Degradation collagen-polyurethane waterborne wood adhesive and preparation method thereof

A technology of wood adhesive and polyurethane, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of high cost and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

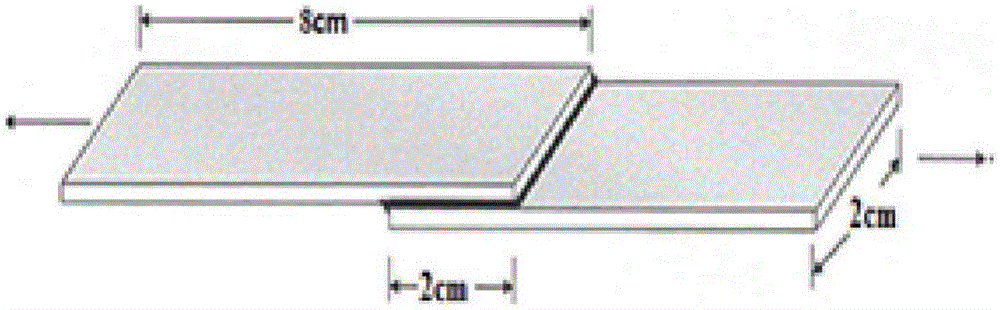

Image

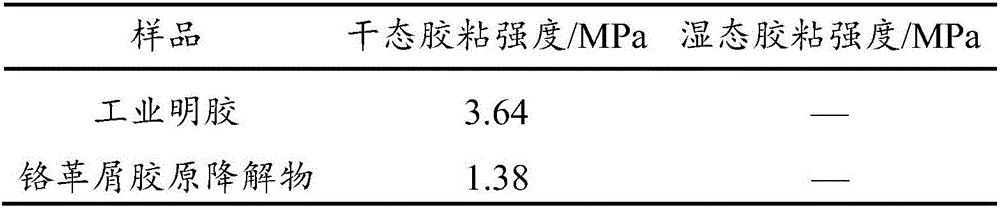

Examples

preparation example Construction

[0037] The invention provides a kind of preparation method of degraded collagen-polyurethane water-based wood adhesive, comprising the following steps:

[0038] 1) Weighing: Weigh the following components by weight: 100-150 parts of isocyanate, 50-75 parts of polyester polyol, 30-45 parts of hydrophilic chain extender, 10-45 parts of small molecule diol chain extender 15 parts, 20-30 parts of neutralizing agent, 50-110 parts of degraded collagen solution; the isocyanate is one of toluene diisocyanate or isophorone diisocyanate; the polyester polyol is polybutylene adipate One of alcohol ester diol or polyethylene adipate. The hydrophilic chain extender is one of dimethylol propionic acid or dimethylol butyric acid, and the small molecule diol chain extender is one of 1,4-butanediol or diethylene glycol The neutralizer is one of triethylamine or tri-n-butylamine; the degraded collagen comes from the alkaline degradation of waste leather shavings to a molecular mass of 6000-100...

Embodiment 1

[0047] A preparation method for degrading collagen-polyurethane water-based wood adhesive, comprising the following steps:

[0048] (1) Weigh 50 parts of polybutylene adipate diol with a molecular weight of 2000, vacuum dehydrate at 110°C for 1 hour, cool down to 65°C, add 100 parts of toluene diisocyanate to react for 1 hour, raise the temperature to 80°C, and keep it warm for 1 hour to obtain the Polymer;

[0049] (2) Add 30 parts of dimethylolpropionic acid to the prepolymer in (1) for chain extension, react at 60°C for 1 hour, add 10 parts of 1,4-butanediol to the system for chain extension, 60°C React for 1h, heat up to 80°C, and react for 2h;

[0050] (3) Cool down to 50°C, add 20 parts of triethylamine neutralizer for neutralization, add deionized water at 1000r / min and stir for 10min to obtain aqueous polyurethane prepolymer emulsion;

[0051] (4) At 300r / min, add 50 parts of collagen degradation product aqueous solution to the prepolymer emulsion, stir for 10 minute...

Embodiment 2

[0053] A preparation method for degrading collagen-polyurethane water-based wood adhesive, comprising the following steps:

[0054] (1) Weigh 50 parts of polybutylene adipate diol with a molecular weight of 2000, vacuum dehydrate at 110°C for 1 hour, cool down to 65°C, add 100 parts of isophorone diisocyanate, dropwise add 0.1 part of dilauric acid diol Butyl tin catalyst, react at 65°C for 1h, raise the temperature to 85°C, and keep it warm for 1h to obtain a prepolymer;

[0055] (2) Add 30 parts of dimethylolbutyric acid for chain extension, react at 60°C for 1 hour, add 10 parts of 1,4-butanediol to the system for chain extension, keep warm at 60°C for 1 hour, heat up to 80°C, and react for 3 hours ;

[0056] (3) Cool down to 50°C, add 20 parts of tri-n-butylamine neutralizer for neutralization, add deionized water at 1100r / min and stir for 5min to obtain aqueous polyurethane prepolymer emulsion;

[0057] (4) At 400r / min, add 85 parts of collagen degradation product aqueo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com