Auxiliary laser repeating punching method and device for ceramics based on static solution

A laser and solution technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large surface residual stress, roundness of inner holes in the recasting layer, and increased cost, so as to reduce micro-cracks on the hole wall and eliminate Inner hole taper, the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

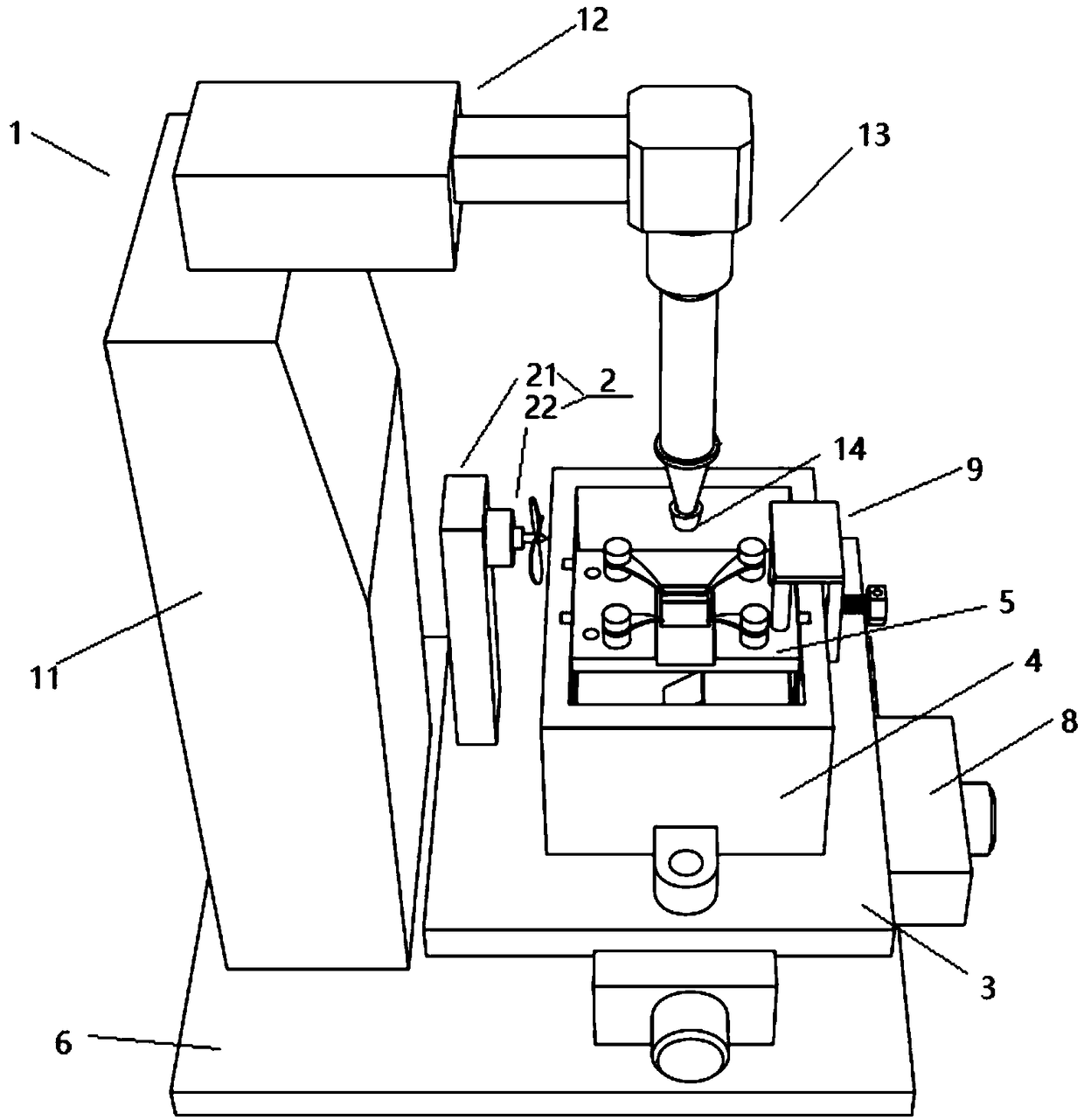

[0041] A method based on static solution-assisted ceramic laser repetitive drilling, comprising the following steps:

