Patents

Literature

124 results about "Leather production processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The leather manufacturing process is divided into three sub-processes: preparatory stages, tanning and crusting. All true leathers will undergo these sub-processes. A further sub-process, surface coating may be added into the sequence. The list of operations that leathers undergo vary with the type of leather.

Animal fur clean depilation and fur fiber loosing method for preparing leather and application thereof

ActiveCN101235421AEliminate pollution and other issuesFine grainPre-tanning chemical treatmentFiberEnzyme system

The invention provides a method for unhairing leather and loosening leather fiber without sodium sulfide and lime in a leather production process and the application of the method. The method is characterized in that a method for combining unhairing by non-sulfur (sodium sulfide) depilatory under the alkaline condition and enzyme fiber loosening under the under the non-lime (lime) alkaline swelling condition are adopted, the enzyme unhearing and the enzyme fiber loosening take protease, lipase, amylase and glucoamylase as a compound enzyme system. The method achieves the effects for unhairing and loosening the leather fiber through adopting the method for combining compound enzyme water immersion, compound enzyme unhairing, unhairing with sodium sulfide depilatory, expansion regulator-sodium hydroxide expansion and the enzyme unhairing under the alkaline condition and eliminates the pollution which is brought by the sodium sulfide and the lime in animal unhairing or leather fiber loosening procedures in the leather production process. The method of the invention is suitable for unhairing and leather fiber dispersed processing of various animal leather of leather with various usages.

Owner:SICHUAN UNIV +1

Sturgeon skin chrome tanning leather production process

InactiveCN102199676ALow fat contentImprove use valueTanning treatmentPre-tanning chemical treatmentSturgeonLeather production processes

The invention discloses a sturgeon skin chrome tanning leather production process, which comprises the following steps: immersing in water; removing meat manually; degreasing; scraping oil slick; liming; scraping oil slick; liming again; scraping oil slick; deliming and softening; bleaching by oxidization; pickling; bleaching by reduction; chrome tanning; dyeing and greasing; re-tanning; washing; hanging and drying; and coating. In the invention, when the sturgeon skin chrome tanning leather production is adopted, the grease content in the sturgeon skin can be reduced obviously and the color of particle surface of the back of the sturgeon skin can be lightened; and thus, dyeing or production of light leather can be facilitated, the finished leather retains the natural attractive scales and special textures of sturgeon skin, the utilization value of the sturgeon skin is improved greatly, and the added value of the product is increased obviously.

Owner:王学川 +1

Zirconium-aluminum-titanium complex tanning agent based less-chrome tanning method

InactiveCN102787181ANo pollution in the processNo releaseTanning treatmentSheep skinEnvironmental engineering

Owner:SICHUAN UNIV

Salt-free, pickling-free, short-process and little-chromium tanning method

ActiveCN104789715AClear grainGrain NaturalTanning treatmentPre-tanning chemical treatmentSalt freeWastewater

The invention discloses a salt-free, pickling-free, short-process and little-chromium tanning method. At present, finished leather produced by a little-chromium tanning method mostly fails to reach or is not close to the current chromium tanned leather requirement. The method comprises the steps that softened naked leather is directly tanned by a non-chromium tanning agent to form wet white leather; pretreatment is performed on the shaved wet white leather by a polycarboxylic acid assistant; and finally the wet white leather is tanned by little chromium powder to form a salt-free, pickling-free and little-chromium tanned wet blue leather blank. The quality and the performance of tanned wet blue leather can be comparable to wet blue leather obtained by the traditional chromium tanning technique. The method can replace the traditional chromium tanning method; the consumption of a chromium tanning agent is reduced by above 50%; the absorptivity reaches above 90%; the content of Cr2O3 in waste water, the quantity of chromium-containing solid waste and the like are greatly reduced; the chromium tanning time is shortened; and waste of chromium salt and pollution of sodium chloride to a human and an environment in a leather production process are reduced.

Owner:JIAXING UNIV

Preparation method of solventless ultraviolet-curing polyurethane for synthetic leather

The invention relates to a preparation method of a solventless ultraviolet-curing polyurethane for synthetic leather, which comprises the following steps: putting 100 parts by weight of vacuum-dehydrated dibasic alcohol and 20-40 parts by weight of liquid isocyanate with two -N=C=O functional groups into a reactor in a nitrogen protective atmosphere, uniformly mixing, adding 15-30 parts by weight of hydroxy acrylic acid monomer and 0.1-0.3 part by weight of catalyst, reacting at 75-85 DEG C for 40-60 minutes, cooling the obtained reaction system, adding 0.05-0.15 part by weight of photoinitiator, and stirring uniformly to obtain the solventless ultraviolet-curing polyurethane. When the polyurethane is used for producing synthetic leather, the coating can be cured under ultraviolet irradiation, can eliminate solvent contamination in the traditional synthetic leather production process, and has the characteristics of energy saving and high efficiency.

Owner:SHAANXI UNIV OF SCI & TECH

Environmentally-friendly and high-grade sofa leather production process

ActiveCN109628653ARaise the pHReduce formaldehyde contentTanning treatmentPre-tanning chemical treatmentOrganic solventAcrylic resin

The invention relates to the technical field of leather manufacturing processes, and provides an environmentally-friendly and high-grade sofa leather production process. According to the environmentally-friendly and high-grade sofa leather production process, an organic pretanning agent F-90 is adopted to pretreat softened leather, main tanning is carried out on pre-tanned white wet leather by adopting an aldehyde tanning agent, a vegetable tanning agent, an aromatic synthetic tanning agent, an amino resin tanning agent and an acrylic resin tanning agent are adopted for retanning, cross-linking can be formed among the vegetable tanning agent, collagen and the aldehyde tanning agent, and a vegetable-aldehyde synergistic tanning effect is achieved, so that the water-washing resistance, organic solvent resistance and shrinkage temperature of obtained crust leather are improved; moreover, the environmentally-friendly and high-grade sofa leather production process is a technical skill integrating tanning, neutralization, retanning and dyeing, uniform patterns are easy to produce on the grain surface of obtained sofa leather, and the process is suitable for the mill operation; and the shrinkage temperature is higher than 85 DEG C, and physical and mechanical properties and sensory properties meet the standard of chrome-free tanning leather.

Owner:XINGYE LEATHER TECH CO LTD

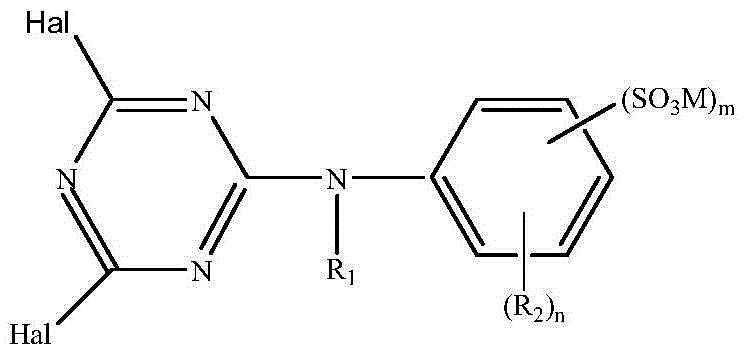

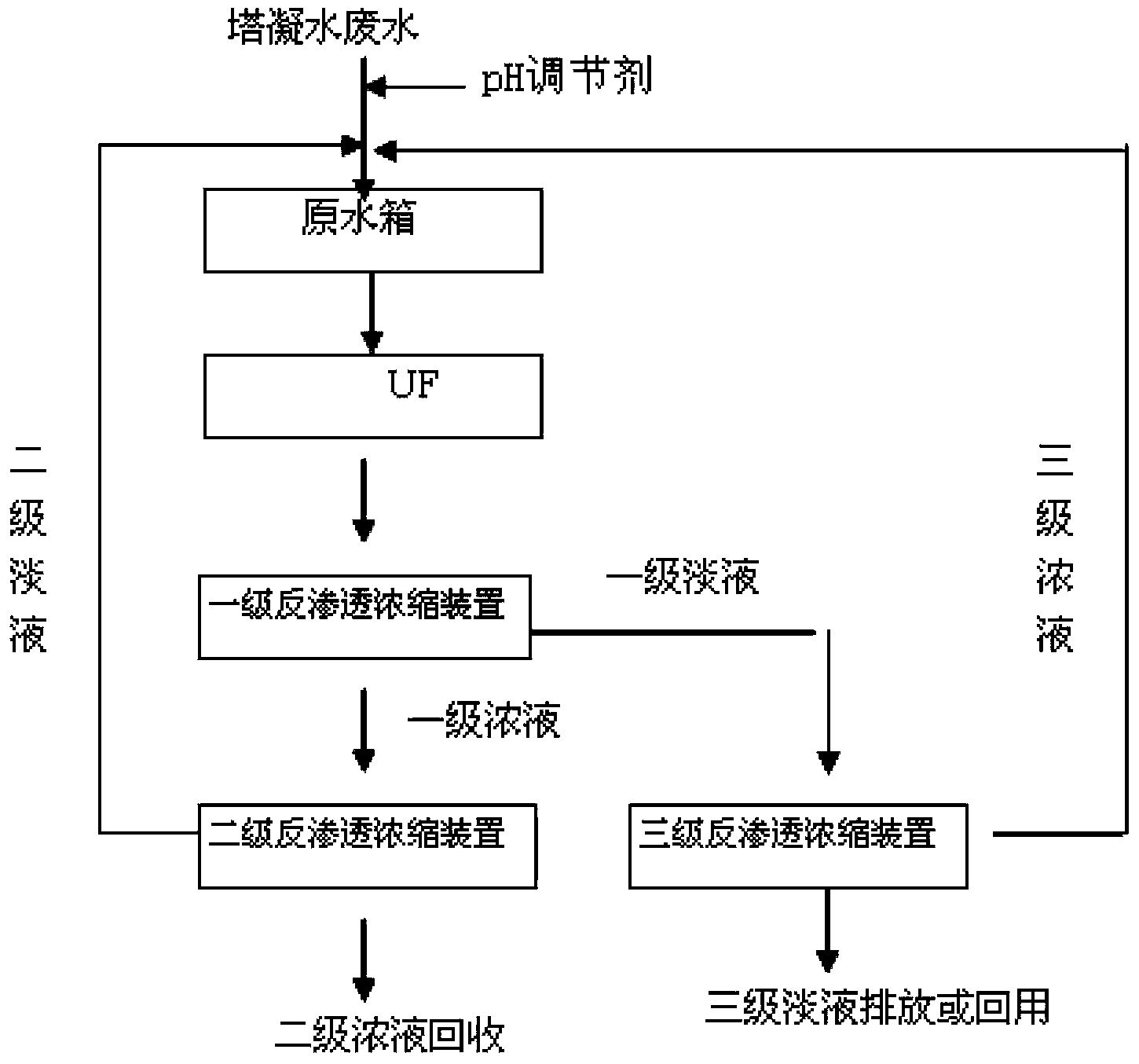

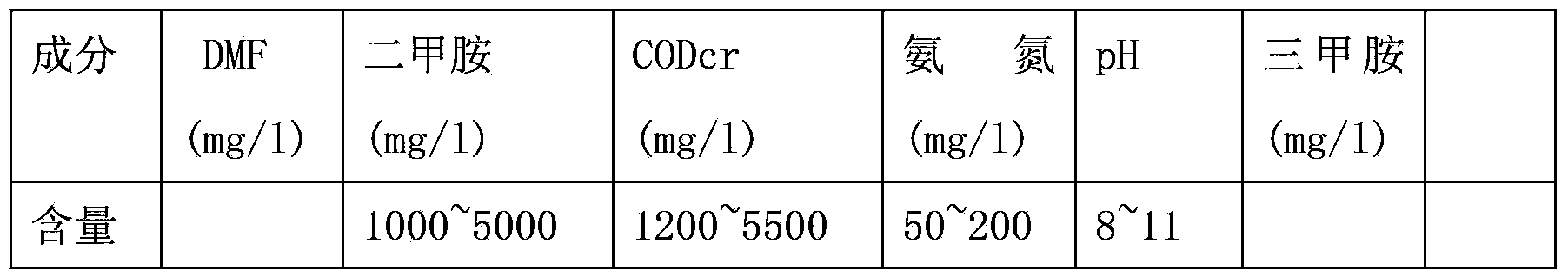

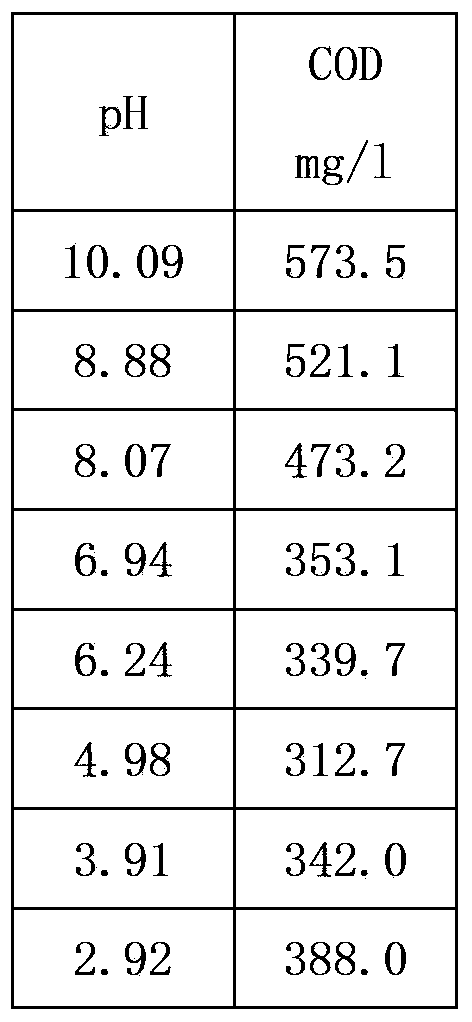

Processing method of rectifying tower condensate of wastewater containing dimethyl formamide

ActiveCN103466838ALow costNo secondary pollutionGeneral water supply conservationCarboxylic acid amide separation/purificationReverse osmosisWastewater

The invention discloses a processing method of rectifying tower condensate of wastewater containing dimethyl formamide, and in particular relates to generation of dimethyl formamide containing wastewater containing dimethyl formamide in a poly urethane (PU) synthetic leather production process. The processing method comprises the steps of regulating pH value of tower condensate, and filtering to obtain clear liquid; condensing the clear liquid in a primary reverse osmosis membrane device to obtain primary weak liquid and primary thick liquid; condensing the primary thick liquid in a secondary reverse osmosis membrane device once again to obtain secondary weak liquid and secondary thick liquid, and circulating the secondary weak liquid in an original water tank, while discharging or recycling the secondary thick liquid; meanwhile, processing the primary weak liquid in a tertiary reverse osmosis membrane device to obtain tertiary weak liquid and tertiary thick liquid, and circulating the tertiary thick liquid in the original water tank, while discharging or recycling the tertiary weak liquid. In the processing process, the method has the advantages of low cost, no secondary pollution and the like, and is convenient to operate and good in effect.

