A production process of high safety sulfobutyl ether-β-cyclodextrin sodium salt

A technology of sodium cyclodextrin and sulfobutyl ether is applied in the field of synthesis of pharmaceutical excipients and achieves the effects of high yield, reduced use risk and simple purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

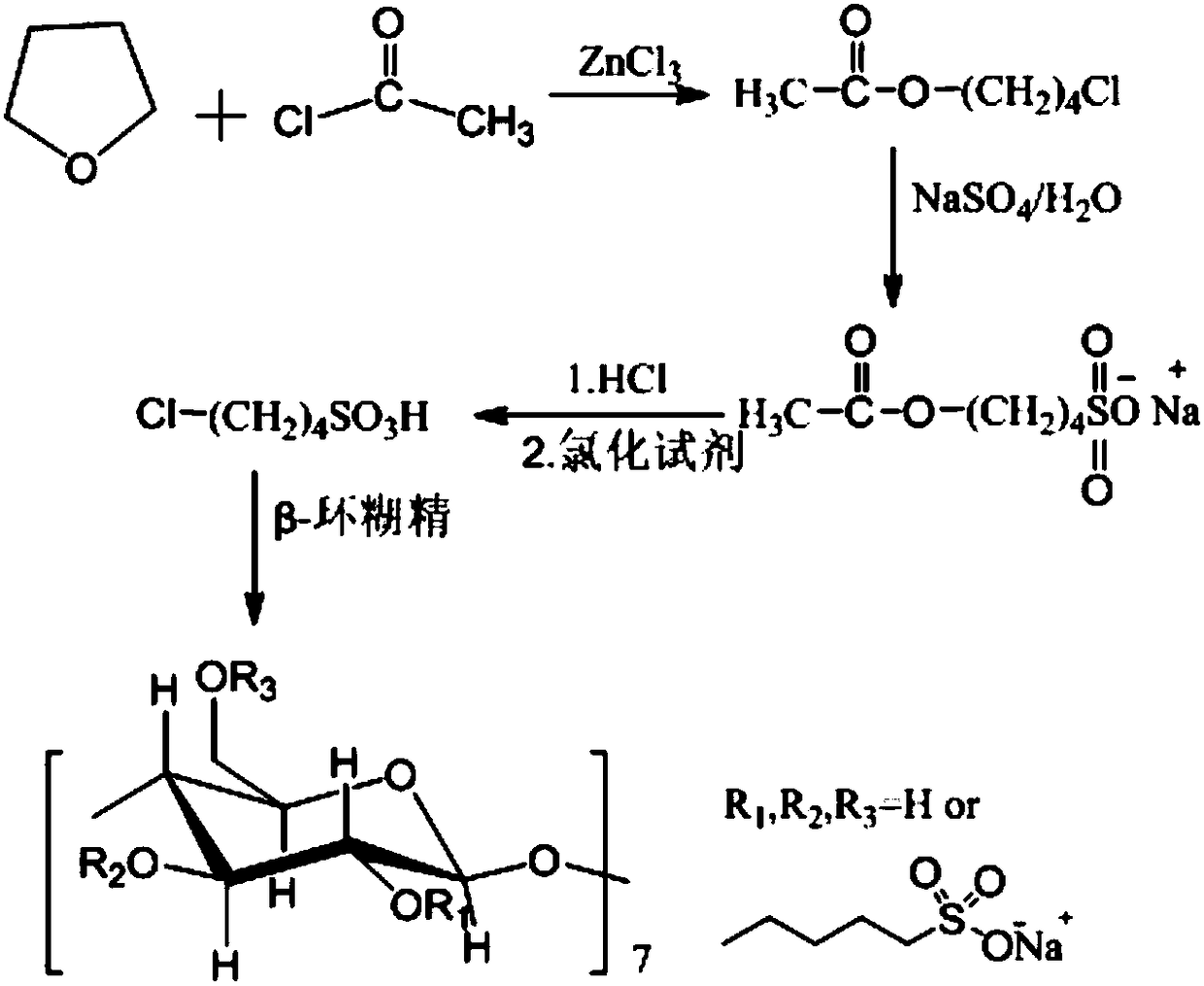

[0040] A kind of production technique of high safety sulfobutyl ether-beta-cyclodextrin sodium salt, comprises steps as follows:

[0041] (1) Preparation of 4-chloro-butanesulfonic acid

[0042] 80kg tetrahydrofuran and 77kg acetyl chloride were reacted under the catalysis of 50g zinc chloride to obtain an intermediate product, and then the intermediate product was fully reacted in 300kg 30wt% sodium sulfite aqueous solution, and then hydrochloric acid was hydrolyzed to obtain 4-chloro-butanesulfonate acid reaction solution.

[0043] (2) Preparation of sulfobutyl ether-β-cyclodextrin sodium salt

[0044] Add 96L of purified water into the K1000 reactor, and start stirring. Add 80kg of β-cyclodextrin, turn on and heat to 100-130°C, the pressure inside the kettle is 0.2-0.4MPa, add sodium hydroxide dropwise (50kg sodium hydroxide is dissolved in 75kg purified water) to adjust the pH of the solution in the kettle to ≈13, and then add dropwise The 4-chloro-butanesulfonic acid r...

Embodiment 2

[0051] A kind of production technique of high safety sulfobutyl ether-beta-cyclodextrin sodium salt, comprises steps as follows:

[0052] (1) Preparation of 4-chloro-butanesulfonic acid

[0053] 80kg tetrahydrofuran and 77kg acetyl chloride were reacted under the catalysis of 50g zinc chloride to obtain an intermediate product, and then the intermediate product was fully reacted in 300kg 30wt% sodium sulfite aqueous solution, and then hydrochloric acid was hydrolyzed to obtain 4-chloro-butanesulfonate acid reaction solution.

[0054] (2) Preparation of sulfobutyl ether-β-cyclodextrin sodium salt

[0055] Add 96L of purified water into the K1000 reactor, and start stirring. Add 80kg of β-cyclodextrin, turn on and heat to 100-130°C, the pressure inside the kettle is 0.2-0.4MPa, add sodium hydroxide dropwise (50kg sodium hydroxide is dissolved in 75kg purified water) to adjust the pH of the solution in the kettle to ≈11, and then add dropwise The 4-chloro-butanesulfonic acid r...

Embodiment 3

[0062] A kind of production technique of high safety sulfobutyl ether-beta-cyclodextrin sodium salt, comprises steps as follows:

[0063] (1) Preparation of 4-chloro-butanesulfonic acid

[0064] 80kg tetrahydrofuran and 77kg acetyl chloride were reacted under the catalysis of 50g zinc chloride to obtain an intermediate product, and then the intermediate product was fully reacted in 300kg 30wt% sodium sulfite aqueous solution, and then hydrochloric acid was hydrolyzed to obtain 4-chloro-butanesulfonate acid reaction solution.

[0065] (2) Preparation of sulfobutyl ether-β-cyclodextrin sodium salt

[0066] Add 96L of purified water into the K1000 reactor, and start stirring. Add 80kg of β-cyclodextrin, turn on and heat to 100-130°C, the pressure inside the kettle is 0.2-0.4MPa, add sodium hydroxide dropwise (50kg sodium hydroxide is dissolved in 75kg purified water) to adjust the pH of the solution in the kettle to ≈11, and then add dropwise The 4-chloro-butanesulfonic acid r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com