Environment-friendly corrosion and scale inhibitor and preparation method thereof

A corrosion and scale inhibitor, an environment-friendly technology, applied in the field of environment-friendly corrosion and scale inhibitors and its preparation, can solve the problem of high price of polyaspartic acid, difficulty in achieving high corrosion and scale inhibition performance, etc. problems, achieve the effect of reducing water cost, reducing pollution, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

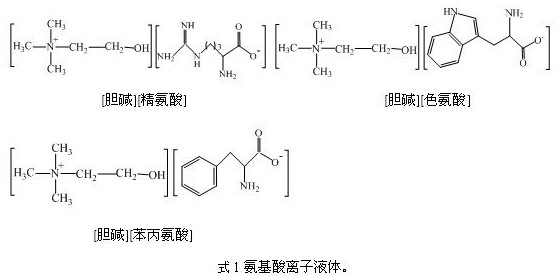

[0028] 1) The steps of compound amino acid ionic liquid are as follows:

[0029] Weigh 0.1 mol of arginine, 0.1 mol of tryptophan, 0.1 mol of phenylalanine and 0.3 mol of choline in 100 mL of deionized water, stir at room temperature until it is completely dissolved, and transfer the mixed solution to a microwave reactor , and then set it at 300 W at 75 o C was reacted for 2 h, and then the mixed solution was transferred to a rotary evaporator to distill off excess water under reduced pressure to obtain a white amino acid ionic liquid mixture.

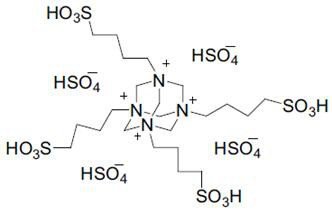

[0030] 2) The preparation steps of polysulfonic acid and ionic liquid are as follows:

[0031] Mix 1,4-butane sultone and hexamethylenetetraammonium in a molar ratio of 6:1 and place it in a microwave reactor, and set it at 90 under the power of 200 W o C was reacted for 4h, and then the sample was taken out for vacuum filtration and dried to obtain an intermediate product; concentrated sulfuric acid was added dropwise to the obtaine...

Embodiment 2

[0036] 1) The steps of compound amino acid ionic liquid are as follows:

[0037] Weigh 0.1 mol of arginine, 0.1 mol of tryptophan, 0.1 mol of phenylalanine and 0.3 mol of choline and dissolve them in 500 mL of deionized water, stir at room temperature until they are completely dissolved, and transfer the mixed solution to a microwave reactor , and then set it at 300 W at 75 o C was reacted for 2 h, and then the mixed solution was transferred to a rotary evaporator to distill off excess water under reduced pressure to obtain a white amino acid ionic liquid mixture.

[0038] 2) The preparation steps of polysulfonic acid, ionic liquid and N-hydroxyphthalimide / acrylic acid / 2-acrylamide-2 methylpropanesulfonic acid copolymer are the same as in Example 1;

[0039] The components in the corrosion and scale inhibitor are calculated by weight ratio: compound amino acid ionic liquid 35%, polysulfonate ionic liquid 5%, sodium gluconate, 16%, N-hydroxyphthalimide / acrylic acid / 2-acrylam...

Embodiment 3

[0041] 1) The steps of compound amino acid ionic liquid are as follows:

[0042] Weigh 0.1 mol of arginine, 0.1 mol of tryptophan, 0.1 mol of phenylalanine and 0.3 mol of choline and dissolve them in 300 mL of deionized water, stir at room temperature until they are completely dissolved, and transfer the mixed solution to a microwave reactor , and then set it at 300 W at 75 o C was reacted for 2 h, and then the mixed solution was transferred to a rotary evaporator to distill off excess water under reduced pressure to obtain a white amino acid ionic liquid mixture.

[0043] 2) The preparation steps of polysulfonic acid, ionic liquid and N-hydroxyphthalimide / acrylic acid / 2-acrylamide-2 methylpropanesulfonic acid copolymer are the same as in Example 1;

[0044] The components in the corrosion and scale inhibitor are calculated by weight ratio: 28% compound amino acid ionic liquid, 8% polysulfonate ionic liquid, 13% sodium gluconate, N-hydroxyphthalimide / acrylic acid / 13% of 2-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com