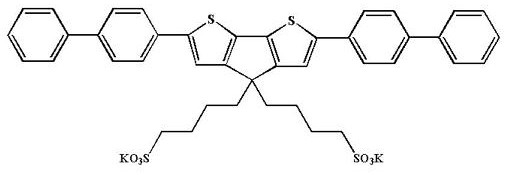

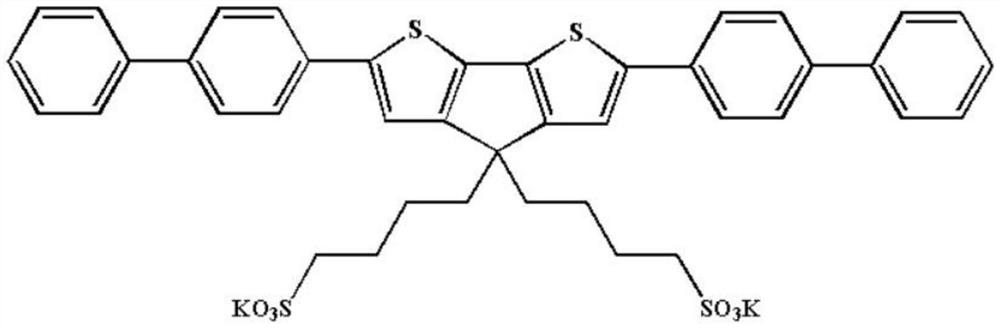

A kind of small molecule hole transport material for organic solar cell and its preparation method

A hole transport material, solar cell technology, applied in organic chemistry, circuits, photovoltaic power generation, etc., can solve the problems of poor repeatability, complicated preparation process, etc., and achieve the effect of simple preparation process, excellent water solubility and film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

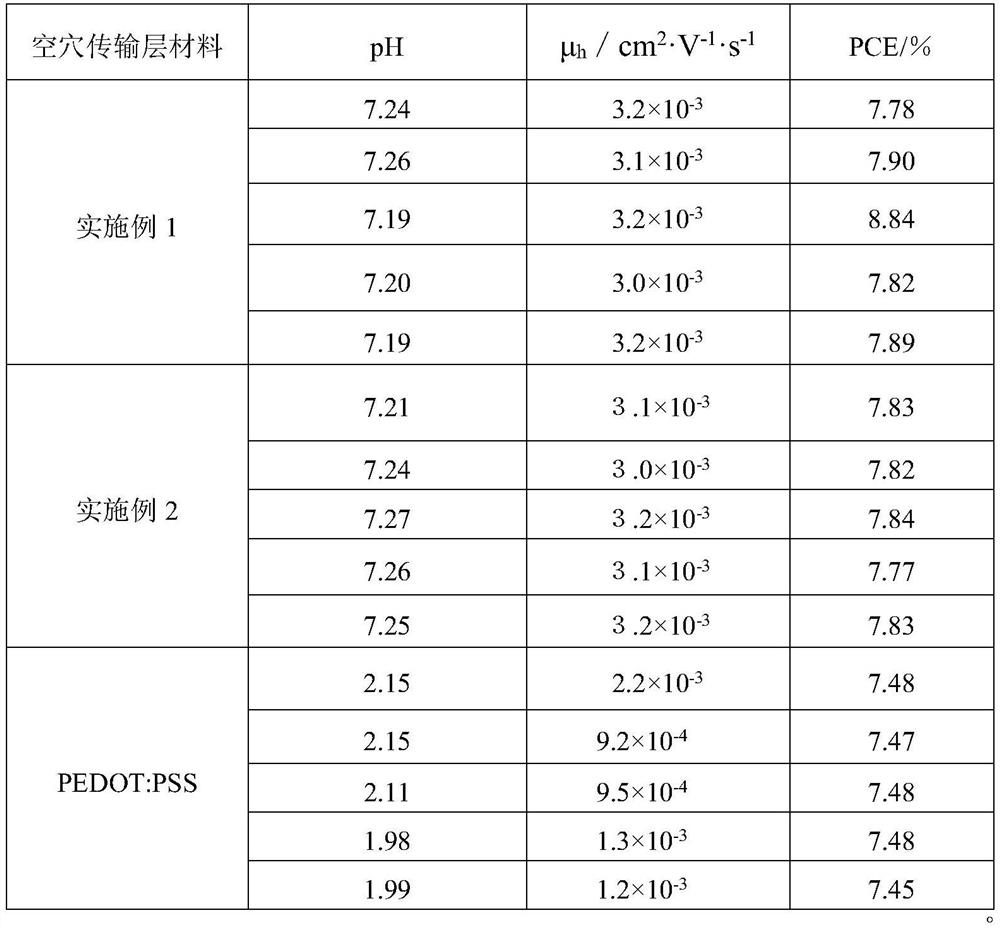

Examples

Embodiment 1

[0020] Add 1.0 molar parts of cyclopentathiophene and 20.0 milliliters of dimethyl sulfoxide to a glass three-necked flask, mechanically stir at room temperature for 20 minutes, then add 20.0 milliliters of 1.0 mol / liter potassium hydroxide aqueous solution and 2.0 molar parts of 1,4 Butane sultone, stirred mechanically at room temperature for 2.0 hours, then poured all the reactants in the glass three-necked flask into 100.0 ml of acetone, stirred mechanically at room temperature for 30 minutes, and then filtered with suction to obtain a solid intermediate product A;

[0021] Add 1.0 molar parts of intermediate product A and 30.0 milliliters of N,N-dimethylformamide to a three-necked glass flask, mechanically stir at room temperature for 20 minutes, then add 20.0 milliliters of N-bromosuccinimide and 20.0 ml of distilled water, stirred mechanically at room temperature for 1.0 hour, then poured all the reactants in the glass three-neck flask into 100.0 ml of acetone, stirred me...

Embodiment 2

[0024] Add 1.0 molar parts of cyclopentathiophene and 20.0 milliliters of dimethyl sulfoxide to a glass three-necked flask, mechanically stir at room temperature for 20 minutes, then add 20.0 milliliters of 1.0 mol / liter potassium hydroxide aqueous solution and 2.0 molar parts of 1,4 Butane sultone, stirred mechanically at room temperature for 3.0 hours, then poured all the reactants in the glass three-neck flask into 100.0 ml of acetone, stirred mechanically at room temperature for 30 minutes, and then filtered with suction to obtain a solid intermediate product A;

[0025] Add 1.0 molar parts of intermediate product A and 30.0 milliliters of N,N-dimethylformamide to a three-necked glass flask, mechanically stir at room temperature for 20 minutes, then add 20.0 milliliters of N-bromosuccinimide and 20.0 ml of distilled water, stirred mechanically at room temperature for 1.0 hour, then poured all the reactants in the glass three-neck flask into 100.0 ml of acetone, stirred mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com