A kind of preparation method of zirconia ceramic ultrafiltration membrane

A technology of zirconia ceramics and ultrafiltration membranes, applied in chemical instruments and methods, ultrafiltration, membrane technology, etc., can solve the problems of insufficient filtration accuracy, small permeation flux, and poor membrane strength, and achieve improved Production efficiency, high-precision filtration effect, effect of porosity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

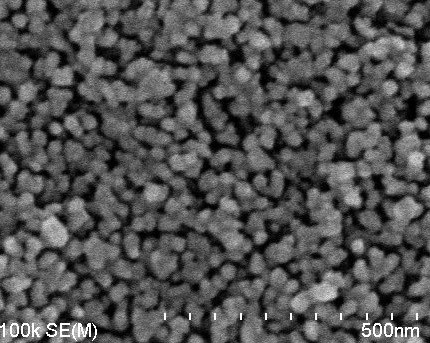

Embodiment 1

[0031] Dissolve 58g zirconium oxychloride octahydrate in 192g water, raise the temperature to 70℃, add 7.5% aqueous ammonia solution with stirring until the PH rises to 8.5, and stir for 2h to form a white emulsion. Filter the white emulsion with a filter, add water and filter several times until the chloride ion concentration is lower than 10PPM. Then, add water to 200g of the precipitate after suction filtration, raise the temperature to 70℃ and stir, slowly add 6.4% nitric acid aqueous solution until the PH of the solution drops to 1.5, and keep stirring at 70℃ for 10 hours. Then take out the solution, add 120g of water, 10g of glycerin, 10g of polyethylene glycol 1000, 20g of 20% polyvinyl alcohol aqueous solution, stir well, and dip the solution on the 200nm ceramic filter membrane substrate. After that, the substrate is dried, put into a high-temperature reaction kettle, and nitric acid aqueous solution with PH of 2 is added into the reaction kettle to submerge the whole cer...

Embodiment 2

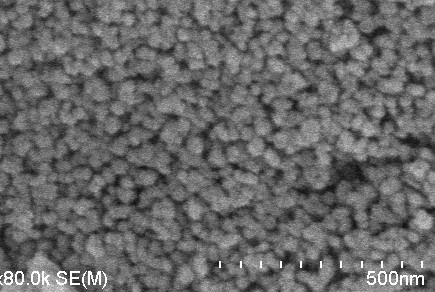

[0033] 50g of zirconium oxychloride octahydrate was dissolved in 192g of water, heated to 75℃ and stirred to add 7.2% aqueous ammonia solution until the PH rose to 8.2, and stirred for 2h to form a white emulsion. Filter the white emulsion with a filter, add water and filter several times until the chloride ion concentration is lower than 10PPM. Then, add water to 180g of the precipitate after suction filtration, raise the temperature to 70℃ and stir, slowly add 5% nitric acid aqueous solution until the PH of the solution drops to 0.5, and keep stirring at 75℃ for 10 hours. Then, take out the solution, add 120g of water, 12g of glycerin, 12g of polyethylene glycol 1000, 20g of 10% polyvinyl alcohol aqueous solution, stir well, and dip the solution on the 100nm ceramic filter membrane substrate. After that, the substrate is dried, put into a high-temperature reaction kettle, and the nitric acid aqueous solution with PH of 3 is added into the reaction kettle to submerge the whole ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com