Belt type foaming forming machine for producing synthetic leather

A technology for the production of synthetic leather and foam forming, which is applied in textiles and papermaking, can solve the problems of producers' personal health threats, increased production costs, air pollution, etc., to reduce production links, increase production capacity, reduce energy consumption and environmental protection. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

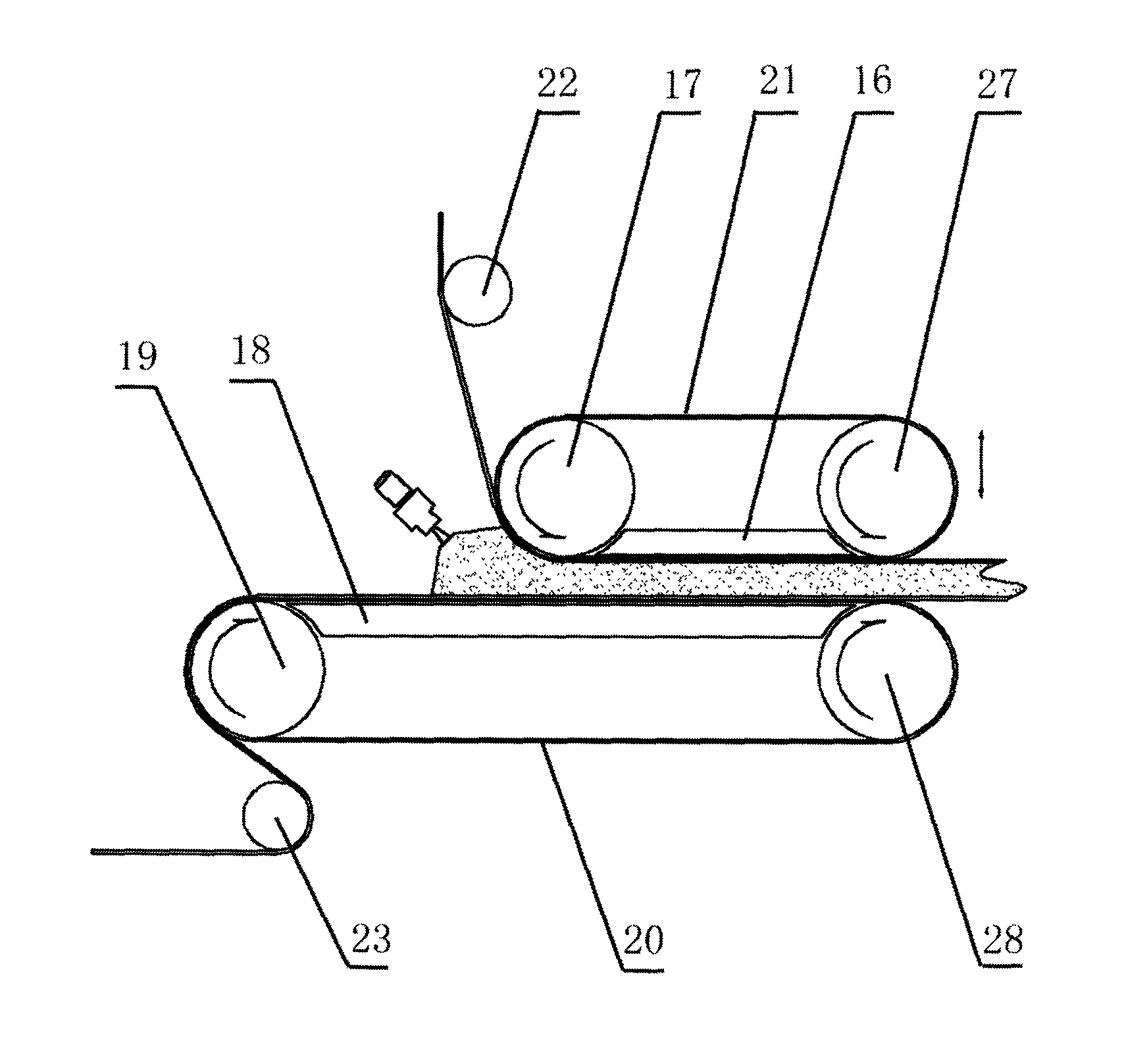

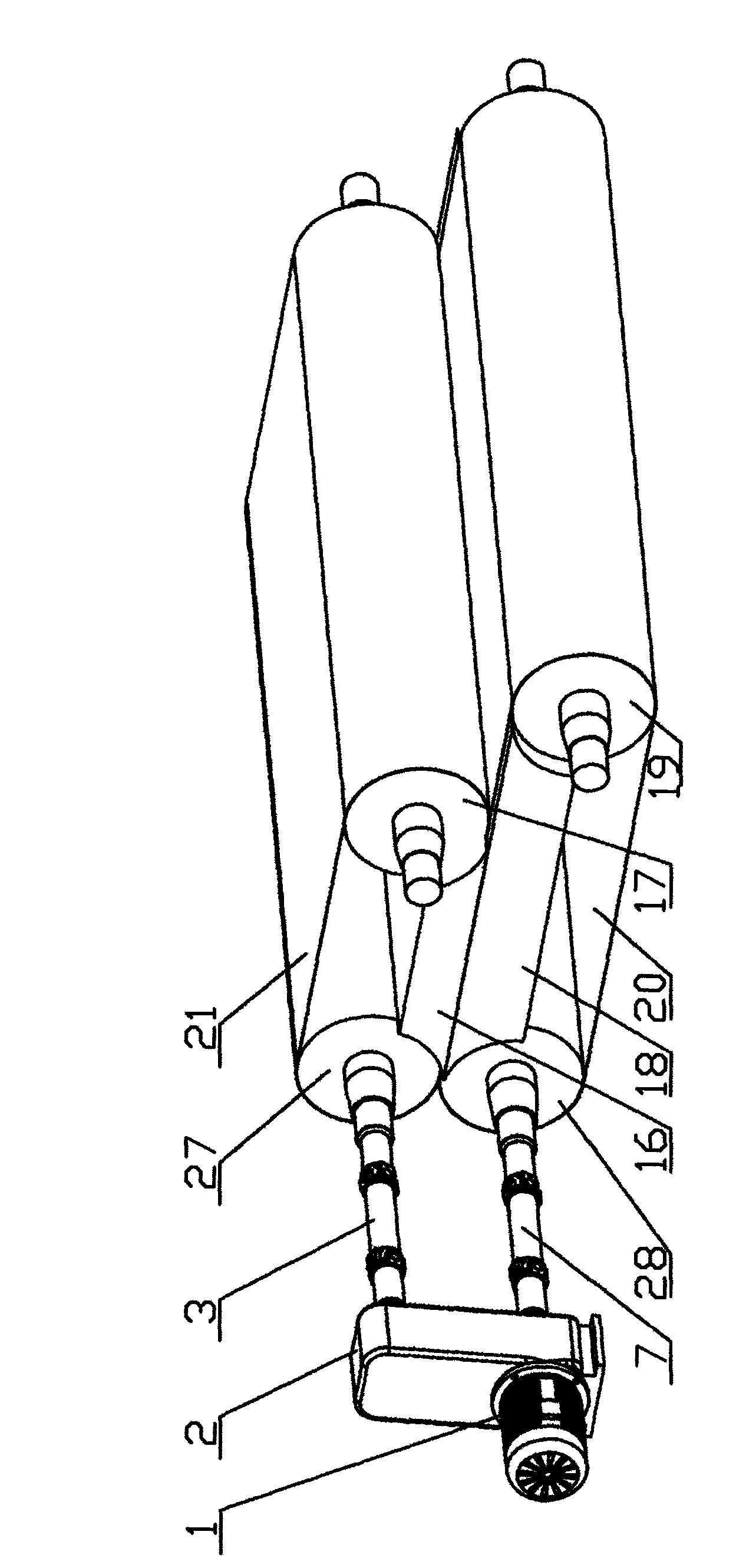

