Complicated surface optical finishing processing device and technique

A technology for finishing and complex surfaces, which is applied in the field of complex surface finishing equipment to achieve the effect of reducing surface roughness and improving surface fit quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0019] Embodiment 1: Immersion processing

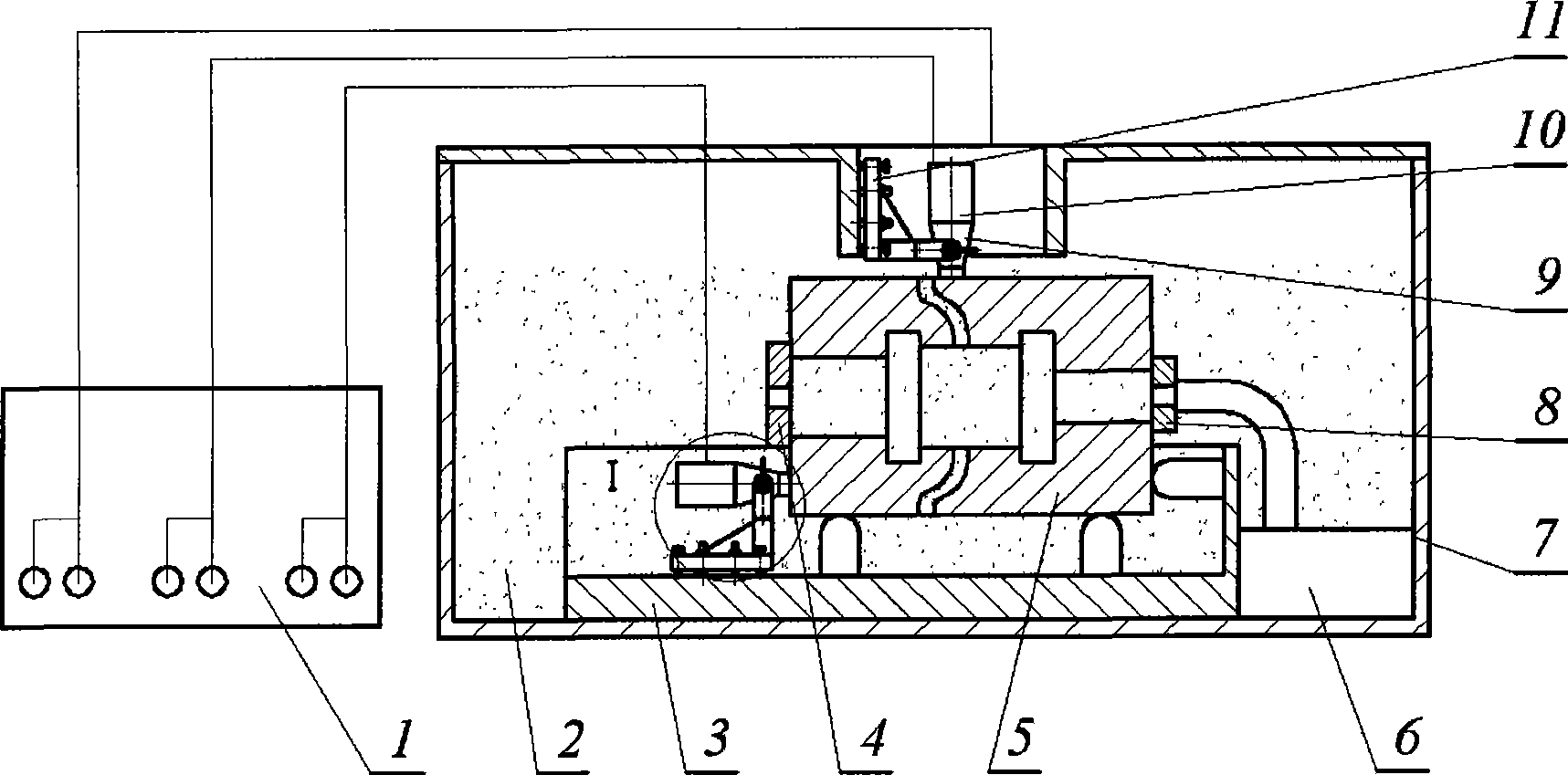

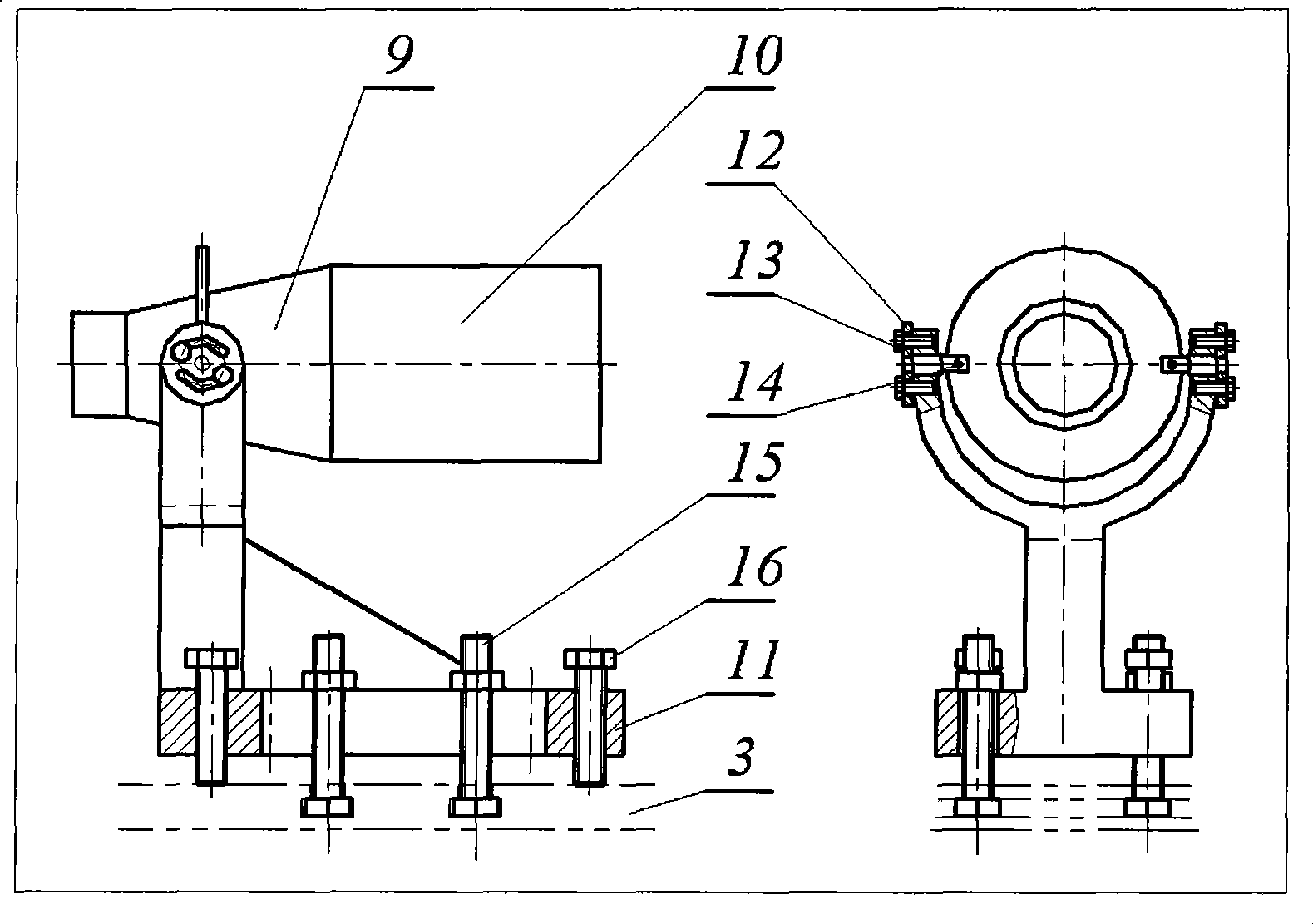

[0020] combined with figure 1 , specifically to further explain how the hexahedral workpiece 5 with complex internal and external surfaces is finished. The workpiece 5 to be processed is placed on the machine table 3, and the position of the workpiece is adjusted so that the hole is connected to the inlet 8 of the mud pump; the three horns 10 are arranged orthogonally, and the horns 10 are moved or rotated to ensure their three-dimensional contact with the workpiece. The two surfaces are in good contact and the workpiece is stably clamped; connect the horn 10 and the ultrasonic power supply 1, add the liquid-solid two-phase fluid 2, start the mud pump 6, and adjust the pressure of the pump so that the flow rate is 2 m / min. Left and right, turn on the ultrasonic power supply, and fine-tune the vibration frequency to make the three horns vibrate well; after 10 minutes of processing, it can meet the requirements of finishing processing...

Embodiment approach 2

[0021] Embodiment 2: Immersion processing

[0022] combined with figure 1 , specifically to further explain how the hexahedral workpiece 5 with complex internal and external surfaces is finished. The workpiece 5 to be processed is placed on the machine table 3, and the position of the workpiece is adjusted so that the