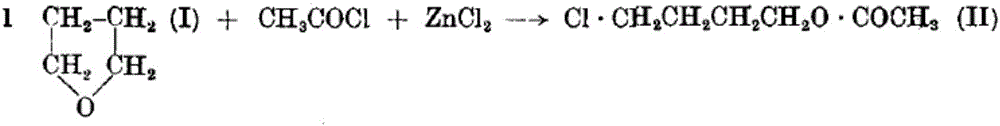

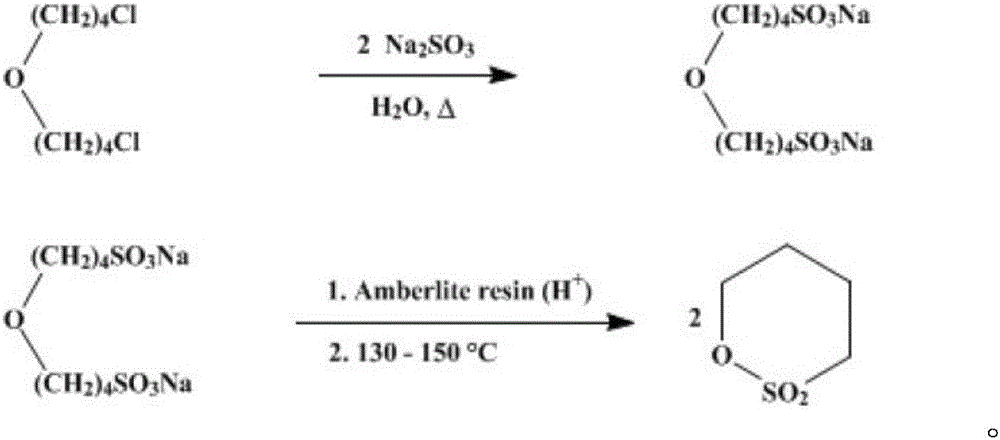

Synthesis method of 1,4-butane sultone

ActiveCN109776484AHigh yieldGuaranteed high and low temperature storage performanceOrganic chemistryFiltrationSynthesis methods

The invention relates to a synthesis method of 1,4-butane sultone and belongs to the technical field of compound synthesis. The synthesis method takes tetrahydrofuran and acetylchloride as raw materials and comprises the following steps: A, preparation of butylchloroacetate: placing tetrahydrofuran and zinc powder in a container, cooling to 15 DEG C or lower, beginning to dropwise add acetylchloride, after dropwise adding, heating to 45 DEG C, holding the temperature for 8-10 hours, then heating to 60 DEG C, holding the temperature for 1-2 hour, performing pressure reduction to extract butylchloroacetate, and B, preparation of 1,4-butane sultone: allowing butylchloroacetate, sodium sulfite and water to give a heating reflux reaction for 14-16 hour, performing pressure reduction till a solid is separated out, cooling to 45 DEG C or lower, dropwise adding methanol hydrochloride solution, performing stirring for 1-2 hours, cooling to 4-6 DEG C, performing suction filtration, performing pressure reduction on filtrate to extract methanol, water and acetic acid, then heating to 130 DEG C, performing high vacuum pressure reduction cyclization for 0.5-1 hour, heating to 150 DEG C, and thenperforming high vacuum pressure reduction to extract 1,4-butane sultone. The synthesis method is simple; a reaction process is mild and stable; a prepared target product is high in yield and purity,and very low in water content and acid content.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

