Immobilized ionic liquid solid acid catalyst and preparation method thereof

A technology of solid acid catalysts and ionic liquids, applied in physical/chemical process catalysts, carboxylate preparation, chemical instruments and methods, etc., can solve problems such as difficult stratification and inability to recycle, and achieve easy recycling, good catalytic effect, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of 3-Aminopropyltrimethoxysilane Ionic Liquid Solid Acid Catalyst Supported

[0029] Preparation of step 1 ylide

[0030] Take 3-aminopropyltrimethoxysilane and 1,4-butane sultone as raw materials, add tetrahydrofuran solvent, the amount is 6 times the mass of 3-aminopropyltrimethoxysilane, at 70 ℃ After heating and stirring for 2 hours, a white solid was obtained, which was then suction-filtered, washed three times with 99% diethyl ether, and vacuum-dried at 60°C to obtain the ylide;

[0031] Step 2 Acidification

[0032] Dissolve 1 g of ylide in 5 g of a mixed solvent of ethanol and water at a volume ratio of 1:1, add sulfuric acid equal to the substance of the ylide, and stir and mix at room temperature for 4 hours to obtain the corresponding anion as hydrogen sulfate. Ionic liquid solution;

[0033] Step 3 Synthesis of Immobilized Ionic Liquid Solid Acid Catalyst

[0034] Add chromatographic silica gel to the above ionic liquid solution, the amount o...

Embodiment 2-4

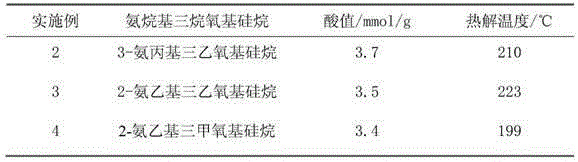

[0036] Except for the following differences, the others are the same as in Example 1, and the aminoalkyltrialkoxysilane is shown in Table 1, respectively, to obtain the following immobilized ionic liquid solid acid material catalyst.

[0037] Table 1 Aminoalkyltrialkoxysilane used in Examples 2-4 and catalyst parameters obtained

[0038]

Embodiment 5-6

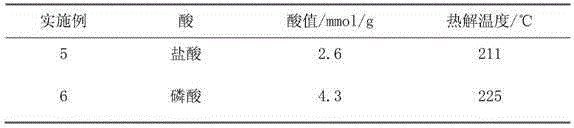

[0040] Except following difference, all the other are with embodiment 1, and acid is shown in table 2 respectively, and the catalyst result that different acids obtain is as table 2.

[0041] The acid used in table 2 embodiment 5-6 and the catalyst parameter that obtains

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com