Synthesis method of 1,4-butane sultone

A technology of butane sultone and synthesis method, applied in the direction of organic chemistry and the like, can solve the problems of many by-products, difficult to control operation mode, etc., achieve high total yield, ensure high and low temperature storage performance, and reduce side reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

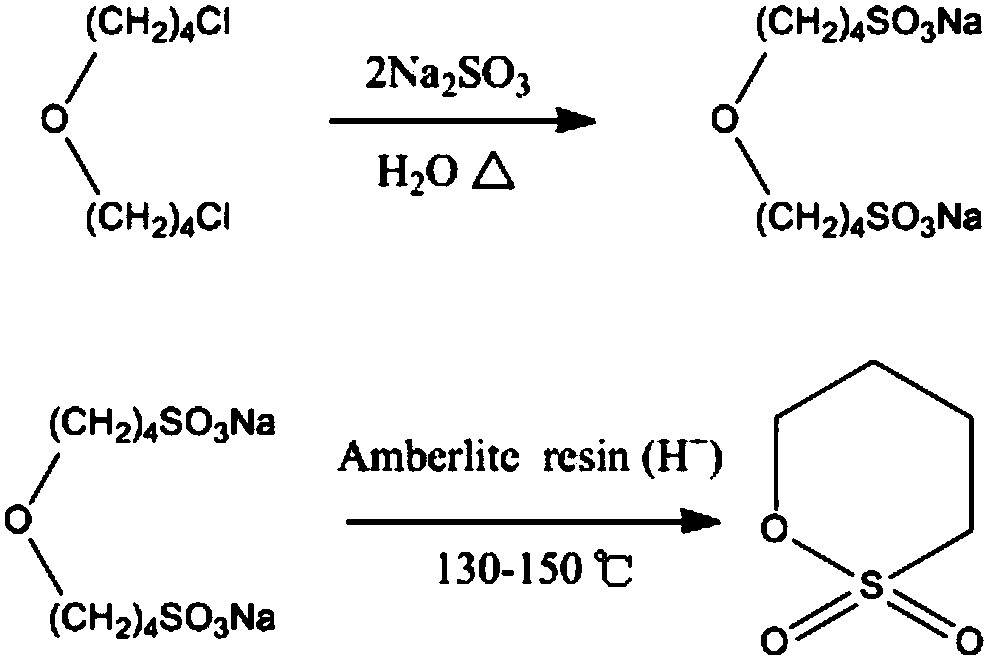

Method used

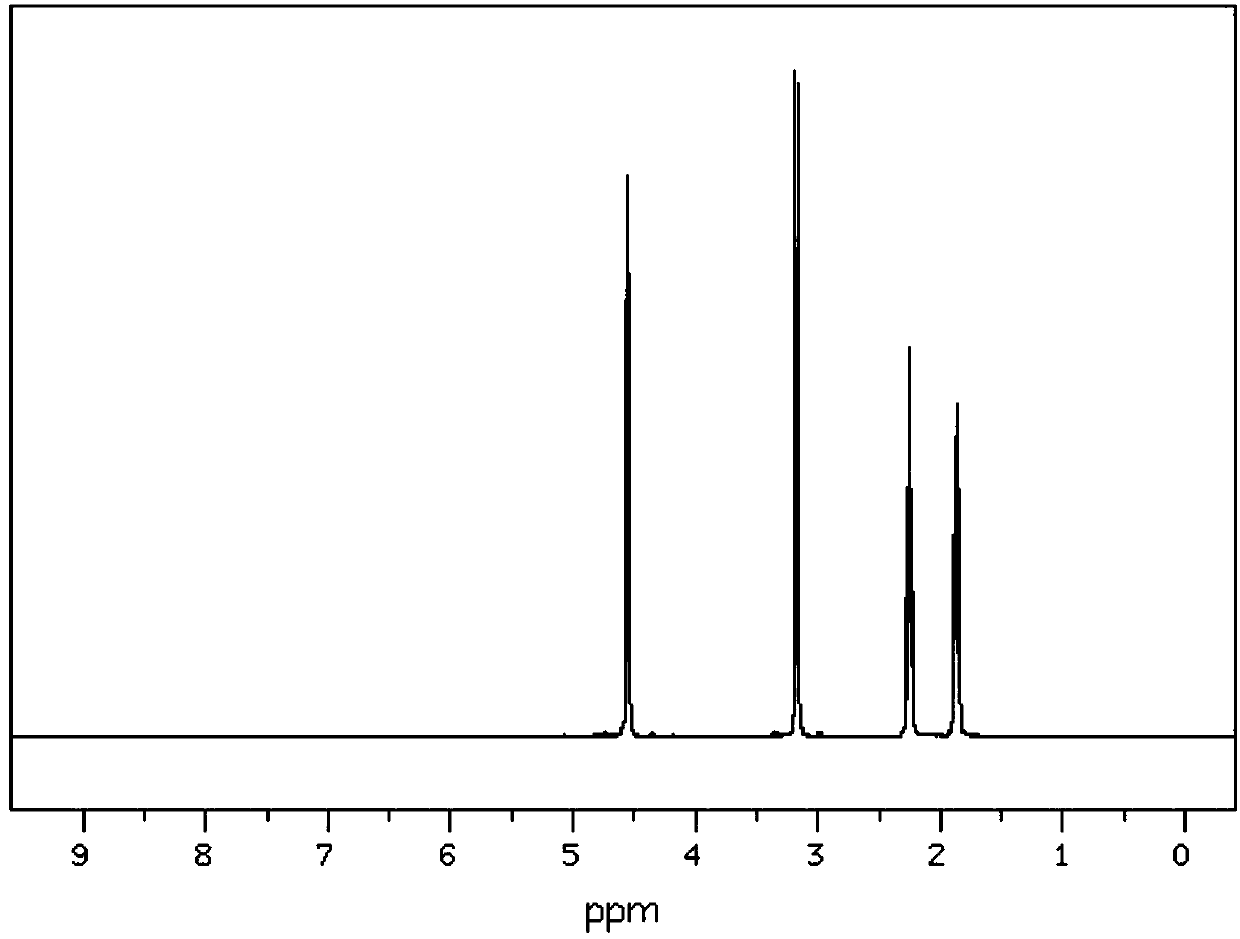

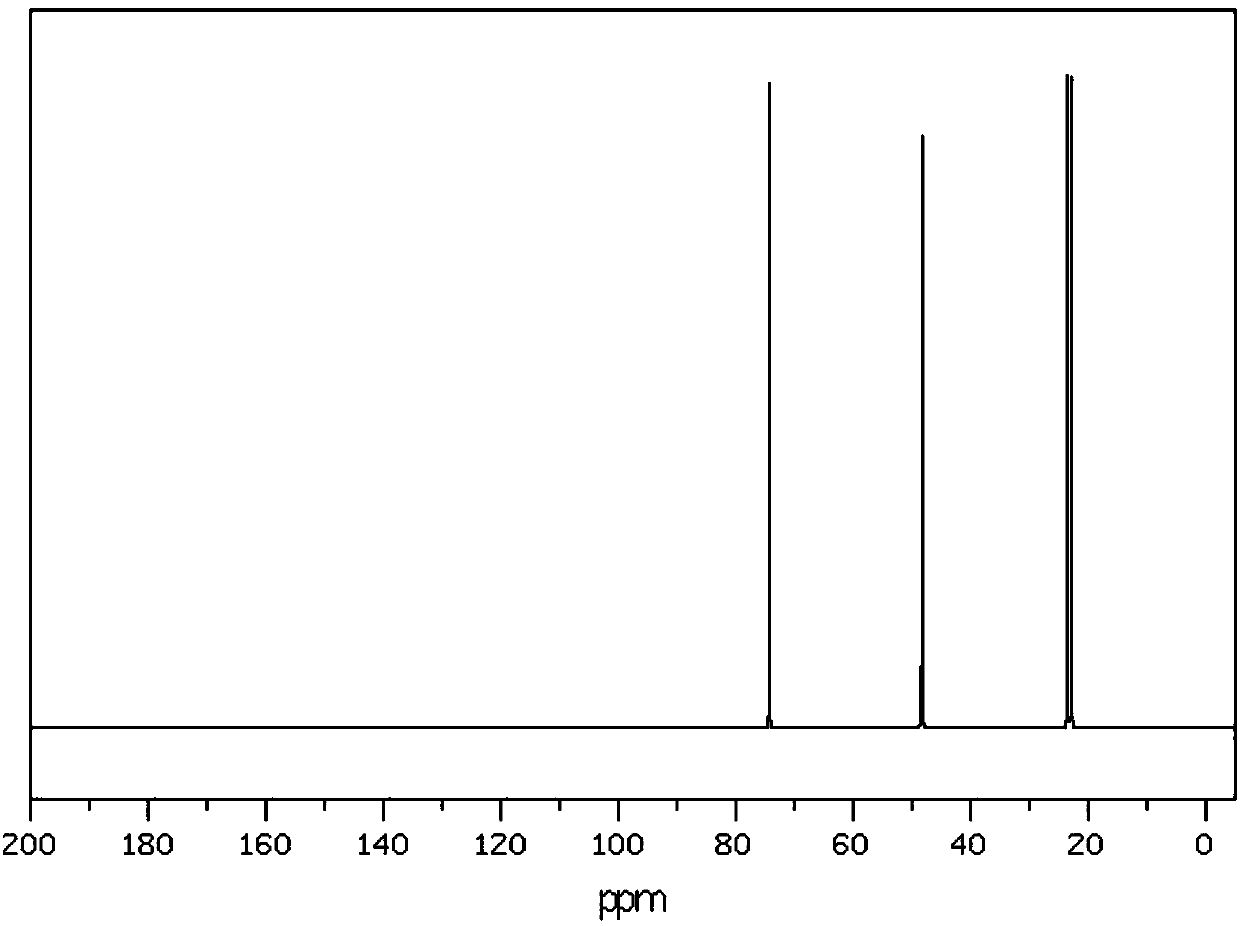

Image

Examples

Embodiment 1

[0030] Preparation of chlorobutyl acetate

[0031] Put 196g of tetrahydrofuran and 42g of zinc powder into the reaction bottle, install a reflux device, stir in an ice-water bath to cool down to below 15°C, start to add 48g of acetyl chloride dropwise, and finish adding in 3 hours. After heat preservation at 60°C for 2 hours, the reaction was completed, and 388.8 g of the intermediate chlorobutyl acetate was recovered under reduced pressure, with a yield of 95%.

[0032] Preparation of 1,4-butane sultone