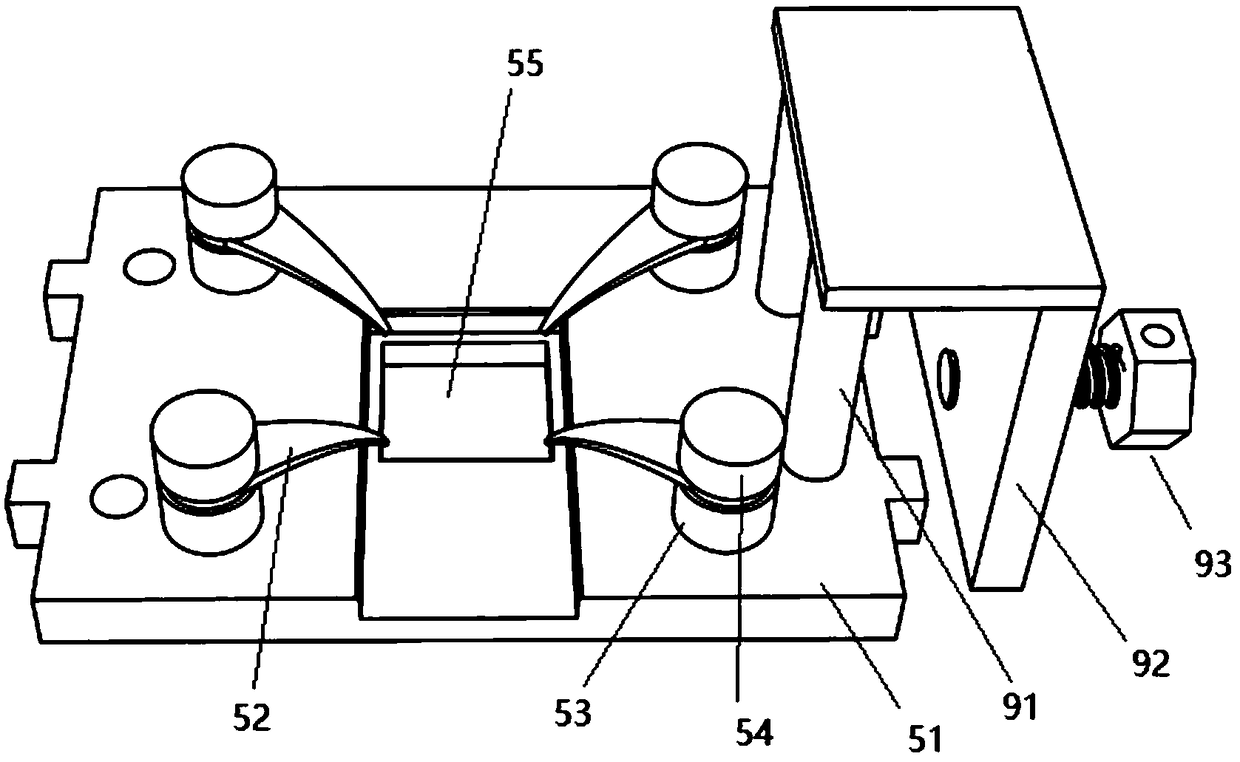

[0042] (1) Workpiece pretreatment: After grinding and polishing the surface of the workpiece to be processed, it is cleaned with absolute ethanol and acetone, and then the workpiece to be processed is fixed on the workpiece fixture of the punching device;