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

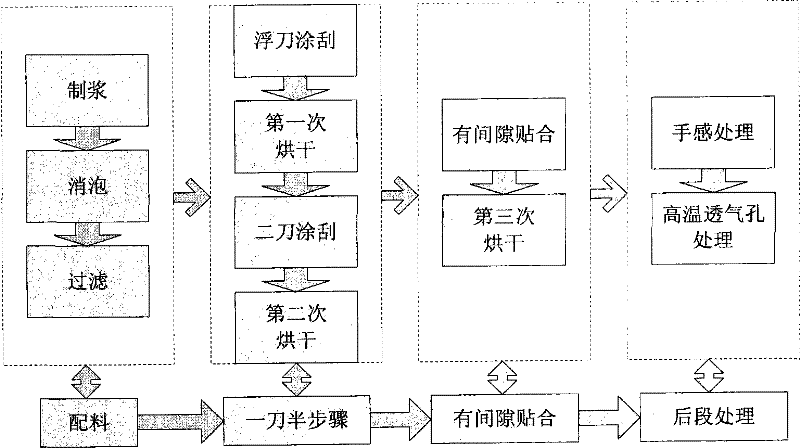

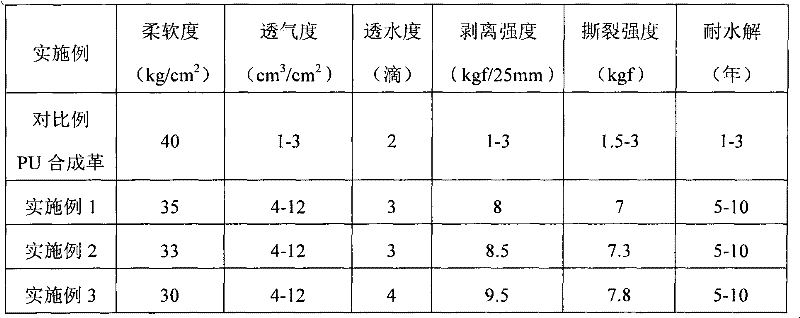

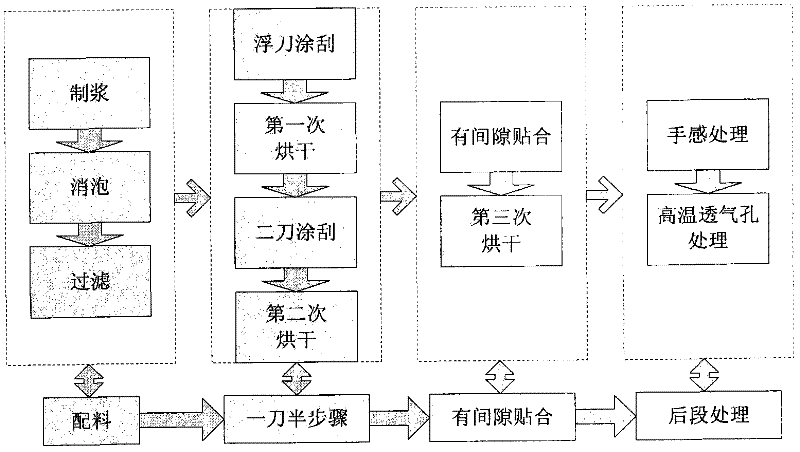

Superfine fiber synthetic leather and production method

InactiveCN102296466ASoftComfortable to wearSynthetic resin layered productsPretreated surfacesHydrolysisUltimate tensile strength

The invention provides a production method of superfine fiber synthetic leather, comprising a superfine fiber bottom blank production step and a dry method surface modeling step. The dry method surface modeling step comprises a burdening step, a draw-off step, an applying step and a post-stage processing step, wherein aqueous polyurethane with the modulus being 30-50Kg / cm<2> is used as a raw material during the burdening step; the draw-off step adopts one knife half production step, which comprises a floating knife draw-off step and a two knife draw-off step; and the applying step adopts the gapped applying. The superfine fiber synthetic leather provided by the invention is produced by the adoption of the superfine fiber and gapped applying production method. The superfine fiber syntheticleather produced in the invention is soft in texture and comfortable to wear. In addition, the peeling strength, tearing strength and hydrolysis resistance of the superfine fiber synthetic leather provided by the invention are improved in comparison with those of common shoe lining synthetic leather.

Owner:浙江元新实业有限公司

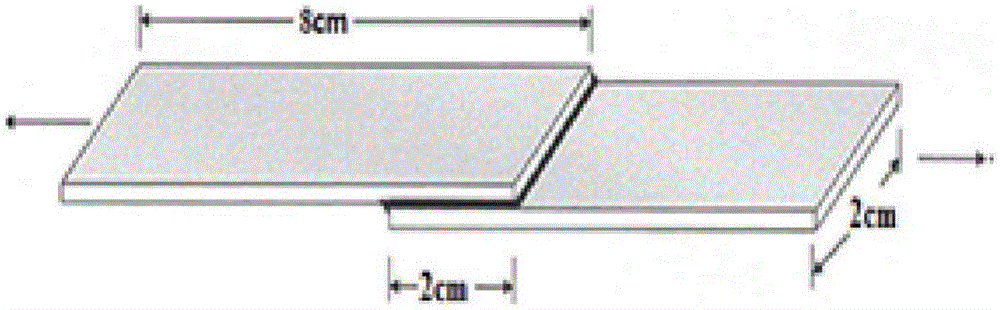

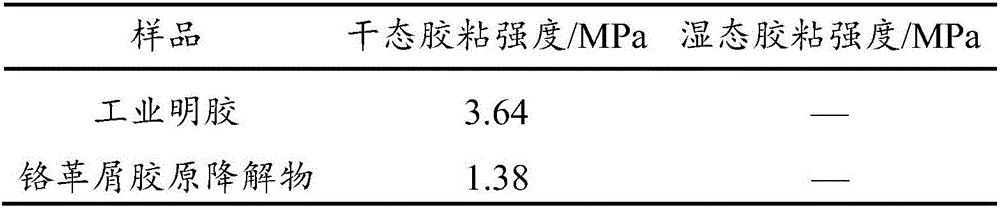

Degradation collagen-polyurethane waterborne wood adhesive and preparation method thereof

ActiveCN106753159ALow viscosityHigh solid contentProtein waste adhesivesPolyureas/polyurethane adhesivesPolyesterWater based

The invention discloses a degrading collagen-polyurethane waterborne wood adhesive, which is prepared from the following ingredients in parts by weight: 100 to 150 parts of isocyanate, 50 to 75 parts of polyester type polyalcohol, 0.1 to 0.2 part of catalysts, 30 to 45 parts of hydrophilic extended chain agents, 10 to 15 parts of micromolecule diglycol chain extenders, 20 to 30 parts of neutralizing agents and 50 to 110 parts of degradation collagen. The invention also discloses a preparation method of the degradation collagen-polyurethane water-based wood adhesive. A chrome shaving waste degradation product generated in a leather production process is used as a raw material; a path is increased for the resource reutilization of the chrome shaving waste; the corresponding economic benefits are brought; meanwhile, the environment pressure is relieved to a certain degree. Meanwhile, through the copolymerization modification with waterborne polyurethane, the problem of high cost of the single polyurethane is solved; meanwhile, the adhesive intensity, the water-resistant performance and the like of the chrome shaving collagen degradation substances are effectively improved.

Owner:SICHUAN UNIV

Leather production process based on transfer film technology

InactiveCN103061160AIncrease added valueReduce manufacturing costLamination ancillary operationsPolyureas/polyurethane adhesivesPolyesterEngineering

The invention discloses a leather production process based on a transfer film technology. The leather production process comprises the following steps of: (1) printing a release layer mixture on the surface of a PET (polyester) film, and drying the release layer mixture to form a release layer; (2) printing colored ink on the surface of the release layer to form decorative patterns, and drying the ink; (3) coating a PU (Poly Urethane) layer mixture on the surface of the release layer printed with the decorative patterns, and drying the PU layer mixture to form a PU layer; (4) coating a bonding layer mixture on the surface of the PU layer, and pre-drying the bonding layer mixture; and (5) compositing the surface of the PU layer coated with the bonding layer mixture with a fabric by hot pressing, rolling and curing the composition at a normal temperature, and then peeling the PET film coated with the release layer, thereby obtaining novel leather. The leather production process has the advantages of low cost and simple process and can be used for producing the leather with multiple sets of decorative patterns, many colors, smooth surface and good texture.

Owner:HUAHAN QUANZHOU NEW FABRIC DEV

Leather production process

InactiveCN104894299AIncreased durabilityLow costTanning treatmentPre-tanning chemical treatmentFiberEngineering

The invention discloses a leather production process, which comprises the steps of 1) lot grouping: classifying the raw hides of leathers similar in width size and thickness; 2) soaking in water: soaking the raw hides in water after the lot grouping step; 3) unhairing and degreasing: removing grease in hide cells and hairs on the surfaces of the raw hides; 4) liming: adding alkali to expand the hides to a certain thickness for facilitating the splitting operation; 5) deliming and pickling: removing redundant alkali in the raw hides during the liming step; 6) tanning: connecting collagen groups in hide fibers by means of trivalent chromic ions, and enhancing the tensile strength and the anti-tear intensity of the leather; 7) re-tanning: selecting a retanning agent of better in filling effect to retan the tanned leather; 8) dyeing; 9) fatliquoring; 10) drying; 11) staking; 12) finishing; 13) examining and warehousing finished products. The leather production process is simple in operation, and the produced leather is good in durability. Meanwhile, the cost of manufacturers is saved, and the requirements of customers can be met at the same time.

Owner:卢家雄

Microfiber artificial leather adhered with TPU film, and production process thereof

InactiveCN102442041APromote environmental protectionIncrease elasticitySynthetic resin layered productsLaminationEngineeringCold resistance

The present invention relates a microfiber artificial leather product, and the technical field of a microfiber artificial leather production process, especially to a microfiber artificial leather adhered with a TPU film, and a production process thereof. The microfiber artificial leather adhered with the TPU film comprises a microfiber artificial leather layer, wherein the microfiber artificial leather layer is adhered with a TPU layer by a glue adhering manner or a hot pressing manner. With the present invention, the performances of environmental protection, elasticity, toughness, abrasion resistance, cold resistance and the like of the microfiber artificial leather are substantially improved; crack and rupture are not easily generated; the manufacture costs of luggages, building materials, shoe materials and other products are substantially reduced.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

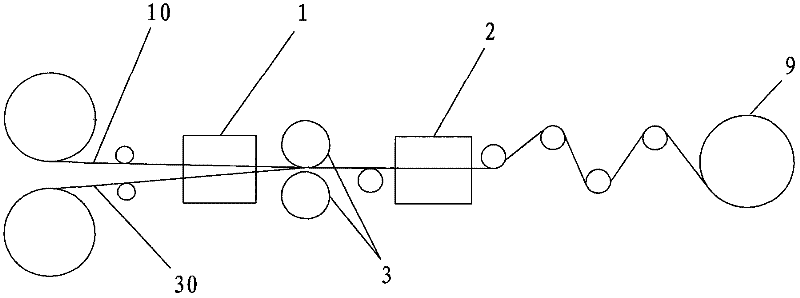

Method for producing two-layer transfer coating leather by aqueous polyurethane dry-method transfer coating process

InactiveCN102501442AImprove hygieneEliminate pollutionLamination ancillary operationsPolyureas/polyurethane adhesivesProduction lineSolvent based

The invention discloses a method for producing two-layer transfer coating leather by aqueous polyurethane dry-method transfer coating process. The method comprises the following steps of: firstly coating a bottom-closing foamed coating material on the surface of the split leather by use of a roll coating machine in leather production, and drying and then ironing by use of a drum-type ironing machine to form a bottom-closing foamed coating; then blade coating a top coating material and an adhesive coating material on release paper by use of a dry-method production line in synthetic leather production process; and finally, bonding the split leather with the bottom-closing foamed coating and the release paper with the adhesive coating, drying in a drying channel, cooling, separating, and transferring the coatings on the release paper onto the bottom-closing foamed coating, to obtain the two-layer transfer coating leather. The method produces the two-layer transfer coating leather by aqueous polyurethane dry-method transfer coating process and replaces the solvent-type polyurethane production system by the aqueous polyurethane production system, so as to eliminate pollution caused by solvents and solve the problem of MDF residues in the two-layer transfer coating leather. Besides, the method can enhance water permeability and vapor permeability of the coatings and improve health performance of the two-layer transfer coating leather final product.

