Automatic digging mechanism of intelligent construction tunneling machine

An automatic excavation and intelligent building technology, applied in tunnels, buildings, rotary drilling rigs, etc., to achieve the effects of improving efficiency, uniform hole size, and improving excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

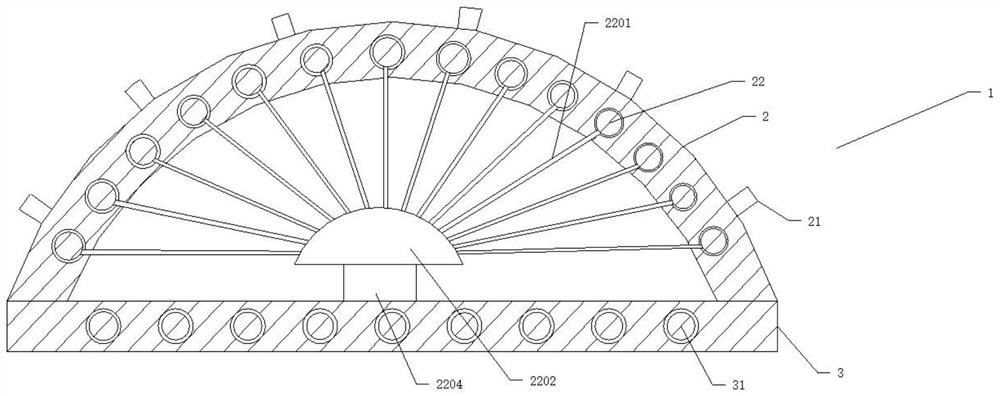

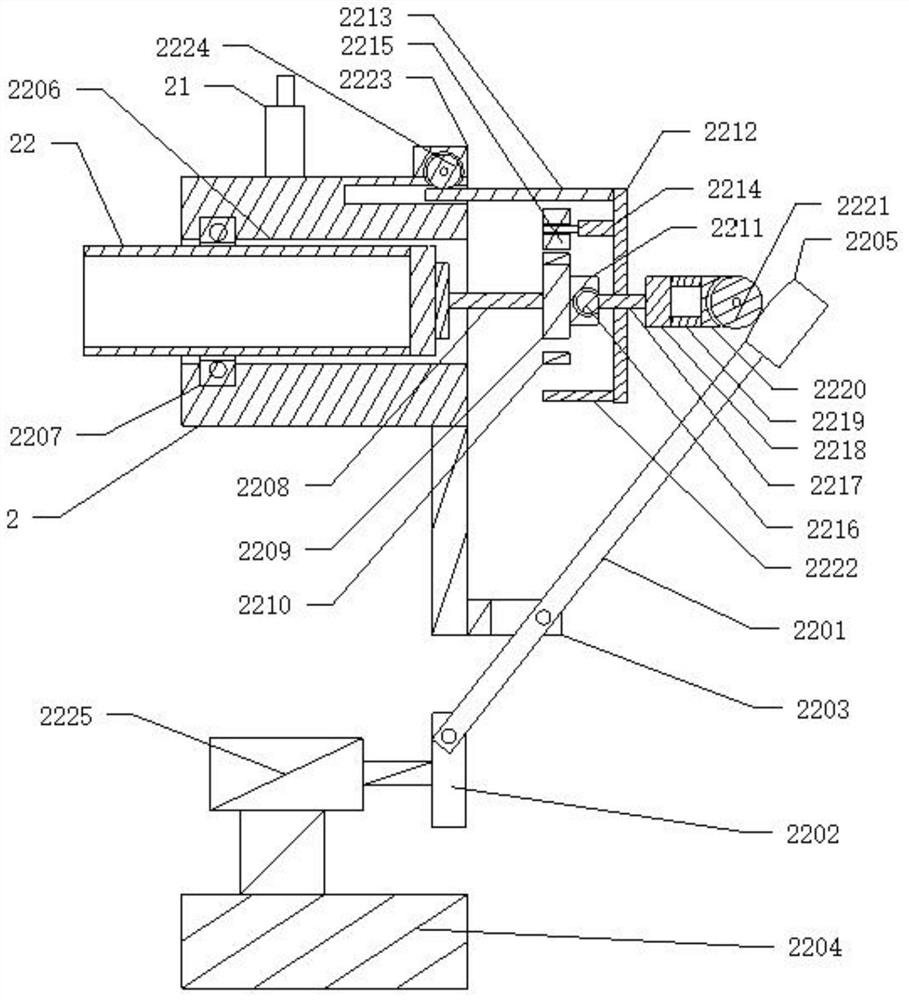

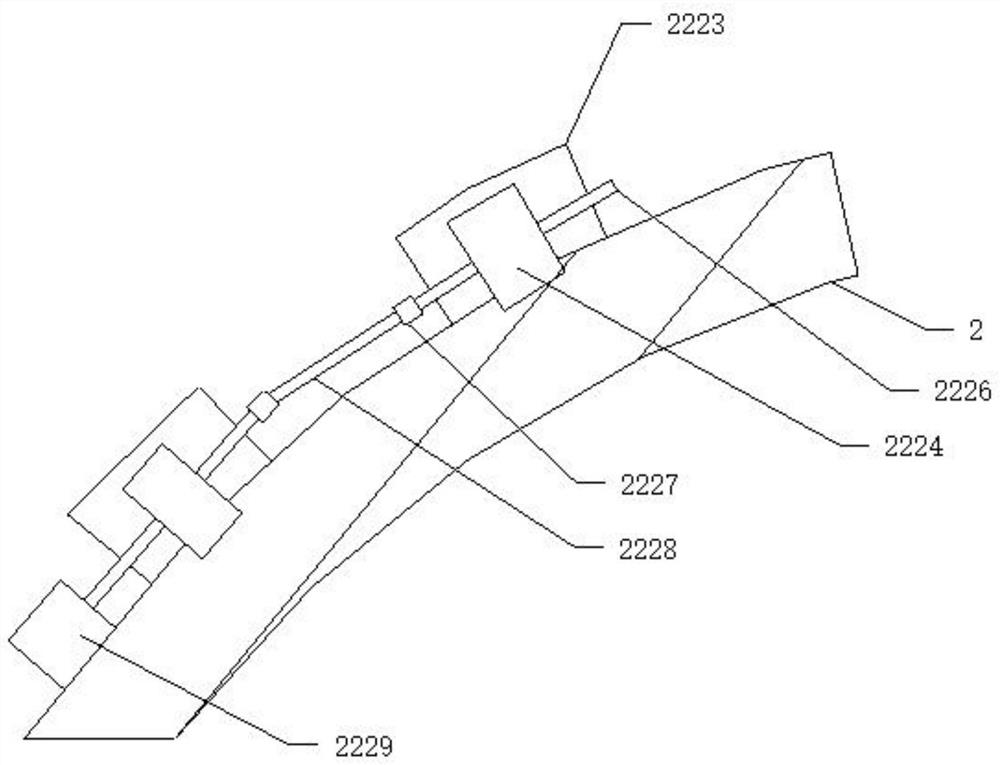

[0046] Such as Figure 1 to Figure 10 Shown, a kind of intelligent building tunnel machine includes automatic digging mechanism 1, knocking mechanism;

[0047] The automatic excavating mechanism 1 includes a first driving mechanism 2 and a second driving mechanism 3;

[0048] The second driving mechanism 3 is a cuboid structure, the first driving mechanism 2 is a semicircular structure, the first driving mechanism 2 is arranged on the second driving mechanism 3, and the first The tunneling mechanism 2 is provided with a first drill bit 22 that rotates synchronously and telescopically. The ends of the first drill bit 22 are respectively provided with a first pressing shaft 2208, and the ends of the first pressing shaft 2208 are respectively provided with a first pressing shaft. A sprocket 2209, the first sprocket 2209 rotates synchronously, a support base 2204 is set on the second driving mechanism 3, a second hydraulic rod 2225 is set on the support base 2204, the second hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com