Bubble generating device with tubular membrane

A technology of bubble generating device and tubular membrane, applied in water aeration, transportation and packaging, sustainable biological treatment, etc. Large equipment operating costs and other issues, to achieve the effect of small resistance, simple structure, energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

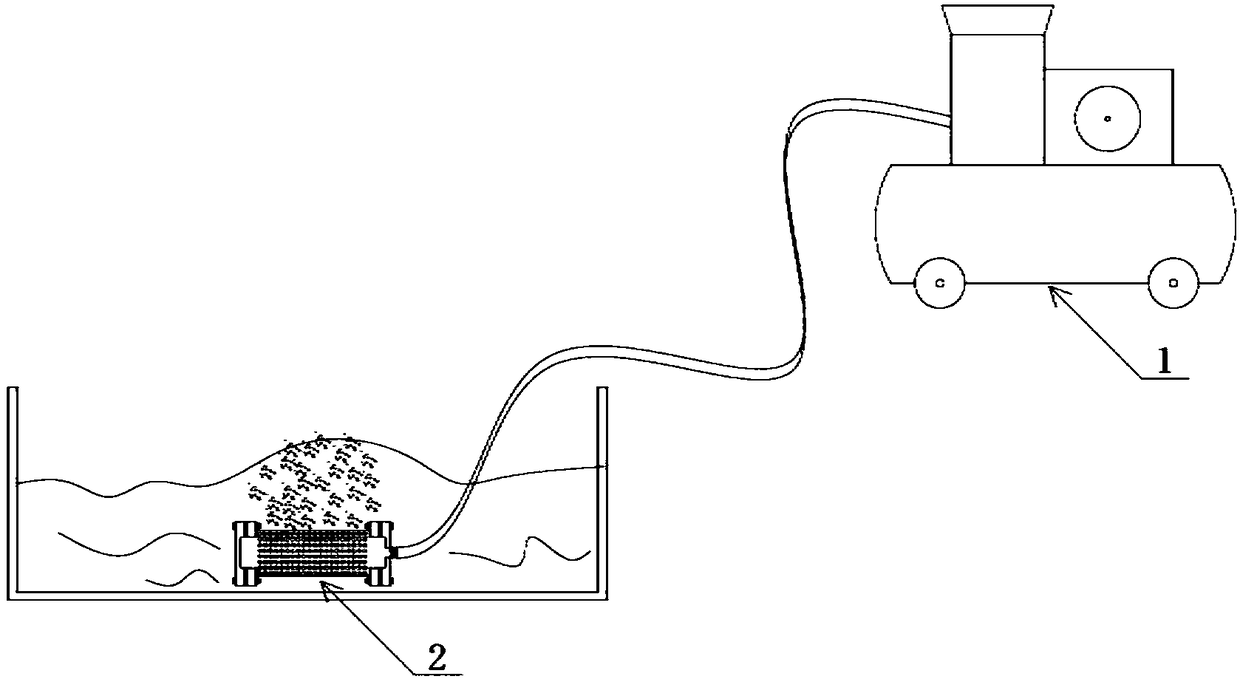

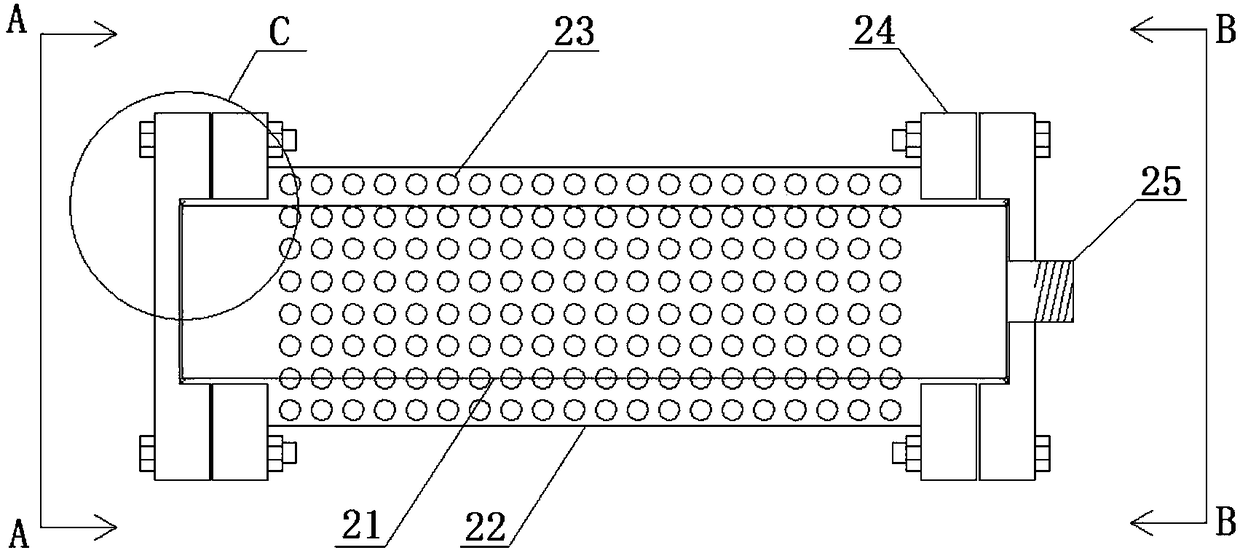

[0025] as attached Figure 1 to Figure 6 As shown, a tubular membrane bubble generating device includes an air compressor 1 and an air distribution head 2 connected to the air compressor 1, and the air distribution head 2 includes a tubular membrane 21 and is sleeved on the tubular membrane. A protective sleeve 22 outside the membrane 21 . The protective sleeve 22 is made of 316L material, and the protective sleeve 22 is uniformly provided with circular holes 23, the diameter of which is 5mm, and the two ends of the protective sleeve 22 respectively pass through the flanges 24 It is fixedly connected with the tubular membrane 21. The connection between the tubular membrane 21 and the flange 24 is provided with a rubber ring 26 for buffering and noise reduction. The tubular membrane 21 adopts a 0.1 μm microporous tubular membrane, and the tubular membrane 21 The air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com