Polyvinyl chloride wearing-resistant flash coloured plastic-flooring and preparation method and device thereof

A technology of polyvinyl chloride and floor leather, applied in the field of high molecular polymer materials, can solve the problems of high wear resistance, failure to achieve, not long-term, etc., and achieve the effect of enhanced surface wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

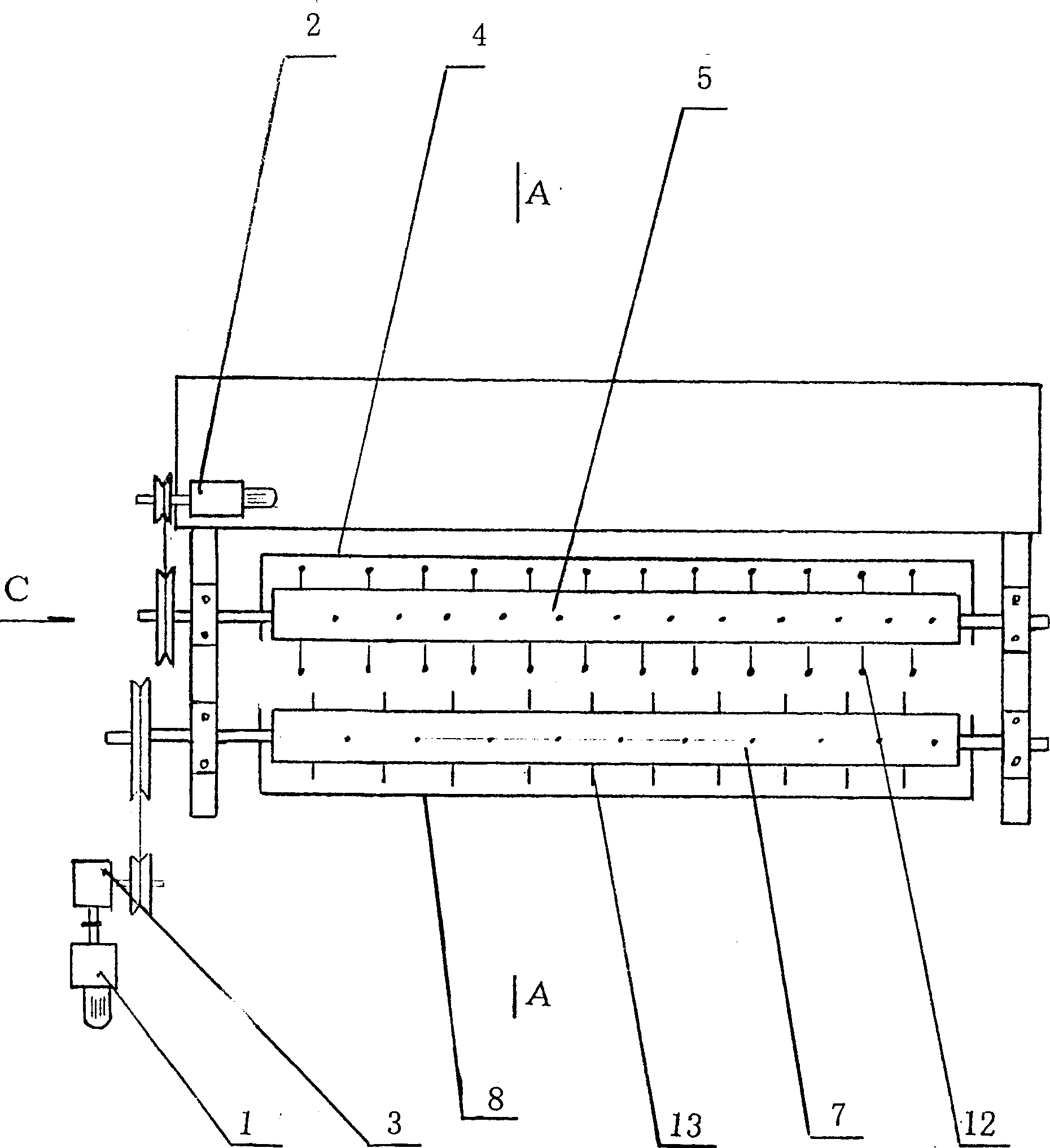

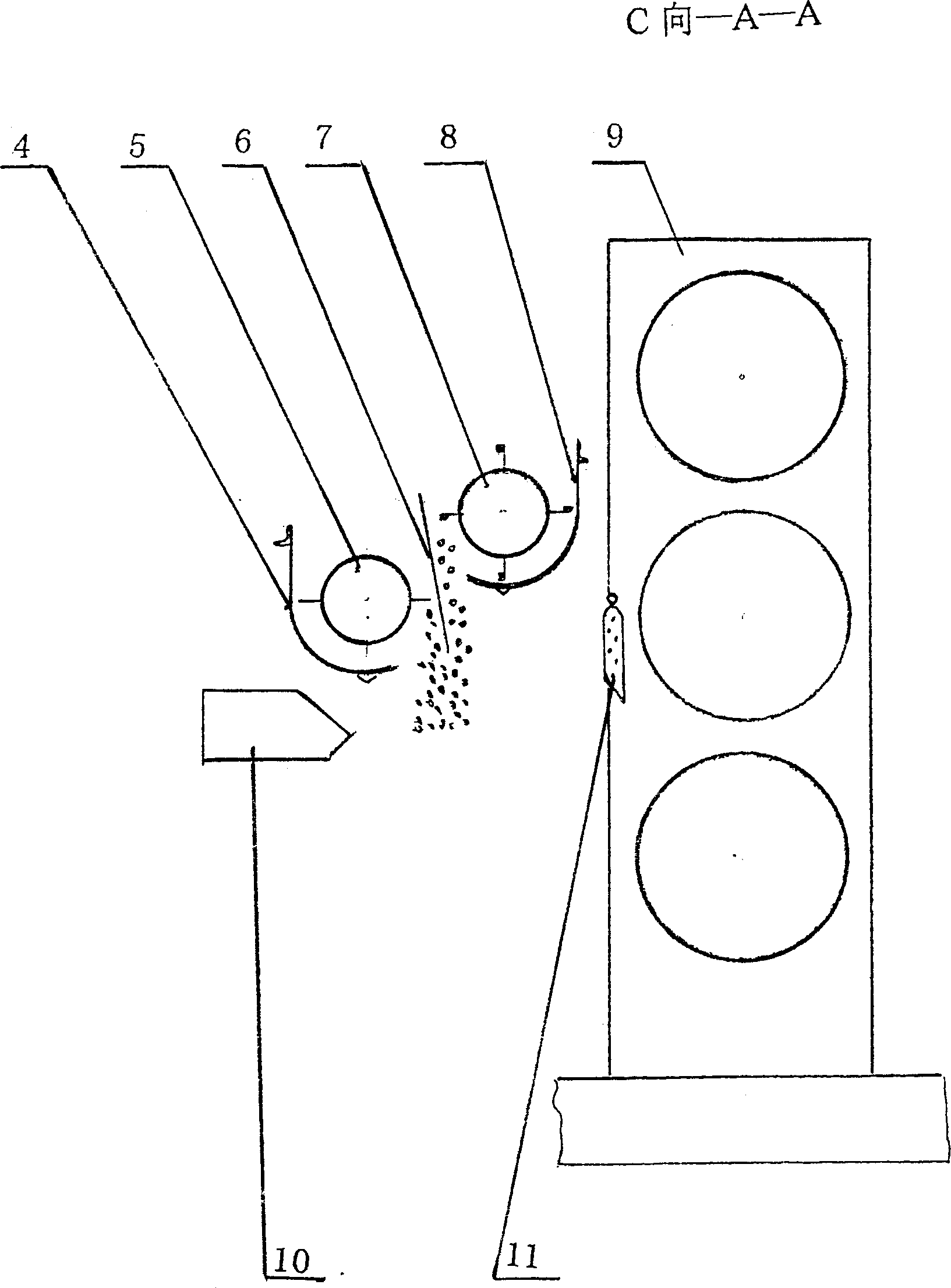

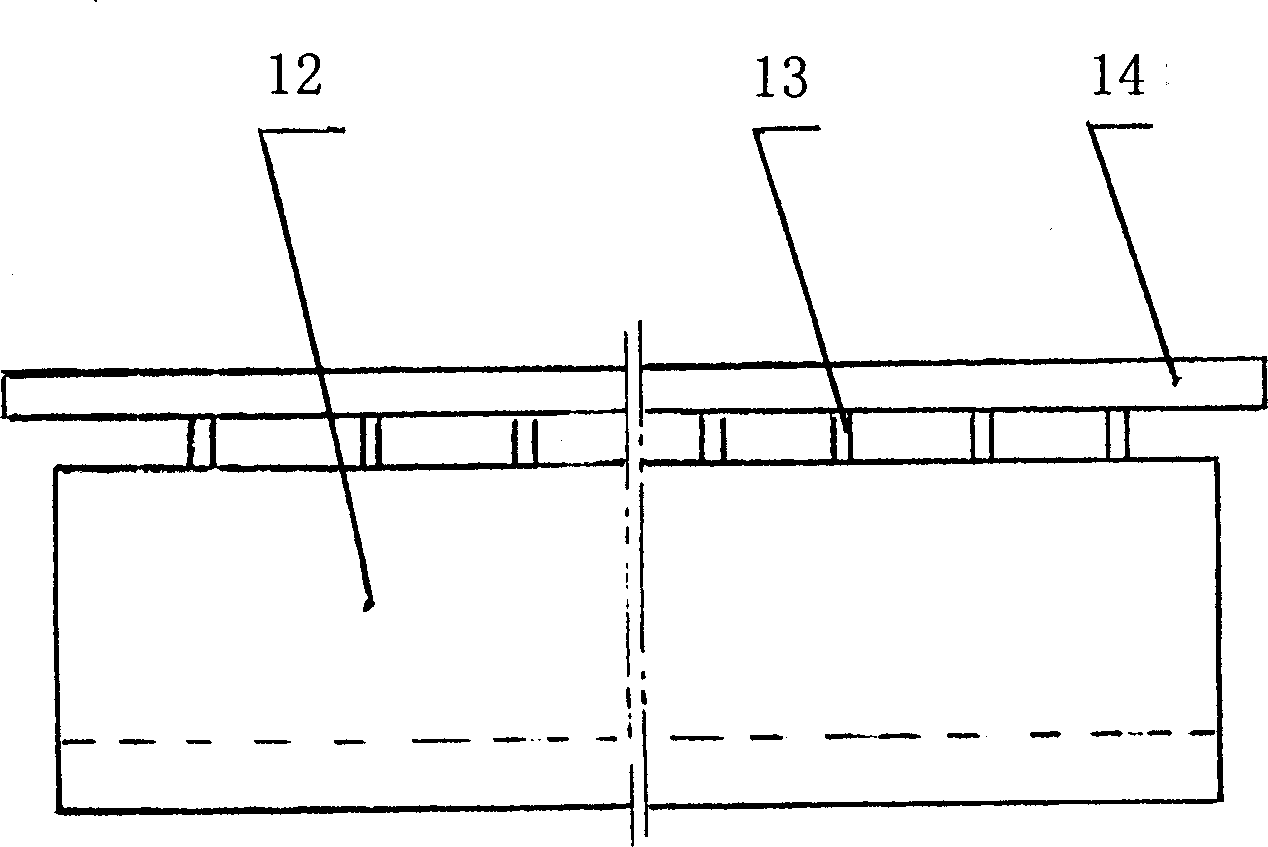

Image

Examples

Embodiment Construction

[0031] One embodiment of the present invention is that the floor leather matrix is made of polyvinyl chloride resin, plastic plasticizer dioctyl phthalate (DOP), dibutyl phthalate (DBP) as main raw materials, adding an appropriate amount of stabilizer, colorant and Filler CaCO 3 and other auxiliary materials. The inorganic wear-resistant particles are SiC, the color is black or green, the shape is flake, and the particle fineness is 30 mesh to 46 mesh. The coupling agent used for the surface activation treatment of SiC particles is SG-Si900 diaminosilane, and the diluent of the coupling agent is alcohol.

[0032] The surface activation treatment process of SiC particles is to dilute the SG-Si900 bisaminosilane coupling agent with alcohol at a ratio of 2:1, and the diluted coupling agent is used as the SiC particle surface treatment solution. The ratio of SiC particles to coupling agent diluent is 100 parts of SiC particles and 0.5-0.8 parts of coupling agent diluent. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com