Owner:SHAANXI UNIV OF SCI & TECH

Sponge foam soft-type full-grain flat leather production process

ActiveCN109628655AImprove overall utilizationGood added valueWax coatingsTanning treatmentLower gradeEconomic benefits

The invention relates to the technical field of leather manufacturing process, and provides a sponge foam soft-type full-grain flat leather production process. According to the sponge foam soft-type full-grain flat leather production process, low-grade heavy-weight cowhide is used as raw leather, a traditional wet dyeing and finishing process framework is broken through, first neutralization and filling is carried out after a softening process, then chrome retanning is carried out, second neutralization and filling is carried out, meanwhile a certain amount of grease is added in the softening,neutralization and filling processes, and materials with selective filling are mainly adopted in the filling process to finally prepare the high-quality and high-utilization full-grain flat leather with good softness, good foam feeling, a uniform and fine grain surface and no obvious position difference. The sponge foam soft-type full-grain flat leather production process effectively solves the problems of coarse grain surfaces, obvious disability, large grain size, a low utilization rate and the like existing in the processing process of the low-grade heavy-weight cowhide, reduces the production cost of manufacturing high-quality and high-utilization sponge foam soft-type full-grain flat leather for enterprises, improves the utilization rate of the low-grade cowhide and the value of finished leather, and brings considerable economic benefits to the enterprises.

Owner:XINGYE LEATHER TECH CO LTD

Polyurethane (PU) synthetic leather production process allowing solid waste recycling

ActiveCN104213432AReduce investmentReduce manufacturing costLamination ancillary operationsLaminationFiberSlurry

The invention discloses a polyurethane (PU) synthetic leather production process allowing solid waste recycling. The process is characterized by including the following steps: mixing buffing powder and dimethyl formamide (DMF) with the mass ratio as 1:5-5.5 in a stirring kettle; remixing the mixture and stopping mixing after the mixture is completely mixed; conducting centrifugal separation of mixed slurry to separate the mixed slurry into the liquid phase and the solid phase, wherein the liquid phase is recycled as a polyurethane resin raw material in a wet method slurry process; processing the solid phase and mixing the solid phase and the DMF with the mass ratio as 1:4-4.5; conducting stirring through a disperser, conducting secondary centrifugal separation to obtain the liquid phase which is utilized as the DMF raw material in the last step, conducting washing on the solid phase obtained through the secondary centrifugal separation, conducting stirring through a stirring machine, and then conducting tertiary centrifugal separation; enabling the liquid phase to flow back into a transfer water tank in a non-metering mode and recycling or reprocessing washed cloth wool. The process reduces production cost, and conversion of the solid waste powder reduces pollution.

Owner:JIANGXI HOPU HIGH TECH COATED FABRIC CO LTD

No-salt pickling-free short-process no-chrome tanning method

ActiveCN105925735AReduce pollutionShort processTanning treatmentPre-tanning chemical treatmentEngineeringPollution

The invention discloses a no-salt pickling-free short-process no-chrome tanning method. One the basis of advantages and disadvantages of chrome and requirements for environment protection, the no-salt pickling-free no-chrome tanning method suitable for production and feasible is needed at the present, and the finished leather quality of the method can be favorably compared with that of a traditional chrome tanning technology. The no-salt pickling-free short-process no-chrome tanning method comprises the steps that softened naked leather is directly tanned with no-chrome tanning agents to obtain wet white leather; the uniformly shaved wet white leather is tanned with substitute type synthetic tanning agents, then tanned with vegetable tanning agents and finally tanned with a defined amount of aluminum tanning agents; and a no-salt pickling-free no-chrome tanning leather blank is obtained. According to the no-salt pickling-free short-process no-chrome tanning method, the shrinkage temperature of the obtained no-chrome tanning crust leather is higher than 95 DEG C, and a body of the finished leather is soft and rich and capable of being favorably compared with chrome tanning leather in the quality, performance and other aspects; and meanwhile, the pickling process is omitted, the tanning time is shortened, and the consumption of sodium chloride and chrome salt in the leather production process and the pollution of the sodium chloride and the chrome salt to human and the environment are eradicated.

Owner:JIAXING UNIV

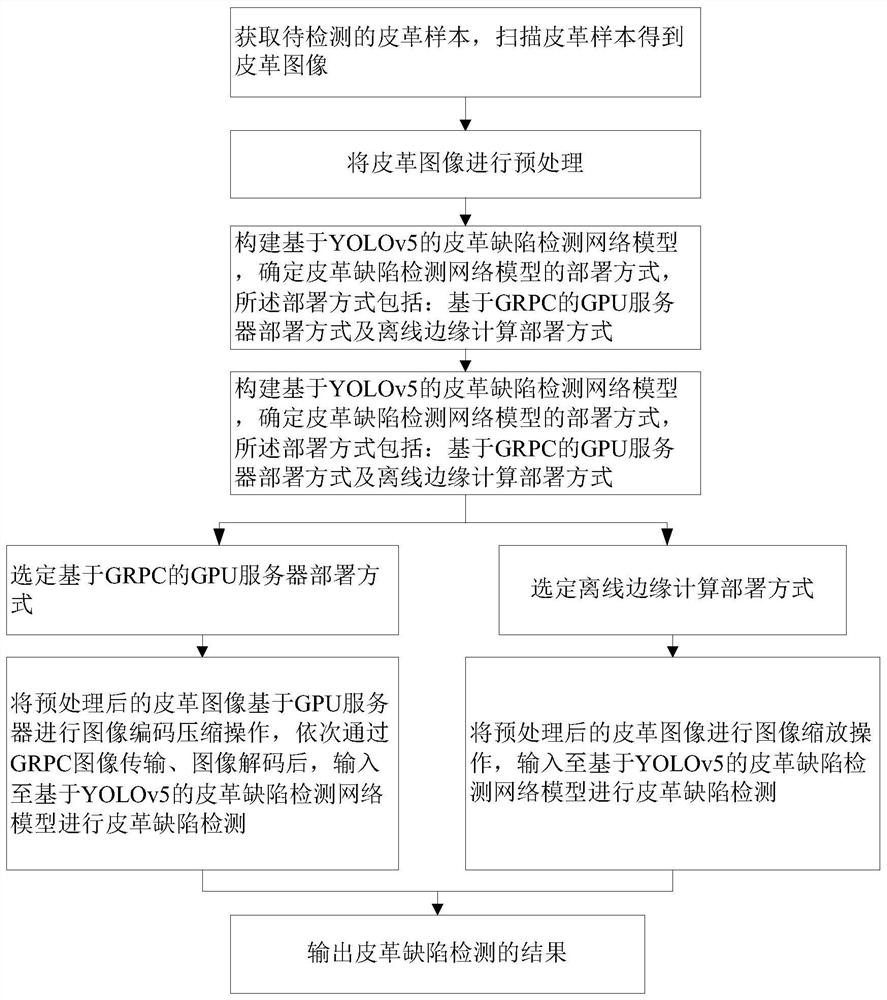

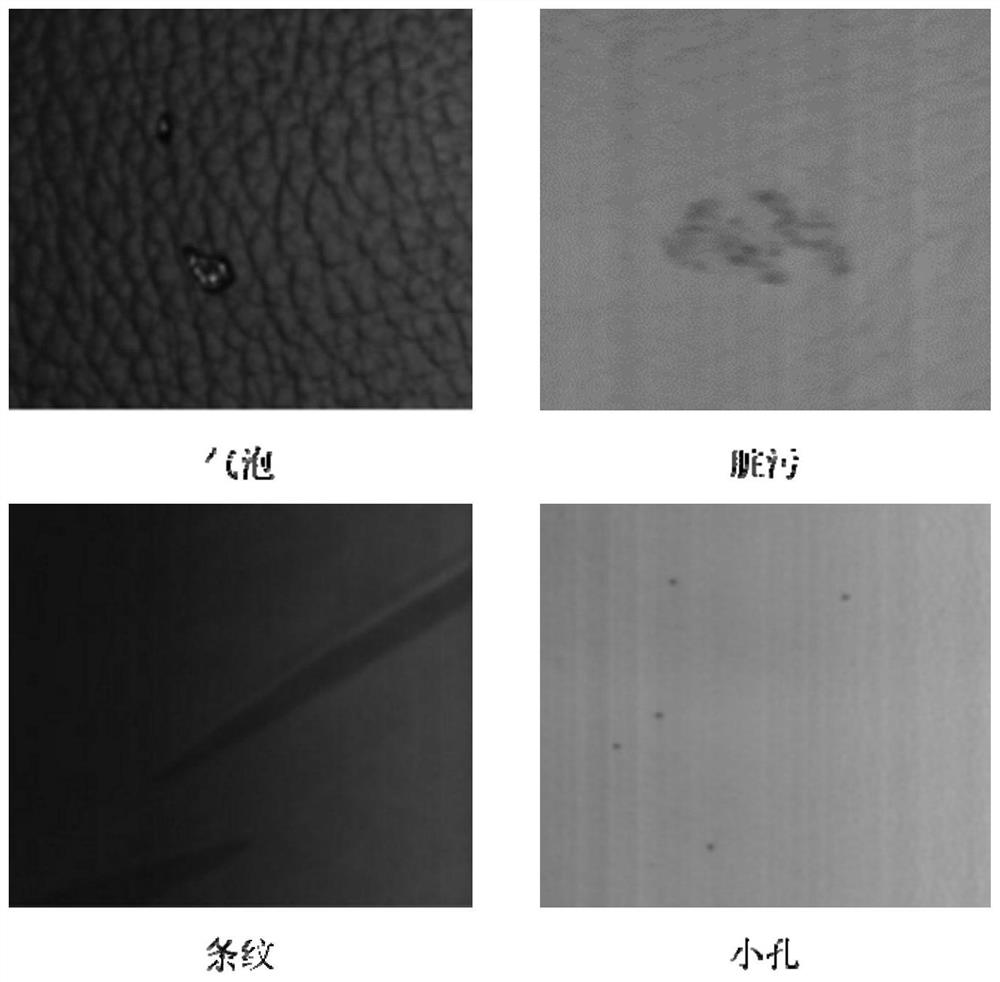

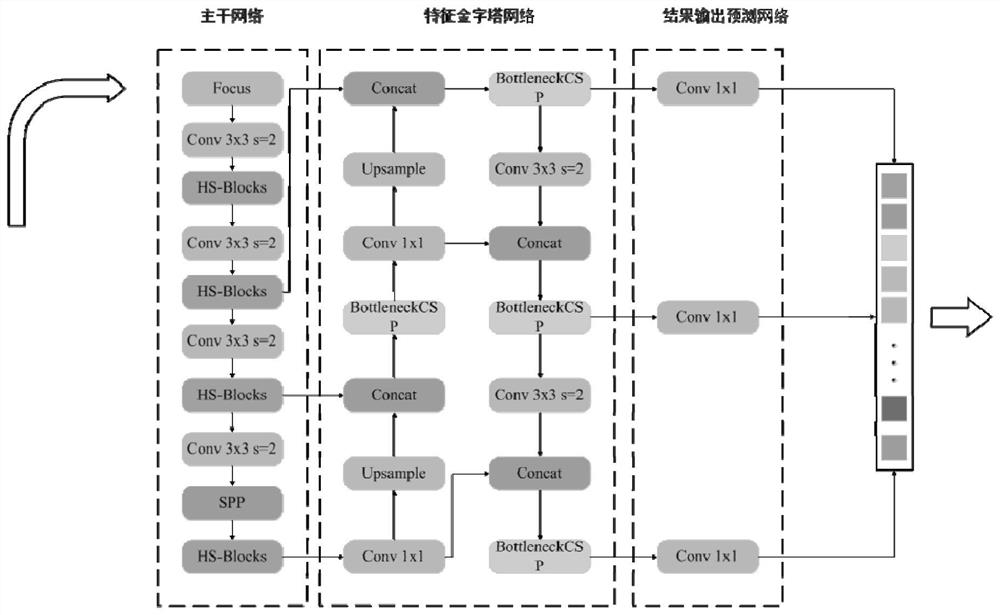

Leather defect detection method, system and device based on YOLOv5

ActiveCN113160123AImprove defect detection efficiencyEnable incremental learningImage enhancementImage analysisNetwork modelIndustrial engineering

The invention provides a leather defect detection method, system and device based on YOLOv5, and solves the problems of single detection mode, high dependency on a deep learning network, difficulty in adapting to leather defect variability and uncertain production environment in an actual leather production process in a current leather defect detection method by utilizing a traditional deep learning network. According to the invention, firstly, the leather defect detection network model based on YOLOv5 is constructed, the detection speed is high, and the accuracy is high; then the leather defect detection network model is deployed by adopting a dual-mode deployment design of a GPU server deployment mode based on GRPC and an offline edge calculation deployment mode, so as to adapt to defect variability in the leather production process, and the requirements of different leather production environments are met.

