Water-based directly-coated microfiber sofa leather

A technology of sofa leather and direct coating, which is applied in the direction of textiles and papermaking, can solve the problems of poor thickness uniformity and poor body shape of the leather, and achieve strong fastness, overcome the poor shape of the body, unique hygroscopicity and air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

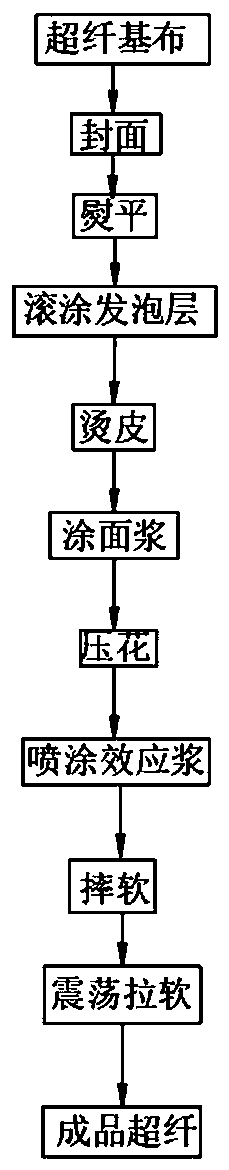

[0033] see figure 1 , the present invention provides the following technical solutions: a water-based direct-coating microfiber sofa leather, comprising a water-based direct-coating microfiber sofa leather production process, the water-based direct-coating microfiber sofa leather includes a microfiber base cloth, a cover, ironing, and a roller coating hair Bubble layer, ironing, surface paste, embossing, spray effect paste, falling softening, shock softening, finished microfiber;

[0034] The production process of water-based direct-coated microfiber sofa leather is as follows:

[0035] (1) Material selection: choose microfiber base cloth as the base material cloth; using microfiber base cloth, the structure is closer to genuine leather, and with the finishing of genuine leather, the microfiber leather has a more leather-like feel and durable characteristics. The performance is even better than that of real leather, making the appearance and internal structure of microfiber s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com