1,4-butane sultone and synthesis process thereof

A technology of butane sultone and synthesis process, applied in 1 field, can solve the problems of unsuitability for industrialized production, high price, and difficulty in obtaining raw materials, and achieves the effects of few synthesis steps, high purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

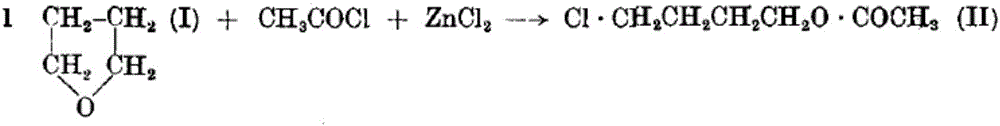

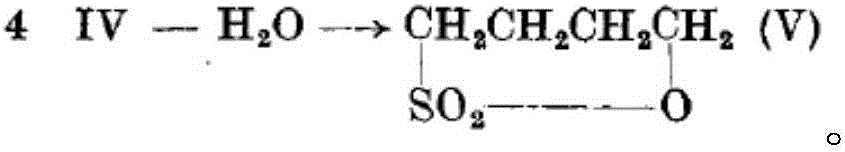

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a kind of 1,4-butane sultone, which is prepared according to the following preparation process:

[0048] S101, 72.11g of 3-buten-1-alcohol (raw material), 29.92g of 25% hydrogen peroxide and 90g of water are prepared into liquid A, the hydrogen peroxide of 25% content is hydrogen peroxide of mass concentration 25%, and 114.4g of Sodium bisulfate (sulfonating agent) and 350g of water are prepared into liquid B. At 40°C, add liquid A and liquid B dropwise into a 1L four-neck flask containing 27.72g of sodium sulfite and 120g of water for sulfonation. The temperature for sulfonation is 40°C; the pH for sulfonation is 6.5-7.5 , when the pH is too low, adjust the pH with sodium sulfite aqueous solution; control liquid A and liquid B to be added dropwise in 40 minutes at the same time, keep warm for 2 hours, that is, the time of sulfonation is 2 hours, and the reaction solution, that is, the first intermediate product, its main component Sodium hydro...

Embodiment 2

[0055] This embodiment provides a 1,4-butane sultone, the preparation process of the 1,4-butane sultone is roughly the same as the preparation process of Example 1, the difference is:

[0056] In the preparation process of this example, the second intermediate product is subjected to azeotropic dehydration with toluene (dehydration solvent) and water at 85° C., that is, azeotropic dehydration and cyclization to obtain a crude toluene solution, and the crude product is obtained after removing the toluene. The crude product is refined and decolorized to obtain the finished product of 1,4-butane sultone.

[0057] In the finished product of 1,4-butane sultone obtained in this example: the total yield of 1,4-butane sultone is 82.47%, the water content is 0.04%, and the acid value is 0.78mg / g , with a purity of 99.95%.

Embodiment 3

[0059] This embodiment provides a kind of 1,4-butane sultone, which is prepared according to the following preparation process:

[0060] S301, 72.11g of 3-buten-1-ol, 29.92g of 25% hydrogen peroxide and 90g of water were prepared into liquid A, and 114.4g of sodium bisulfite and 350g of water were prepared into liquid B. At 35°C, drop liquid A and liquid B into a 1L four-neck flask containing 27.72g sodium sulfite and 120g water at the same time, control the temperature at 35°C; control the pH to 6.5-7.5, when the pH is too low, use sodium sulfite Adjust the pH of the aqueous solution, control the dropwise addition of liquid A and liquid B for 40 minutes, and keep warm for 1.5 hours to obtain the first intermediate product, the main component of which is sodium hydroxybutane sulfonate.

[0061] S302. Slowly add 75g of concentrated sulfuric acid to the first intermediate product, control the temperature at 50°C, and acidify for 3h; first dehydrate until solids are precipitated,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com