Method for reinforcing fractured lining of existing railway tunnel

A technology of existing lines and railways, applied in tunnel lining, tunnel, shaft lining and other directions, it can solve problems such as low remediation efficiency, secondary cracking of lining, and falling blocks, so as to avoid secondary interference, resist surrounding rock pressure, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

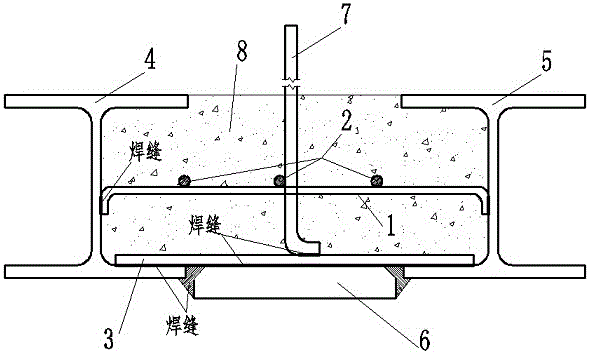

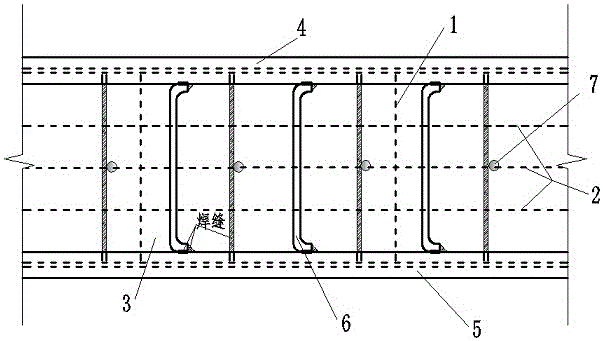

[0015] A method for reinforcing a cracked lining of an existing railway tunnel, comprising a steel arch (4), a steel arch (5), a steel plate (3), a circumferential steel bar (2), a longitudinal connecting steel bar (1), and a steel plate reinforcing steel bar (6), the anchor rod (7), and the formwork concrete (8), characterized in that: the steel plate (3) is welded on the inner side of the outer edge of the steel arch (4) and the steel arch (5), and the steel plate (3) is welded according to the site The radian of the steel arch is bent, three circumferential steel bars (2) are erected between the steel arch (4) and the steel arch (5), and longitudinal connecting steel bars (1) are laid to form a circumferential steel mesh, and steel plates reinforce the steel bars (6) Weld the outside of the steel plate (3) between the steel arch (4) and the outer edge of the steel arch (5), weld the bolt (7) to the steel plate (3), and connect the steel plate (3) to the chisel. Concrete (8)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com