Owner:GUANGDONG UNIV OF TECH

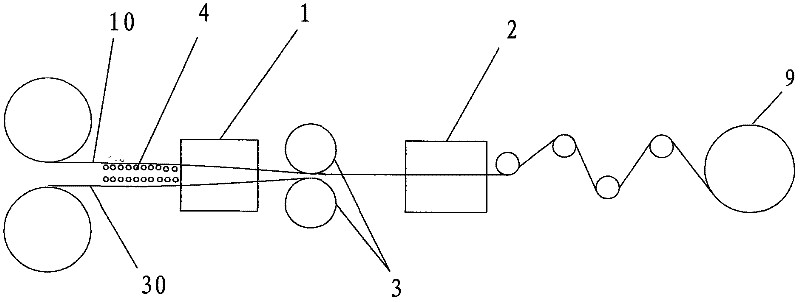

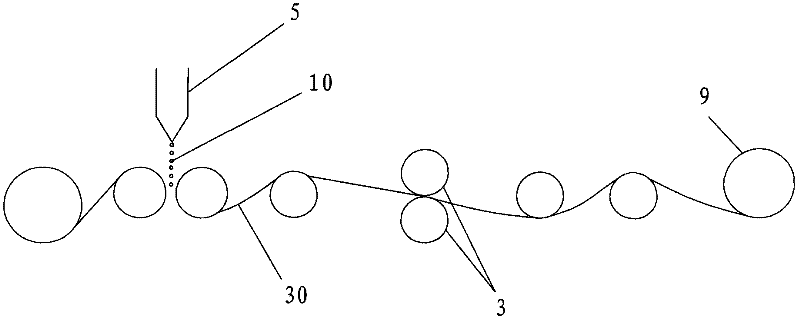

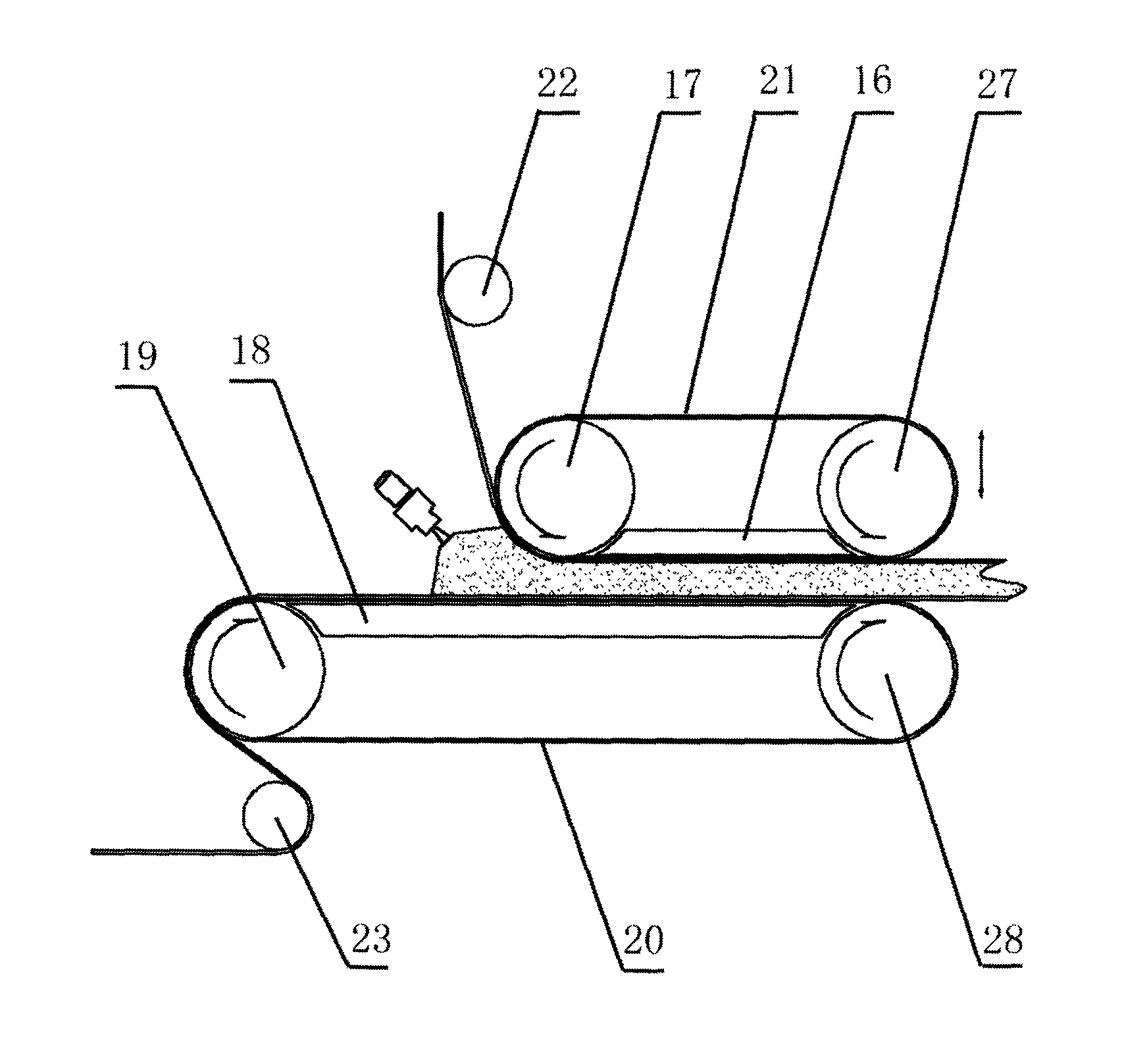

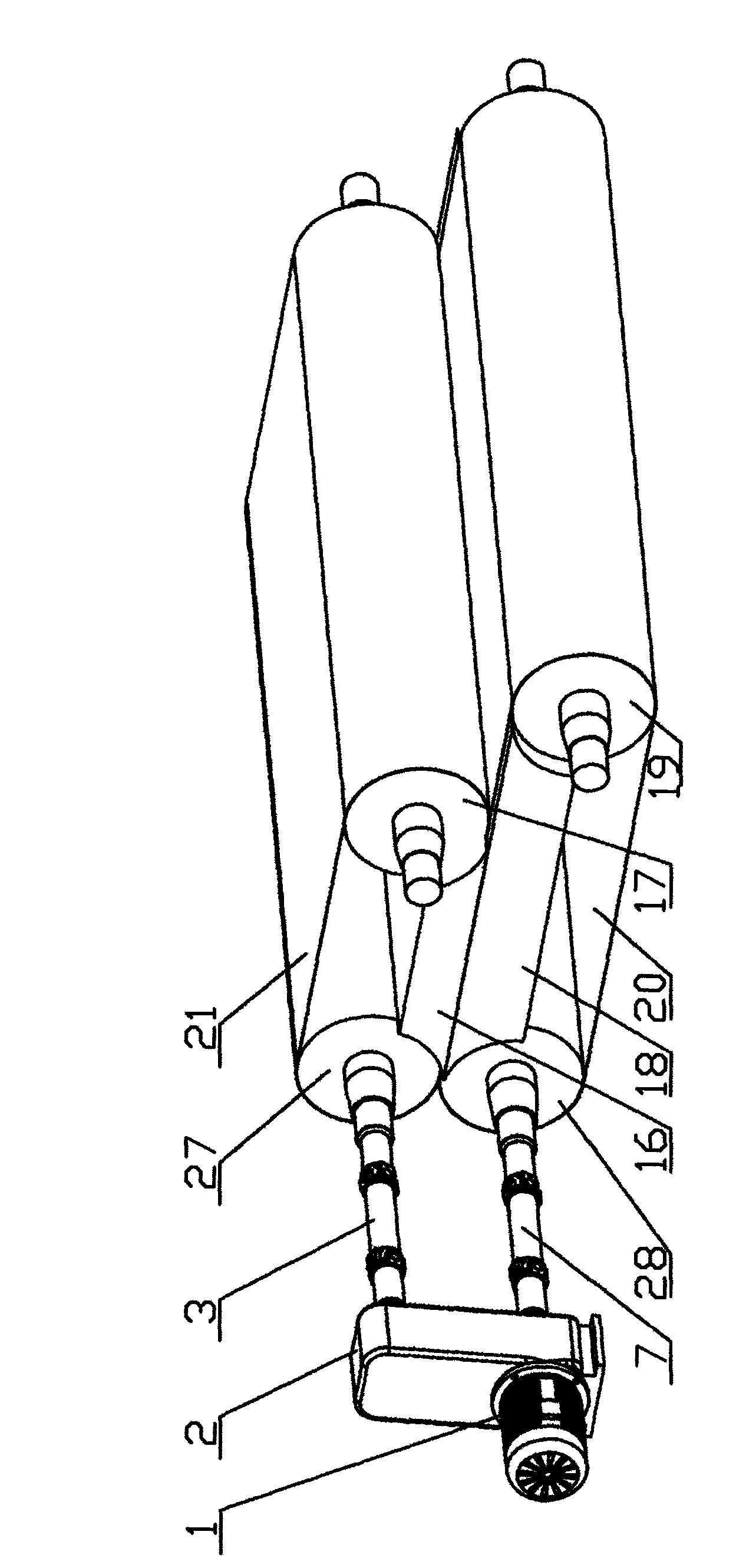

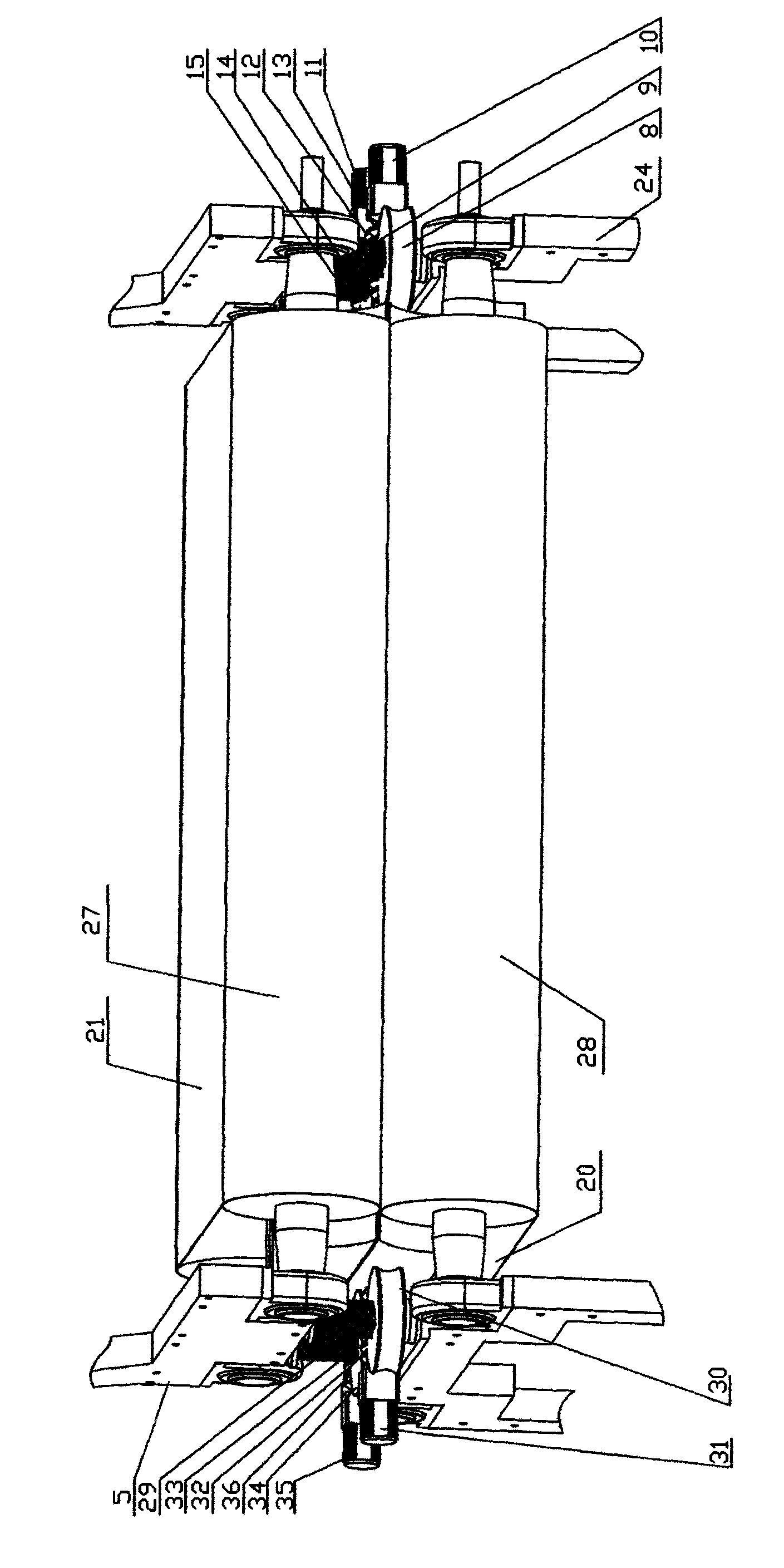

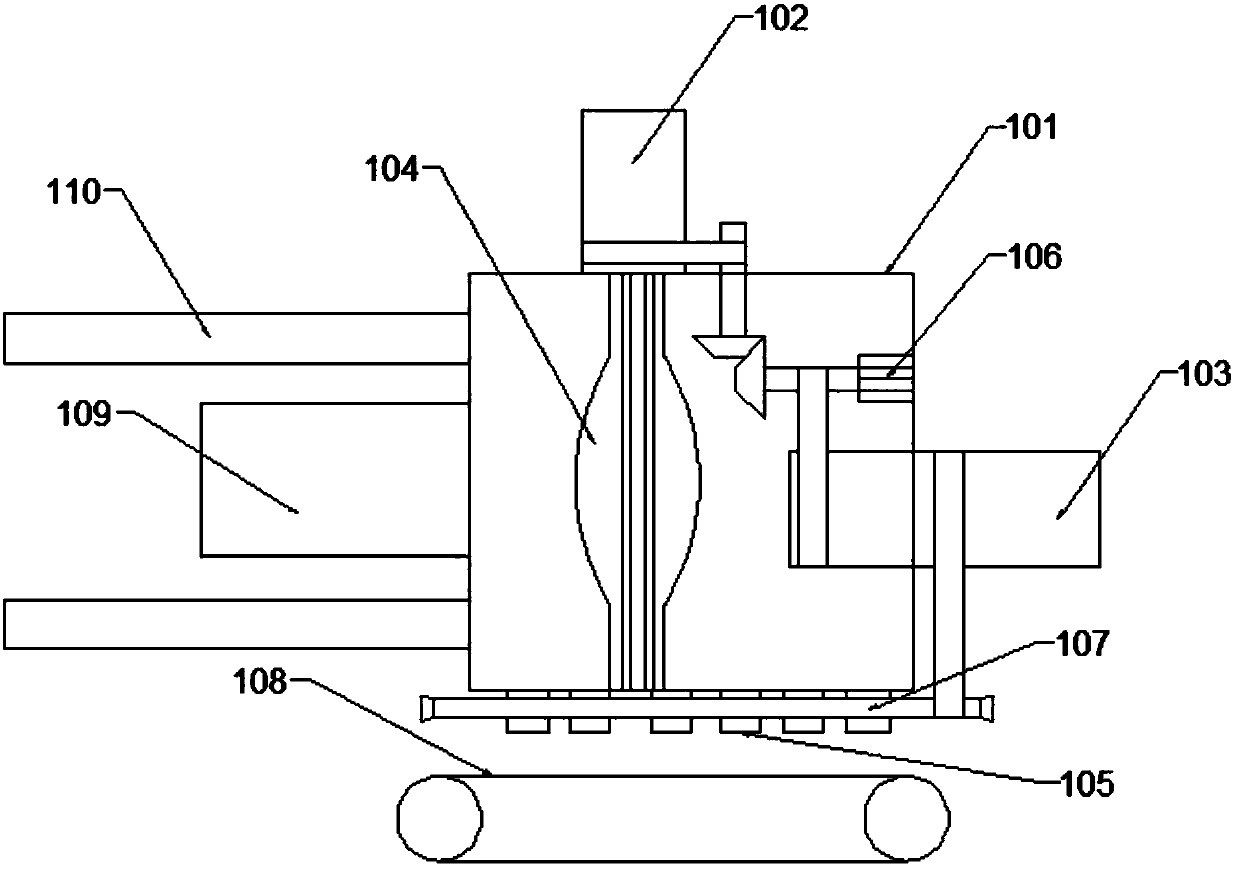

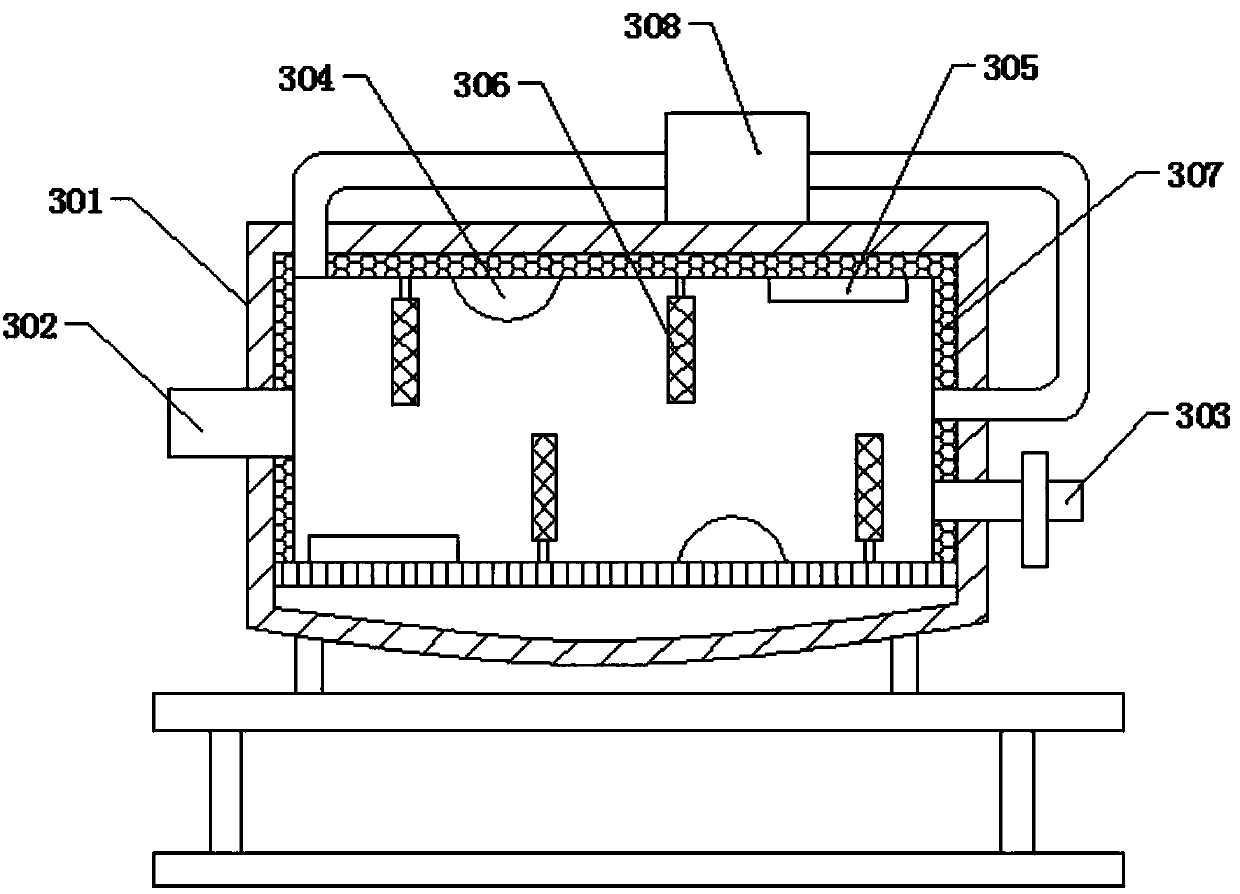

Belt type foaming forming machine for producing synthetic leather

ActiveCN102995456AReduce consumptionReduce pollutionTextiles and paperEngineeringMechanical engineering

The invention relates to the field of equipment for manufacturing polyurethane synthetic leather, and in particular relates to a belt type foaming forming machine for producing synthetic leather. The belt type foaming forming machine comprises a stand, a base material guide roll (22), a release paper guide roll (23) and a foaming and curing forming mechanism, wherein the foaming and curing forming mechanism comprises an upper forming belt mechanism and a lower forming belt mechanism, a foaming gap is formed between the upper foaming belt mechanism and the lower foaming belt mechanism, the base material guide roll (22) and the release paper guide roll (23) are respectively arranged on the top and bottom of the stand, and the foaming and curing forming mechanism is arranged between the base material guide roll (22) and the release paper guide roll (23). The invention has the beneficial effects that 1, the belt type foaming forming machine is matched with bicomponent polyurethane to produce the synthetic leather so as to replace the traditional wet leather production process; and 2, production links are reduced, the productivity is improved, in addition, energy consumption and environment pollution are reduced greatly, and the high-quality polyurethane synthetic leather is obtained.

Owner:杭州云知本实业有限公司

Production process of thick cattlehide-simulating top grade sofa decorative shell fabric

InactiveCN107287917AAvoid environmental issues such as pollutionImprove breathabilitySynthetic resin layered productsWarp knittingSurface layerChamois leather

The invention discloses a production process of a thick cattlehide-simulating top grade sofa decorative shell fabric. The production process comprises the following steps: selecting a warp knitted chamois leather-simulated shell fabric as base cloth of a surface layer, performing galling, dyeing, sanding and printing, and compounding the base cloth with PU resin to prepare a surface layer; selecting warp knitted like lint and performing processes such as dyeing, galling and sizing as an intermediate layer; and selecting galled cloth by a looped pile by a circular knitting machine and performing processes such as dyeing, sizing and galling as a bottom layer. According to the production process of the thick cattlehide-simulating top grade sofa decorative shell fabric disclosed by the invention, the produced shell fabric is good in ventilating property, similar to genuine leather in hand feel and texture, and meets the demand of cattlehide in thickness. The production process avoids environmental pollution in a genuine leather production process.

Owner:TONGXIANG LONGXIANG TEXTILE

Ecological environment-friendly vegetable tanning yellow cattle upper leather production process

ActiveCN109628659AMeet the requirementsEasy to fixTanning treatmentPre-tanning chemical treatmentCross-linkOrganic solvent

