Production process of green and nontoxic sulfobutyl ether-beta-cyclodextrin sodium salt

A technology of sulfobutyl ether and cyclodextrin sodium is applied in the production process field of green non-toxic sulfobutyl ether-β-cyclodextrin sodium salt, which can solve the problem of difficulty in industrial production, low product yield and safety. problems such as low coefficient, to achieve the effect of high production efficiency, high product yield and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

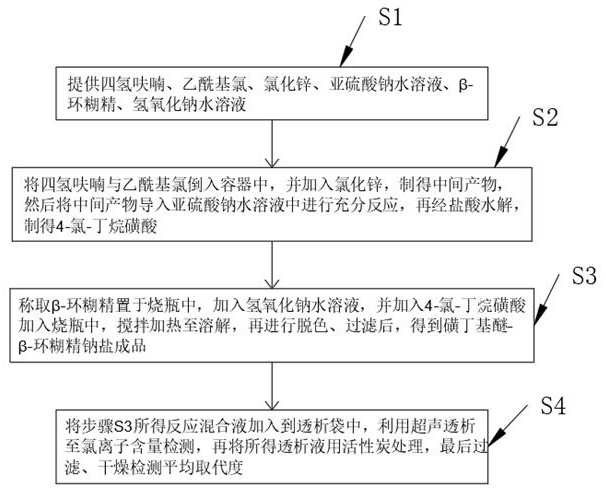

[0029] like figure 1 As shown, the embodiment is as follows: the present invention provides a production process of green non-toxic sulfobutyl ether-β-cyclodextrin sodium salt, comprising the following steps:

[0030] S1: provide 80kg tetrahydrofuran, 77kg acetyl chloride, 50mg zinc chloride, 300kg sodium sulfite aqueous solution, 5g β-cyclodextrin, 10ml 200g / L sodium hydroxide aqueous solution;

[0031] S2: Preparation of monomeric 4-chloro-butanesulfonic acid:

[0032] Pour 80kg of tetrahydrofuran and 77kg of acetyl chloride into the container, and add 50mg of zinc chloride, then react under the catalysis of 50mg of zinc chloride to first obtain an intermediate product, then the intermediate product is fully reacted in 300kg of sodium sulfite aqueous solution, and then through Hydrochloric acid hydrolysis to obtain 4-chloro-butanesulfonic acid;

[0033] S3: Synthesis reaction: Synthesis of sulfobutyl ether-β-cyclodextrin sodium salt:

[0034] Weigh 5g of β-cyclodextrin an...

Embodiment 2

[0038] like figure 1 As shown, the embodiment is as follows: the present invention provides a production process of green non-toxic sulfobutyl ether-β-cyclodextrin sodium salt, comprising the following steps:

[0039] S1: Provide 80kg tetrahydrofuran, 70kg acetyl chloride, 45mg zinc chloride, 300kg sodium sulfite aqueous solution, 5g β-cyclodextrin, 10ml 200g / L sodium hydroxide aqueous solution;

[0040] S2: Preparation of monomeric 4-chloro-butanesulfonic acid:

[0041] Pour 80kg of tetrahydrofuran and 77kg of acetyl chloride into the container, and add 50mg of zinc chloride, then react under the catalysis of 50mg of zinc chloride to first obtain an intermediate product, then the intermediate product is fully reacted in 300kg of sodium sulfite aqueous solution, and then through Hydrochloric acid hydrolysis to obtain 4-chloro-butanesulfonic acid;

[0042] S3: Synthesis reaction: Synthesis of sulfobutyl ether-β-cyclodextrin sodium salt:

[0043] Weigh 5g of β-cyclodextrin an...

Embodiment 3

[0047] like figure 1 As shown, the embodiment is as follows: the present invention provides a production process of green non-toxic sulfobutyl ether-β-cyclodextrin sodium salt, comprising the following steps:

[0048] S1: provide 80kg tetrahydrofuran, 65kg acetyl chloride, 40mg zinc chloride, 300kg sodium sulfite aqueous solution, 5g β-cyclodextrin, 10ml 200g / L sodium hydroxide aqueous solution;

[0049] S2: Preparation of monomeric 4-chloro-butanesulfonic acid:

[0050] Pour 80kg of tetrahydrofuran and 77kg of acetyl chloride into the container, and add 50mg of zinc chloride, then react under the catalysis of 50mg of zinc chloride to first obtain an intermediate product, then the intermediate product is fully reacted in 300kg of sodium sulfite aqueous solution, and then through Hydrochloric acid hydrolysis to obtain 4-chloro-butanesulfonic acid;

[0051] S3: Synthesis reaction: Synthesis of sulfobutyl ether-β-cyclodextrin sodium salt:

[0052] Weigh 5g of β-cyclodextrin an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com