Microfiber artificial leather adhered with TPU film, and production process thereof

A production process and artificial leather technology, applied in layered products, synthetic resin layered products, lamination devices, etc., can solve the problems of easy cracking, rupture, high cost, elasticity, toughness, wear resistance, and cold resistance. And other problems, to achieve the effect of not easy to crack and break, good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, the superfiber artificial leather with TPU film attached according to the present invention, it includes a superfiber artificial leather layer, and the superfiber artificial leather layer is pasted with a TPU layer by glue sticking or hot pressing. Further, the TPU layer is provided with an embossed or printed layer, which can emboss or print characters and patterns. Further, the PU film layer is provided with an embossed or printed layer, which can emboss or print characters and patterns.

Embodiment 2

[0023] Embodiment two, a kind of production technology of the superfiber artificial leather of sticking TPU film described in above-mentioned embodiment one, comprises the following steps:

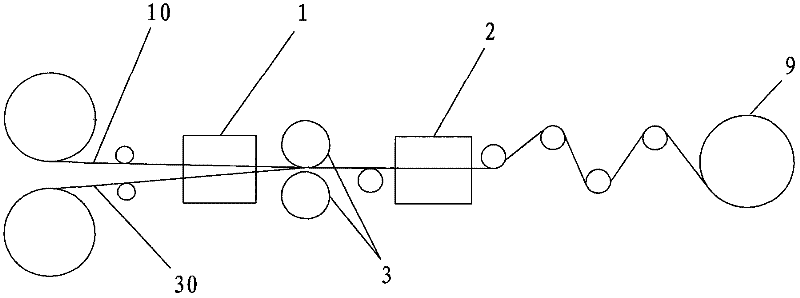

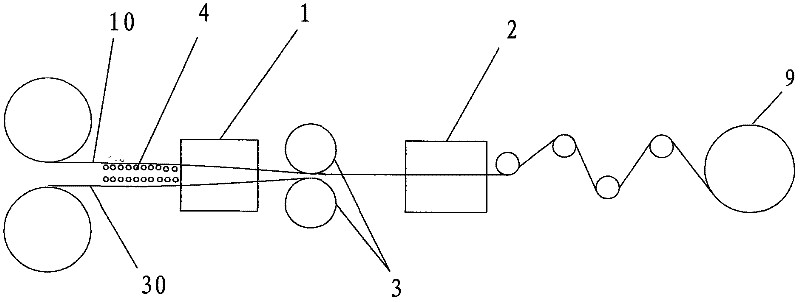

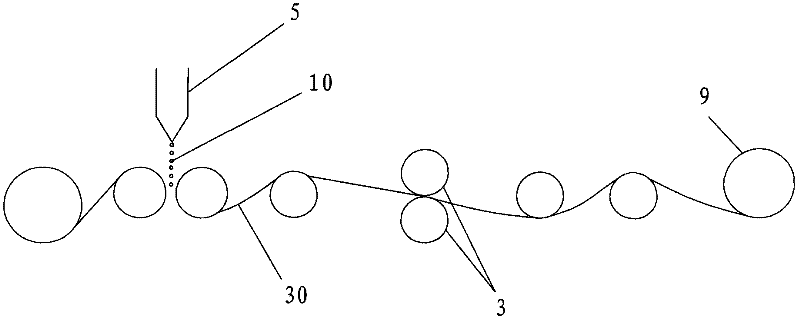

[0024] In step A, the rolled microfiber artificial leather material 30 and TPU material 10 are fed by feeding rollers respectively. If no glue is added between the microfiber artificial leather material 30 and the TPU material 10, then enter step B. The production schematic diagram is as follows figure 1 Shown; If add glue between microfiber artificial leather material 30 and TPU material 10, then enter step C, glue 4 can stick to TPU material 10 earlier, also can stick to superfiber artificial leather material 30 earlier, its production schematic diagram is as follows figure 2 shown;

[0025] Step B, heat and pressurize the microfiber artificial leather material 30 and the TPU material 10, so that the microfiber artificial leather material 30 and the TPU material 10 are heat-pressed into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com