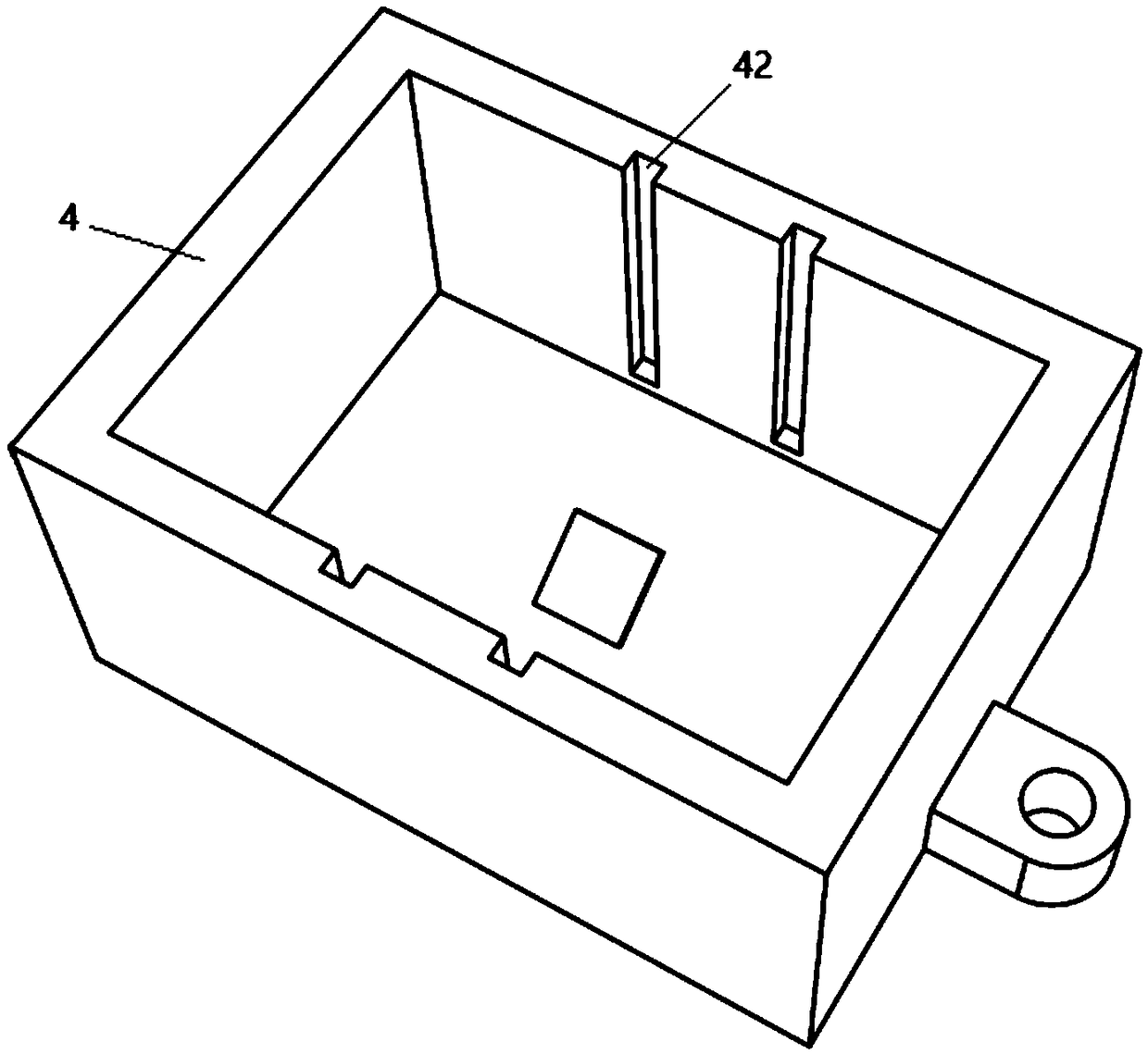

[0043] (2) Focus adjustment: The workpiece to be processed is lowered and immersed in the cooling liquid of the solution tank through the lifting device set on the workpiece fixture, the defogging fan is turned on, and the ball screw under the workbench is adjusted to align the laser with the workpiece to be processed;

[0044] (3) Drilling: adjust the defocus amount from the laser to the workpiece to be 0, adjust the pulse width of the laser to 0.5ms, adjust the frequency to 20Hz, turn on the laser, and the laser beam generated by the laser directly acts on the surface of the workpiece to be processed. Dri...

Embodiment 2

[0047] Change the pulse width and frequency of the laser in Embodiment 1 to 1.5 ms and 100 Hz respectively, and other steps and operations are consistent with Embodiment 1.

Embodiment 3

[0049] Change the pulse width and frequency of the laser in Embodiment 1 to 1.0 ms and 70 Hz respectively, and other steps and operations are consistent with Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com