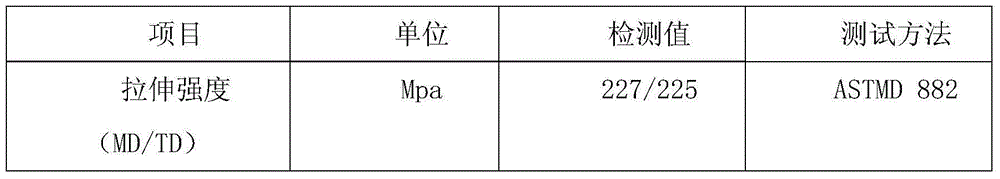

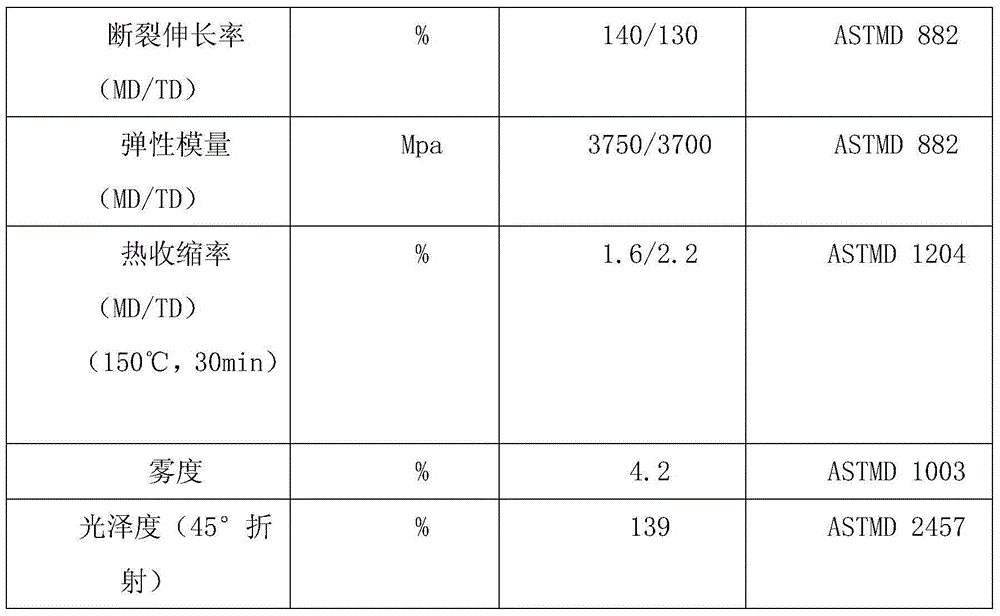

Glass microsphere for TPU reflecting film and preparation method of glass microsphere

The invention discloses a glass microsphere for a TPU reflecting film and a preparation method of the glass microsphere. The glass microsphere is prepared from such raw materials in parts by weight: 25-35 parts of sepiolite, 36-49 parts of glass cullet, 22-38 parts of variscite, 16-27 parts of rutile, 22-36 parts of leucite, 30-40 parts of gold tailings, 5-10 parts of polymerized alpha-olefin, 3-6 parts of sorbitan olivate, 2-4 parts of dodecafluoropropyltrimethoxysilane, 3-6 parts of ethoxylated castor oil, 4-8 parts of 1,4-butanesultone and 8-14 parts of additives. Due to reasonable proportioning and scientific preparation process and technique, the production of high-quality, high-refractive index and high-stability of glass microspheres is realized; besides, the glass microspheres have good mechanical properties, corrosion resistance, weather resistance and high temperature resistance; furthermore, large-scale batch production can be realized.

Owner:HEFEI DINGLIANG OPTICAL TECH

Method for preparing 2, 4-butane sultone

PendingCN114805288AThe synthetic process route is simpleThe reaction conditions are mild and stablePreparation by halogen introductionChemical recyclingPtru catalystSulfite salt

The invention relates to a method for preparing 2, 4-butane sultone, which comprises the following steps: A, by taking 1, 3-butanediol and hydrochloric acid as raw materials and strong basic resin as a catalyst, reacting to obtain a 3-chlorobutanol crude product, and carrying out reduced pressure distillation to obtain 3-chlorobutanol; b, taking 3-chlorobutanol and a sodium sulfite aqueous solution as raw materials, reacting to obtain a solution containing 3-hydroxy butane sodium sulfonate, and dehydrating under reduced pressure for later use; c, acidifying the material subjected to decompression dehydration with concentrated hydrochloric acid, cooling to room temperature, filtering, and concentrating filtrate to obtain a concentrated solution containing 3-hydroxybutane sulfonic acid; d, carrying out flash evaporation dehydration cyclization on the 3-hydroxy butane sulfonic acid concentrated solution to obtain a 2, 4-butane sultone crude product; and E, performing rectification treatment. The method has the advantages that the process route is simple, the condition is mild, the reaction substrate and the catalyst are cheap and easy to obtain, the strongly basic resin is used as the catalyst, the loss and the production cost of an intermediate reaction link are effectively reduced, the post-treatment is simple, and the product yield is more than 80%.

Owner:武汉松石科技股份有限公司

Synthesis method of 1,4-butylenesulfone

The invention discloses a synthesis method of 1,4-butylenesulfone, and belongs to the technical field of medical intermediate synthesis. The synthesis method is characterized by comprising the following steps: adding hydrosulfite into water in advance, stirring to dissolve hydrosulfite to obtain a solution; then adding sodium sulfite to adjust the pH to 7.5-9; heating to a temperature of 45 to 55 DEG C, dropwise adding butenol within 10 to 20 minutes at an even speed, controlling the addition reaction temperature in a range of 60 to 70 DEG C, after the butanol is completely added, keeping on carrying out reactions for 20 to 30 minutes, then stopping reactions, cooling the temperature to the room temperature; wherein the mole ratio of butenol to hydrosulfite is 1:1.05-1:3; after cooling, dropwise adding acid into the system until the system turns acidic, stirring the solution for 50 to 70 minutes, adding alcohol to carry out crystallization, filtering to obtain a clarified solution, and subjecting the clarified solution to rectification to obtain 1,4-butylenesulfone. The synthesis method has the advantages that the steps are few, the yield is high, the side products and water can be recovered, and the environment pollution is little.

