Self-propelled movable formwork for construction of double-rectangle water conservancy aqueduct

A mobile formwork and self-propelled technology, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems of large construction loss of full-scale supports, a large amount of labor and materials, and high requirements for foundation bearing capacity. Simple structure, good linear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

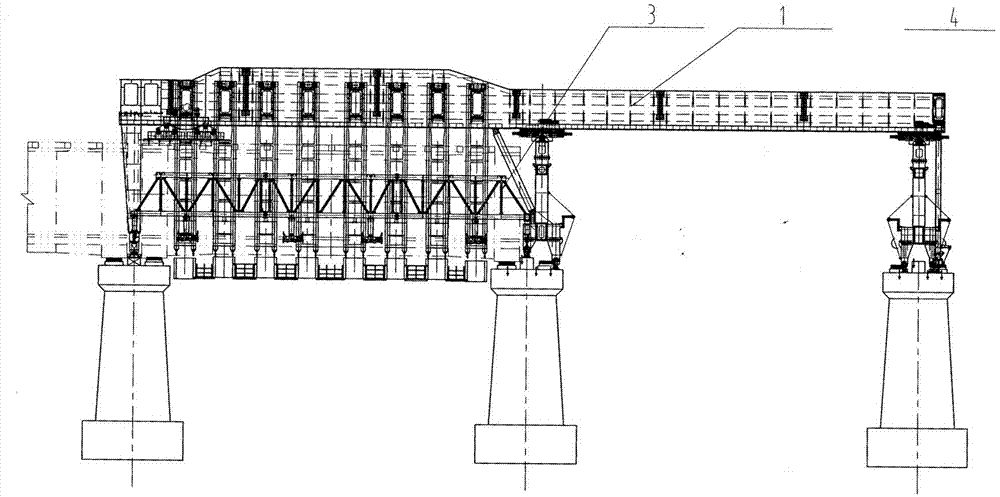

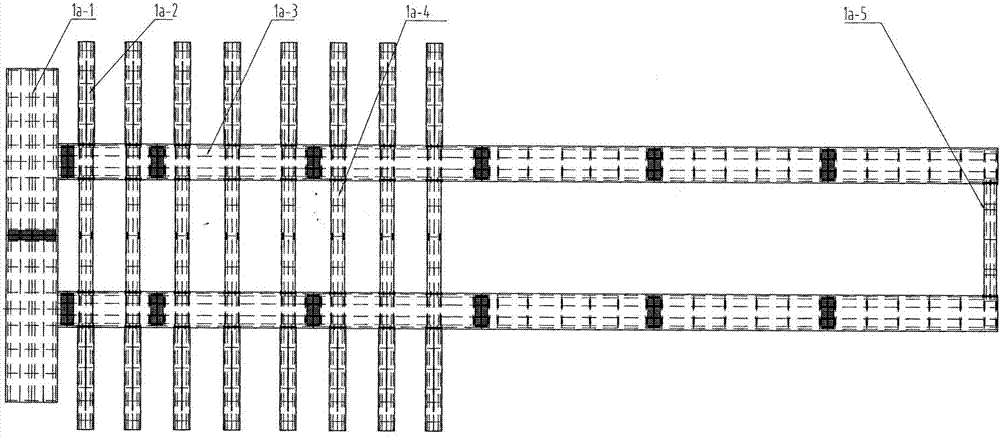

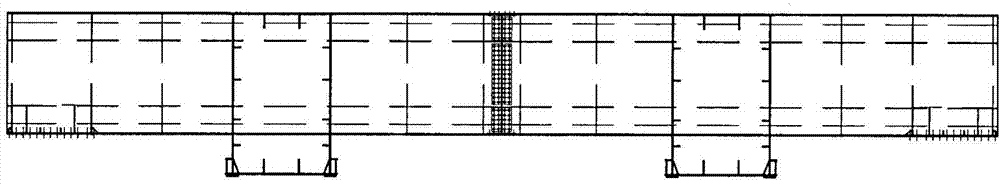

[0069] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, the self-propelled mobile formwork for the construction of double rectangular hydraulic aqueducts of the present invention includes an outer beam system (1), an outer mold system (2), an inner beam system ( 3), the outer mold system (4), the electric control system (5) and the hydraulic system (6); the outer beam system (1) is the main bearing system of the equipment, mainly composed of the outer beam (1a) , outer beam No. 1 leg (1b), outer beam No. 2 leg (1c), outer beam No. 3 leg (1d), outer beam No. 4 leg (1e), and outer beam rear travel (1f). where the outer beam (1a) (see Figure 9~14 As shown) is in the form of a box-shaped composite beam, which is in the form of double longitudinal beams (1a-3). The distance between the centers of the double longitudinal beams (1a-3) is 9.5 meters. -5), the rear con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com