hole is connected to the inlet 8 of the mud pump; the three horns 10 are arranged orthogonally, and the horns 10 are moved or rotated to ensure their three-dimensional contact with the workpiece. The two surfaces are in good contact and the workpiece is stably clamped; connect the horn 10 and the ultrasonic power supply 1, add the liquid-solid two-phase fluid 2, start the mud pump 6, and adjust the pressure of the pump so that the flow rate is 1 m / min. Left and right, turn on the ultrasonic power supply, fine-tune the vibration frequency, so that the three horns vibrate well; after 5 minutes of processing, it can meet the requirements of finishing processing. I...

Embodiment approach 3

[0023] Embodiment 3: Immersion processing

[0024] combined with figure 1, specifically to further explain how the hexahedral workpiece 5 with complex internal and external surfaces is finished. The workpiece 5 to be processed is placed on the machine table 3, and the position of the workpiece is adjusted so that the hole is connected to the inlet 8 of the mud pump; the three horns 10 are arranged orthogonally, and the horns 10 are moved or rotated to ensure their three-dimensional contact with the workpiece. The two surfaces are in good contact and the workpiece is stably clamped; connect the horn 10 and the ultrasonic power supply 1, add the liquid-solid two-phase fluid 2, start the mud pump 6, and adjust the pressure of the pump so that the flow rate is 3 m / min. Left and right, turn on the ultrasonic power supply, fine-tune the vibration frequency, so that the three horns vibrate well; after 15 minutes of processing, it can meet the requirements of finishing processing. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com