Owner:SHANDONG YINGHUAN CHEM

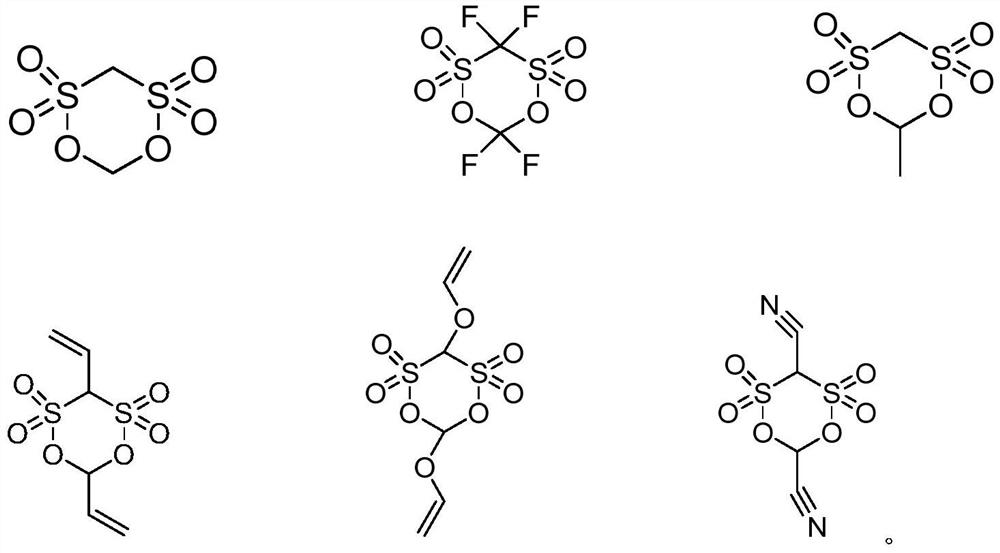

Lithium ion battery electrolyte and application thereof

PendingCN114583268AImprove high temperature storage performanceInhibit high temperature gas productionSecondary cellsOrganic electrolytesButanesultoneElectrolytic agent

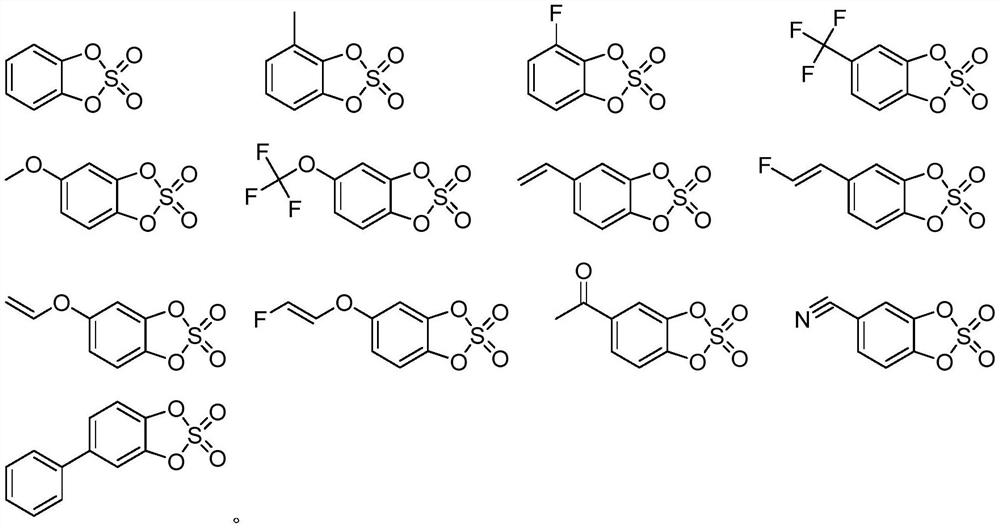

The invention relates to a lithium ion battery electrolyte and an application thereof, the lithium ion battery electrolyte comprises a lithium salt, an organic solvent and an additive, the additive comprises a compound A as shown in a formula (I) and a compound B as shown in a formula (II), and the additive can further comprise 2, 4-butane sultone and other additives. According to the lithium ion battery electrolyte, the high-temperature storage performance of the lithium ion battery can be improved, high-temperature gas production is inhibited, impedance is reduced, meanwhile, the low-temperature charge-discharge performance is improved, and the cycle performance at normal temperature and high temperature is improved.

Owner:SHENZHEN YANYI NEW MATERIALS CO LTD

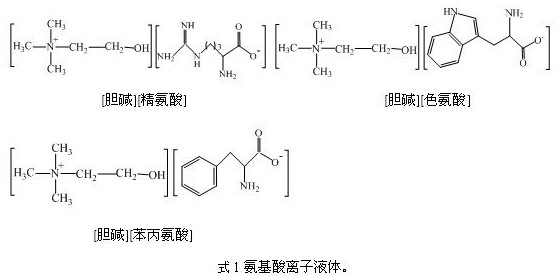

Environment-friendly corrosion and scale inhibitor and preparation method thereof

InactiveCN112777758AGood corrosion inhibitionExtend the life cycleSpecific water treatment objectivesScale removal and water softeningMeth-Polyvinyl alcohol

The invention discloses an environment-friendly corrosion and scale inhibitor, which is composed of a compound amino acid ionic liquid, a polysulfonate ionic liquid, sodium gluconate, an N-hydroxyphthalimide / acrylic acid / 2-acrylamide-2-methylpropanesulfonic acid copolymer, ammonium tungstate, polyvinyl alcohol, tea polyphenol and water. The molar ratio of [choline] [arginine] to [choline] [tryptophan] to [choline] [phenylalanine] in the compound amino acid ionic liquid is 1: 1: 1; and the multi-sulfonate ionic liquid is prepared from 1, 4-butane sultone and hexamethylenetetramine. The corrosion and scale inhibitor disclosed by the invention has the advantage of no phosphorus, and can greatly reduce the pollution to the environment in the use process; and an excellent corrosion and scale inhibition effect can be achieved at a relatively low concentration.

