Processing method of rectifying tower condensate of wastewater containing dimethyl formamide

A technology of dimethylformamide and treatment method, which is applied in the field of condensate treatment of dimethylformamide wastewater rectification tower, can solve the problems of secondary pollution of dimethylamine and high cost of wastewater, and achieve no secondary pollution, The effect of low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

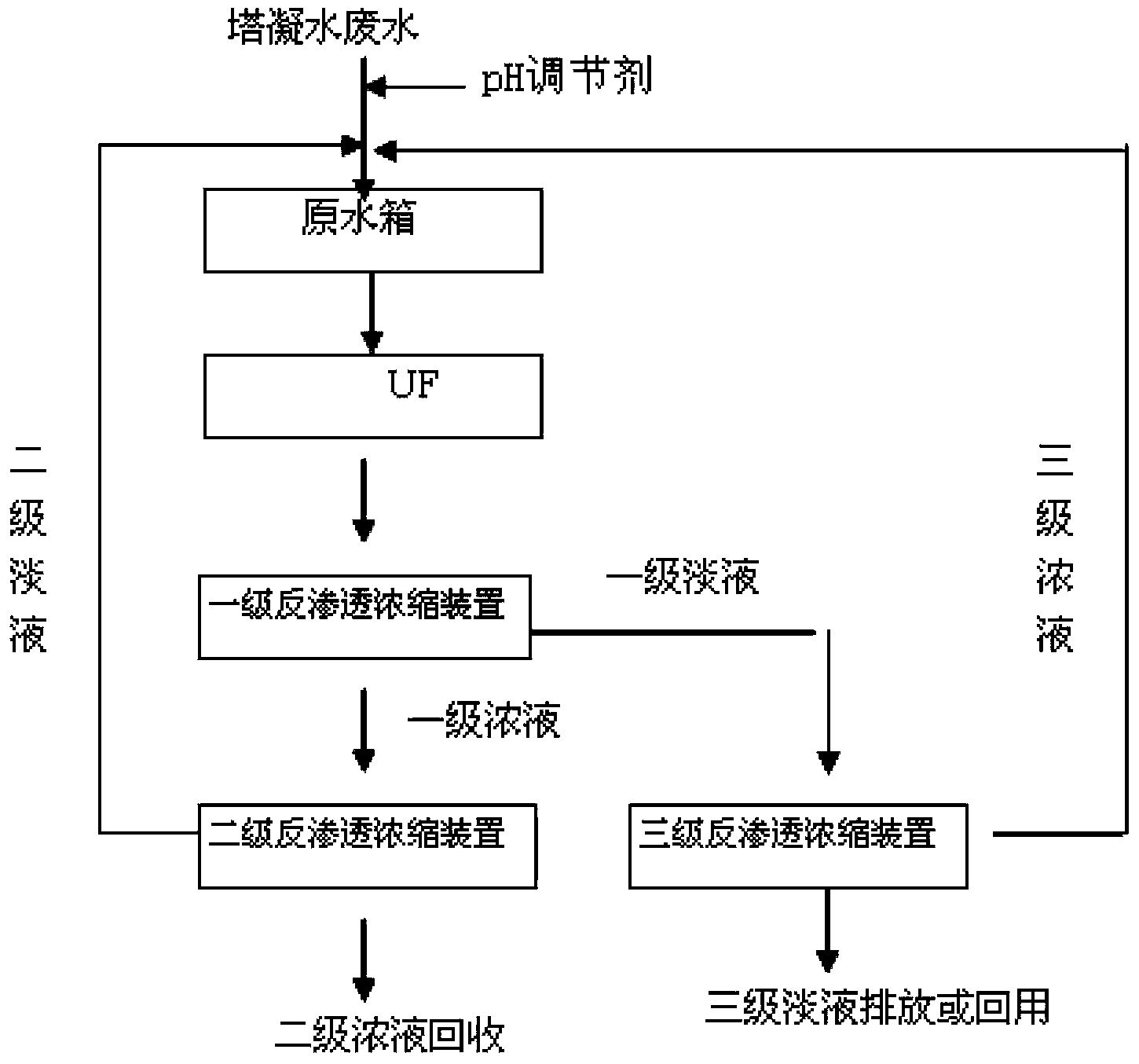

[0028] Select reverse osmosis membranes on the market and ultrafiltration membranes made of PP materials, with a pore size of 0.03 μm, and connect several reverse osmosis membranes to form a three-stage treatment device.

