Mortar template for high intensity adjustment

A high-strength, mortar technology, applied in the field of construction, can solve problems such as difficult to achieve effects, irregular height differences, labor costs, etc., and achieve the effect of strong plasticity, simple and convenient production, and meet the strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Mix the mortar with 32.5 grade cement, water, sand with a fineness modulus of 2.3-3.7 and 902 glue in a weight ratio of 1:0.4:1.8:0.1.

[0022] 2. According to the needs, use the above-mentioned mixed mortar to make the mortar template for adjustment:

[0023] Taking the vase-shaped column piers of urban viaducts as an example, the vase-shaped column piers of the same type have the same height and form of the variable section section, but the standard section (straight section) has different heights, and the height difference is irregular. The mantissa of the difference is usually in millimeters, so it is inconvenient to customize a complete set of general templates for the standard section of the vase-shaped column piers of urban viaducts.

[0024] In order to solve the above problems, the steel formwork can be customized for the standard section of the pier according to a certain pier with centimeters as the unit of measurement, and then the mortar formwork of this...

Embodiment 2

[0028] 1. Mix the mortar with 42.5 grade cement, water, sand with a fineness modulus of 2.3-3.7 and 903 glue in a weight ratio of 1:0.4:1.8:0.2;

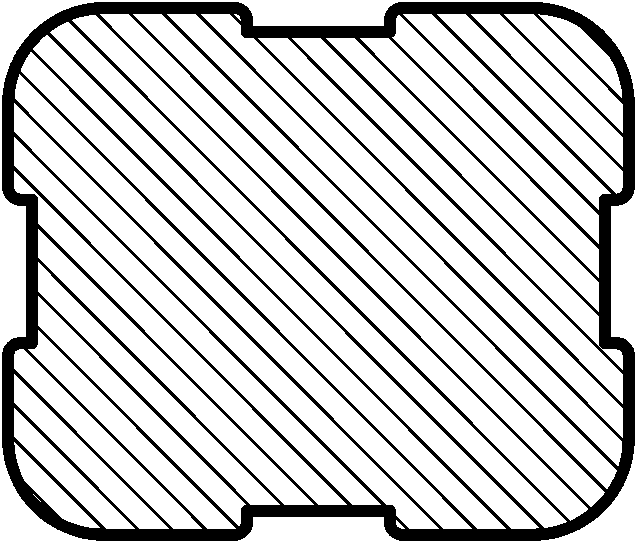

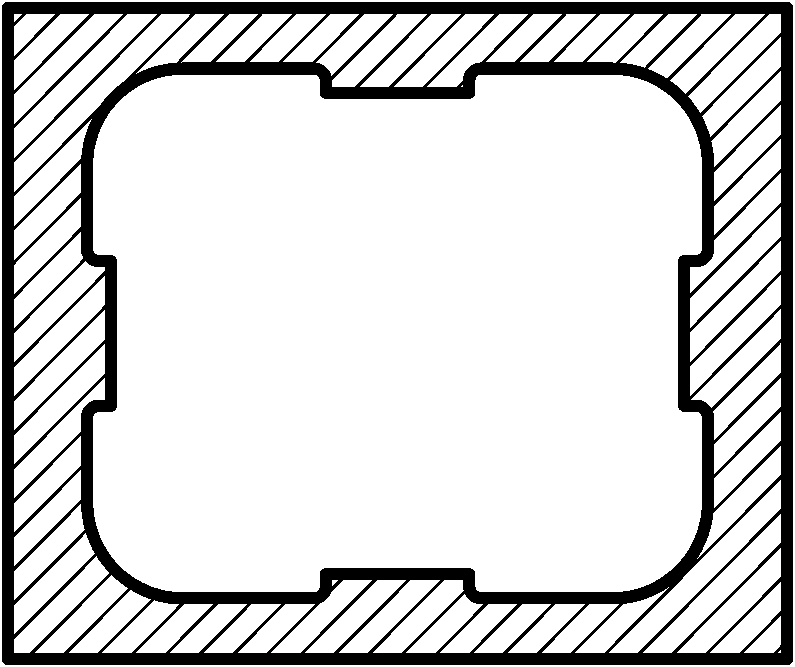

[0029] 2. to image 3 (A cross-section of the pier standard section) shown in the urban viaduct vase-shaped pier pier standard section as an example, according to Figure 4 ( image 3 The shown cross-section of the mortar formwork of the standard section of the pier) First make a large sample of the pier edge, then draw the pier edge on the cap, and then build the mortar prepared in step 1 layer by layer. The thickness of each layer of masonry should not exceed 2cm , and during the masonry process, after each layer of mortar masonry is completed, the release agent is applied and cured to obtain image 3 The mortar formwork for the adjustment of the standard section of the pier shown.

[0030] Strength measurement: After mixing the mortar according to this mix ratio, make two groups of mortar test blocks, and carry out compressive...

Embodiment 3

[0032] 1. Mix the mortar with 32.5 grade cement, water, sand with a fineness modulus of 2.3-3.7 and 901 glue in a weight ratio of 1:0.4:2.2:0.1;

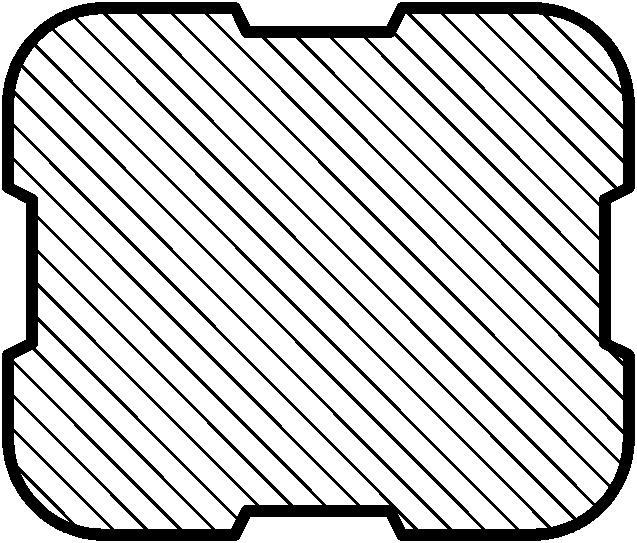

[0033] 2. to Figure 5 (A kind of cross-section of the pier standard section) shown in the urban viaduct vase-shaped column pier standard section as an example, according to Figure 6 ( Figure 5 The shown cross-section of the mortar formwork of the standard section of the pier) First make a large sample of the pier edge, then draw the pier edge on the cap, and then build the mortar prepared in step 1 layer by layer. The thickness of each layer of masonry should not exceed 2cm , and during the masonry process, after each layer of mortar masonry is completed, the release agent is applied and cured to obtain Figure 5 The mortar formwork for the adjustment of the standard section of the pier shown.

[0034] Strength measurement: After mixing the mortar according to this mix ratio, make two groups of mortar test blocks, and carry ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com