Owner:王强

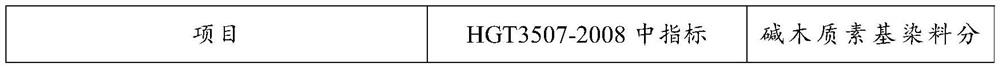

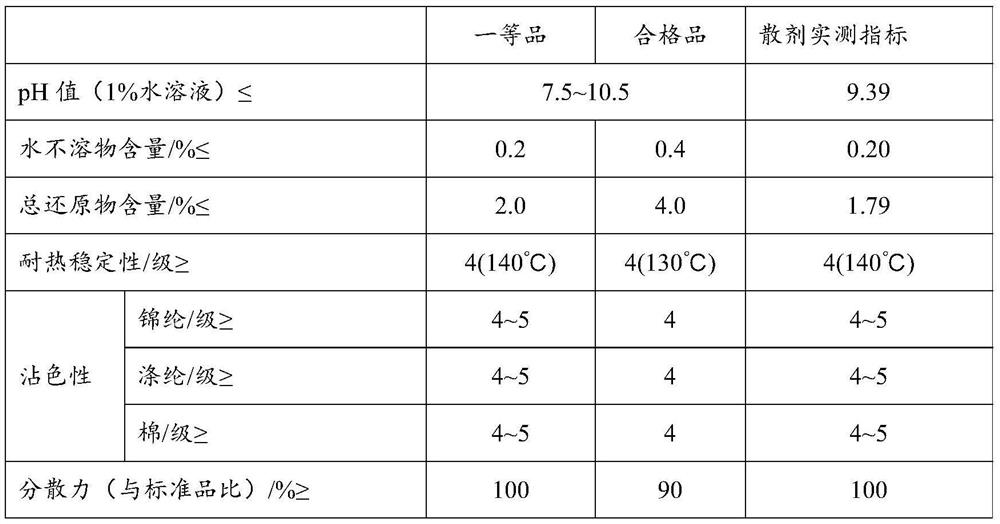

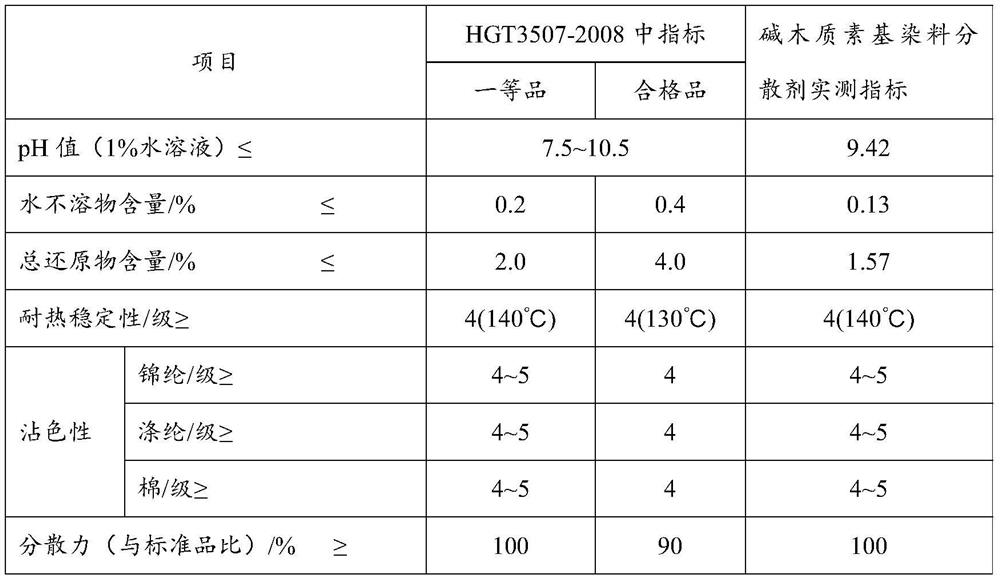

Preparation method of alkali lignin-based dye dispersant

The invention belongs to the field of alkali lignin utilization in pulping and papermaking industry, and relates to a preparation method of an alkali lignin-based dye dispersant. The method comprises the following steps: purifying alkali lignin, and carrying out molecular weight regulation and ultrafiltration in a 1, 6-dibromohexane / dimethylformamide system to obtain high molecular weight alkali lignin; and sulfonating the high molecular weight alkali lignin by using 1, 4-butanesultone to obtain the alkali lignin-based dye dispersant. The alkali lignin-based dye dispersant is prepared by taking alkali lignin in the pulping and papermaking industry as a raw material, firstly regulating and controlling the alkali lignin by adopting a novel alkylation system of 1, 6-dibromohexane / dimethylformamide, and then sulfonating the regulated and controlled alkali lignin by using 1, 4-butanesultone. The prepared alkali lignin-based dye dispersant is high in dispersion grade, high in high-temperature stability and low in contamination to fibers, and all indexes reach or exceed the indexes of first-grade sodium lignin sulfonate dispersants in HGT 3507-2008.

