Preparation method of environment-friendly sofa leather used outdoors

An environmentally friendly, sofa leather technology, applied in chemical instruments and methods, synthetic resin layered products, textiles and papermaking, etc., can solve problems such as hydrolysis resistance, poor aging performance, and poor wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

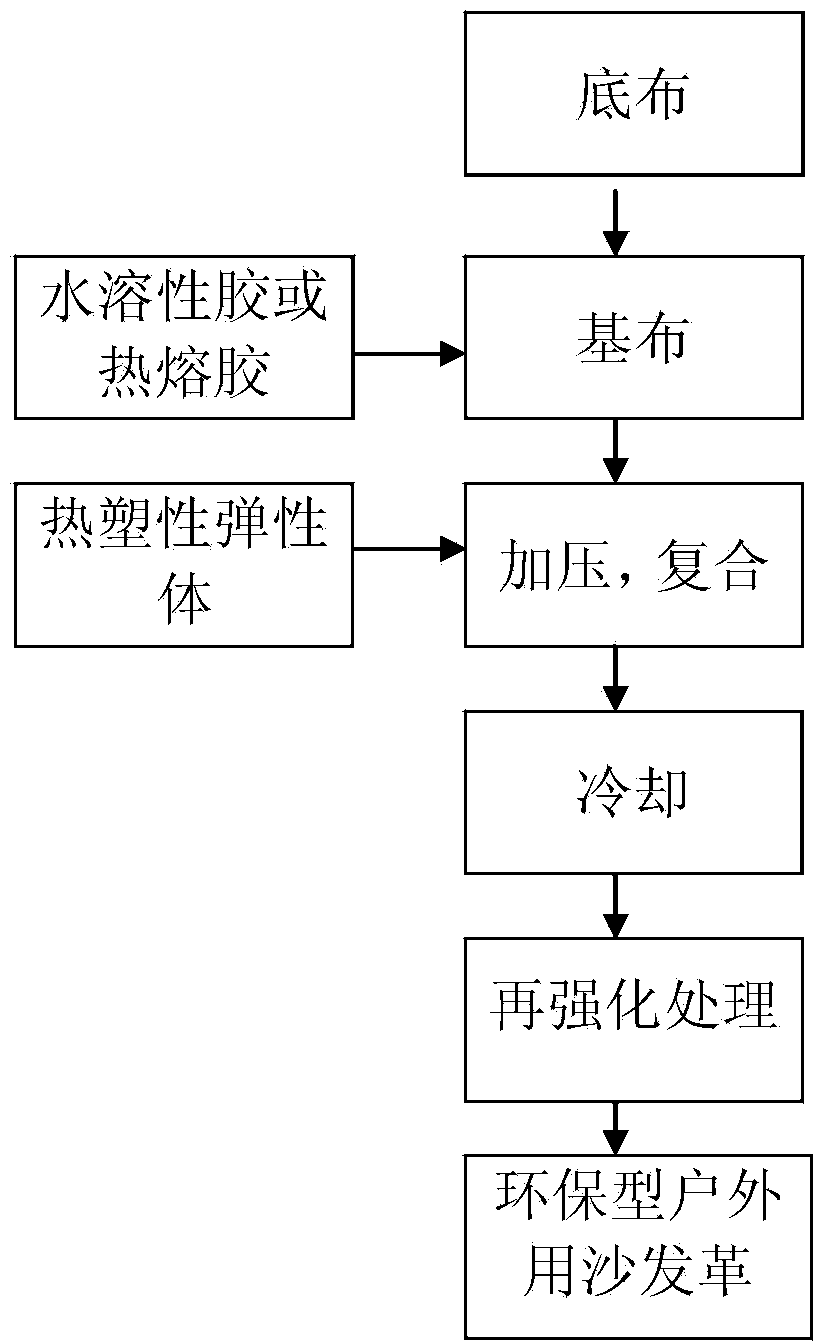

[0018] A kind of preparation method of environment-friendly outdoor sofa leather, such as figure 1 shown. Follow the steps below in order:

[0019] The non-woven fabric is used as the base fabric, and water-soluble polyvinyl alcohol is coated on the base fabric at 100°C, and dried at 110°C to obtain the base fabric.

[0020] 0.8 parts by weight of rubber-like elastomer TPR, 0.2 parts by weight of silicone oil, and 1 part by weight of environmentally friendly masterbatch are melted and mixed by extruder heating at 160 ° C, and then passed through the die and the release mold with texture The paper and the base cloth prepared above are compounded under a pressure of 0.5 MPa to make preliminary outdoor special sofa leather.

[0021] The preliminary outdoor special sofa leather is strengthened in 35°C water and dried to make a fully environment-friendly outdoor special sofa leather.

