Modularized detachable constructed wetland

A constructed wetland and dismantling technology, which is applied in the field of distributed domestic organic wastewater treatment, can solve the problems of shortened wetland construction time and low land shape requirements, and achieve the effects of low cost, convenient management, and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

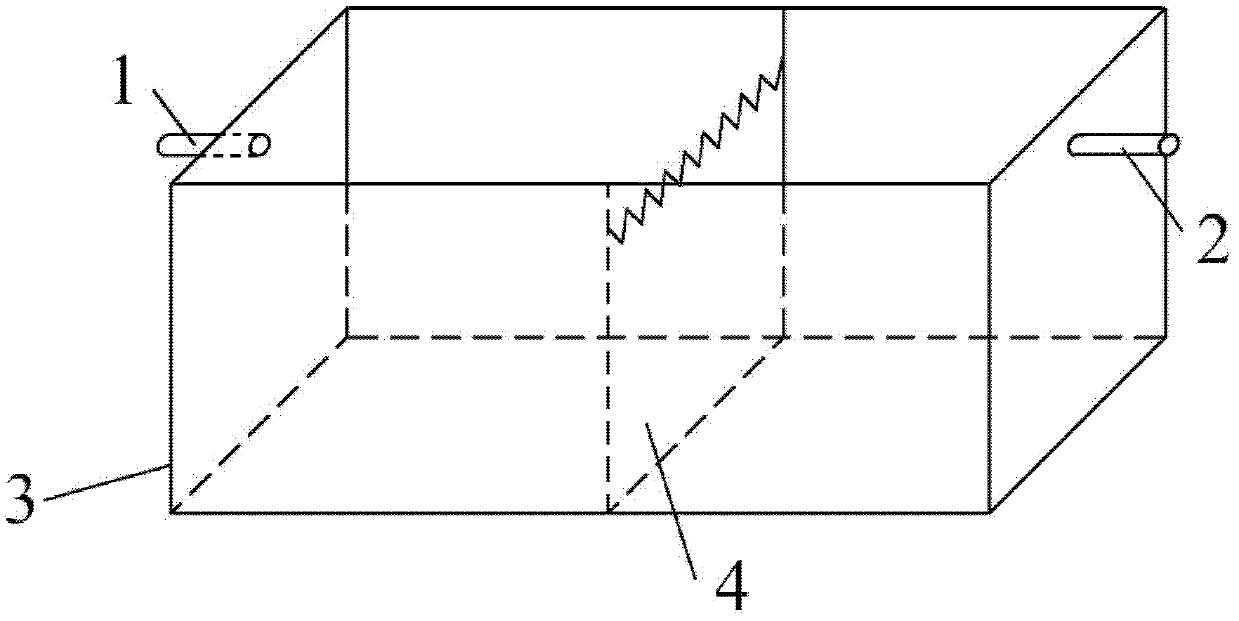

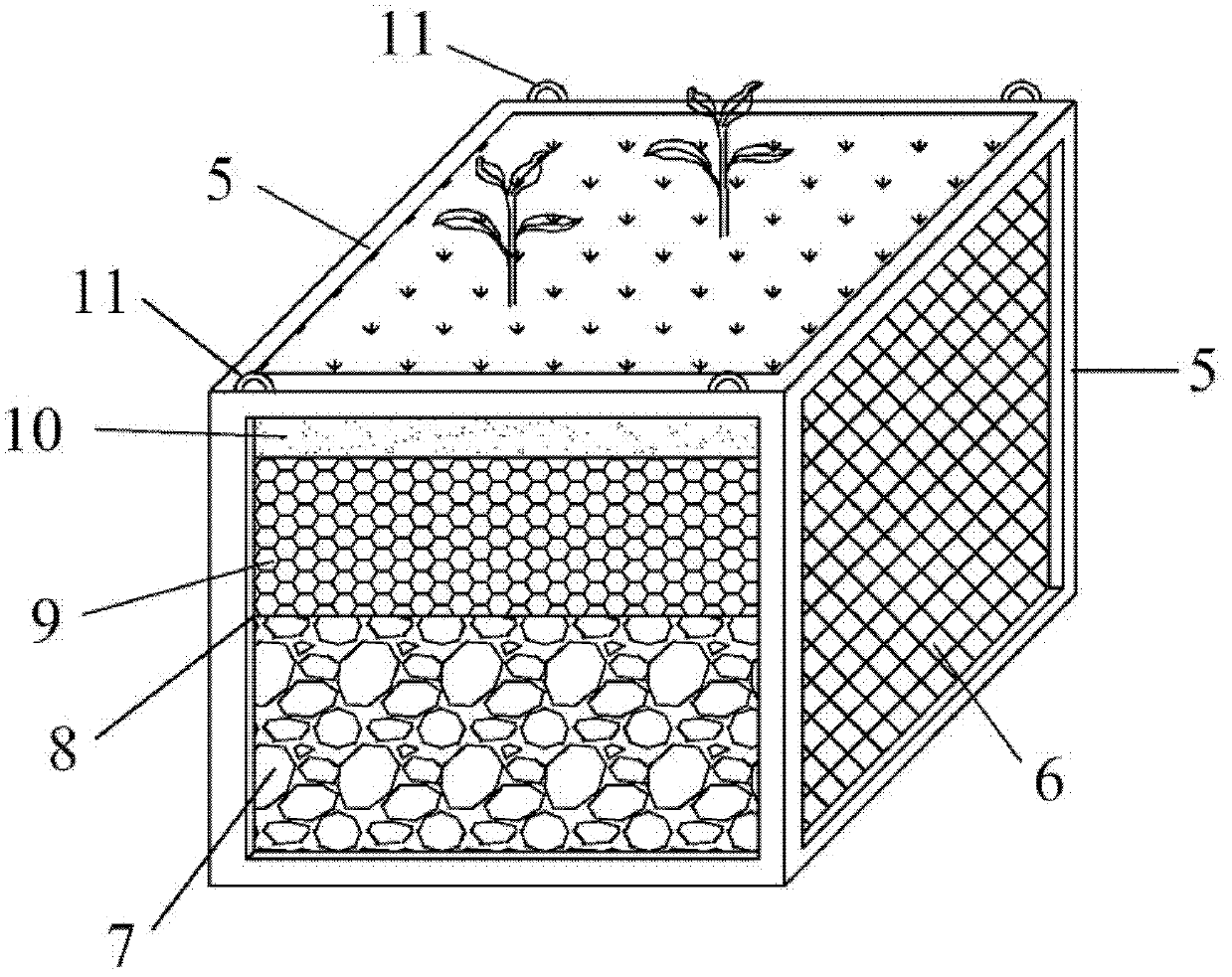

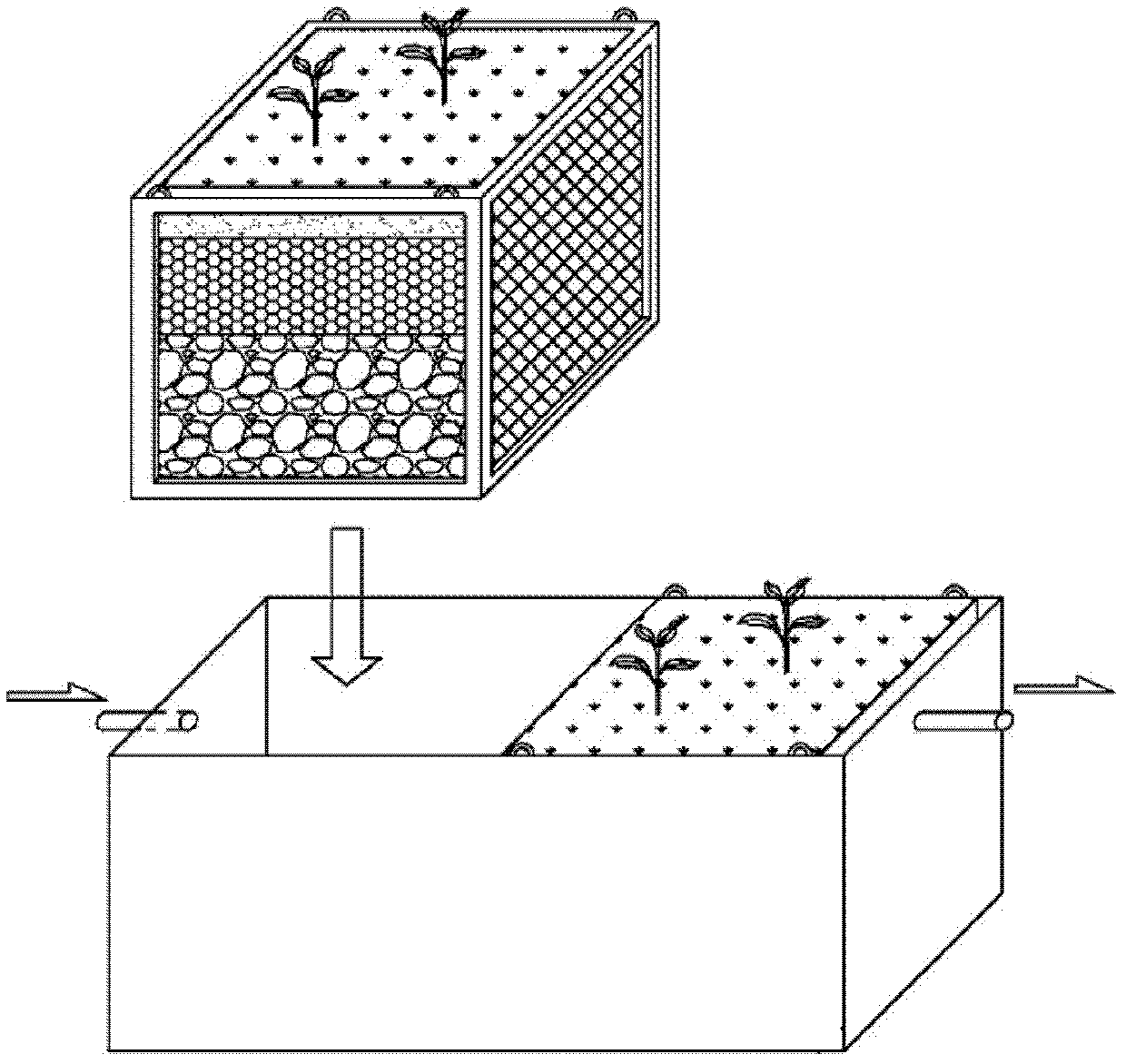

[0027] The artificial wetland described in the figure is composed of four independent modular units (12) combined in series and parallel connection. The modular units (12) are set up and made of iron plate materials to form a modular box (3). (3) A water inlet pipe (1) is arranged at the front, a water baffle (4) is arranged between the filling units (13), and a water outlet pipe (2) is arranged at the rear of the module box (3). Each module unit (12) is provided with four packing units (13), the packing unit frame (5) of the packing unit (13) is made of metal, and the