The invention relates to the technical field of leather manufacturing, and provides an ecological environment-friendly vegetable tanning yellow cattle upper leather production process. According to the ecological environment-friendly vegetable tanning yellow cattle upper leather production process, an organic pre-tanning agent is used for pretreating softened leather, the tanning agent based on avegetable tanning agent is used for tanning, wherein the vegetable tanning agent is mainly a condensed vegetable tanning agent, and then an aldehyde tanning agent is combined for retanning; the vegetable tanning agent, collagen, the aldehyde tanning agent can form cross-linking to produce a vegetable-aldehyde synergistic tanning effect, the fixation effect of the vegetable tanning agent is improved to improve the absorptivity of the vegetable tanning agent, the washing resistance, organic agent resistance performance and shrinkage temperature of the obtained green leather are improved, and thedistribution of vegetable tanning agent on each layer of green leather is more uniform; and the green leather has fine grain size, good compactness, good softness, good fullness and good elasticity,and accords with the characteristics of upper leather products.

Owner:XINGYE LEATHER TECH CO LTD

Antibacterial mildew-proof synthetic leather production process

The invention discloses an antibacterial mildew-proof synthetic leather production process in the technical field of synthetic leathers. The process includes the following steps: step I. preparing anorganic silicon / aqueous polyurethane interpenetrating network polymer emulsion containing zinc phthalocyanine, a foaming slurry material and a surface treatment agent; step II. sending release paper into a preheating oven for heating; step III. coating the organic silicon / aqueous polyurethane interpenetrating network polymer emulsion containing the zinc phthalocyanine on the release paper to forma surface layer, and sending the surface layer into a first oven; step IV. uniformly coating the foaming slurry material on the surface layer to form a foaming layer, and sending the foaming layer into a second oven; step V. uniformly coating glue on the foaming layer, coating a polyester cloth on the foaming layer, and sending the foaming layer into a third oven; step VI. peeling the release paper and the surface layer after cooling to obtain a semi-finished product of the antibacterial mildew-proof synthetic leather; step VII. coating the surface treatment agent on the surface of the semi-finished product of the antibacterial mildew-proof synthetic leather, and sending the surface treatment agent into a fourth oven to prepare the antibacterial mildew-proof synthetic leather. The processhas the advantages of safe use and obvious antibacterial and mildew-proof effects.

Owner:YANGZHOU DERWINS PLASTICS TECH

Preparation method for sealing type solvent-free polyurethane for synthetic leather and application

ActiveCN107759759ANo pollution in the processMild preparation conditionsFilm/foil adhesivesPolyureas/polyurethane adhesivesSolvent freeKetone

The invention discloses a preparation method for sealing type solvent-free polyurethane for synthetic leather and application. The preparation method comprises the following steps: firstly, uniformlymixing 100-150 parts of dihydric alcohol, 10-20 parts of methyl ethyl ketone oxime, 10-20 parts of acetylacetone and 10-20 parts of diethyl malonate after vacuum dehydration, further adding 130-210 parts of diisocyanate, uniformly stirring and mixing, performing reaction for 60-120 minutes at 70-90 DEG C, and cooling, thereby obtaining the sealing type solvent-free polyurethane. By adopting a preparation technique of synchronous polymerization sealing of multiple sealing agents, the sealing type solvent-free polyurethane of which the viscosity is smaller than 5000mPa / s can be prepared, preparation conditions are mild, and clean and environment-friendly effects are achieved, a production process is simple and stable when synthetic leather is produced from the sealing type solvent-free polyurethane, solvent pollution in conventional synthetic leather production process is eliminated, and meanwhile, the preparation method has the characteristics of energy conservation and high efficiency.