[0033] Drop into intermediate chlorobutyl acetate 151g, sodium sulfite 190g, water 360g in the reaction bottle, install reflux device, stir and heat reflux, timing 16h, solution becomes clear, reaction finishes, extract part of water under reduced pressure until there is solid to separate out, cool down to Below 45°C, add methanol hydrochloride (41.9%, 300ml) dropwise, stir for 2 hours, cool down to 5°C, and filter with suction. To 130°C, 1-3mmHg high-vacuum decompression ...

Embodiment 2

[0036] Preparation of chlorobutyl acetate

[0037] Put 73g of tetrahydrofuran and 85g of zinc powder into the reaction bottle, install a reflux device, stir in an ice-water bath to cool down to below 15°C, start to add 86g of acetyl chloride dropwise, and the dropwise addition is completed in 2.5 hours. Keep warm at 60°C for 1.5h, the reaction is over, and 142.67g of intermediate chlorobutyl acetate is extracted under reduced pressure, with a yield of 93.8%.

[0038] Preparation of 1,4-butane sultone

[0039] Put 142g of the above-mentioned intermediate chlorobutyl acetate, 220g of sodium sulfite, and water into the reaction flask until sodium sulfite is a saturated solution, install a reflux device, stir and heat to reflux, and count for 15 hours, the solution becomes clear, the reaction is over, and part of the water is extracted under reduced pressure When there is solid precipitation, cool down to below 45°C, add dropwise methanol hydrochloride (41.9%, until the pH value ...

Embodiment 3

[0042] Preparation of chlorobutyl acetate

[0043] Put 145g of tetrahydrofuran and 160g of zinc powder into the reaction bottle, install a reflux device, stir in an ice-water bath to cool down to below 15°C, start to add 175g of acetyl chloride dropwise, and finish the dropwise addition in 2 hours. After the reaction was completed at 60°C for 1 hour, 285.2 g of the intermediate chlorobutyl acetate was recovered under reduced pressure, with a yield of 94.2%.

[0044] Preparation of 1,4-butane sultone

[0045] Put 151g of the above-mentioned intermediate chlorobutyl acetate, 252g of sodium sulfite, and water into the reaction bottle until the sodium sulfite is a saturated solution, install a reflux device, stir and heat to reflux, and count for 14 hours. When there is solid precipitation, lower the temperature to below 45°C, add dropwise methanol hydrochloride (41.9%, until the pH value is 3.2), stir for 1 hour, cool down to 4°C, filter with suction, the filter cake is the by-pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com