Owner:QILU UNIV OF TECH

Preparation method of 2,4-butanesultone

PendingCN114075165AThe synthetic process route is simpleThe reaction conditions are mild and stableOrganic chemistryPtru catalystDistillation

The invention relates to a preparation method of 2,4-butanesultone. The preparation method comprises the following steps: A, with 2-butenol and an aqueous sodium hydrogen sulfite solution as raw materials and an aqueous sodium nitrate solution as a catalyst, carrying out heating reflux reaction under a stirring condition to obtain a solution containing sodium 3-butanediol sulfonate; B, acidifying the solution with ion exchange resin, adding a dehydrating agent, carrying out distilling under normal pressure to remove water and a dehydrating agent, then performing reduced-pressure distillation, and collecting a 3-butanediol sulfonic acid fraction; and C, carrying out continuous flash evaporation dehydration cyclization on a 3-butanediol sulfonic acid concentrated solution under a high-temperature vacuum condition to obtain 2,4-butanesultone. The method has the advantages of simple process route, mild conditions, cheap and easily available reaction substrates and catalysts, adoption of resin acidification, guarantee of continuous production, reduction in loss and production cost of intermediate reaction links, simple post-treatment, and realization of target product yield of 80% or more.

Owner:武汉松石科技股份有限公司

A production process of high safety sulfobutyl ether-β-cyclodextrin sodium salt

ActiveCN105924545BReduce the risk of useReduce usagePharmaceutical non-active ingredientsSulfite saltSodium salt

Owner:SHANDONG BINZHOU ZHIYUAN BIO TECH CO LTD

Sulfobutyl-alpha-cyclodextrin and preparation method thereof

ActiveCN102993338BThe preparation conditions are mild and controllableImprove stabilitySolubilityButanesultone

The invention provides sulfobutyl-alpha-cyclodextrin and a preparation method thereof. The structural formula of the sulfobutyl-alpha-cyclodextrin is shown in the specification, wherein R=H, and the molecular weight is 1,108.17-2,605; and the sulfobutyl-alpha-cyclodextrin is prepared by the reaction of 1,4-butanesultone and alpha-cyclodextrin in a strong alkali solution. The water solubility of the sulfobutyl-alpha-cyclodextrin provided by the invention reaches 80g at 20 DEG C and is improved by 4 times over the existing alpha-cyclodextrin. The preparation method of the sulfobutyl-alpha-cyclodextrin provided by the invention is simple and has high reaction efficiency; the prepared sulfobutyl-alpha-cyclodextrin has strong stability and good water solubility; the whole preparation method has strong operability; and the sulfobutyl-alpha-cyclodextrin can be conveniently prepared into various guest molecule inclusion compounds and compositions.

Owner:SHAANXI UNIV OF SCI & TECH

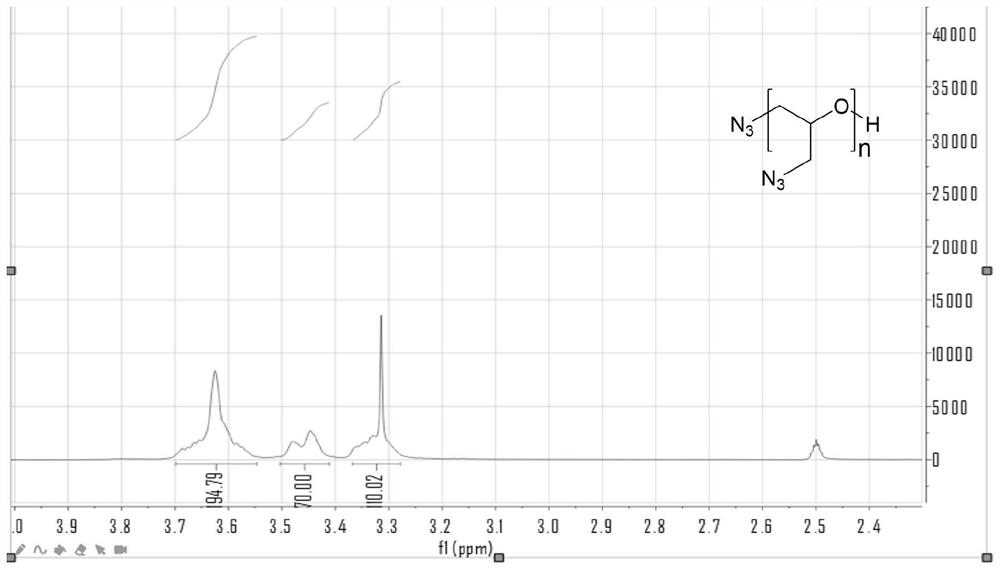

Cationic polymer gene vector and preparation method thereof

ActiveCN113061254ALow cytotoxicityGood biocompatibilityGenetic material ingredientsGene therapyPolymer sciencePolythylene glycol

The invention discloses a cationic polymer gene vector and a preparation method thereof, the cationic polymer gene vector is modified polyglycidyl amine, and a modification agent is p-methylbenzenesulfonyl terminated polyethylene glycol monomethyl ether, carboxyl terminated polyethylene glycol monomethyl ether, oligosaccharide, an organic hydrophobic substance or zwitter-ions. The oligosaccharide is at least one of maltose, glucose and mannose, the organic hydrophobic substance is at least one of lauric acid, lauric aldehyde, polylactic acid, polycaprolactone, a lactic-co-glycolic acid copolymer and cholesterol, and the zwitterions are at least one of propiolactone, butyrolactone, valerolactone, caprolactone, 1, 3-propane sultone, 1, 4-butane sultone, and 1, 5-pentane sultone; wherein the grafting rate of the modification agent on the polyglycidyl amine is 5%-50%. The modified polyglycidyl amine provided by the invention is used as a non-viral gene transfection vector, and has very high biocompatibility and gene transfection capability and relatively low cytotoxicity.