Owner:SHAANXI UNIV OF SCI & TECH

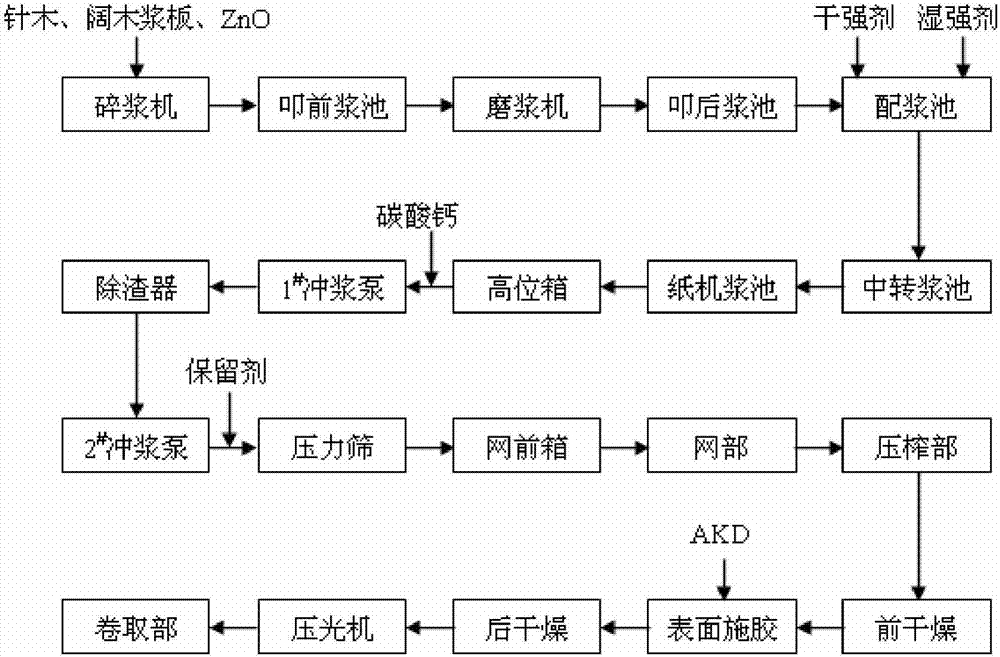

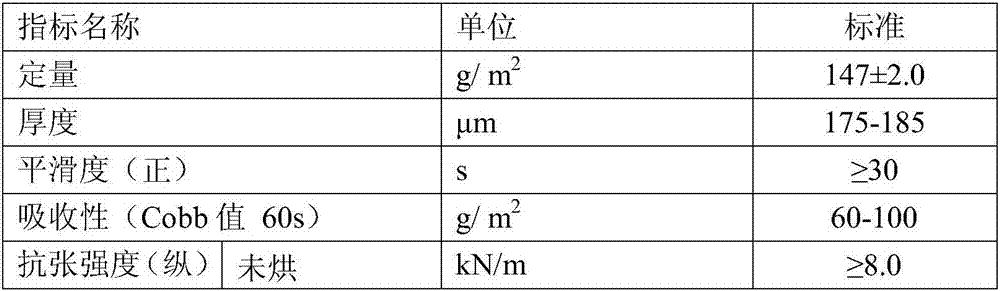

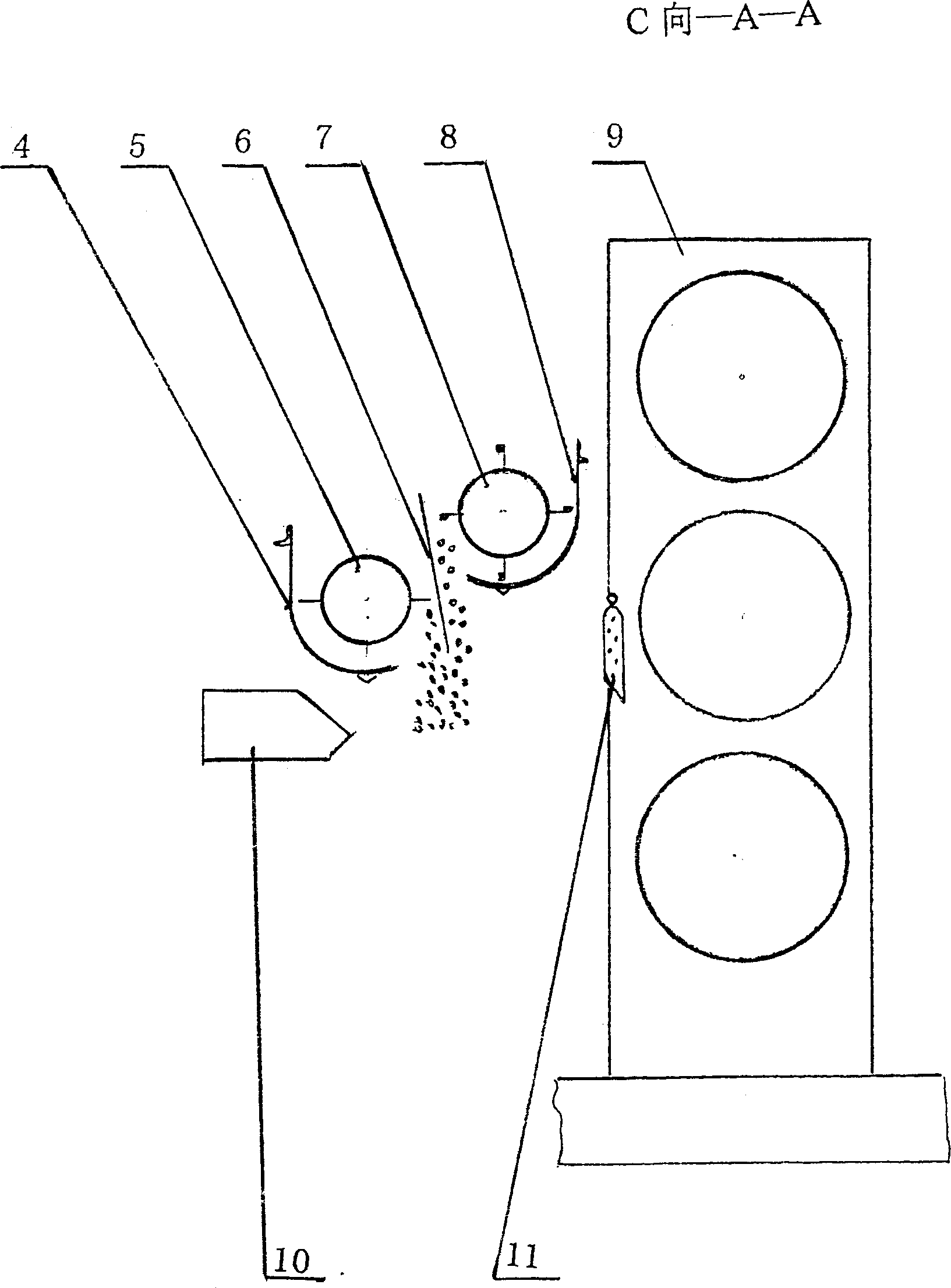

A method for producing leather release type base paper

InactiveCN107354802AImprove uniformityFine and smooth paper surfaceWater-repelling agents additionPaper coatingSlagSulfate

The invention belongs to papermaking techniques and relates to a method for producing leather release type base paper. According to the method, base raw materials which are bleached sulfate softwood pulp and bleached sulfate hardwood pulp are subjected to steps of pulping, pulp preparing, sizing, papermaking with pulp, drying for the first time, surface sizing, after-drying, calendaring, and taking up in order to obtain finished-product paper; auxiliary raw materials are added in process steps; according to a material transferring sequence, materials in the pulping step pass through a pulper, a before-beating pulp pool, a pulp grinding machine and an after-beating pulp pool in order; materials in the pulp preparing step pass through a pulp preparing pool, a transit pulp pool, a paper machine pulp pool and a high-attitude tank in order; materials in the sizing step pass through a first pulp washing pump, a slag separator, a second pulp washing pump and a pressure sieve in order; materials in the papermaking step pass through a head box, a screen part and a squeezing part in order. The base paper produced by the method has good uniformity, fine and smooth paper surfaces, high strength, proper anti-permeation performance and good heat resistance and can adapt to requirements if subsequent leather production processes.

Owner:ZHENJIANG DADONG PULP & PAPER

Leather production process

InactiveCN107164583AImprove antioxidant capacityImprove the bactericidal effectTanning treatmentPre-tanning chemical treatmentSurface layerAntioxidant

The invention discloses a leather production process. The leather production process comprises the following steps of (1), material selection, specifically, animal furs are selected, and the furs of the similar thickness are placed in the same drum to be processed; (2), immersion with liquid, specifically, a proper amount of leather immersion liquid is added into the drum in the above step, the furs are made to recover to the fresh fur state, and meanwhile sterilization and inoxidizability of the furs can be improved. The leather immersion liquid contains a leaching agent, a sterilizing agent, an antioxidant and a degreaser, when moisture enters the furs under the action of the leaching agent, the sterilizing agent and the antioxidant can be carried into the furs, the inoxidizability and sterilizing effect of the leather are improved, the degreaser can remove oil stains on the surface layers of the furs, convenience is brought to full-filling of a coating in a subsequent process, the moisture is controlled to be 15-30 degrees, the leaching effect of the leather immersion liquid at the temperature can be the optimal, and the inoxidizability and sterilizing effect of the leather are promoted.

Owner:安徽英特罗斯服饰有限公司

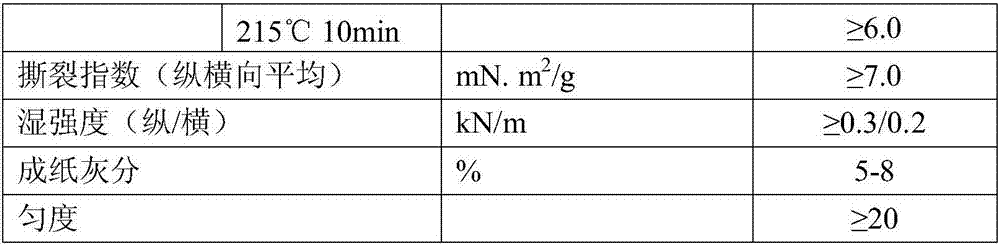

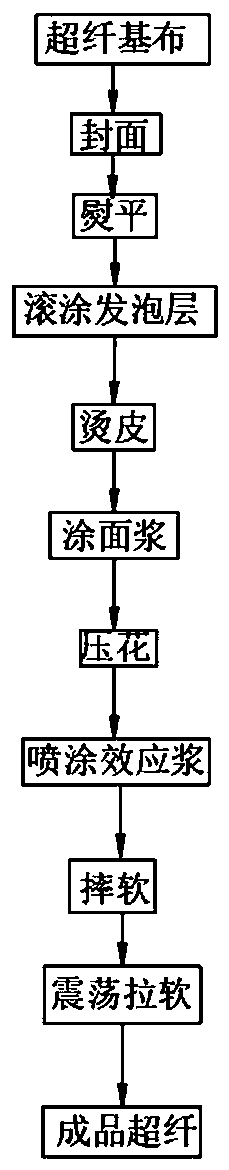

Water-based directly-coated microfiber sofa leather

InactiveCN110592956AOvercome body shape differencesOvercoming poor thickness uniformityTextiles and paperWater basedSpray coating

The invention belongs to the technical field of leather, and particularly discloses water-based directly-coated microfiber sofa leather, and a water-based directly-coated microfiber sofa leather production process. The water-based directly-coated microfiber sofa leather is prepared by preparing a microfiber base fabric and a cover, conducting ironing, roll-coating a foaming layer, conducting scalding, coating surface slurry, conducting embossing, spray-coating effect slurry, and conducting milling and oscillation staking to obtain the finished product (microfiber sofa leather). By means of microfiber gray cloth, the sofa leather has a microstructure similar to that of natural leather, overcomes the poor body form part and poor thickness uniformity of genuine leather, has super moisture absorption performance, and has the structure closer to that of genuine leather; in cooperation with the finishing of the genuine leather, the microfiber leather is more environmentally friendly, even has the texture of the genuine leather and has the unique moisture absorption performance and breathability, is higher in firmness and more durable in use, and even has performance on some aspects better than that of the genuine leather; in addition, the finishing process is close to the processing method of the genuine leather, and therefore the water-based directly-coated microfiber sofa leather has the appearance and the internal structure both close to those of the natural leather.

