Rubber shock insulation system between steel structure module building columns

A technology of rubber vibration isolation pad and steel structure, applied in the direction of buildings, building components, building types, etc., can solve the problems of structural damage, large axial force, structural axial deformation, etc., to reduce adverse effects and improve bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of this patent will be further described below in conjunction with the accompanying drawings.

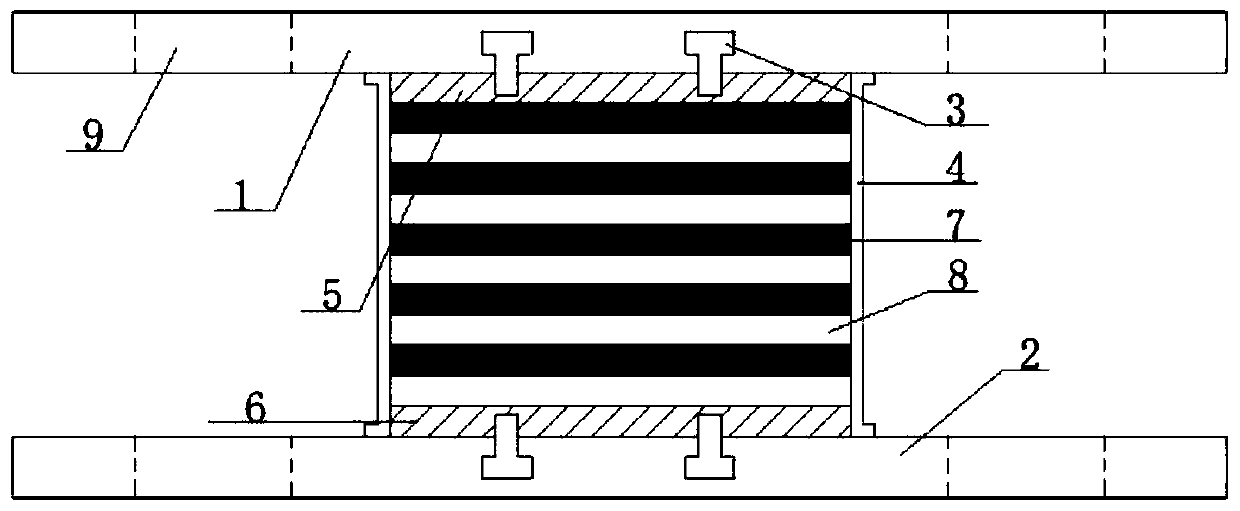

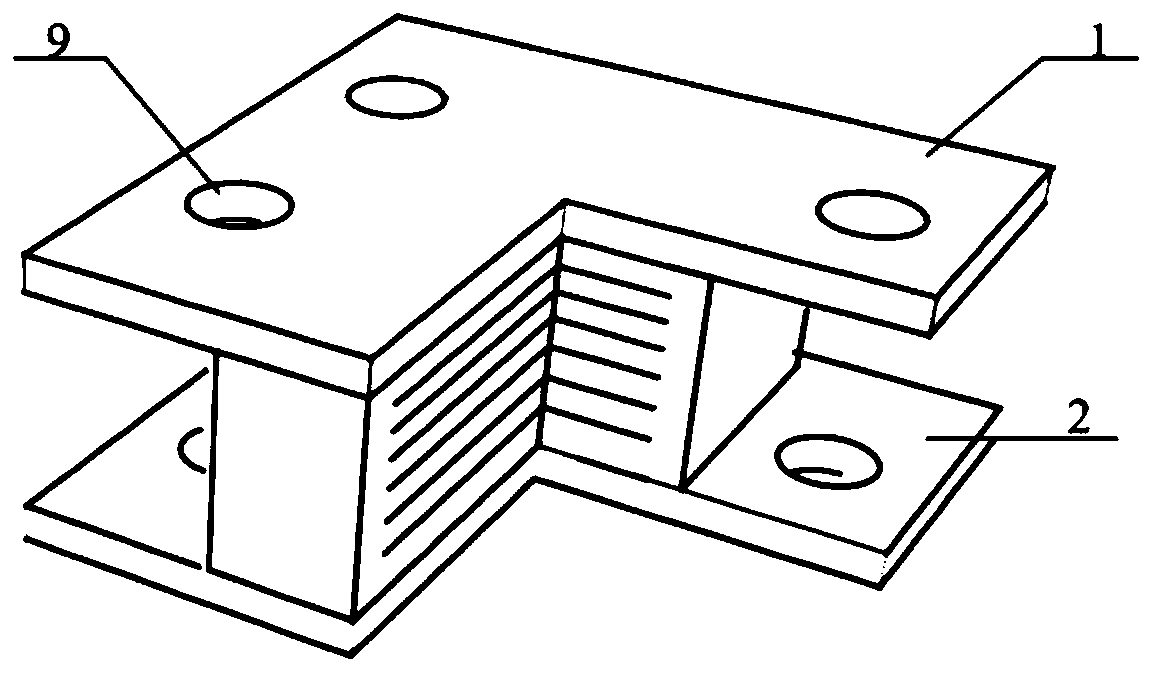

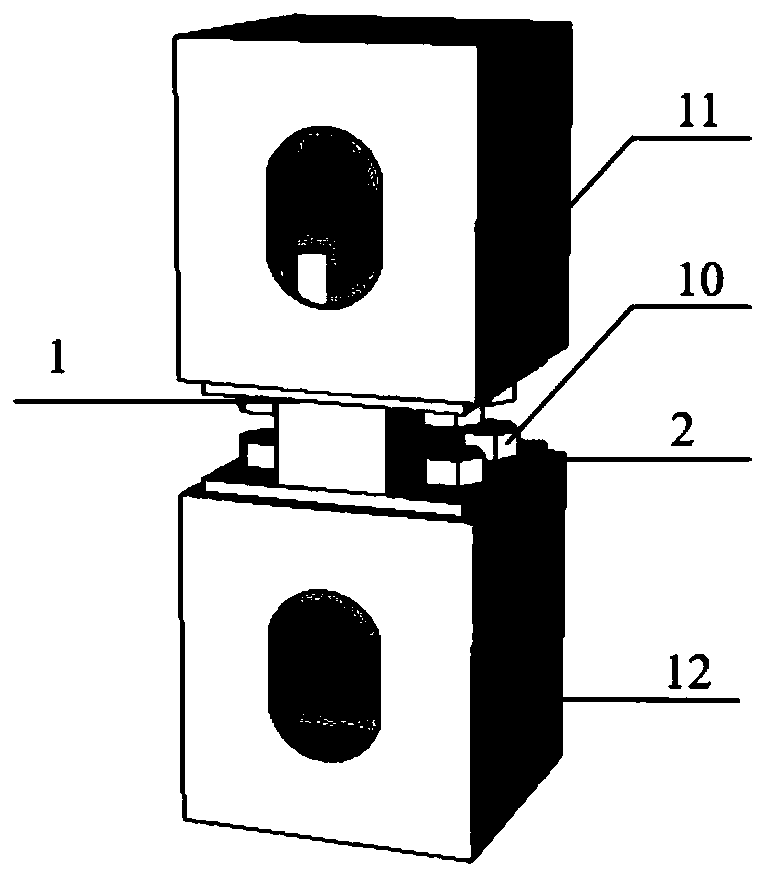

[0020] The present invention provides a steel structure modular building rubber shock-isolation system, comprising an upper module column 13, a lower module column 14, an upper module beam 15, a lower module beam 16, an upper module column corner piece 11, a lower module column corner piece 12 and rubber Shock-isolation pad 17, rubber shock-isolation pad 17 plays the effect of good connection, and whole rubber shock-isolation system 18 is connected as a whole (as Figure 4 shown). Among them, the welding connection between the upper module column 13, the lower module column 14, the upper module beam 15, the lower module beam 16 and the upper module column corner piece 11 and the lower module column corner piece 12 are all processed in the factory. Among them, such as figure 1 As shown, the rubber shock-absorbing pad includes an upper conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com