Owner:ZHEJIANG UNIV OF TECH

Synthesis process of 1,4-butane sultone

The invention discloses a synthesis process of 1,4-butane sultone. The synthesis process comprises the following steps: sulfonating 3-buten-1-ol and a sulfonating agent under the action of an initiator to obtain an intermediate product; carrying out rotary evaporation and concentration on the intermediate product until the intermediate product is viscous, adding strong acid, carrying out a microwave-assisted esterification reaction, conducting cooling to separate out salt after the reaction is finished, performing filtering, and taking a filtrate to obtain crude 1,4-butane sultone; and refining the crude 1,4-butane sultone to obtain a finished 1,4-butane sultone product. According to the invention, microwave-assisted esterification is adopted, and the strong acid is used as an acidifying reagent and a catalyst, so reaction selectivity can be improved, by-product generation can be reduced, reaction time can be shortened, and yield can be improved; and no organic solvent needs to be added in the process, so the organic solvent recovery process is avoided, and steps are simple.

Owner:湖北吉和昌化工科技有限公司

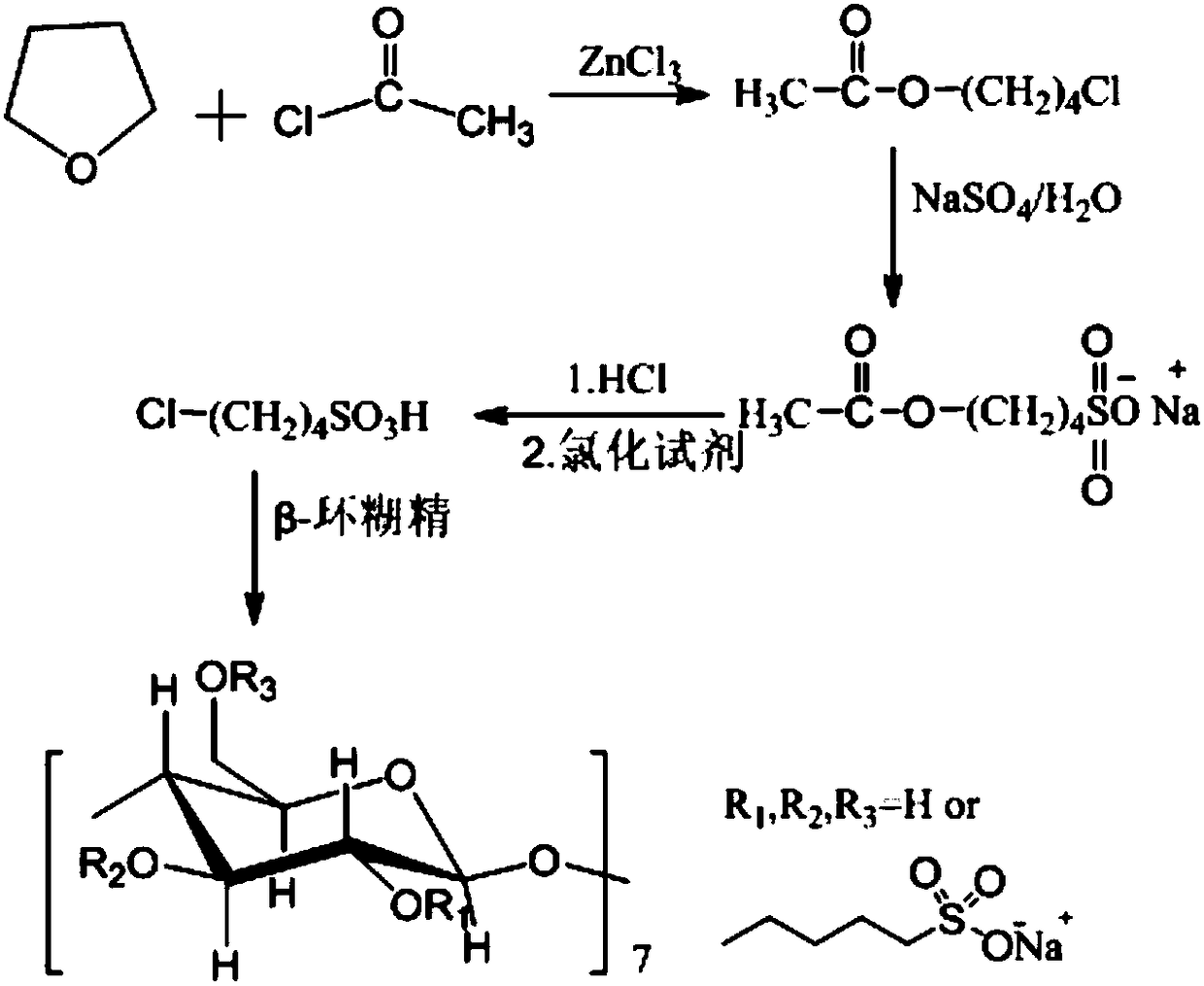

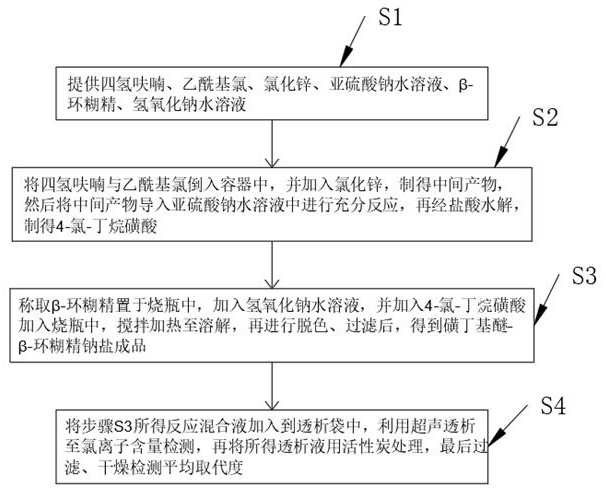

Production process of green and nontoxic sulfobutyl ether-beta-cyclodextrin sodium salt

The invention discloses a production process of green and nontoxic sulfobutyl ether-beta-cyclodextrin sodium salt, and particularly relates to the field of sulfobutyl ether-beta-cyclodextrin sodium salt. The process comprises the following steps: S1: providing tetrahydrofuran, acetyl chloride, zinc chloride, a sodium sulfite aqueous solution, beta-cyclodextrin and a sodium hydroxide