Owner:江苏优贝斯新材料科技有限公司

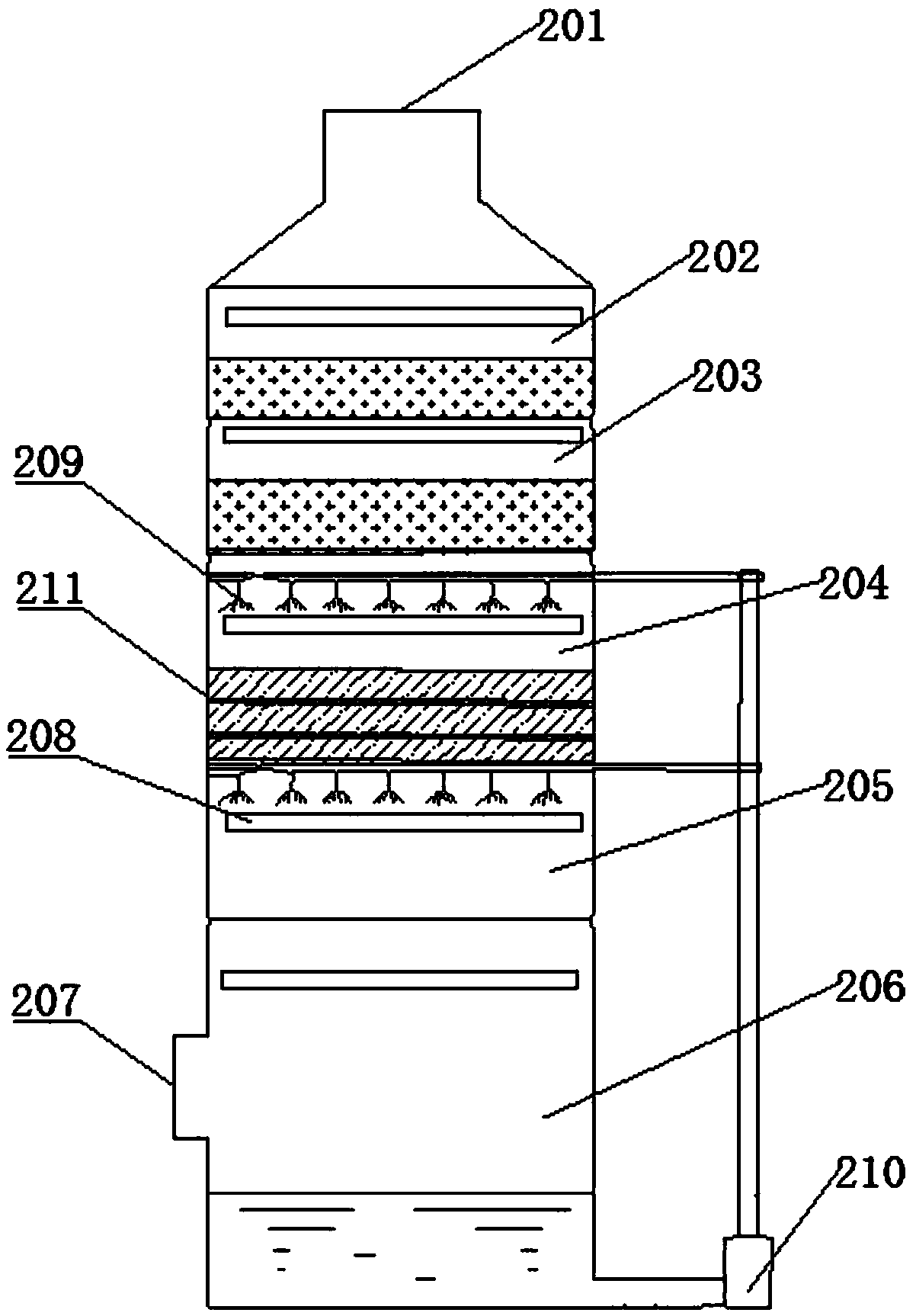

Method for controlling organic waste gas

The invention discloses a method for controlling organic waste gas, and belongs to the field of treatment of waste gas. The method comprises the following steps of A, collecting of waste gas: enablinga gas collecting device to collect the organic waste gas in a workshop, and enabling a centrifugal fan to send the collected organic waste gas to a spraying device to spray, wherein the flow rate ofthe organic waste gas is 10 to 15m<3> / h; B, spraying: enabling a spraying tower to spray to the collected organic waste gas; C, photolysis: sending the organic waste gas subjected to spraying into photolysis treatment equipment, and degrading harmful gas; D, discharging in a overhead place: sending the gas subjected to photolysis to the overhead place to discharge. The method and the equipment have the advantage that the organic waste gas can be controlled, and the organic waste gas can be effectively degraded and harmlessly treated, so that the pollution to environment when the organic wastegas is finally discharged in a PVC (polyvinyl chloride) artificial leather production process is avoided.

Owner:清远市德晟嘉恒能源环保工程有限责任公司

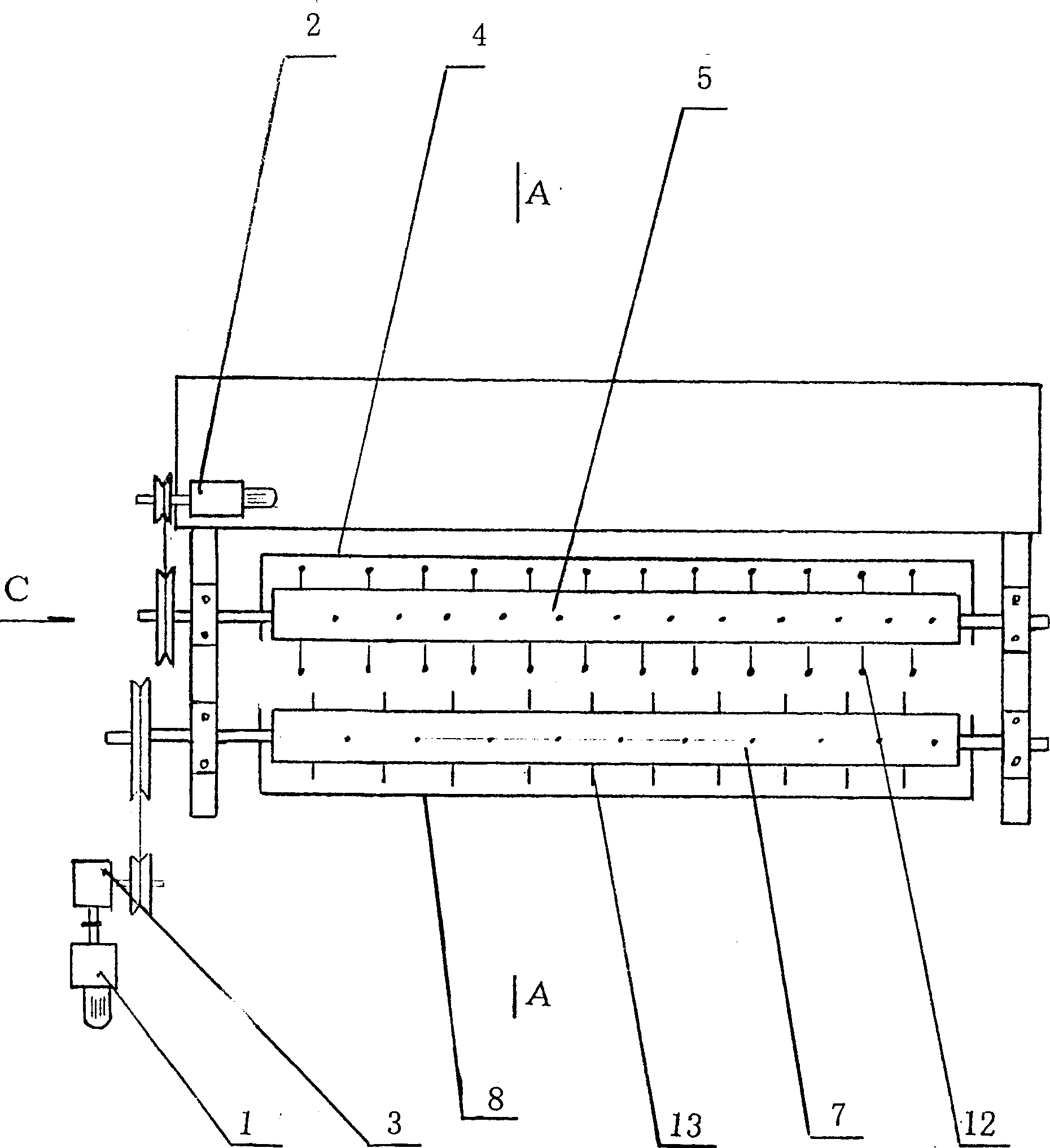

Polyvinyl chloride wearing-resistant flash coloured plastic-flooring and preparation method and device thereof

The present invention belongs to a high-molecular polymer material, and relates to a polyvinyl chloride wear-resistant flashing multi-color plastic-flooring, its preparation method and equipment. Said invention uses PVC resin and plastic plasticizer as main raw material, uses proper quantity of stabilizing agent, colouring agent and filling material as auxiliary raw material, on the basis adds the inorganic wear-resistant flashing granules and multi-colour PVC granules which are undergone the process of activation treatment by using coupling agent, and adds the processes of spreading granulesand heating surface between the processes of forming and binding of existent PVC floor board leather production process so as to make granules uniformly distributed on the surface of base body and firmaly combined together.

Owner:CHANGCHUN JIALIN INDAL GROUP

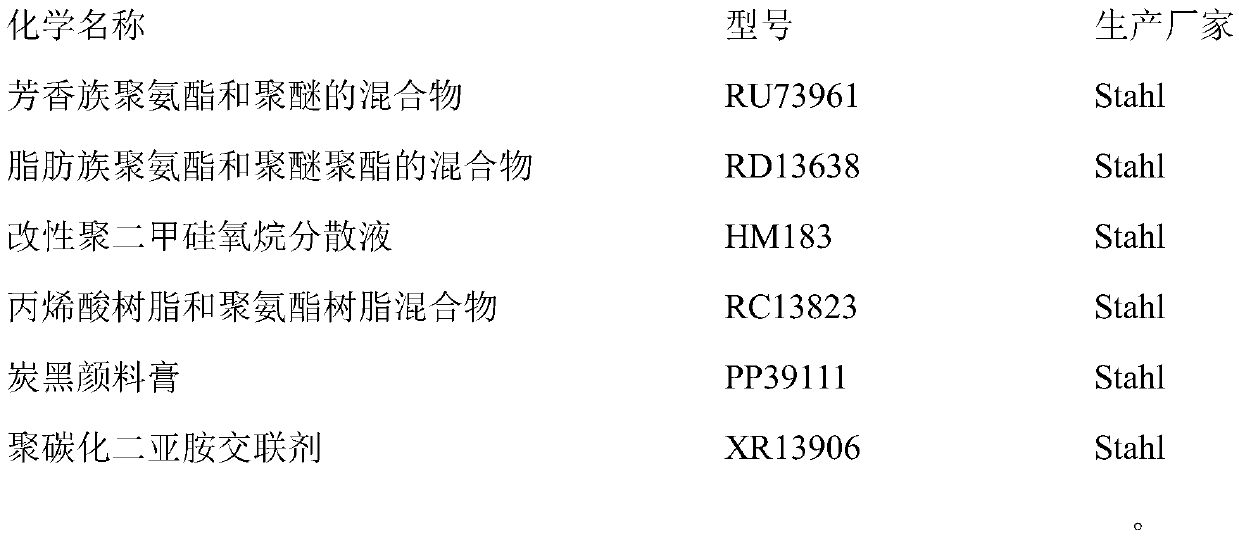

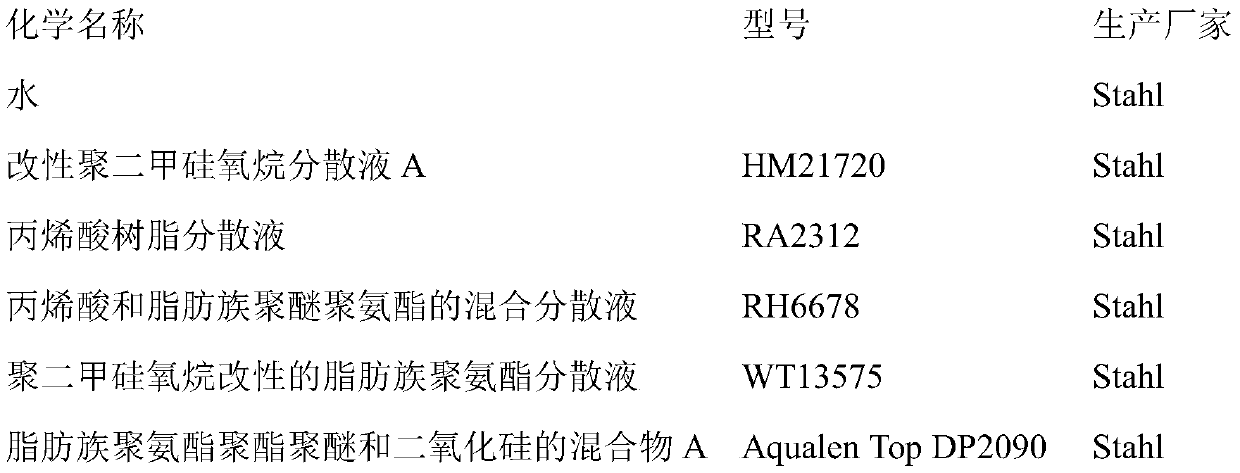

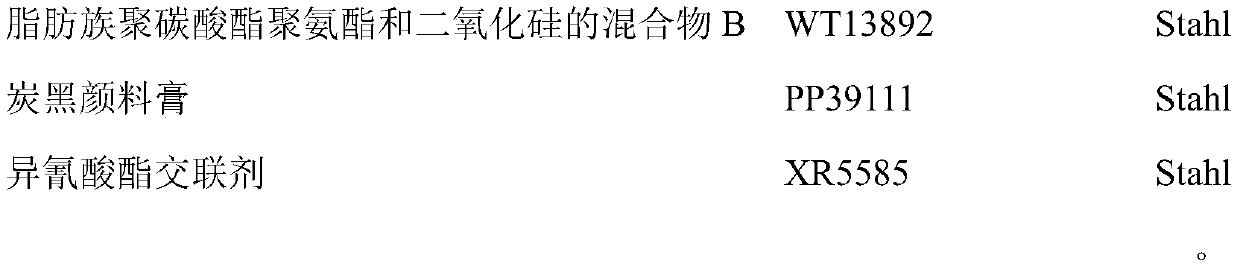

Sterilizable leather production process

InactiveCN111518964AHigh fastnessImprove adhesionPolyurea/polyurethane coatingsLeather softeningKnurlingCross linker

