Construction Method for Assembling Ventilation Ducts in Metro Vaulted Roofs

A technology for ventilation pipes and construction methods, which is applied in the field of assembly-type construction of ventilation and air-conditioning pipes, and can solve the problems of high-quality personnel, construction without using limited space, and high risks in cutting and welding operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

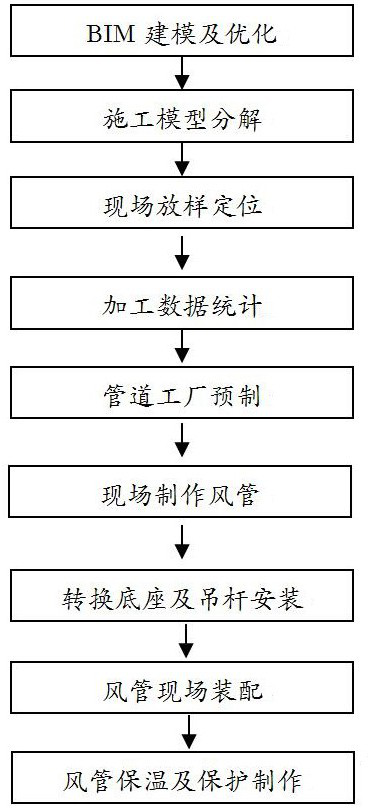

[0061] This embodiment provides a construction method for assembling ventilation ducts on a subway vaulted roof, which includes the following steps.

[0062] Step 1: BIM modeling and optimization

[0063] Establish the model according to the professional drawings of ventilation and air conditioning, use BIM technology to model the actual installation situation on site, and fully reflect the pipelines, equipment and walls related to the construction and installation of the air duct in the model, so as to achieve visual disclosure and determine the air duct installation location;

[0064] Carry out collision detection between the air duct and other pipelines, count and classify the collision points, form a statistical table of influencing factors, and draw their frequency curves, and optimize them according to the following principles:

[0065] (1) The wind is above, the electricity is in the middle, and the water is below;

[0066] (2) Big first and then small, the small tube...

Embodiment 2

[0106] Take the installation of the large-end refrigerated air-conditioning machine room at Pingguoyuan South Road Station as an example. The total air duct installation of the air-conditioning machine room at Pingguoyuan South Road Station is 2000m 2 , The "fixed-length board + on-site" assembly of the galvanized air duct on the arched roof of the subway, the process is simplified, safe and efficient.

[0107] See Table 1 for the statistics of the influencing factors in Step 1.

[0108]

[0109] According to the above table, make a graph of the frequency of occurrence, such as Figure 4 shown.

[0110] In steps 4 and 5, the reserved length of the bite is 0.035m.

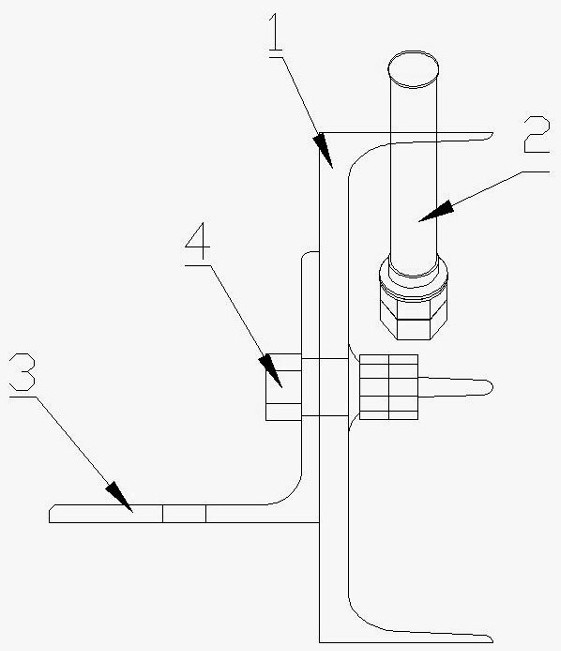

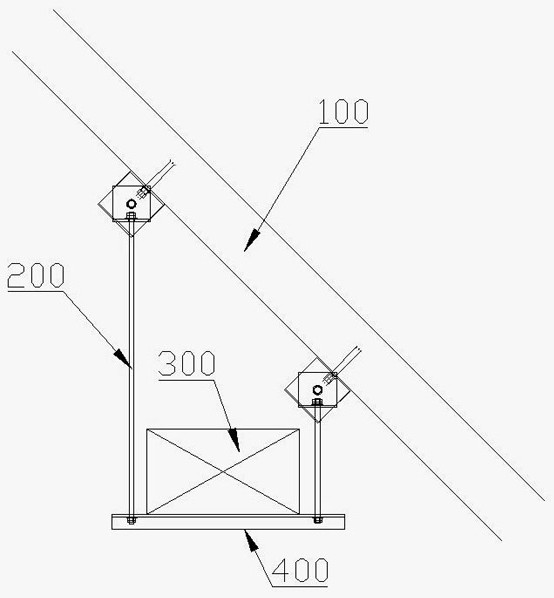

[0111] The use of the conversion base solves the problem of air duct hoisting and vertical installation. The introduction of galvanized fixed-length plates greatly reduces the loss of the plates, facilitates transportation, and reduces the time for workers to adjust the air ducts. See Table 2 for the benefit co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com