aqueous solution; S2: preparation of a monomer 4-chloro-butanesulfonic acid: pouring tetrahydrofuran and acetyl chloride into a container, adding zinc chloride to prepare an intermediate product, introducing the intermediate product into a sodium sulfite aqueous solution for full reaction, and carrying out hydrolyzing with hydrochloric acid to obtain the 4-chloro-butanesulfonic acid. According to the invention, tetrahydrofuran and acetyl chloride react to obtain 4-chlorine-butanesulfonic acid, then beta-cyclodextrin and 4-chlorine-butanesulfonic acid serve as raw materials and are added into a container to react, and compared with the method that 1, 4-butanesultone with toxicity serves as a preparation raw material, the process is more environmentally friendly and free of toxicity, and improves certain safety.

Owner:秦大伟

Lithium battery electrolyte and preparation method thereof

PendingCN111082144AAnti-agingImprove stabilityLi-accumulatorsOrganic electrolytesElectrolytic agentOrganosolv

The invention discloses a lithium battery electrolyte. The electrolyte comprises the following raw materials: a carbonic ester organic solvent, a conductive lithium salt, a stabilizer, an SEI film-forming additive, triphenyl phosphate, tris (trimethylsilane) borate, 1,4-Butanesultone, lithium hexafluorophate and modified sepiolite. The SEI film forming additive is formed by combining vinylene carbonate, propylene carbonate ethyl ester and butylene sulfite, the ratio of vinylene carbonate to propylene carbonate ethyl ester to butylene sulfite is (1-1.5): (0.5-1): (1-2). The invention further discloses a preparation method of the lithium battery electrolyte. Compared with the prior art, the flame retardance and the stability are better.