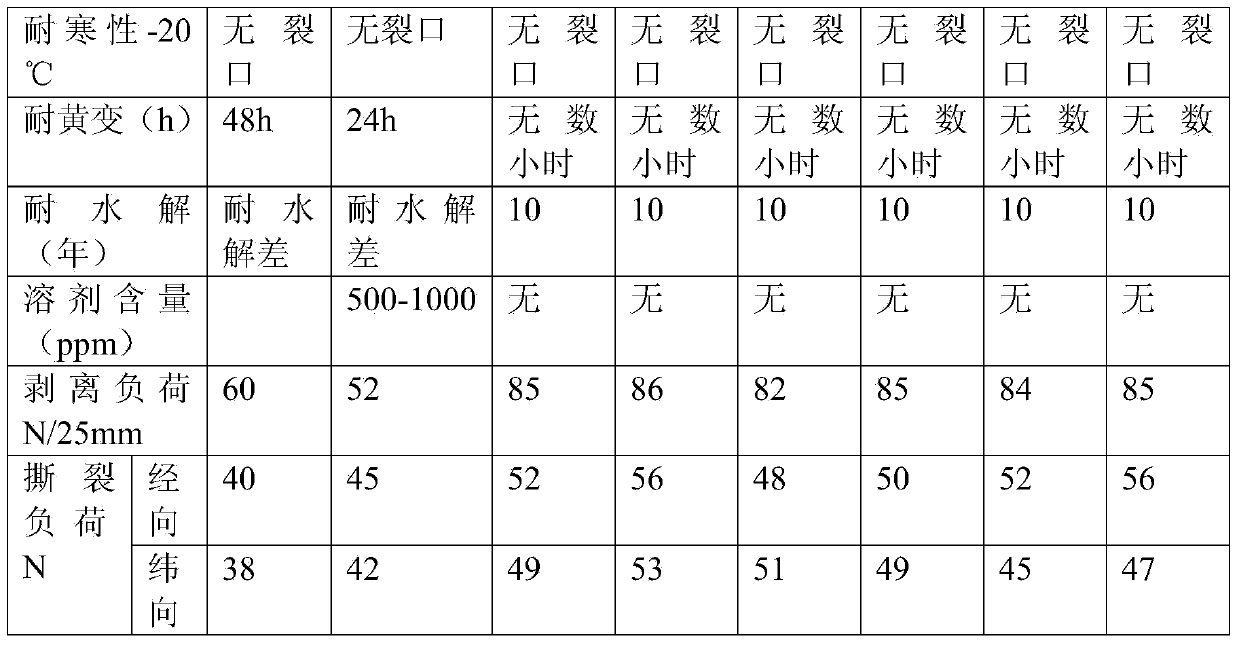

[0022] The performance indexes of the obtained environment-friendly outdoor sofa leather are s...

Embodiment 2

[0024] A kind of preparation method of environment-friendly outdoor sofa leather, such as figure 1 shown. Follow the steps below in order:

[0025] The woven fabric is used as the base fabric, and the water-soluble acrylic acid is coated on the base fabric at 140°C, and dried at 120°C to obtain the base fabric.

[0026] 0.7 parts by weight of thermoplastic elastomer TPU, 0.2 parts by weight of paraffin, and 1 part by weight of environmentally friendly toner are melted and mixed through an extruder at 240°C, and then passed through a die head and textured release paper and The base cloth prepared above is compounded under a pressure of 0.7 MPa to make preliminary outdoor special sofa leather.

[0027] The preliminary outdoor special sofa leather is strengthened in 65°C water, and dried to make a fully environment-friendly outdoor special sofa leather.

[0028] The performance indexes of the obtained environment-friendly outdoor sofa leather are shown in Table 1.

Embodiment 3

[0030] A kind of preparation method of environment-friendly outdoor sofa leather, such as figure 1 shown. Follow the steps below in order:

[0031] Microfiber cloth was used as the base cloth, water-soluble acrylic was coated on the base cloth at 150°C, and dried at 90°C to obtain the base cloth.

[0032] 0.6 parts by weight of thermoplastic polyester elastomer TPEE, 0.4 parts by weight of polypropylene, and 0.1 parts by weight of environmentally friendly toner are melted and mixed through an extruder at 200°C, and then passed through a die and a cleave with texture. The pattern paper and the above-mentioned base cloth are compounded under a pressure of 0.6 MPa to make preliminary outdoor special sofa leather.

[0033] The preliminary outdoor special sofa leather is strengthened in 75°C water and dried to make a fully environment-friendly outdoor special sofa leather.

[0034] The performance indexes of the obtained environment-friendly outdoor sofa leather are shown in Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com