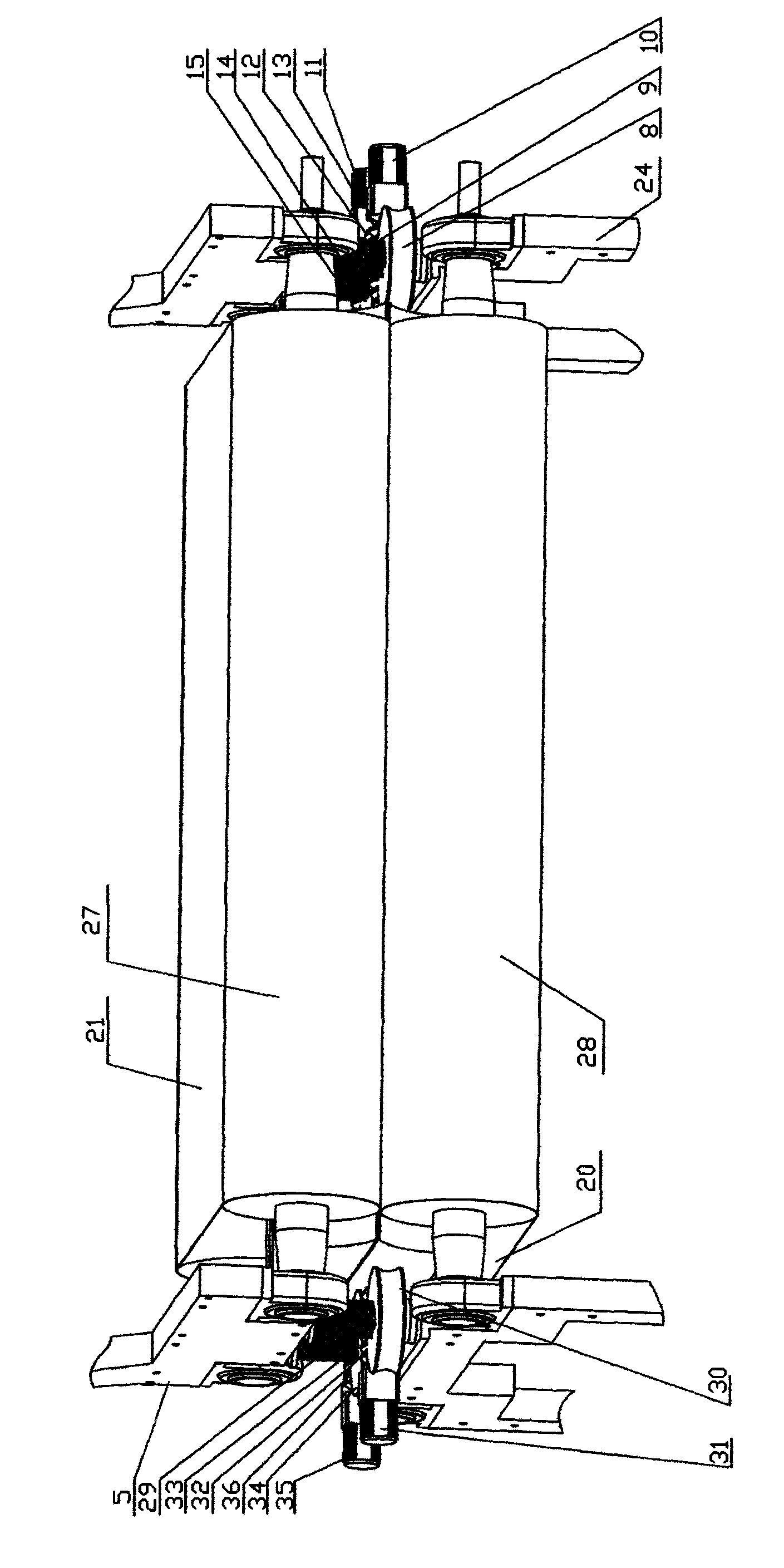

[0020] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , shown in Fig. 6, a kind of belt-type foam forming machine of synthetic leather is produced, is connected by motor 1, transfer case 2, upper forming drive roller transmission shaft 3, bearing shaft seat 4, upper frame 5, and upper frame Rod 6, lower forming belt driving roller transmission shaft 7, 1# foaming gap adjustment worm wheel 8, 1# foaming gap adjustment screw 9, 1# foaming gap adjustment motor 10, 1# foaming gap adjustment worm 11, 2 #Foam gap adjustment worm wheel 12, 2# Foam gap adjustment motor 13, 2# Foam gap adjustment screw 14, 2# Foam gap adjustment worm 15, upper roller chain blanket 16, upper forming belt rotary roller 17 , Lower roller chain blanket 18, lower forming belt rotary roller 19, lower forming belt 20, upper forming belt 21, substrate guide roller 22, release paper guide roller 23, lower frame 24, lower frame connecting rod 25 , Lower forming belt deflection corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com