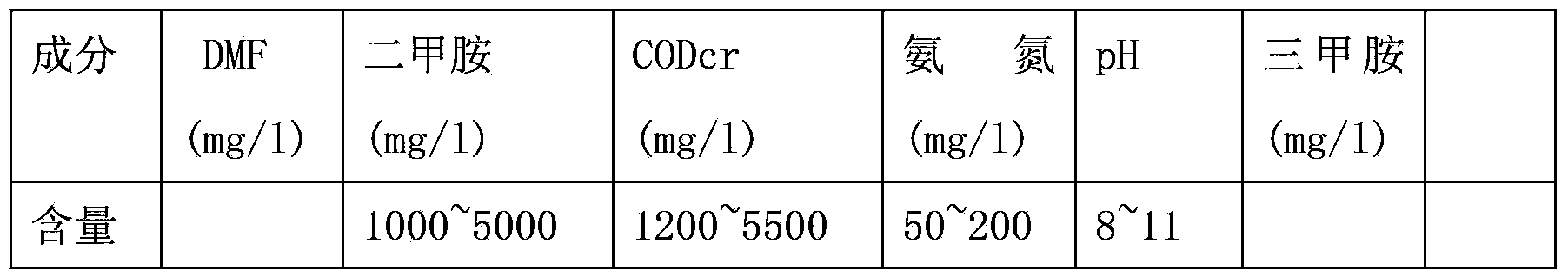

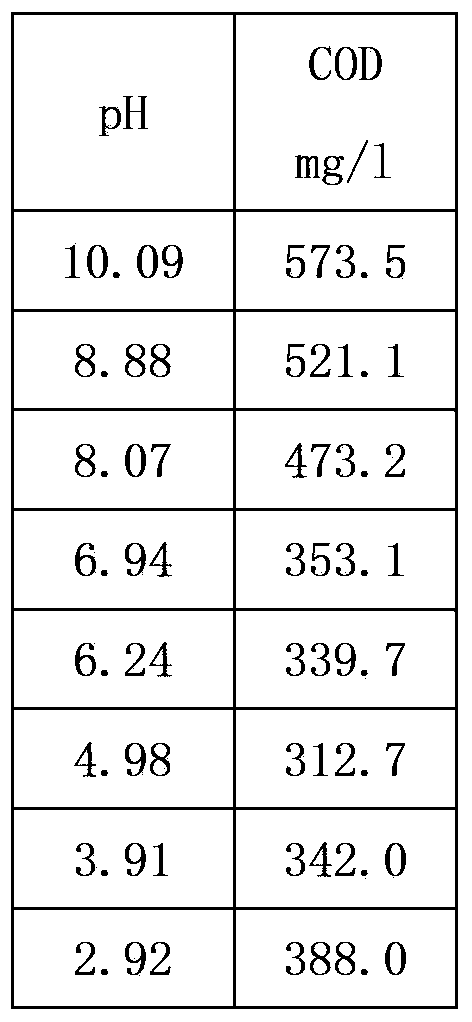

[0029]With the treatment method of the condensed water of the rectifying tower containing dimethylformamide wastewater, it is determined that the CODcr in the condensed water of the rectifying tower of the dimethylformamide wastewater is 3000 mg / L, and the ammonia nitrogen is 100 mg / L. First, the pH value is measured to obtain a pH of 10, adjusted to a pH of 5 by acid, and then filtered through the filter membrane with a pore size of 0.03 μm to obtain the clear liquid, wherein the ultra-microfiltration membrane is a hollow fiber membrane; the filtered clear liquid The liquid enters the first-stage reverse osmosis membrane device for concentration. The operating conditions of the first-stage reverse osmosis membrane device during the concentration process are ...

Embodiment 2

[0031] Select reverse osmosis membranes on the market and ultrafiltration membranes made of PVDF materials, with a pore size of 0.06 μm, and connect several reverse osmosis membranes into a three-stage treatment device.

[0032] With the treatment method of the condensed water of the rectifying tower containing the dimethylformamide waste water, after measuring, the CODcr in the condensed water of the rectifying tower of the dimethylformamide waste water is 4000mg / L, and the ammonia nitrogen is 150mg / L. Firstly, the pH is determined to be 9.5 by the pH value, and then adjusted to pH 6 with a small amount of acid, and then filtered through the filter membrane with a pore size of 0.06 μm to obtain the clear liquid, wherein the ultra-microfiltration membrane is a hollow fiber membrane; the filtered clear liquid The liquid enters the first-stage reverse osmosis membrane device for concentration. The operating conditions of the first-stage reverse osmosis membrane device during the ...

Embodiment 3

[0034] Select reverse osmosis membranes on the market and ultrafiltration membranes made of PVC materials, with a pore size of 0.06 μm, and connect several reverse osmosis membranes to form a three-stage treatment device. Pressure 8.0Mpa, under normal temperature conditions.

[0035] With the treatment method of the condensed water of the rectifying tower containing dimethylformamide waste water, the CODcr in the condensed water of the rectifying tower of the dimethylformamide waste water is 4800 mg / L and the ammonia nitrogen is 250 mg / L. First adjust the pH value, adjust the pH to 7 with 8% hydrochloric acid with a mass concentration, and then filter through the above-mentioned filter membrane with a pore size of 0.1 μm to obtain the clear liquid, wherein the ultra-microfiltration membrane is a hollow fiber membrane; the filtered clear liquid The liquid enters the first-stage reverse osmosis membrane device for concentration. The operating conditions of the first-stage revers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com