Method for synthetizing 2, 4-butane sulfonic acid lactone

A kind of technology of butane sultone and synthesis method, which is applied in the field of preparation method of sultone derivatives, and can solve the problems of complicated process and low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

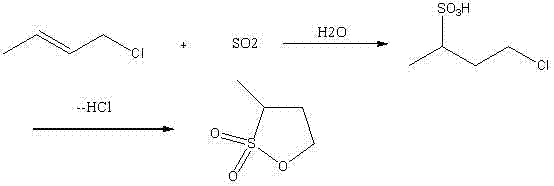

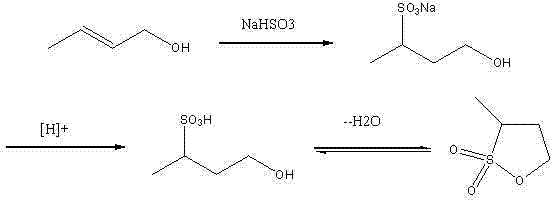

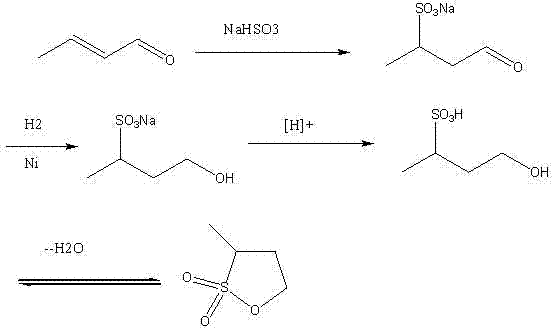

Image

Examples

Embodiment 1

[0021] Add 252 grams (2mol) of anhydrous sodium sulfite and 500ml water into a 1000ml three-necked flask equipped with a stirrer and a thermometer, and stir until they are evenly mixed. Control the reaction temperature not to exceed 50°C, the pH value is 6.5, and ensure the presence of sodium sulfite and sodium bisulfite in the system, add a mixed solution of 72 grams (1mol) of butenol and 20ml of sulfuric acid dropwise within 2 hours, dropwise After completion, continue to stir for 30 minutes, then adjust the pH value to 3.0, concentrate the reaction solution, cool, filter to remove crystalline sodium sulfate, and wash with absolute ethanol several times, combine the filtrate and washing solution to form sodium hydroxybutanesulfonate aqueous solution.

[0022] Add 90ml of concentrated hydrochloric acid and 200ml of absolute ethanol to the aqueous solution of sodium hydroxybutane sulfonate, stir for 15 minutes and freeze in a freezer to 0°C, filter to remove the precipitated s...

Embodiment 2

[0025] Add 150 g (1.5 mol) of anhydrous sodium bisulfite and 500 ml of water into a 1000 ml three-neck flask equipped with a stirrer and a thermometer, so that the sodium bisulfite and water are fully miscible. Control the reaction temperature not to exceed 50°C, and the pH value is 6.5. Add 72 grams (1mol) of butenol solution dropwise within 2 hours. After the dropwise addition, continue to stir for 30 minutes. After adjusting the pH value to 3.0, the reaction solution is Concentrate, cool, filter to remove crystalline sodium sulfate, and wash several times with absolute ethanol. The filtrate and the washing solution are combined to form an aqueous solution of sodium hydroxybutane sulfonate.

[0026] Add 90ml of concentrated hydrochloric acid and 200ml of absolute ethanol to the aqueous solution of sodium hydroxybutane sulfonate, stir for 15 minutes, place in a freezer to freeze to 0°C, remove the precipitated sodium chloride by filtration, and wash the sodium chloride crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com