Foamed aluminum substrate sound barrier of U-shaped beam of metro

A foamed aluminum and sound barrier technology, applied in construction, noise absorption devices, etc., can solve the problems of brittle sound-absorbing board material, complicated manufacturing process, unfavorable on-site installation, etc., and achieve simple processing and manufacturing, convenient rectification and disassembly, and convenient The effect of installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

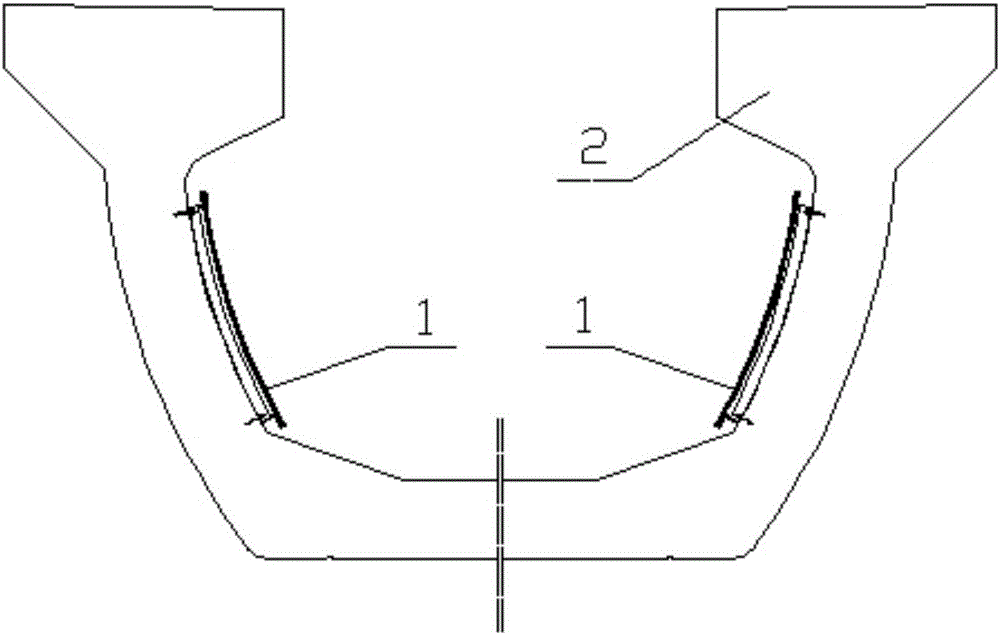

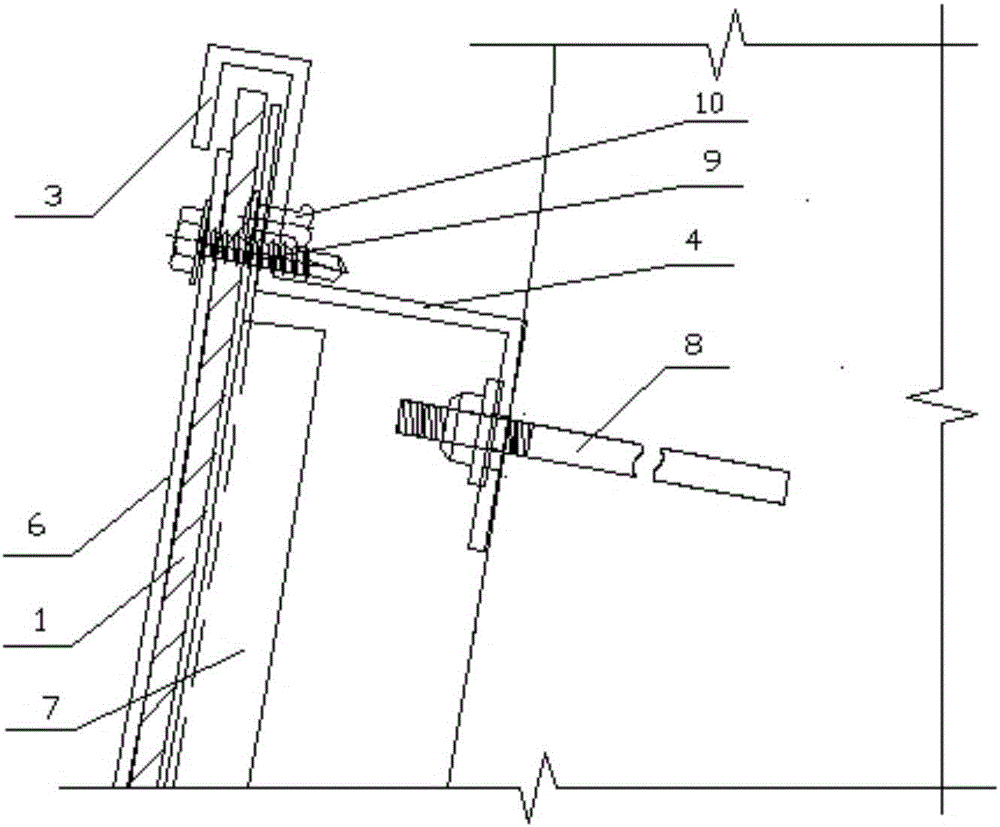

[0015] Such as figure 1 As shown, the subway U-beam foam aluminum substrate sound barrier includes a plurality of chemical anchor bolts 8 with a strength of 10.9, which are fixed to the webs on both