Owner:广东博龙能源科技有限公司

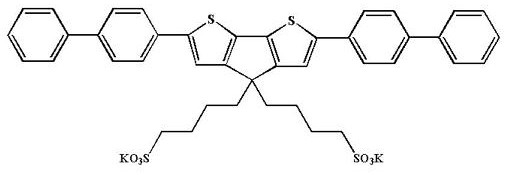

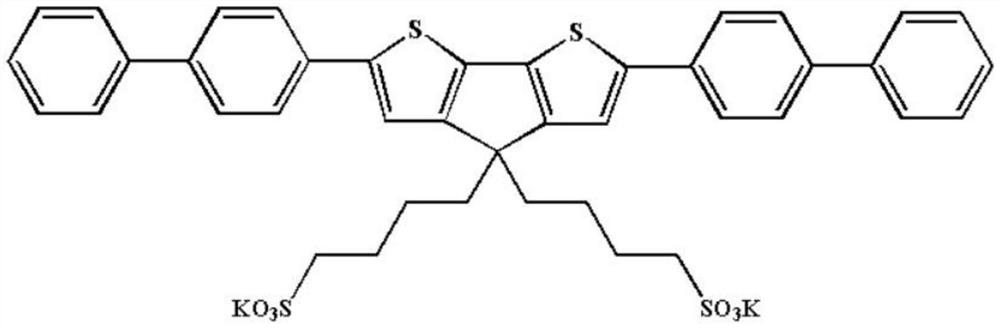

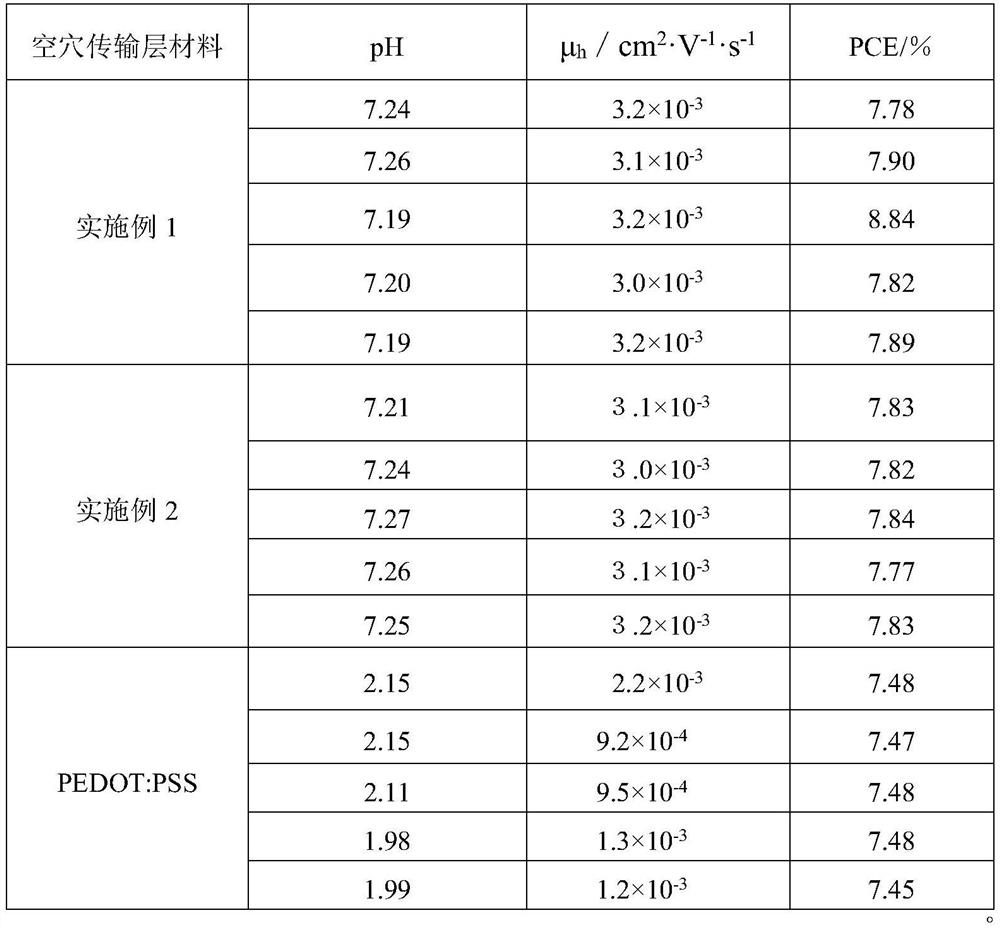

A kind of small molecule hole transport material for organic solar cell and its preparation method

ActiveCN110563745BSimple preparation processGood water solubilityOrganic chemistrySolid-state devicesOrganic solar cellSolar battery

The invention relates to a small molecule hole transport material for organic solar cells and a preparation method thereof. The preparation method specifically obtains an intermediate product through the addition reaction of cyclopentathiophene and 1,4-butane sultone, and then combines with N-bromosuccinimide reacts to obtain a brominated intermediate product, and the brominated intermediate product is reacted with 4-biphenylboronic acid to obtain the small molecule hole transport material 2,6-di-biphenyl-4,4 of the present invention ‑Potassium di‑butylsulfonate‑cyclopentathiophene. The small molecule hole-transporting material 2,6-di-biphenyl-4,4-di-butylsulfonate potassium-cyclopentathiophene prepared by the present invention is used for the hole-transporting layer of organic solar cells, and has the advantages of simple preparation process, It has the advantages of high purity and high photoelectric conversion efficiency.

Owner:NANCHANG HANGKONG UNIVERSITY

A kind of synthetic method of high-purity 1,4-butane sultone

ActiveCN109293625BImprove the mixing effectShorten the sulfonation reaction timeOrganic chemistrySulfite saltAzeotrope

The invention discloses a method for synthesizing high-purity 1,4-butane sultone. The steps are as follows: 1. Add 4-chlorobutanol and sodium sulfite solution into an alcohol solvent, heat up to reflux for 6 hours, After the reflux is completed, the mixed solution A is obtained. Concentrate the mixed solution A to recover the alcohol solvent, then add hydrochloric acid to acidify, concentrate until the material becomes viscous, then add the alcohol solvent, precipitate sodium chloride crystals, filter, and concentrate the filtrate to recover the alcohol Solvent to obtain 4-hydroxybutanesulfonic acid; 2. Continuous flash dehydration of 4-hydroxybutanesulfonic acid at a vacuum degree of 1-8mmHg and a temperature of 130-165°C to obtain industrial grade 1,4-butane 3. Add azeotrope to industrial grade 1,4-butane sultone, and recover the azeotrope by fractional distillation at normal pressure, then carry out fractional distillation under reduced pressure at a vacuum of 2-4mmHg, and collect 120 ‑121 °C fraction to obtain high-purity 1,4‑butane sultone. The method is simple and environment-friendly, greatly improves the sulfonation yield, and greatly improves the purity and yield of 1,4-butane sultone.

Owner:JINGCHU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com