Sterilizable leather production process

A production process and leather technology, which is applied in the field of sterilizable leather production process, and can solve problems such as leather damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

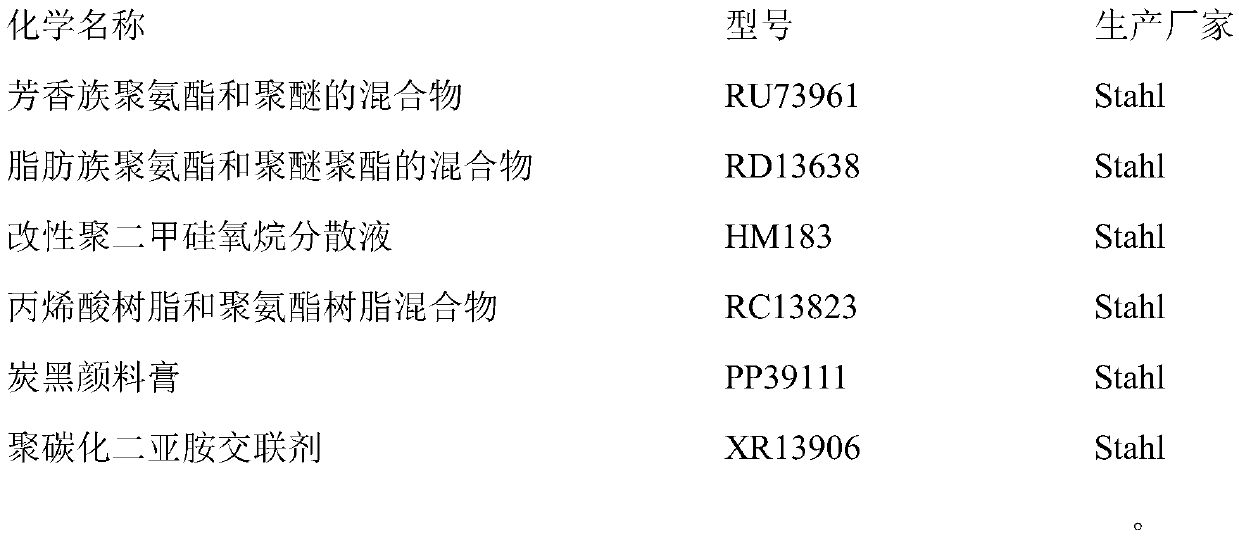

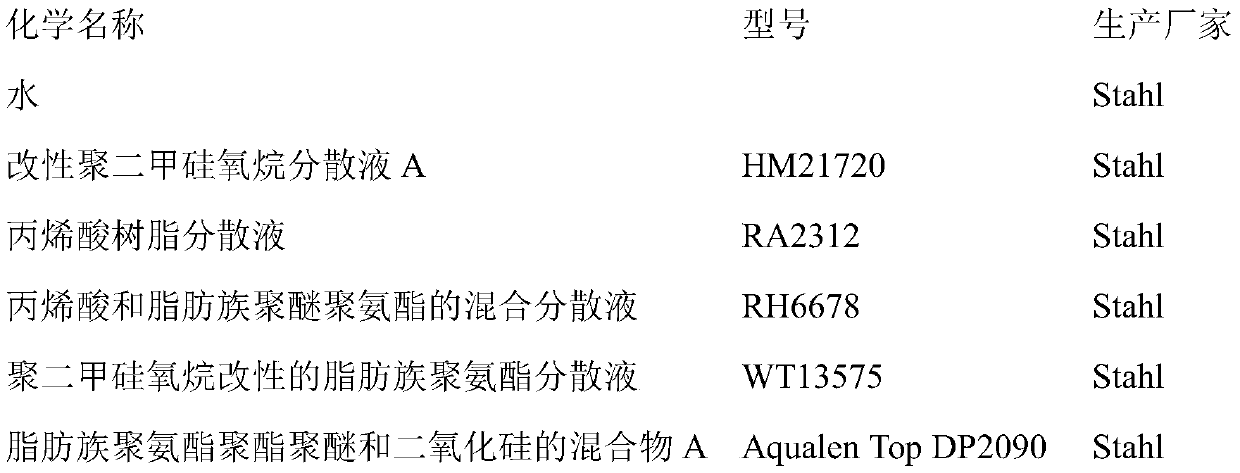

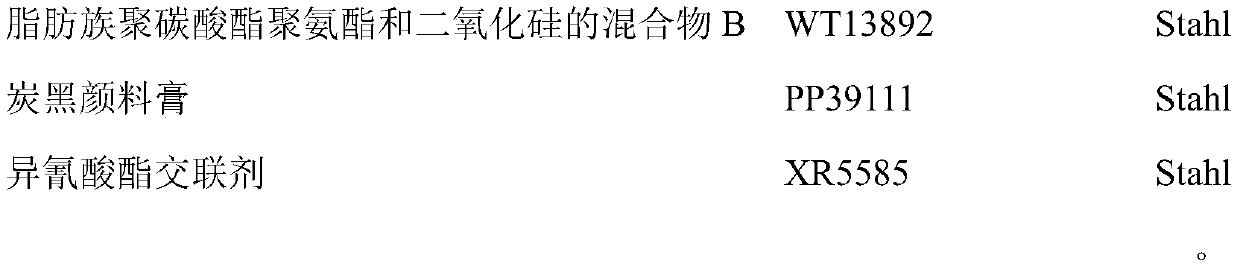

Method used

Image

Examples

Embodiment

[0054] This embodiment describes in detail the production process of the sterilizable leather by taking the natural lychee pattern car seat leather as an example

[0055] (1) Out of the warehouse, usually every 500 square meters is a production unit.

[0056] (2) Sorting of skins, sampling and checking the tear strength of the skins, the requirement is greater than 25N, the thickness is required to be 1.1-1.4mm, the degree of looseness, blood tendons, and growth lines are checked, and the unqualified products are placed in the rejection area according to the standards of the skins. and record.

[0057] (3) Crude skin is softened, put 500 square meters of skin into the softening drum, the temperature of the drum is 43-45 degrees, the humidity is 50-70%, the rotating speed is 18-22 rpm, and the softening time is 6 hours.

[0058] (4) Break the drum out of the soft, put the grain side of the skin upwards and ride on the horse according to the shape of the skin.

[0059] (5) Dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com