The invention belongs to the field of leather making chemistry and technology engineering, and particularly relates to a sterilizable leather production process. The process carries out machining sequentially according to the procedures of leather blank sorting, leather blank throwing to be soft, leather blank dust removal, leather blank inside sealing, leather blank bottom coating, standing for passing the night, knurling, throwing to be soft, dust removal, color layer treatment, top coating I / II, standing for passing the night, and vibration to be flat, and sterilizable car leather can be obtained. High-physical-property resin, a feeling agent and a cross-linking agent are screened, a proper ratio is adopted, through matched application of an online 2K mixing machine and a high-level roller coating machine, and application of a multiple poly-carbonization diimine cross-linking agent, wear resistance, sweat resistance firmness, dry and wet rubbing resistance firmness and sterilizing performance of the leather can be improved, and the experiment proves that the leather can be subjected to repeated wiping and sterilizing, and the leather is not damaged. Health of passengers can be effectively protected, needs of a consumer can be met, and the advantage of an enterprise in market competition can be improved.

Owner:柏德皮革(中国)有限公司

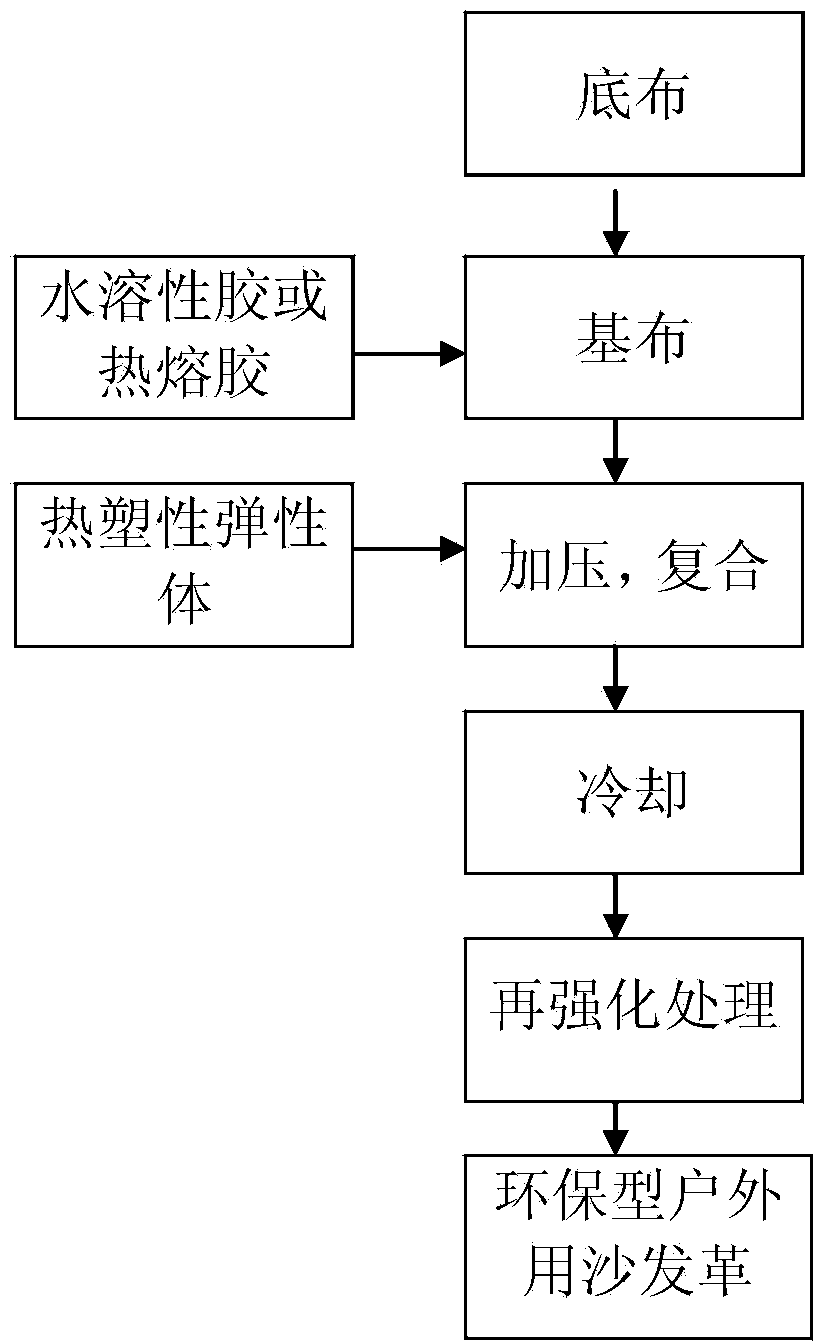

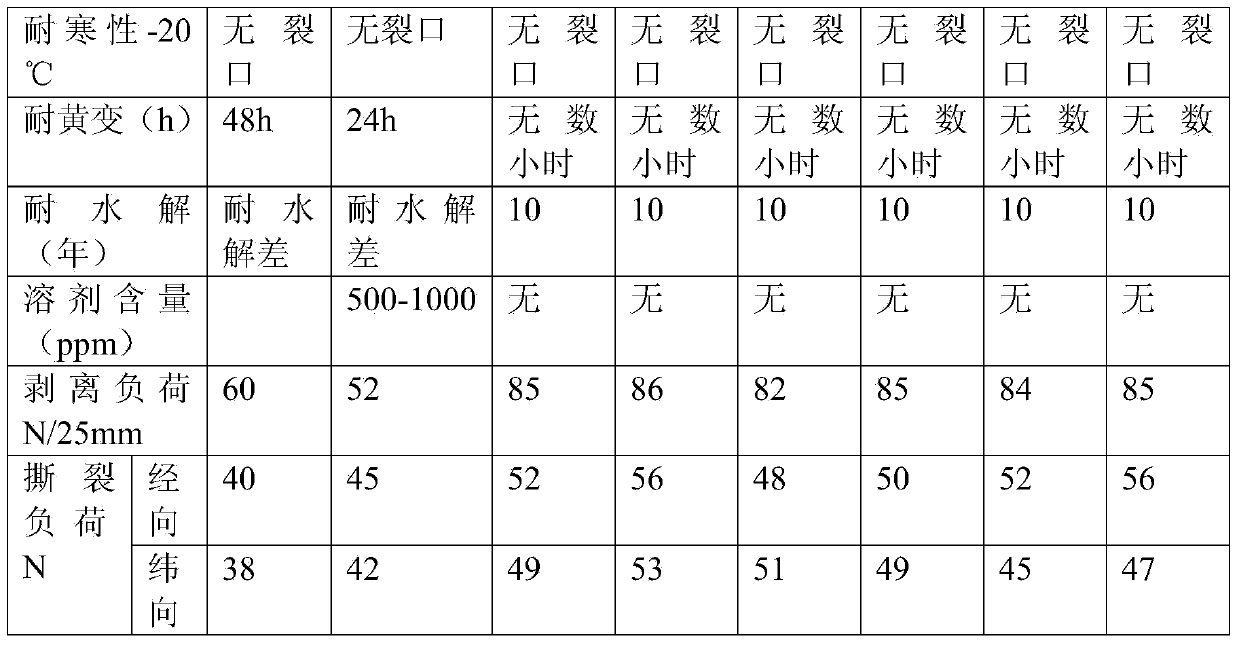

Preparation method of environment-friendly sofa leather used outdoors

ActiveCN103556484ANo pollutionSolve pollutionSynthetic resin layered productsTextiles and paperEnvironmental resistanceThermoplastic elastomer

The invention provides a preparation method of environment-friendly sofa leather used outdoors. The preparation method comprises the following steps: coating a water soluble adhesive or a hot melt adhesive on base cloth at temperature of 100-150 DEG C and carrying out drying treatment at temperature of 60-150 DEG C, thus preparing the base cloth; adding 0.05-0.2 parts by weight of colorant and 0.6-0.8 parts by weight of auxiliary to 0.6-1 part of thermoplastic elastomer, mixing the materials to be uniform, heating the mixture at temperature of 100-360 DEG C, compositing the mixture with the base cloth after melting, pressing the composite at 0.2-0.8MPa and then cooling the product; strengthening the prepared product in water at temperature of 30-80 DEG C and carrying out drying treatment, thus preparing the environment-friendly sofa leather used outdoors. The preparation method has the advantages that solvents are not used in the production process, so that the environment cannot be polluted; the adopted raw materials are environment-friendly and can be reused; the offcut can be reused; the problem of environmental pollution in the traditional synthetic leather production processes is solved and the requirements of outdoor products are met.

Owner:HUALUN LEATHER & PLASTIC SUZHOU

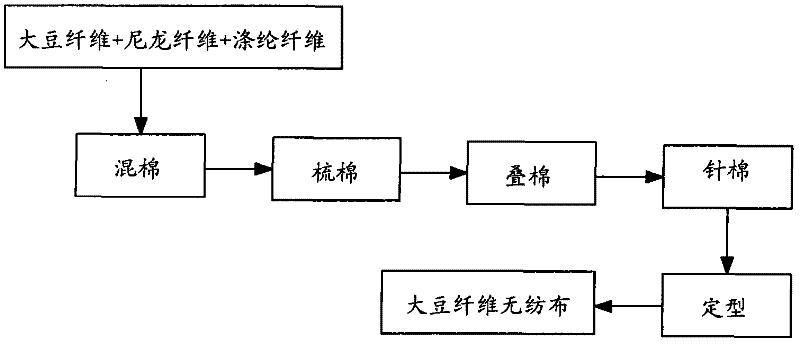

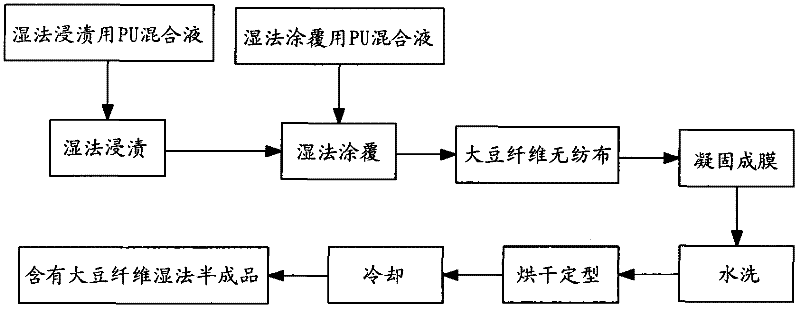

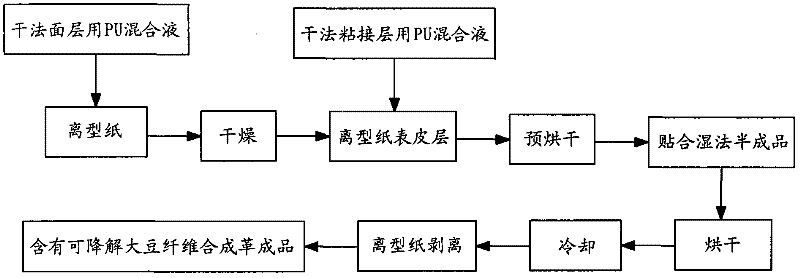

Production method of degradable soybean fiber synthetic leather

The invention relates to a production method of synthetic leather, and specifically relates to a production method of degradable soybean fiber synthetic leather. The production method comprises the following steps of 1) selecting soybean fiber with excellent physical properties, blending the selected soybean fiber and chemical synthetic leather fiber according to a certain proportion to obtain a mixture, and carrying out the processes of cotton carding, cotton lapping, needling and design fixing on the mixture to obtain soybean fiber non-woven fabrics, and 2) carrying out a synthetic leather production process by a wet method and a synthetic leather production process by a dry method to obtain soybean fiber synthetic leather finished products. The production method changes a present situation that 100% of fiber of traditional synthetic leather is checamical synthetic fiber, and introduces degradable biological soybean fiber into traditional synthetic leather thereby reducing a contentof chemical fiber. The production method is beneficial to reduce environmental pollutions, and has the characteristics of low carbon and environmental protection. On the premise of no change of mechanical properties, synthetic leather produced by the production method has cashmere-like soft hand-feel belonging specially to soybean fiber, silk-like soft luster, cotton-like heat-retention property,good skin affinity and observable bacteriostasis functions.

Owner:TIANSHOU FUJIAN SUPERFIBER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com