sides of the U-beam 2 of the subway track as the top support 4 and bottom support of the keel. Part 5, the strength of the chemical anchor bolt is 10.9, the top support 4 and the bottom support 5 are fixed to the U-shaped beam web with nuts using pre-embedded chemical anchor bolts, which is easy to install.

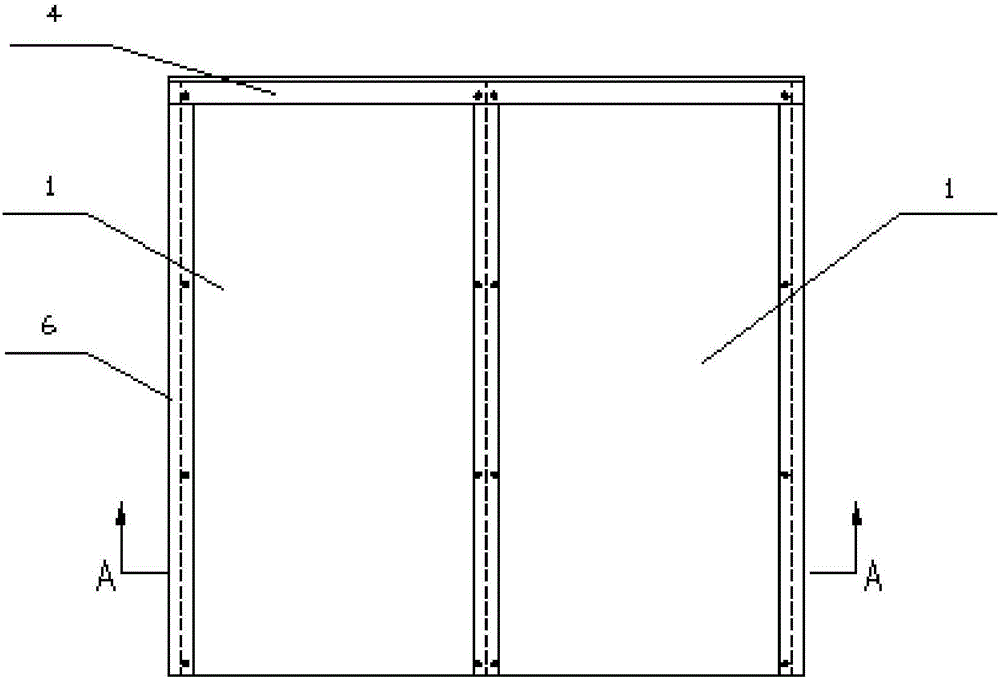

[0016] Such as Figure 2-5 As shown, the aluminum foam sound-absorbing panel 1 is arranged between the top support 4 and the bottom support 5 , and the top support 4 , bottom support 5 and the sound-absorbing panel 1 are fixed by blind rivets 10 . The aluminum foam board used as the sound-absorbing board 1 has a through-hole structure with a thickness ≥ 5mm, a throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com