packing unit frame (5) is equipped with a lifting ring (11), and the packing unit Metal grids (6) are arranged around and at the bottom of the unit frame (5); the filler unit (13) is filled with foam ceramics (7), filter sponges (8), light porous ceramsites (9) and sand from bottom to top. (10) Planting wetland plants on sandy soil.

Embodiment 2

[0029] The constructed wetland is composed of three independent modular units (12) combined in series. The modular unit (12) is made of cement modules to form a modular box (3), and a water inlet pipe is set in the front of the modular box (3) (1) A water baffle (4) is arranged between the packing units (13), and a water outlet pipe (2) is installed at the rear of the module box (3). Each module unit (12) is equipped with two packing units (13), the packing unit frame (5) of the packing unit (13) is made of metal, and the packing unit frame (5) is equipped with a lifting ring (11), and the packing unit Plastic grids (6) are arranged around and at the bottom of the unit frame (5); the packing unit (13) is filled with foam ceramics (7), filter sponges (8), light porous ceramsites (9) and sand from bottom to top. (10) Planting wetland plants on sandy soil.

Embodiment 3

[0031] This constructed wetland is composed of six independent modular units (12) combined in parallel. The modular units (12) are set up to be made of plastic and steel as a framework to form a modular box (3), in the front of the module box (3) A water inlet pipe (1) is arranged, a water baffle (4) is arranged between the filling units (13), and a water outlet pipe (2) is installed at the rear of the module box body (3). Each module unit (12) is equipped with two packing units (13), the packing unit frame (5) of the packing unit (13) is made of metal, and the packing unit frame (5) is equipped with a lifting ring (11), and the packing unit Plastic grids (6) are arranged around and at the bottom of the unit frame (5); the packing unit (13) is filled with foam ceramics (7), filter sponges (8), light porous ceramsites (9) and sand from bottom to top. (10) Planting wetland plants on sandy soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com